Abstract

We analyzed the surfaces of vitreous silica (quartz) and borosilicate glass (Pyrex) substrates exposed to rubidium (Rb) vapor by X-ray photoelectron spectroscopy (XPS) to understand the surface conditions of alkali metal vapor cells. XPS spectra indicated that Rb atoms adopted different bonding states in quartz and Pyrex. Furthermore, Rb atoms in quartz remained in the near-surface region, while they diffused into the bulk in Pyrex. For these characterized surfaces, we measured light-induced atom desorption (LIAD) of Rb atoms. Clear differences in time evolution, photon energy dependence, and substrate temperature dependence were found; the decay of LIAD by continuous ultraviolet irradiation for quartz was faster than that for Pyrex, a monotonic increase in LIAD with increasing photon energy from 1.8 to 4.3 eV was more prominent for quartz, and LIAD from quartz was more efficient at higher temperatures in the range from 300 to 580 K, while that from Pyrex was almost independent of temperature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Alkali metal vapor cells have been widely used for optical studies of alkali metal atoms, e.g., in optical pumping and laser cooling. These cells are crucial components of high-precision applications, such as atomic magnetometers [1] and clocks [2]. Atoms in the alkali metal vapor cells can be treated as isolated atomic samples in the gas phase in the first approximation, but they actually have some interactions with each other and also with the inner surface of the cell walls, which are often made of glass. Specifically, the atom–surface interactions cause undesired effects that cannot be easily understood and controlled, such as broadening and frequency shifts of resonance lines [3, 4]. There have been many studies to understand surface-related phenomena in alkali metal vapor cells, such as anti-spin-relaxation coatings [5], surface modification to cause conductivity of cells [6] and stray electric fields [7], testing of several different surface materials for laser traps [8], direct measurements of adsorption/desorption dynamics [9], and measurement of passivation of a surface with alkali metal atoms, called “curing” [10]. However, there have mostly been only indirect studies of surfaces via atoms in the gas phase. Direct characterization of surfaces using standard surface science techniques has been very limited for atomic physics purposes [11].

The same is true for studies of light-induced atom desorption [12]. This phenomenon has attracted particular attention in laser cooling and trapping experiments using ultrahigh vacuum cells, into which atoms can be loaded quickly on demand from the surface by LIAD techniques [13, 14]. However, most LIAD studies [13, 15–19] focused only on desorbed atoms, and lack of basic knowledge of the surface itself leads to a poor understanding of desorption mechanisms and also some contradictory practical information. For example, one group reported that LIAD from quartz glass is not effective [20], but another loaded a magneto-optical trap in a quartz cell by LIAD [16].

Following our previous study [21], we introduce surface analysis for glass surfaces, for which LIAD measurements were then carried out by focusing on differences between vitreous silica (synthetic quartz) and commercial borosilicate glass (Pyrex), which are the most commonly used materials for alkali vapor cells. Glass substrates exposed to rubidium (Rb) vapor were analyzed by X-ray photoelectron spectroscopy (XPS), which is a non-destructive surface analysis technique that is particularly useful for insulators. We found that Rb adopted different chemical bonding states between quartz and Pyrex, and also diffused deeper into Pyrex than quartz. We carried out LIAD measurements for these characterized surfaces. Clear differences in time evolution, photon energy dependence, and substrate temperature dependence of LIAD were obtained between quartz and Pyrex. The former exhibited a more rapid decrease over time and larger LIAD yields for higher photon energies and at higher temperatures. Our systematic study clearly revealed the differences between quartz and Pyrex exposed to alkali metal vapor and provided basic knowledge on the surfaces for numerous experiments using alkali metal vapor cells.

The paper is organized as follows. The experimental setup and procedure are described in Sect. 2, followed by the presentation and discussion of the results obtained by XPS surface analysis and LIAD measurement. Finally, the paper is concluded in Sect. 4.

