Abstract

The hole transport buffer layer (HTL) known as PEDOT:PSS is found to be sensitive to polar solvents often used in the preparation of solution-processed perovskite-based solar cell. We employed \(\hbox {CH}_{3}\,\hbox {NH}_{3}\,\hbox {PbI}_{3}\) perovskite absorber sandwiched between two charge transport layers to analyze the effect of precursor solvent. By introducing skin-depth interfacial defect layer (IDL) on PEDOT:PSS film we studied the overall performance of the devices using one-dimensional device simulator. Both enhanced conductivity and variations in valence band offset (VBO) of IDL were considered to analyze device performance. A power conversion efficiency (PCE) of the devices was found to grow by 35 % due to increased conductivity of IDL by a factor of 1000. Furthermore, we noted a drastic reduction in PCE of the device by reducing the work function of IDL by more than 0.3eV . The thickness of interfacial defect layer was also analyzed and found to decrease the PCE of the devices by 18 % for fourfold increase in IDL thickness. The analysis was remarkably reproduced the experimentally generated device parameters and will help to understand the underlying physical process in perovskite-based solar cell.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Methylamine lead halide perovskites have emerged as a remarkable light harvester for thin-film photovoltaic devices. The most common halides for higher-efficiency solar cells are iodine, chlorine, bromine and their mixture. These materials have an ideal band gap for single-junction solar cells, low exciton binding energy, broad absorption spectrum, large electron–hole diffusion length and good electrical transport properties [1–6]. The tuneable absorption bands and the possibility of device fabrication on flexible substrate are other added advantages of the perovskite solar cell. A certified power conversion efficiency of over 20 % was already reported through interfacial modification of the perovskite layers which put them in par with silicon-based solar cell [7]. A deeper understanding of the fundamental working mechanisms of the absorber and charge collector layers becomes increasingly important to further improve device performance and stability.

Poly(ethylene-3,4-dioxythiophene):poly(styrenesulfonic acid) (PEDOT:PSS) is the most common hole transport buffer layer in planar heterojunction organic molecules and perovskite-based solar cells. Besides, it is a suitable candidate for potential application as an electrode on flexible substrates. The PEDOT:PSS layer in perovskite solar cell is often exposed to various solvents due to solution-processed top layer depositions, which in turn alter the film morphology and electrical property. The most common organic solvents in the preparation of perovskite solar cell such as IPA [8], DMSO, DMF, GBL [9–12] are reported to have caused modifications on the properties of PEDOT:PSS layer [13–16]. The extent of the modification will in fact depend on the nature of the solvent used, the exposure time and the annealing temperature. Therefore, the need for better understanding of the effect of solvents on HTL became essential in order to be able to optimize device preparation parameters for better performances. The conductivity of PEDOT:PSS can vary from 10−3 S cm−1 up to \(10^{2}\) S \({\rm cm}^{-1}\) due to the interaction with solvents [9, 10]. By definition, the conductivity of the HTL \((\sigma _{HTL}\)) is given by

where e is the charge of an electron, \(\mu _h\) and \(\mu _e\) are the mobility of hole and electron, respectively. The letters p and n represent the density of holes and electrons in HTL. PEDOT:PSS is a p-type polymer and expected to have high concentration of holes than electrons in the medium. Injected free electrons will immediately recombine at oxidized PEDOT sites; hence, the electrons concentration is insignificant to the overall current in HTL. Therefore, in order to increase the conductivity of HTL one needs to enhance either the concentration of holes in the medium or improve the mobility of the carriers. This can be achieved by increasing the doping level of HTL which generates more holes in HTL or/and improve the charge mobility due to the phase segregation of PSS chains from PEDOT:PSS and conformational change of PEDOT chain [14].

