Abstract

We show the fabrication and characterization of a suspended GaN-based nanostructure in the visible wavelength region that combines InGaN/GaN multiple quantum wells (MQWs) active layer with rib waveguides and then creates multiple separate beamlets. It is implemented on a GaN-on-silicon platform, where silicon substrate is removed and suspended epitaxial films are thinned by back wafer etching technique. When the InGaN/GaN MQWs active layer is optically excited, part of the emitted light is confined inside epitaxial films and acts the light source. The lateral propagation direction is controlled by the rib waveguide, and the light intensity and the propagation mode can be tuned by changing the rib waveguide structure. Experimental and simulated results indicate the proposed suspended GaN-based structure is promising for the integration of emitting device with planar optical circuit in the visible wavelength region.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Integrated optical devices are of great interest for optical communication [1–3], and novel photonic platforms are intensively investigated for developing multifunctional and ultra-compact integrated photonic circuits [4, 5]. Regarding the potential monolithic integration of emitter, waveguide and detector structures, it requires a material system with multiple optoelectronic functions. From the material point of view, GaN as a direct-bandgap semiconductor exhibits unique optical and electrical properties. It can play the three functions of light emission, transmission and detector simultaneously, enabling the development of compact guided wave circuits and beam splitter [6–9]. GaN-on-silicon platform with InGaN/GaN multiple quantum wells (MQWs) may offer a feasible choice.

With the advances in the epitaxial growth, group III layers can be successfully grown on silicon substrate, and GaN-based light-emitting diode (LED) has been demonstrated with the mandatory use of the nitrogen carrier gas process [10–13]. GaN-based LED is promising for visible light communication due to its modulation behaviour. When the GaN-based LED die on a GaN-on-silicon platform is fabricated by cleaving the wafer, there are some escape cones parallel to the wafer surface except for the two escape cones perpendicular to the wafer surface. Part of the emitted light is confined inside suspended epitaxial films when silicon substrate is removed. The confined light is guided and laterally propagates for suspended membrane devices. Hence, escape cones parallel to the wafer surface can be used for the development of planar photonic circuit for optical communication. Moreover, back wafer thinning technique has been used to tune the thickness of suspended epitaxial film for a variety of photonic devices [14–16].

Here, we propose, fabricate and characterize a suspended GaN-based nanostructure on a GaN-on-silicon platform. Six rib waveguides are connected to the central emission region. The emitted device intrinsically provides its own light source when the InGaN/GaN MQWs active layer is optically pumped. The confined light laterally propagates along rib waveguides, where the propagation direction, light intensity and propagation mode can be tuned. Scanning electron microscope (SEM) and atomic force microscope (AFM) are used to perform the physical characterizations of fabricated GaN-based nanostructure. The light propagation performance is experimentally demonstrated, and finite difference time domain (FDTD) simulation is carried out to evaluate the suspended GaN-based nanostructure.

Figure 1a schematically illustrates a suspended GaN-based rib waveguide. The silicon substrate is removed, and part of suspended epitaxial films is thinned from the backside. Most of the emitted light is confined inside the epitaxial films due to the large refractive index contrast between GaN and air. Thick epitaxial films can support many optical modes, and the confined light laterally propagates inside epitaxial films. The wave guiding layer consists of the slab and the rib. The variables are rib waveguide width w and guiding layer thickness t. For a given guiding layer thickness t, the slab thickness t s correspondingly decreases when the rib height t r increases, leading to different optical confinement inside suspended rib waveguide. There is a trade-off between the thickness of rib and slab, where optimal light propagation performance can be obtained. The optically pumping integrated optical device is schematically demonstrated in Fig. 1b. Escape cones parallel to the wafer surface are designed as different rib waveguides. A flower-petal arrangement is used in a 360°-star beam splitter, where six rib waveguides are equally spaced in angle and impinging on the circular disc. Multiple beam splitting achieved in our work is not due to the self-imaging properties of multimode waveguides [17, 18]. The incoming beam originates from the excited light when the central disc is optically pumped. With the introduction of rib waveguides, the emitted light that is confined inside epitaxial films can be divided into various propagation directions. Hence, the light propagation direction is controllable and the output can be tuned by changing the rib waveguide. Furthermore, the central disc can be fabricated as electrically driven GaN-based LED, which can be switched on and off at very high rates. As a result, the intensity of the output light can be modulated, which is promising for the development of integrated photonic circuits for planar visible light communication services. As the GaN-based LED is turned off, it can also be used as receivers just like photodiodes. It means the suspended GaN-based nanostructure can sense the incoming light from different propagation directions.

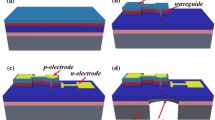

The suspended GaN-based nanostructure is implemented on one commercial GaN-on-silicon wafer from AZZURRO Semiconductors AG, which consists of ~120-nm-thick p-GaN layer, ~125-nm InGaN/GaN MQWs, ~2.8-μm-thick n-GaN layer and ~4-μm buffer layer. The dry etching of GaN-based nanostructures is a challenging issue [19]. Since the proposed nanostructures are defined by electron beam (EB) lithography, and the EB resist is thin and not suitable for the hard etching mask, HfO2 film is used as etching mask [20]. Figure 2 illustrates the schematic fabrication process. A 200-nm-thick HfO2 film is evaporated onto the top device layer by EB evaporation and subsequently crystallized at 800 °C. A 350-nm-thick positive EB ZEP520A resist is spin-coated onto the HfO2 layer, and the beam splitter patterns are defined in ZEP520A resist using EB lithography. The patterns are then transferred to the HfO2 film by fast atom beam etching, which is generated by the neutralization of ions extracted from direct-current SF6 plasma (steps a–b). The waveguide structures are then etched by reactive ion etching (RIE) with Cl2 and BCl3 hybrid gases at the flow rate 10 and 25 sccm, respectively, where the HfO2 film acts as hard etching mask (step c). Subsequently, silicon substrate is patterned by backside alignment photolithography and removed by deep reactive ion etching of silicon, where alternating steps of SF6 etching and C4F8/O2 passivation are conducted and the buffer layer acts as the etching stop layer (steps d–e). Suspended epitaxial membrane is then thinned with the guiding layer thickness t of 4 μm from backside by RIE of GaN. Finally, the suspended GaN-based nanostructure is generated by removing the residual photoresist (steps f–h).