2 Experiment

(Color online) a Side view of the experimental apparatus. The substrate lies at a take-off angle \({\theta }\) with respect to the electron analyzer. b Top view of the experimental apparatus. The substrate faces the alkali metal atom detector. The desorption light is reflected by the copper stage and released from the experimental chamber

The experimental arrangement is shown schematically in Fig. 1. We used two types of glass substrate, i.e., synthetic quartz (\(\hbox {SiO}_{2}\)) and Pyrex, because they are commonly used materials for alkali metal vapor cells. Pyrex (Corning Code 7740, \(83.0\hbox {SiO}_{2}{-}11.6\hbox {B}_{2}\hbox {O}_{3}{-}1.4\hbox {Al}_{2}\hbox {O}_{3}{-}4.0\hbox {Na}_{2}\hbox {O}\), in mol% [22]) is a type of commercial borosilicate glass. The substrates were 20 mm in diameter and 0.5 mm in thickness. The substrates were first cleaned by ultrasonication with methanol and acetone and then introduced into the experimental chamber. A copper stage attached to an \(\hbox {XYZ}{\Theta }\) manipulator held the substrate. The stage was equipped with a thermocouple, a resistive heater, and a liquid nitrogen tank to allow us to control the temperature of the substrate. After introduction of the substrate, it was heated to \(200\,^{\circ }\mathrm {C}\) and kept overnight (\({\sim }10\) h) for degassing. When the temperature was returned to room temperature, the typical pressure in the experimental chamber was about \(3 \times 10^{-7}\) Pa.

XPS can determine the elemental composition and chemical states of components by measuring kinetic energies (and hence binding energies) of emitted photoelectrons due to X-ray irradiation. The binding energies of core-level electrons are mainly determined by elements and are also slightly dependent on chemical bonding states of atoms; the small shifts in binding energies are called chemical shifts. To obtain XPS spectra, which are photoelectron intensities as a function of the binding energy, we used an \(\mathrm {AlK}\upalpha \) X-ray (1486.6 eV). We calibrated the binding energies by adjustment of the Si 2p peak to 103.5 eV for \(\hbox {SiO}_{2}\), because the binding energy of silicon has been reported to be least dependent on the composition of silicate glass [23, 24]. We removed baselines from the spectra using the Shirley method [25] and fitted them with Voigt functions to investigate the chemical bonding states of elements composing the surfaces. A depth of a few nanometers was typically measured by XPS, determined by the inelastic mean free path (IMFP) of photoelectrons in the sample.

Angle-resolved XPS (ARXPS), which provides information about depth profiles, was carried out by changing the take-off angle \(\theta \) of the sample with respect to the electron analyzer (see Fig. 1a). At larger take-off angles, spectra reflect more surface-localized species. The signal intensity I for photoelectrons for a given core level of a given element can be expressed as

where C is a constant coefficient, \({\sigma }\) is an ionization cross section, n(z) is the density of the element depending on depth z (\(z = 0\) at the outermost surface), and l(z) is the IMFP of the photoelectrons. The IMFP depends on materials changing as a function of z. The exponential term represents the Beer–Lambert law, which the inelastic scattering of photoelectrons obeys [26]. The inverse cos\(\theta \) out of the integral is for normalization of variable observed areas that depends on the take-off angle \(\theta \).

Rb vapor was deposited on the substrate from an alkali metal dispenser, toward which the substrate faced for deposition. After a certain amount of Rb deposition at room temperature, Rb signals measured by XPS increased little with repeated depositions. We assumed that this indicated nearly “cured” surface conditions [10], for which we performed all measurements except for confirmation of Rb aggregate formation at low temperatures.

For LIAD experiments, two types of desorption light source were used: a xenon (Xe) lamp and an ultraviolet laser diode (UVLD). The Xe lamp, from which we could select a specific wavelength from \({\uplambda } = 290\) to 700 nm with cold mirrors and interference filters, was used for measurements of photon energy dependence, while the UVLD (\({\uplambda = 375~\hbox {nm}}\)) was used for other LIAD measurements. We introduced desorption light from a synthetic quartz view port and illuminated the substrate. The illuminated area was \({\sim }3\,\hbox { cm}^2\) for the Xe lamp and \({\sim }1\,\hbox {cm}^2\) for the UVLD. LIAD experiments were performed tens of minutes after Rb deposition onto the substrate to ensure a low thermal desorption rate from the substrate, and also to lower the pressure which increased during Rb deposition.

Desorbed Rb atoms were detected with a homemade Langmuir–Taylor detector (LT detector) [27] arranged such that the substrate faced the detector, as shown in Fig. 1b. The LT detector consisted of a platinum (Pt) filament and a secondary electron multiplier (SEM). When alkali metal atoms were adsorbed onto the Pt filament surface, they were ionized due to the high work function of Pt. As the Pt filament was heated at \(1600\,^\circ \mathrm {C}\), which was evaluated from Eq. (A1) in Ref. [27], ionized alkali metal atoms were thermally desorbed and then attracted to the SEM due to the applied high voltage. The Pt filament and the SEM were surrounded by a stainless steel cylinder equipped with a \({\upphi }\) 8 mm aperture at the entrance to provide shielding from external electric fields and Rb atoms, as a background gas in the experimental chamber. Rb ions could be detected directly by SEM, but we found no LIAD signals without heating of the Pt filament and therefore concluded that Rb did not desorb as ions. Here, we should note that although the LT detector is only sensitive to low ionization species, such as alkali metal atoms, there is a small probability that other atoms or molecules would be detected by surface ionization [27]. We confirmed few signal counts when bare glass substrates were illuminated with the light; therefore, we assumed that signals of the LT detector originated only from Rb atoms.