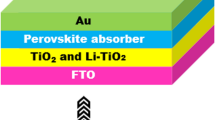

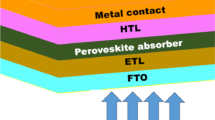

A number of investigations confirmed that the interaction of hole transport layer with precursor solvents would lead to the alterations of work function and surface roughness of the PEDOT:PSS layer. For instance, the use of IPA was found to lower the work function of PEDOT:PSS from about 5.1 eV up to 4.43 eV [8]. Similar investigations on perovskite film deposition on HTL reported to have work function reduction from 5.2 to 4.8 eV [14–17]. The change in the work function of HTL will result in alteration in the valance band offset (VBO) between HTL/absorber which impacts on the hole transport across the interface. Under normal circumstances the difference in the conduction band of the HTL and the perovskite absorber layer is of the order of 1eV which makes HTL a very good electron blocking layer. The HTL is p-type semiconductor, and at high level of doping the work function is very close to the valance band. Injection of charges from the HTL to the absorber can take place depending on the size of the work function (Fig. 1) . Thus, it is possible to discuss the alignment of the valance band energy levels of the HTL with that of the absorber in terms of HTL work function. The duration of contact between the perovskite precursor solution and hole transport layer is relatively short because of postdeposition heat treatment of the samples and hydrophilic nature of PEDOT:PSS layer. Therefore, the alteration of the film property is taken at skin depth rather than the whole thickness of the layer. Hence, in this analysis the modified layer can be considered as a thick interfacial defect layer (IDL) between the absorber and HTL. The thickness of the IDL can be expressed in terms of extended grain size caused by the change in the morphology and the density of traps at the HTL/absorber interface. We carried out the investigation employing one-dimensional device simulator platform and device structure PEDOT:PSS/IDL/perovskite/PCBM.

2 Simulation parameter

Device simulation was performed using the solar cell capacitance simulator (SCAPS) (ver. 3.3.01) [18]. The physical parameters for absorber \(\hbox {CH}_{3}\,\hbox {NH}_{3}\,\hbox {PbI}_3\) were taken from references [19–21] while the PEDOT:PSS and PCBM from [17–22]. The nature of conduction of the layers of the hole transport, absorber and PCBM is p-type, intrinsic and n-type, respectively [13], which suggest that the device has a p-i-n junction configuration. The thickness of each layer was obtained from experimentally determined values from various literature. An interface layer is also inserted between HTL/ absorber as well as absorber/ETL layers. The summary of the parameters for each layer is given in Table 1.

Where \(N_{A}\) and \(N_{D}\) are acceptor and donor concentrations in the medium whose values are approximated by the concentrations of electrons and holes in the material by assuming complete ionization condition of the impurities. The quantity \(\varepsilon \) is the relative permittivity, \(\chi \) is the electron affinity, \(E_g\) is the energy band gap. In this study the absorber is regarded as an intrinsic medium carrying low level of impurity and trap concentrations which are set to the values \(10^{13}\,{\rm cm}^{-3}\) and trap density \(N_t = 2.5\times 10^{13}\,{\rm cm}^{-3}\), respectively [20]. The following parameters not given in Table 1 are considered to be identical in all layers of the device. These are thermal velocity of electrons and holes at the value \(10^{7}\,{\rm cm/s}\), and the effective density of states of conduction band and valance band was set to be \(2.2\times 10^{18}\) and \(1.8\times 10^{19}\), respectively. Defect energy levels lie near the center of the absorber energy gap (\(E_g\)), and defect type is neutral. We have chosen Gaussian energy distribution of defects with characteristic energy about 0.1 eV. Capture cross section of electron and hole is \(2 \times 10^{14}\,\hbox {cm}^2\). To obtain absorption coefficient \(\alpha \) was derived from the function \(\alpha (h\nu )= A^{*}(h\nu -E_g)^{1/2}\), employing the pre-factor \(A^{*}\) which is set to the value \(10^5\).

2.1 Energy level alignments

The electronic energy configurations of the HTL and IDL need to be properly synchronized for efficient collection of charges from photoactive medium. When it comes to the hole transport across \(\hbox {CH}_{3}\,\hbox {NH}_{3}\,\hbox {PbI}_{3}\) and PEDOT:PSS the valence band offset (VBO) plays a critical role in the extraction free charge carriers. In the absence of any interfacial modified layer on the HTL there is -0.2eV VBO between the HTL and the absorber. Figure 2a shows the energy levels alignment in the absence of external applied field. The current–voltage characteristic (J–V) was calculated for a device with unmodified HTL, and the parameters are given in Table 1. The result of the analysis given in Fig. 2b is representing a typical J–V curve for an ideal perovskite-based solar cell. Note that the reflection from interfaces, i.e., air to device, layer to layer in the device and series resistance arising from HTL side or the ETL side, is not considered. However, the solar cell parameters derived from the calculations are short-circuit current density (\(J_{sc} = 20.3\,{\rm mA/cm}^2\)), open-circuit voltage (\(V_{oc} = 1.02\,V\)) and fill factor (FF = 85.4 %). These cell parameters are not far from highly efficient solar cell reported from CH\(_3\)NH\(_3\)PbI\(_3\) absorber [15].

