Abstract

An Yb–Er co-doped phosphate glass double-clad fiber with hexagonal inner cladding was fabricated by stack-and-draw method. Output power of 4.9 W was extracted with slope efficiency of 30 % from the fiber with 55 cm in length.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Double-clad (DC) high pump absorption efficiency (PAE) and thus short-length rare earth-doped fiber are always attractive research subjects in fiber lasers [1, 2]. There are two ways to enhance the PAE: increasing the doping level fiber core and making the inner cladding noncircular to depress the spiral light [3]. On one hand, to realize the first method, the soft glasses with much higher rare earth solubility than silica, such as silicate glass [4], phosphate glass [5, 6], germanium glass [7], and fluoride glass [8], might be ideal candidates as the fiber matrix. In addition, adjusting the refractivity of soft glasses is much easier than silica glass [9], making it possible to acquire a much smaller numerical aperture (NA) and thus much larger single-mode core. On the other hand, some techniques including drilling [10], extruding [11], and casting [12] can be used to acquire a DC fiber with noncircular inner cladding. However, the above-mentioned methods have their own drawbacks. Drilling is time-consuming and short-length limited. Extruding method is only feasible for glasses with low softening temperature and is high cost because the dies used to acquire the certain shape are easily destroyed by the high temperature and high pressure imposed by the extruding instrument. Casting technique is also complicated in manufacturing process, and the acquired glasses are inhomogeneous. By comparison, the stack-and-draw method might be an alternative way to reduce the symmetry of the fiber’s inner cladding. In the first place, acquiring an asymmetrical inner cladding such as rectangle, hexagon, and D shape is easy by stack-and-draw method [13, 14]. On the other hand, this method is economic and is feasible for all types of glasses.

In this paper, an Yb–Er co-doped phosphate double-clad fiber with hexagonal inner cladding was fabricated with stack-and-draw method. The concentration of the Yb and Er ions is 6 and 0.5 wt%, respectively. Output power of 4.9 W was extracted from a 55-cm-long fiber with 30 % slope efficiency.

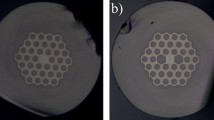

The compositions of the undoped outer cladding glass G2, inner cladding glass G1 and Er–Yb co-doped core glass G0 are 65P2O5–15Al2O3–8Y2O3–10BaO–2La2O3, 65P2O5–15Al2O3–2Y2O3–10BaO–8La2O3, and 65P2O5–15Al2O3–6Yb2O3–10BaO–3.5La2O3–0.5Er2O3, respectively. The concentration of the Yb and Er ions is 6 and 0.5 wt%, respectively. The measured refractive indices of the undoped outer cladding glasses G2, inner cladding glasses G1, and Er–Yb co-doped core glasses G0 are 1.5133, 1.5378, and 1.5398 at 1.55 µm, respectively, measured by the V-prism method with accuracy of 5 × 10−5. The luminescence spectrum and luminescence decay of G0 are shown in Figs. 1 and 2. The life time at 1535 nm is measured to be 8.2 ms. Stack-and-draw method was used to prepare the fiber preform which was then fed into the drawing tower and fabricated into fibers. The process has been detailed in the Ref. [15] and will not be illustrated here. Figure 3 shows the fiber end, from which one can find that the outer cladding was circular and the inner cladding is hexagonal.

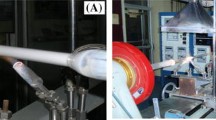

A fiber with 55 cm is used to build up the laser. The laser scheme is shown in Fig. 4. The NA of the core and the inner cladding is 0.078 and 0.28, respectively. The diameter of the doped core, the inner cladding, and the outer cladding is 25, ~150, and ~280 µm, respectively. A loss of 2.6 dB/m at ~1310 nm and a pump absorption coefficient of ~8 dB/m at 927 nm were measured by cut-off method. A fiber-coupled laser diode operating at 927 nm was used as pump source. A collimating lens was applied to align the pump beam, and a coupling lens with NA of 0.3 served as laser input coupler. The cavity was composed by a butt-coupled dichroic mirror with 99 % reflectivity around 1550 nm and a cleaved fiber end with ~4.5 % Fresnel reflectivity.