To estimate the detection efficiency of the LT detector, we measured thermal desorption signals at increasing temperatures of the substrate, which corresponded to the decrease in adsorbed Rb atoms measured by XPS. LIAD rates derived from the efficiency of the LT detector had uncertainties of a factor of 3. The estimated efficiency was consistent with a geometrical estimation.

3 Results and discussion

3.1 X-ray photoelectron spectroscopy

Figure 2 shows wide-scan XPS spectra measured at the take-off angle \(\theta =0^{\circ }\) for quartz and Pyrex substrates exposed to Rb vapor. We found oxygen (O), silicon (Si), carbon (C), and Rb in both spectra, and sodium (Na) only for Pyrex. O, Si, and Na were components of the glass substrates, while C was a contaminant. Boron and aluminum, the other components of Pyrex, were not found in the spectra, probably because of their small ionization cross sections and concentrations.

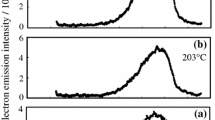

Figure 3 shows narrow-scan spectra of the Rb 3d region. Splitting of the Rb 3d peaks resulted from the \(J=3/2\;\text{and}\;5/2\) doublet. Plasmon loss peaks, which were attributed to photoelectrons that excite the bulk plasmon of metal aggregates [26, 28], were not observed, indicating that Rb atoms did not form metal aggregates at room temperature. Plasmon loss peaks were found for Rb deposition at 130 K, as shown in Fig. 4. They disappeared when the substrate was returned to room temperature, as Rb aggregates thermally evaporated.

The binding energies of the Rb 3d electrons were chemical-shifted lower than the value of Rb in the literature (Rb \(3d_{5/2}\): 111 eV [26]), indicating that Rb atoms were bound to other elements. Furthermore, a clear difference in the binding energy between quartz and Pyrex was found, indicating that Rb atoms were in different chemical bonding states. We found that the O 1s peak of quartz changed with Rb deposition, as shown in Fig. 5. The shoulder on the low binding energy side in the O 1s peak increased. On curve fitting, two components were found at 531.5 and 529.8 eV. We considered that the new components were bridging oxygen (BO) and non-bridging oxygen (NBO) bound to Rb atoms for several reasons, as outlined below. It has been reported that alkali metal atoms on quartz surfaces are most likely bound to both BO and NBO according to first-principle calculations [29]. Moreover, the signal of NBO bound to potassium has been found experimentally to be approximately \(-2.7\) eV below the original peak (SiO\(_2\)) in the XPS spectrum [30]. The shift value agrees with that of the lowest component in our results.

The O 1s and Na 1s peaks of Pyrex also changed by Rb deposition, as shown in Fig. 6. The chemical shifts of the O 1s peak were similar to the case of quartz, but the widths and heights of the new peaks were different. The Na 1s peak of Pyrex shifted by \(-1.5\) eV and also increased after Rb deposition. It has been reported that Na ions in Pyrex are exchanged with other alkali ions [31]. This ion exchange can probably cause the chemical shift of Na. It was not obvious whether the increase in the Na 1s peak was caused by Rb deposition, because a long-duration XPS experiment indicated an increase in Na concentration on a soda lime silicate glass surface [23].