Nevertheless, in most experimental results, the perovskite solar cell parameters are well below the ideal prediction. Among other factors that affect the performance of devices is the formation of interfacial modified layer (IDL) on HTL due to the interaction with precursor solvents. Depending on the type of polar solvent used and the annealing condition of the perovskite film the magnitude of the VBO between the modified layer and the absorber can be increased or decreased. The energy level misalignments were often used to take into account the interfacial properties inorganic thin-film solar cells which well explains the experimental phenomena [23]. The +/- sign of the VBO is attributed to change in the barrier height at the interface and significantly influence the transport of the photogenerated charge carrier. Figure 3 represents the various possible energy level alignments at IDL/absorber interface. If the valence band edge of the IDL (\(E_{v,IDL}\)) is less than the HOMO of PEDOT:PSS, i.e., \(E_{v,IDL} < 5.3\), as shown in Fig. 3a, b and c; energy cliff is formed at the interface, and no barrier for holes in the IDL/absorber interface is formed, this value corresponds to negative VBO. On the other hand, if \(E_{v,IDL} > 5.3\) as shown in Fig. 3d, the energy spike is formed at the interface which can act as barrier for holes which corresponds to the positive VBO.

Schematic representation of the band diagram a when the energy level of the HTL is not modified by solvents. b The modification is in such a way that the VB of the defect layer is in between the absorber and the HTL. In case of c and d, the energy level of the IDL makes a hill and a valley structure, respectively

3 Results and discussion

A number of calculations were carried out on the performance of perovskite-based solar cell composed of various layers of materials PEDOT:PSS/IDL/perovskite/PCBM. The investigations are based on the creation of solvent-modified HTL thin film (10 nm) called interfacial defect layer (IDL) located between unmodified HTL and the absorber. The device was first analyzed by considering the enhancement of conductivity of IDL due to the interaction with precursor solvent. This interaction attributed to increase the doping level in IDL relative to HTL. By considering a complete ionization condition in which the number of holes generated in IDL is the same as the number of acceptors (\(N_A\)) or (impurities) causing the doping, the calculations were carried out by varying the acceptor concentration from \(10^{17}\) to \(10^{21}\,\hbox {cm}^{-3}\) which corresponds to the level doping from pristine to the highly doped of the IDL. Note that the rest of the HTL kept to remain in the pristine state. The result of the analysis is presented in the form of J–V curves as depicted in Fig. 4 for different doping levels of the IDL. Generally, all the solar cell parameters have shown steady growth with increasing the concentration. However, the current density is basically grown by small fraction compared to the rest of the cell parameters. These could be attributed to the small volume IDL where the doping level changed. The increase in the doping level in IDL increases the FF by up to 20 % and power conversion efficiency by up to 35 % at the highest doping level compared to the pristine HTL (Table 2).

Further analysis was also conducted by introducing defect traps at various concentrations in the medium between IDL and absorber. The defects are expected to have been caused by structural deformation and the formation of grain boundaries as the result of the interactions of the precursor solvents with HTL. The main photovoltaic parameters are plotted against the logarithm of the acceptor density \({N}_A\) for various trap concentrations \({N}_t\). All the parameters are steadily increased with acceptor concentrations as expected but decreases with high trap density at the interface. The current density (\({J}_{sc}\)) does seem to be unaffected by the concentration of acceptors at low trap densities; however, it drops significantly as trap density increases to \(10^{17}\hbox { cm }^{-3}\). Moreover, the values of \({V} _{oc}\) and PCE appeared to reach at some saturation values in the range between \({N}_A = (10^{20}\) and \(10^{21}\hbox { cm }^{-3}\)) for the lowest trap concentration. At higher trap concentrations though all photovoltaic parameters (\({V}_{oc}\), \({J}_{sc}\), FF and PCE) are monotonically increased with acceptor concentrations, experimental observation by premodification of HTL with IPA solvent and applying DMSO in the perovskite solution [14–16] shows lower FF and PCE compared to the device without premodification of HTL with the solvents [15]. This could be attributed to the decrease in the work function of HTL due to the formation of IDL at the interface. This has in fact demanded further investigations on the effect of lowering the work function of the HTL in the system which will be discussed below.

