Abstract

All-fiber source at 2.2 μm is investigated with amplified spontaneous Raman scattering process in highly Ge-doped silica fiber. By optimizing the gain fiber length, the second-order Raman Stokes light at 2.43 μm is suppressed and 3 W first-order Raman Stokes light at 2.2 μm is obtained with a homemade 2-μm Q-switched Tm3+-doped fiber laser as pump source. The conversion efficiency is 35.9 % from 2.0 to 2.2 μm, and the peak power of the 2.2-μm laser is about 400 W.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Mid-infrared laser sources in the wavelength range between 2 and 2.5 µm have many important applications. 2–2.5 µm is one of the atmospheric transmission windows. Considering the availability of high-sensitivity detectors, 2–2.5 µm band is still the most important mid-infrared transmission window of the atmosphere for remote sensing applications, comparing to the 4- or 10-μm windows [1]. On the other hand, high-power and high-brightness lasers at 2–2.5 µm can be used as pump sources for other devices, such as ZnGeP2 (ZGP) optical parametrical oscillators (OPO), to generate longer wavelength mid-infrared laser sources [2, 3].

In recent years, fiber lasers have attracted a lot of attention due to the advantages of high conversion efficiency and good beam quality. Fiber laser sources at 2–2.5 µm are of great interest. Tm3+- and Ho3+-doped silica fiber lasers and amplifiers can operate efficiently at 1.9–2.1 μm wavelength range [4–7]. In addition, owing to the cross-relaxation processes between Tm3+ ions, the quantum efficiency of a TDF laser can be up to 200 % when it is pumped at 790 nm. But they are not able to work efficiently at wavelength longer than 2.1 μm, limited by the emission spectrum. Raman shifting of Tm3+- and/or Ho3+-doped fiber lasers is a natural way to generate lasers at longer wavelength. Soft glass fibers, such as fluoride [8, 9] and chalcogenide [10], were studied as Raman gain media for the mid-infrared range for lower loss. But for the wavelength range from 2.0 to 2.5 μm, highly Ge-doped silica fiber is also a good candidate. It has higher Raman gain coefficient and lower propagation loss than the traditional silica fiber. On the other hand, it is mechanically stronger and easier to handle, compared to the soft glass fibers. There are already some reports on >2.1 μm Raman lasers with highly Ge-doped silica fibers [11–15], with wavelength as long as 2.5 μm. But the output power is low. There is no report on more than one watt output of silica fiber Raman laser at wavelength ≥2.2 μm until now.

In this paper, we report a 2.2-μm highly Ge-doped silica fiber Raman source with amplified spontaneous Raman scattering process, which features simple all-fiber configuration without the need of fiber components like FBGs and couplers. The amplifier performance is optimized by adjusting the fiber length with the unwanted higher-order Raman Stokes light suppressed. Up to 3 W of first-order Stokes light at 2.2 μm is generated with a homemade pulsed 2-μm Tm3+ doped fiber laser as pump source. The conversion efficiency is 35.9 % from 2.0 to 2.2 μm. The peak power of the 2.2-μm laser is about 400 W. To the best of our knowledge, this is the highest power reported for pulsed silica-based fiber Raman source at 2.2 μm wavelength region.

2 Experimental setup

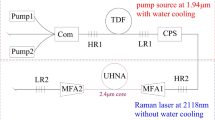

As shown in the Fig. 1, the experimental setup consists of a 2-μm acousto-optic modulator (AOM) Q-switched Tm3+-doped fiber laser as seed source, a Tm3+-doped fiber amplifier, and a piece of highly nonlinear Raman gain fiber (Nufern, UHNA7) in which the 2.2-μm Stokes light is generated.

3 Results and discussion

The 2-μm AOM Q-switched seed source consists of a pair of 2008-nm FBGs, a fiber-pigtailed multimode diode lasers at 793 nm, a (2 + 1) × 1 combiner, a piece of 3-m-long Tm3+-doped double-clad single-mode fiber (Nufern, PM-TDF-10P/130-HE, cladding-absorption of 4.7 dB/m at 793 nm), and a fiber-pigtailed AOM. A homemade cladding pump light stripper (CPS) is spliced between the gain fiber and AOM to remove the residual pump light. At a repetition rate of 30 kHz, the max output power at 2008 nm is 600 mW. A high-power broadband isolator is followed after the seed laser to ensure that the seed laser is not affected by possible backward light from the amplifier. The loss caused by isolator is about 2 dB.