The laser performance of the fiber is shown in Fig. 5. The laser spectrum is shown in Fig. 6. Maximum output power of 4.9 W with slope efficiency of 30 %. The central wavelength of the laser is 1535 nm, and the full width at half maximum (FWHM) is around 1.1 nm. The low slope efficiency mainly results from the high propagation loss and low pump absorption coefficient. The former can be improved by developing the manufacture technology of the raw glasses and the fiber. And the latter can be improved by further increasing the dope level and by optimizing the fiber structure further. The measured beam quality is shown in Fig. 7. The fiber laser is multimode, and the M 2 factor is 2.1.

In summary, we report an Yb–Er co-doped double-clad fiber with hexagonal inner cladding fabricated by stack-and-draw method. Output power of 4.9 W was obtained from fiber with 55 cm in length. By improving the fabrication technology of the glasses and the fiber and by using heavily doped glasses, the performance of the fiber can be further improved.

References

R. Su, P. Zhou, X. Wang, R. Tao, X. Xu, High Power Laser Sci. Eng. 2, e3 (2014)

C. Jauregui, J. Limpert, A. Tuennermann, Nat. Photonics 7, 861 (2013)

A. Liu, K. Ueda, Opt. Commun. 132, 511 (1996)

J. Fang, L. Jiang, Q. Cao, Y. Yuan, L. Qu, J. Duan, Y. Lu, Chin. Opt. Lett. 12, 121402 (2014)

M. Franczyk, R. Stepien, D. Pysz, I. Kujawa, R. Buczynski, Laser Phys. Lett. 11, 851048 (2014)

B.I. Denker, B.I. Galagan, V.A. Kamynin, A.S. Kurkov, Y.E. Sadovnikova, S.L. Semenov, S.E. Sverchkov, V.V. Velmiskin, E.M. Dianov, Laser Phys. Lett. 10, 55109 (2013)

T. Xue, L. Zhang, L. Wen, M. Liao, L. Hu, Chin. Opt. Lett. 13, 81602 (2015)

F. Huang, X. Liu, W. Li, L. Hu, D. Chen, Chin. Opt. Lett. 12, 51601 (2014)

L. Hu, S. Chen, J. Tang, B. Wang, T. Meng, W. Chen, L. Wen, J. Hu, S. Li, Y. Xu, Y. Jiang, J. Zhang, Z. Jiang, High Power Laser Sci. Eng. 2, e1 (2014)

Y.W. Lee, S. Sinha, M.J.F. Digonnet, R.L. Byer, S. Jiang, Opt. Lett. 31, 3255 (2006)

V.V. Kumar, A. George, W. Reeves, J. Knight, P. Russell, F. Omenetto, A. Taylor, Opt. Express 10, 1520 (2002)

Z. Guiyao, H. Zhiyun, L. Shuguang, H. Lantian, Appl. Opt. 45, 4433 (2006)

G. Zhang, Q. Zhou, C. Yu, L. Hu, D. Chen, Opt. Lett. 37, 2259 (2012)

J. Hou, J. Zhao, C. Yang, Z. Zhong, Y. Gao, S. Chen, Photon. Res. 2, 59 (2014)

L. Wang, D. He, L. Hu, D. Chen, Laser Phys. 25, 045108 (2015)

Acknowledgments

The National Nature Science Foundation of China (51272262 and 61405215).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, L., Wang, L., He, D. et al. Yb–Er co-doped phosphate fiber with hexagonal inner cladding. Appl. Phys. B 122, 68 (2016). https://doi.org/10.1007/s00340-016-6339-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6339-6