In a highly doped p-type HTL the work function approaches very close to the valance band of the IDL. Thus, lowering the work function of IDL has direct implication on the values of its valance band edge (\({E}_v\)). The value of \({E}_v\) in turn affects the valance band offset (VBO) which has significant consequences on the charge transport phenomena between HTL and absorber. The calculations were carried out by using the valance band edge \({E}_v\) of the IDL for the collection of charges from the absorber. Tunneling through the barrier was not considered in the present calculation which is expected to occur at high bias voltages. The various possible valance band offsets as discussed in previous section are:

Case 1 When \(\Delta E_v\) of the hole transport layer forms a steeping potential with that of absorber as shown in Fig. 3b. In this case photogenerated charges can be easily transferred to the HTL.

Case 2 When \(\Delta E_v\) forms an extraction potential well for holes from the absorber to the transport layer as shown in Fig. 3c and

Case 3 When \(\Delta E_v\) forms an injection barrier for holes from the transport layer to the absorber as shown in Fig. 3d.

The optical absorption of the hole transport layer is negligible because of its large band gap and thin layer. The formation of barrier for the extraction of hole in Case 2 and the formation of valley potential at the interface in Case 3 result in lower photovoltaic performance as compared to the ideal condition given in Case 1. J–V characteristics of the device are plotted as a function of the values of VBO in Fig. 6. The performance of the device (i.e., the PCE) was found to be very high when the VBO values are −0.15 and −0.05. This corresponds to the condition set in Case 1 which produced the highest recorded device parameters like FF = 86.4 % ,\(\hbox {V}_{oc}\) = 1.08 V and PCE = 18.98 %. However, when the value of VBO reaches 0.05 and 0.15eV we found marked reduction on the FF and PCE of the device due to the high barrier height for hole extraction. For large value of negative VBO such as −0.35 and −0.45eV, the \(\hbox {V}_{oc}\), FF and PCE of the device decrease by up to 20.5, 23 and 38.5 %, respectively.

The performance of the device was also analyzed for different values of valence band offsets between IDL and the absorber. The main parameters of the solar cell were plotted as a function of VBO and density of traps in Fig. 7. All the parameters grew monotonically with increasing VBO from −0.45 up to −0.15 for the chosen trap concentrations. Eventually, the values of the parameter saturate up until 0.00 value of VBO. As the VBO enters into the positive values (0.05, 0.1, etc.) the magnitude of \({V}_{oc}\), FF and PCE began to drop for all trap densities. This is attributed to the formation of enhanced barrier height for hole extraction from the absorber in positive VBO values. The \({J}_{sc}\) appeared to remain constant except for lower interfacial trap density. The reality suggests that an IPA solvent-treated film of the HTL caused the reduction of the work function as reported in literature [4] which in turn reduces the performance of the devices unlike the case in which the performance increased due to enhanced conductivity of the IDL. Therefore, the effect of precursor solvent in the preparation of perovskite-based solar cell needs to be taken into account for better performing device architecture. A further detailed experimental investigation on the effect of the polar solvents for specific material is an important task for detailed understanding of the process and in the preparations of transparent, highly conductive flexible HTL material.

The interface quality is decisive parameter for highly efficiency thin film-based solar cells. In all of the simulations given above, the trap densities between the IDL and absorber were varied from \(10^{13}\) to \(10^{17}\)cm\(^3\) as depicted in Figs. 5 and 7. The results suggest that increasing trap density contributes negatively to the performance of the device as expressed in terms of lower photovoltaic parameters. This indicates that the defect density at the HTL/absorber interface has significant impact on photocurrent extraction.