The peak integral intensity including all components for each XPS peak is shown as a function of the take-off angle in Fig. 7 based on the results of ARXPS measurements. In general, with increasing take-off angle, peak intensities of surface-localized species increase, while those of the components in the deeper region decrease. Hence, C and Rb were localized at the surface, and O, Si, and Na were located in deeper regions (below C and Rb). In addition, the Rb peak intensity of Pyrex was increased to a lesser extent than that of quartz; Rb atoms of Pyrex were less localized at the surface than those of quartz. To gain quantitative information, we derived fitting equations from Eq. (1) and fitted them on the plots. We used the following model to determine the fitting equations: First, a uniform hydrocarbon contamination layer covered the outermost surface with a thickness of \(t_{\mathrm {C}}\) from \(z=0\) to \(t_C\) [32], while the substrate components (O, Si, and Na) were present below the contamination layer (\(z > t_{\mathrm {C}}\)); second, Rb atoms penetrate exponentially into the deeper side: \(n_{\mathrm {Rb}}(z) = n_{0\mathrm {Rb}} \mathrm {exp} (-z/\tau _{\mathrm {Rb}})\); finally, photoelectrons are not scattered by Rb atoms because of their low concentrations. We assumed that Rb atoms did not form thick metal layers but penetrated into the glass, because we confirmed that Rb atoms did not form aggregates at room temperature and associated with oxygen in the glass. For the IMFP of photoelectrons in the hydrocarbon contamination layer and in the substrate region, we used the approximate values derived from Eq. (3) in Ref. [32] and the values in SiO\(_2\) [33], respectively.

We then estimated the parameters of \(\tau _{\mathrm {Rb}}\) and \(t_{\mathrm {C}}\) that indicated the distribution depths of Rb and C. For the quartz substrate \(\tau _\mathrm {Rb} \mathrm {(Quartz)} = 1.1 \pm 0.2\) nm and \(t_\mathrm {C} \mathrm {(Quartz)} = 0.96 \pm 0.04\) nm, and for the Pyrex substrate \(\tau _\mathrm {Rb} \mathrm {(Pyrex)} = 9 \pm 2\) nm and \(t_\mathrm {C} \mathrm {(Pyrex)} = 0.73 \pm 0.04\) nm. Note that the total times and amounts of Rb deposition for both substrates were almost the same. Therefore, we concluded that Rb tends to diffuse deeper into the bulk in Pyrex than in quartz. This result was consistent with previous reports. No diffusion of potassium into the bulk of vitreous silica was suggested by a theoretical molecular dynamics calculation [34]. On the other hand, diffusion of ionic cesium atoms for sodium borosilicate glasses has been reported in Ref. [35].

We estimated atomic concentrations for both substrates from comparison of the densities derived by fitting for the ARXPS results. Densities at the outermost surfaces (\(n_{0\mathrm {Rb}}\)) were adopted for Rb. Excluding the C contaminant, the concentrations were O: 54 %, Si: 26 %, Rb: 20 % for quartz, and O: 64 %, Si: 20 %, Na: 7 %, and Rb: 9 % for Pyrex.

Finally, it is not clear at the moment whether the C contamination, which is ubiquitous on the surface [32], affected the following LIAD results. Further experiments for glass surfaces with the C contamination removed, for example, by ion sputtering will give useful information in this respect.

3.2 Light-induced atom desorption

A typical LIAD signal is shown in Fig. 8. The vertical axis represents the desorption rate, and the horizontal axis represents the time. Small background signals without light irradiation reflects thermal Rb desorption and a Rb background gas in the experimental chamber. When the quartz substrate is irradiated at t = 0 s, the signal sharply increases and then begins to decay. The following LIAD signals, starting at 20 and 40 s, also decay, but the decay rates clearly decrease compared to that of the first signal. In this slow decaying region (in the relaxed decay phase mentioned below), we measured the light intensity dependence of LIAD. We alternately flashed the UVLD at two different powers for a few seconds at the substrate and then compared the LIAD rates. The light intensity dependences are shown in Fig. 9. The rates are normalized relative to their maximum rates. LIAD rates are linearly dependent on the light intensity, which has also been reported in Ref. [16, 17]. This linear dependence indicates that the observed LIAD is a one-photon process and is not caused by heating effects.

We continuously irradiated the substrate with the UVLD (169 or 30 mW) and measured the time evolution of the LIAD rates, as shown in Fig. 10. Background signals without irradiation have been removed from the graphs. For both quartz and Pyrex substrates, LIAD signals decay rapidly in the first several seconds and then gradually shift to a later “relaxed decay phase.” We can also see that the decay rate in the first “rapid decay phase” depends on the light intensity, but the decay rate in the following relaxed decay phase is almost independent. The light intensity independence of the decay rate in the relaxed decay phase implies the existence of second processes that are independent of light, such as atomic diffusion in the substrates [36].