In the thulium-doped fiber power amplifier, the active fiber is the same as that used in the seed laser. A high-power fiber-pigtailed diode laser at 793 nm with a maximum output power of 30 W is employed as the pump source. A piece of 0.5-m single-clad fiber (SMF-28) is spliced after the amplifier for stripping the residual 793 nm pump laser. As shown in the Fig. 2a, with 21.6 W incident pump power, the amplifier produces 9.26 W average output power at 2008 nm. Figure 2b shows a typical output pulse, whose width is about 180 ns. The peak power of the pump laser is then calculated to be 1.71 kW.

The highly nonlinear Raman gain fiber used in the experiments is UHNA7 from Nufern, which is a highly Ge-doped step-index fiber with a core diameter of 2.4 μm and an NA of 0.41. The UHNA7 fiber has a zero dispersion of ~2.6 μm due to large normal waveguide dispersion. The silica-clad UHNA7 fiber is directly fuse spliced to the single-mode SMF-28 fiber with a splice loss of 0.5 dB. So after the splice point, the pump peak power is reduced to about 1.5 kW.

To obtain high-efficiency generation of the 2.2-μm Stokes light with amplified spontaneous Raman scattering process, the suppression of higher-order Raman Stokes light is one of the key issues. Traditional methods to suppress higher-order Stokes light include the decrease of the laser intensity in the fiber and the shortening of the fiber length. Specially designed fibers, such as Raman filter fiber, are also used to suppress higher-order Raman Stokes light. In our experiments, we chose to shorten the Raman gain fiber length. However, if the fiber length is too short, the pump light can not be converted to first-order Stokes light adequately. So to find the optimized fiber length with the 1.5-kW pump peak power, the conversion efficiency of the different Stokes light along the fiber is simulated according to a coupled equations model and parameters provided in Ref. [15]. Gaussian pulse is assumed in the laser simulation. As shown in the Fig. 3, for the first-order Stokes light at 2.2 μm, the optimized fiber length is about 4.8 m, corresponding to a conversion efficiency of 73 %. With increasing Raman gain fiber length, the second-order Stokes light will build up from noise, which leads to the decrease of the first-order Stokes light.

In the experiment, we have tested with 4, 4.4, and 4.8 m of UHNA7 fiber. The output spectra are analyzed with an optical spectrum analyzer (SM301-EX, Spectral Products), which has a resolution of 15 nm at 2–5 μm wavelength range. The output from the Raman fiber laser contains residual pump light, first-order Stokes light and second-order Stokes light. The maximum total output power is 4.63, 4.59, and 4.55 W for the 4, 4.4, and 4.8 m UHNA7 fiber, respectively, as shown in Fig. 4a. With the laser output spectrum, the fraction of the 2.2-μm laser in the total output can be calculated, and the result is shown in the Fig. 4b. It is seen that in the case of 4 m fiber length, the fiber is too short to convert the pump light to first-order Stokes light adequately. In the case of 4.8 m fiber length, the fiber is so long that the second-order Stokes light builds up from noise, which reduces the fraction of the first-order Stokes light in the output.

In comparison, the 4.4-m case is close to the optimum in the experimental condition, which produces the highest output at 2.2 μm, and a fraction of 64.2 % in the total output. The power of the 2008-nm (residual pump), 2.20-μm (first Stokes), and 2.43-μm (second Stokes) laser from the 4.4-m-long Raman fiber amplifier versus the 2008-nm incident pump power is plotted in Fig. 5a. With 9.26 W incident pump power, the total output is 4.59 W, of which 3 and 0.53 W is at 2.20 and 2.43 μm, respectively. The corresponding optical efficiency from 2008 nm to 2.20 μm is 35.9 %. The output spectrum of the Raman fiber amplifier at maximum power is depicted in Fig. 5b. Although the linewidth is broad, the Raman Stokes are clearly separated. The total pulse width detected directly from the Raman amplifier is about 250 ns, as shown in the Fig. 5c. The peak power of 2.20 μm pulse is estimated to about 400 W.