In particular for p-i-n-type device, where the illumination of the device takes place from the HTL/absorber side, most of photogenerated electron and hole pairs occur near the HTL/absorber interface. This will enhance the recombination rate in the bulk of the photoactive layer which reduces the extractable current density as well as device performance. The interfacial modified layer is representing several structural deformations such as surface roughness as well as formation of defect grain [9] created by the interaction of HTL and precursor solvent. We carried out device simulation for various sizes of IDL in order to study the effect of the thickness of IDL on the hole transport layer. We take the various defect grain sizes of the defect layer in terms of thickness of IDL from 10 to 50nm in each 10-nm steps. Figure 8 shows the J–V curve of the device for different thicknesses of the IDL. An increase in the thickness of IDL eventually reduces the \({J}_{sc}\), FF and PCE of the device (see Fig. 8 and Table 3). A 15 % lose in efficiency is observed with an increase in thickness from 10 to 50 nm.

4 Summary

The deposition of \(\hbox {CH}_{3}\,\hbox {NH}_{3}\,\hbox {PbI}_{3}\) perovskite precursor from polar solvent solution on PEDOT:PSS is found to affect the properties of the hole transport layer. This in turn plays a critical role in the device performance. We studied here solvent-induced modifications of hole transport layer (PEDOT:PSS) on the overall device performance using one-dimensional device simulator. By assuming the modification confined at skin depth of the PEDOT:PSS, we found 35 % growth on the power conversion efficiency of the device by increasing the conductivity of IDL by a factor of \(10^3\) \(S cm^{-1}\). This enhancement is not unrealistic estimate compared to the five order of magnitude change in conductivity measured experimentally [14]. However, the reduction in the work function by more than 0.25eV of the IDL will cause a lose of nearly 38 % power conversion efficiency of the device. The theoretical analysis indicated that increasing the thickness of IDL will cost 18 % reduction in device PCE but still can attain a fill factor as high as 85 %. These results are consistent with experimental observations [14, 16]. The analysis will provide insight on the mechanisms responsible for device performance due to the interaction of polar solvents with hole transport layer.

References

Q. Dong, Y. Fang, Y. Shao, P. Mulligan, J. Qiu, L. Cao, J. Huang, Electron-hole diffusion lengths 175 mm in solution-grown \(\text{ CH }_{3}\,\text{ NH }_{3}\,\text{ PbI }_{3}\) single crystals. Science 347(6225), 968–970 (2015)

Y. Chen, J. Peng, S. Diqing, X. Chen, Z. Liang, Efficient and balanced charge transport revealed in planar perovskite solar cells. ACS Appl. Mater. Interfaces 7, 4471–4475 (2015)

Y.-C. Hsiao, W. Ting, M. Li, Q. Liu, W. Qin, H. Bin, Fundamental physics behind high-efficiency organo-metal halide perovskite solar cells. J. Mater. Chem. A 3, 15372–15385 (2015)

S. Luo, W.A. Daoud, Recent progress in organic-inorganic halide perovskite solar cells: mechanisms and material design. J. Mater. Chem. A 3, 8992–9010 (2015)

G.T. Mola, Enhanced photon harvesting in OPV using optical reflective surface. Appl. Phys. A: Mater. Sci. & Process. 118, 425–429 (2015)

G. Tessema, Charge transport across bulk-heterojunction organic thin film. Appl. Phys. A: Mater. Sci. & Process. 106, 53–57 (2012)

W.S. Yang, J.H. Noh, N.J. Jeon, Y.C. Kim, S. Ryu, J. Seo, S.I. Seok, High-performance photovoltaic perovskite layers fabricated through intramolecular exchange. Science 348(6240), 1234–1237 (2015)

W. Zhang, X. Bi, X. Zhao, Z. Zhao, J. Zhu, S. Dai, L. Yalin, S. Yang, Isopropanol-treated PEDOT:PSS as electron transport layer in polymer solar cells. Organ. Electron. 15, 3445–3451 (2014)

T.-R. Chou, S.-H. Chen, Y.-T. Chiang, Y.-T. Lina, C.-Y. Chao, Highly conductive PEDOT:PSS films by posttreatment with dimethyl sulfoxide for ITO-free liquid crystal display. J. Mater. Chem. C 3(15), 3760–3766 (2015)

O.P. Dimitrieva, D.A. Grinkoa, Y.V. Noskovb, N.A. Ogurtsovb, A.A. Pud, PEDOT:PSS films effect of organic solvent additives and annealing on the film conductivity. Synth. Metals 159, 2237–2239 (2009)