To measure the wavelength or photon energy dependence of LIAD, we flashed the Xe lamp alternately at 3.1 eV and another photon energy for a few seconds at the substrate in the relaxed decay phase and then compared those LIAD rates normalized by photon fluxes. We compensated for the absorption of ultraviolet light reflected from the copper stage by Pyrex. The relative rates with respect to those for 3.1 eV are shown in Fig. 11. The LIAD rates increase monotonically with increasing photon energy for both substrates, as reported in Refs. [15, 17, 21]. The tendency is prominent for quartz: The rate at 4.3 eV is over 10 times higher than that at 3.1 eV, while at photon energies of 1.8 and 2.1 eV, the desorption signals are below the levels of background noise. Incidentally, the absolute desorption rates measured at 3.1 eV for both substrates were close (within a factor of 2). Therefore, we could roughly estimate that larger desorption rates were obtained from quartz within the ultraviolet region. On the other hand, within the visible region, the desorption rates from Pyrex were larger. It is noted that the present photon energy dependence was stronger than that in our previous report [21]. This may be attributed to a larger amount of Rb on the surfaces in the previous study.

(Color online) Relative desorption rates as a function of photon energy or wavelength of desorption light. The horizontal error bars represent the bandwidths of the selected photon energies. The desorption rates at 3.1 eV with relatively large error bars were the averages of the results for desorption light with wavelength \(\lambda \) = 380, 390, and 410 nm. The desorption rates were normalized by photon fluxes and the rates at 3.1 eV

Finally, to measure the substrate temperature dependence of LIAD, we repeatedly flashed the UVLD (30 mW) at the substrate for a few seconds with a constant interval of 100 s while increasing the temperature of the stage at a constant rate of 0.05 K/s. The measurements started at the relaxed decay phase at room temperature. LIAD rates obtained from increments from background signals are plotted with respect to those at room temperature in Fig. 12. LIAD from quartz clearly increased at higher temperature; monotonic increases in the LIAD rate were observed from various surfaces [36]. In contrast, LIAD from Pyrex increased up to about 400 K, then became flat, and finally decreased. It is noted that the background signals, reflecting both thermally desorbed Rb atoms and background Rb gas in the experimental chamber, increased with increasing temperature in a similar manner for quartz and Pyrex; they were about 2 times and 4 times larger than LIAD signals at 450 K and 570 K for quartz, respectively.

The specific origins of these different properties of LIAD between quartz and Pyrex are not yet clear, but they are very likely attributable to different chemical bonding states, as revealed by the XPS measurements. This study provided useful information from a practical viewpoint. Quartz has higher LIAD rates than Pyrex with short-wavelength desorption light in the ultraviolet region (Fig. 11). Thus, quartz can be an appropriate atomic source in the case of use of short-wavelength light. On the other hand, Pyrex has a lower decay rate than quartz and allows a larger amount of atomic supply with long irradiation times, as shown in Fig. 10. Thus, Pyrex has favorable characteristics as an alkali metal atom source with regard to time dependence. This conclusion was further supported by another measurement indicating that LIAD rates of Pyrex were higher than those of quartz with the UVLD when the substrates were left without irradiation for 10 hours after Rb deposition.

4 Conclusions

We investigated the surface conditions of quartz and Pyrex glass substrates exposed to Rb vapor at room temperature by XPS and systematically measured some features of LIAD from both of the characterized surfaces. We found some clear differences in surface conditions and LIAD of Rb atoms between quartz and Pyrex. Rb exhibited different chemical shifts in XPS spectra as an indication of different chemical bonding states. Rb atoms in quartz remained near the surface, while they diffused into the bulk in Pyrex. The decay rates of LIAD from quartz with continuous ultraviolet irradiation were higher than those of Pyrex. The monotonic increase in LIAD with increasing photon energy from 1.8 to 4.3 eV was more prominent for quartz. LIAD from quartz was more efficient at higher temperatures in the range from 300 to 580 K, while that from Pyrex was almost independent of temperature. These results provide fundamental and practical insights for efficient atomic loading in atomic physics experiments, such as laser cooling and trapping.

References

D. Budker, M. Romalis, Nat. Phys. 3, 227 (2007)

J. Camparo, Phys. Today. 60, 33 (2007)

R.G. Brewer, J. Chem. Phys. 38, 3015 (1963)

E.P. Corsini, T. Karaulanov, M. Balabas, D. Budker, Phys. Rev. A 87, 022901 (2013)

M.A. Bouchiat, J. Brossel, Phys. Rev. 147, 41 (1966)

M.A. Bouchiat, J. Guéna, P. Jacquier, M. Lintz, A. Papoyan, Appl. Phys. B 68, 1109 (1999)

J.M. Obrecht, R.J. Wild, E.A. Cornell, Phys. Rev. A 75, 062903 (2007)