The experimental results are qualitatively consistent with the numerical simulations in terms of fiber length dependence and high-order Raman Stokes generation. However, the conversion efficiency is only about half of the simulation result. Possible explanation could be the wrong estimation of the fiber loss and the broad spectrum of Raman emission. Also, a much broader pulse width is measured compared to the pump pulse, which also requires further investigation.

4 Summary

In conclusion, we report the first experiment demonstration of a pulsed amplified spontaneous Raman emission in silica-based fiber at wavelength ≥2.2 μm with average out power higher than 1 W. Highly Ge-doped silica fiber is used in gain medium, and amplified spontaneous Raman scattering process is utilized to generate a 2.2-μm laser with a simple all-fiber configuration. Special attention is paid to the optimization of gain fiber length for suppressing the higher-order Stokes light. Up to 3 W, 2.2-μm Stokes light is obtained with a conversion efficiency of 35.9 % from 2.0 to 2.2 μm. The peak power is about 400 W. In the future, we will continue to improve the conversion efficiency and output power of pulsed silica-based fiber Raman laser at wavelength >2.1 μm. And we think the watt-level pulsed silica-based fiber Raman laser at wavelength >2.1 μm will find many practical applications.

References

I.T. Sorokina, V.V. Dvoyrin, N. Tolstik, E. Sorokin, IEEE J. Sel. Top. Quantum Electron. 20, 1 (2014)

M. Henriksson, M. Tiihonen, V. Pasiskevicius, F. Laurell, Appl. Phys. B 88, 37–41 (2007)

G. Stoeppler, N. Thilmann, V. Pasiskevicius, A. Zukauskas, C. Canalias, M. Eichhorn, Opt. Express 20, 4509–4517 (2012)

P.F. Moulton, G.A. Rines, E.V. Slobodtchikov, K.F. Wall, G. Frith, B. Samson, A.L.G. Carter, IEEE J. Sel. Top. Quantum Electron. 15, 85 (2009)

G.D. Goodno, L.D. Book, J.E. Rothenberg, Opt. Lett. 34, 1204 (2009)

K. Yin, B. Zhang, G.H. Xue, L. Li, J. Hou, Opt. Express 22, 19947 (2014)

N. Simakov, A. Hemming, W.A. Clarkson, J. Haub, A. Carter, Opt. Express 21, 28415 (2013)

V. Fortin, M. Bernier, J. Carrier, R. Vallée, Opt. Lett. 36, 4152–4154 (2011)

V. Fortin, M. Bernier, D. Faucher, J. Carrier, R. Vallee, Opt. Express 20, 19412 (2012)

M. Duhant, W. Renard, G. Canat, T.N. Nguyen, F. Smektala, J. Troles, Q. Coulombier, P. Toupin, L. Brilland, P. Bourdon, G. Renversez, Opt. Lett. 36, 2859–2861 (2011)

E.M. Dianov, I.A. Bufetov, V.M. Mashinsky, V.B. Neustruev, O.I. Medvedkov, A.V. Shubin, M.A. Melkumov, A.N. Gur’yanov, V.F. Khopin, M.V. Yashkov, Quantum Electron. 34, 695 (2004)

B.A. Cumberland, S.V. Popov, J.R. Taylor, O.I. Medvedkov, S.A. Vasiliev, E.M. Dianov, Opt. Lett. 32, 1848–1850 (2007)

P.T. Rakich, Y. Fink, M. Soljačić, Opt. Lett. 33, 1690 (2008)

J. Liu, F. Tan, H. Shi, P. Wang, Opt. Express 22, 28383 (2014)

H.W. Jiang, L. Zhang, Y. Feng, Opt. Lett. 40, 3249 (2015)

Acknowledgments

The work was supported by the National Natural Science Foundation of China (Nos. 61575210 and 61378026).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, H., Zhang, L., Yang, X. et al. Pulsed amplified spontaneous Raman emission at 2.2 μm in silica-based fiber. Appl. Phys. B 122, 74 (2016). https://doi.org/10.1007/s00340-016-6344-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6344-9