X. Zhang, J. Wu, J. Wang, J. Zhang, Q. Yang, Y. Fu, Z. Xie, Highly conductive PEDOT:PSS transparent electrode prepared by a post-spin-rinsing method for efficient ITO-free polymer solar cells. Solar Energy Mater. Solar Cells 144, 143–149 (2015)

S.-I. Na, G. Wang, S.-S. Kim, T.-W. Kim, O. Seung-Hwan, Y. Byung-Kwan, T. Leea, D.-Y. Kim, Evolution of nanomorphology and anisotropic conductivity in solvent-modified PEDOT:PSS films for polymeric anodes of polymer solar cells. J. Mater. Chem. 19, 9045–9053 (2009)

L.-C. Chen, J.-C. Chen, C.-C. Chen, W. Chun-Guey, Fabrication and properties of high-efficiency perovskite/PCBM organic solar cells. Nanoscale Res. Lett. 10, 312 (2015)

Y. Xia, K. Sun, J. Chang, J. Ouyang, Effects of organic inorganic hybrid perovskite materials on the electronic properties and morphology of poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) and the photovoltaic performance of planar perovskite solar cells. J. Mater. Chem. A 3, 15897–15904 (2015)

W. Chun-Guey, C.-H. Chiang, Z.-L. Tseng, K. Md Nazeeruddin, A. Hagfeldt, M. Gratzel, High efficiency stable inverted perovskite solar cells without current hysteresis. Energy Environ. Sci. 8, 2725–2733 (2015)

P. Docampo, J.M. Ball, M. Darwich, G.E. Eperon, H.J. Snaith. Efficient organometal trihalide perovskite planar-heterojunction solar cells on flexible polymer substrates. Nat. Commun. 4(2761) 2013

S.A. Rutledge, A.S. Helmy, Carrier mobility enhancement in poly(3,4-ethylenedioxythiophene)-poly (styrenesulfonate) having undergone rapid thermal annealing. J. Appl. Phys 114, 133708 (2013)

M. Burgelman, P. Nollet, S. Degrave, Modelling polycrystalline semiconductor solar cells. Thin Solid Films 361(362), 527–532 (2000)

T. Minemoto, M. Murata, Device modeling of perovskite solar cells based on structural similarity with thin film inorganic semiconductor solar cells. J. Appl. Phys. 116, 054505 (2014)

D. Shi, V. Adinolfi, R. Comin, M. Yuan, E. Alarousu, A. Buin, Y. Chen, S. Hoogland, A. Rothenberger, K. Katsiev, Y. Losovyj, X. Zhang, P.A. Dowben, O.F. Mohammed, E.H. Sargent, O.M. Bakr, Low trap-state density and long carrier diffusion in organolead trihalide perovskite single crystals. Science 347(6221), 519–522 (2015)

M. Saidaminov, A.L. Abdelhady, B. Murali, E. Alarousu, V.M. Burlakov, W. Peng, I. Dursun, L. Wang, Y. He, G. Maculan, A. Goriely, T. Wu, O.F. Mohammed, O.M. Bakr, High-quality bulk hybrid perovskite single crystals within minutes by inverse temperature crystallization. Nat. Commun. 6, 7586 (2015)

V.D. Mihailetchi, J.K. Van Duren, P.W.M. Blom, J.C. Hummelen, R.A.J. Janssen, J.M. Kroon, M.T. Rispens, W.J.H. Verhees, M.M. Wienk, Electron transport in methanofullerene. Adv. Funct. Mater. 13, 44 (2013)

T. Minemoto, Y. Hashimoto, T. Satoh, T. Negami, H. Takakura, Y. Hamakawa, Cu(In, Ga)Se2 solar cells with controlled conduction band offset of window/Cu(In, Ga)Se2 layers. J. Appl. Phys. 89, 8327–8330 (2001)

Acknowledgments

The authors would like to thank Professor Marc Burgelman, University of Gent, for the development of the SCAPS software package and allowing us for use and Dr. Mulugeta Bekele, Department of Physics, AAU, for helpfully encouraging to do the work. This work is supported by the International Programs in the Physical Science (IPPS), Sweden, and National Research Foundation (NRF), South Africa.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gebremichael, B., Mola, G.T. The effect of skin-depth interfacial defect layer in perovskite solar cell. Appl. Phys. B 122, 215 (2016). https://doi.org/10.1007/s00340-016-6492-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6492-y