M. Stephens, R. Rhodes, C. Wieman, J. Appl. Phys. 76, 3479 (1994)

H. De Freitas, M. Oria, M. Chevrollier, Appl. Phys. B 75, 703 (2002)

J. Ma, A. Kishinevski, Y.Y. Jau, C. Reuter, W. Happer, Phys. Rev. A 79, 042905 (2009)

S.J. Seltzer, D.J. Michalak, M.H. Donaldson, M.V. Balabas, S.K. Barber, S.L. Bernasek, M.A. Bouchiat, A. Hexemer, A.M. Hibberd, D.F.J. Kimball et al., J. Chem. Phys. 133, 144703 (2010)

A. Gozzini, F. Mango, J.H. Xu, G. Alzetta, F. Maccarrone, R.A. Bernheim, Il Nuovo Cimento D 15, 709 (1993)

B.P. Anderson, M.A. Kasevich, Phys. Rev. A 63, 023404 (2001)

W. Hänsel, P. Hommelhoff, T. Hänsch, J. Reichel, Nature 413, 498 (2001)

C. Klempt, T. van Zoest, T. Henninger, O. Topic, E. Rasel, W. Ertmer, J. Arlt, Phys. Rev. A 73, 013410 (2006)

P. Zhang, G. Li, Yc Zhang, Y. Guo, J. Wang, T. Zhang, Phys. Rev. A 80, 053420 (2009)

G. Telles, T. Ishikawa, M. Gibbs, C. Raman, Phys. Rev. A 81, 032710 (2010)

E. Mimoun, L. De Sarlo, D. Jacob, J. Dalibard, F. Gerbier, Phys. Rev. A 81, 023631 (2010)

L. Torralbo-Campo, G.D. Bruce, G. Smirne, D. Cassettari, Sci. Rep. 5, 14729 (2015)

S. Du, M.B. Squires, Y. Imai, L. Czaia, R.A. Saravanan, V. Bright, J. Reichel, T.W. Hänsch, D.Z. Anderson, Phys. Rev. A 70, 053606 (2004)

K. Kitagami, K. Hosumi, K. Goto, A. Hatakeyama, Phys. Rev. A 85, 062901 (2012)

M.M. Smedskjaer, R.E. Youngman, J.C. Mauro, Appl. Phys. A 116, 491 (2014)

A. Sharma, H. Jain, A.C. Miller, Surf. Interface Anal. 31, 369 (2001)

C. Hsieh, H. Jain, A. Miller, E. Kamitsos, J. Non-Cryst, Solids 168, 247 (1994)

A. Proctor, P.M.A. Sherwood, Anal. Chem. 54, 13 (1982)

D. Briggs, J.T. Grant, Surface Analysis by Auger and X-Ray Photoelectron Spectroscopy (IM Publications and SurfaceSpectra Limited, Chichester, 2003)

R. Delhuille, A. Miffre, E. Lavallette, M. Büchner, C. Rizzo, G. Trénec, J. Vigué, H.J. Loesch, J.P. Gauyacq, Rev. Sci. Instrum. 73, 2249 (2002)

M. Wilde, I. Beauport, F. Stuhl, K. Al-Shamery, H.J. Freund, Phys. Rev. B 59, 13401 (1999)

N. Lopez, F. Illas, G. Pacchioni, J. Am. Chem. Soc. 121, 813 (1999)

R. Caracciolo, S.H. Garofalini, J. Am. Ceram. Soc. 71, C-346 (1988)

H.M. Garfinkel, J. Phys. Chem. 73, 1766 (1969)

G.C. Smith, J. Electron Spectrosc. Relat. Phenom. 148, 21 (2005)

S. Tanuma, C.J. Powell, D.R. Penn, Surf. Interface Anal. 11, 577 (1988)

S.H. Garofalini, D.M. Zirl, J. Vac. Sci. Technol. A 6, 975 (1988)

K. Ishikawa, J. Magn. Reson. 249, 94 (2014)

B.V. Yakshinskiy, T.E. Madey, Icarus 168, 53 (2004)

Acknowledgments

This work was supported by Grants-in-Aid for Scientific Research (Nos. 23244082 and 26610122) from the Japan Society for the Promotion of Science (JSPS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumagai, R., Hatakeyama, A. Light-induced atom desorption from glass surfaces characterized by X-ray photoelectron spectroscopy. Appl. Phys. B 122, 186 (2016). https://doi.org/10.1007/s00340-016-6457-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6457-1