Figure 3a illustrates the optical micrograph of the suspended GaN-based nanostructure. The measured radius of the circular suspended membrane is 113.6 μm. Six rib waveguides with different propagation directions are connected to the circular emission region, which is used for optical pump. The rib waveguides are 50 μm long. The results experimentally show that the suspended GaN membrane is suitable for developing membrane photonic circuit because of high material strength of GaN. Figure 3b shows the SEM image of the fabricated GaN-based nanostructure. The circular disc for optical pump is 10 μm in diameter. In our optical excitation measurement, the laser beam can be focused onto the sample with a light spot of ~3 μm in diameter. The circular emission region is large enough for optical characterization. Rib waveguides with various propagation directions are fabricated with the rib waveguide width w of 2, 4 and 6 μm. The inset is an AFM image of one of the rib waveguides, where the measured rib height t r is 0.4 μm and the rib waveguide width w is 2 μm.

The PL measurement is performed using a microzone confocal Raman spectroscope equipped with a colour charge-coupled device camera. The 325-nm He–Cd laser is used as the excitation source. Figure 4a shows the measured PL spectra of suspended epitaxial film at room temperature. The dominant PL peak locates at 435.5 nm, which is attributed to the excitation of InGaN/GaN MQWs. When the light is generated in the central disc, part of the emitted light escapes from the GaN/air interface when the escape cone condition is fulfilled, and the rest is guided inside suspended epitaxial films. Figure 4b shows that the guided light laterally travels along the 50-μm-long rib waveguides and is diffracted into the air at the waveguide output ports. Six emission spots are clearly observed at the six waveguide output ports. There are no emission spots except the central disc and the waveguide output ports, indicating that the rib waveguides can effectively control light propagation direction and the lateral propagation should match the confinement requirements of the rib waveguide.

Different light intensities are observed at the output ports of different waveguides by optically pumping the central disc. Figure 5 shows the light intensities of emission spots. The emission spot is weaker for 2-μm-wide rib waveguides in comparison with those of 4- and 6-μm-wide rib waveguides. With increasing the rib waveguide width, the emission spot becomes brighter and the light intensity is clearly increased. It means that wider rib waveguide can support more optical modes inside the rib waveguide and higher light intensity can be obtained at the waveguide output ports.

As the intensity of the excited laser increases from 3 to 7.5 and 15 μW, the intensity of the emitted light by the central disc correspondingly increases, as shown in Fig. 6a, b, respectively. Thus, higher light intensities are observed at the waveguide output ports. Figure 6c, d shows the measured light intensities at the waveguide output ports with the waveguide width w of 6 μm. It can be seen that the light intensity at the waveguide output ports is enhanced as the excited power increases.

When the emitted light laterally travels along the rib waveguides, stable propagation modes are dependent on the rib waveguide structure and light wavelength. Several optical modes that have different propagation constants can propagate inside the rib waveguide. The finite element method (FEM) is used to calculate the TE mode confined inside the rib waveguide. A three-dimensional rib waveguide with the guiding layer thickness t of 4 μm is constructed in the FEM calculation. The Gaussian light source is used with the wavelength of 435 nm, which corresponds to the measured dominant PL peak. Table 1 shows the TE mode distribution inside the rib waveguide region with different waveguide widths w and rib heights t r . The waveguide can support more optical modes with increasing the rib height t r , as well as the waveguide width w. It means that more light power can be transmitted through the rib waveguide when the rib height t r is larger and the waveguide width w is wider.

According to the calculated mode data, the three-dimensional simulation is converted into a two-dimensional FDTD calculation, which is used to evaluate the light propagation performance. The 435-nm light source is used for the simulation, and the intensity at the waveguide outputs is monitored for different excitation conditions. The rib waveguide width w is 4 μm, and the guiding layer thickness t is 4 μm. Figure 7a shows that the optical confinement is weak due to the small effective index difference between the rib waveguide region and the surrounding medium, where the rib height t r is 0.5 μm. Figure 7b–d demonstrates that the optical confinement is strengthened with increasing the rib height t r to 1, 2 and 3 μm. Figure 7e–h illustrates the calculated mode profiles inside the rib waveguide region. When the rib height t r is 3 μm, TE7 mode can also be supported and propagate inside the rib waveguide, indicating that more optical modes can propagate along the rib waveguide as the rib height t r increases.

The rib waveguides with various waveguide widths are calculated to investigate the influence on the light propagation performance, where the rib height t r is 3 μm and the slab thickness t s is 1 μm. As shown in Fig. 8, rib waveguide can control light propagation direction and more optical modes are supported inside rib waveguide with increasing the waveguide width w from 2 to 6 μm. Figure 8a–c shows the calculated light emission images for the central disc with the rib waveguides at the waveguide width w of 2, 4 and 6 μm, respectively. Figure 8d–f illustrates the corresponding mode profiles of TE3, TE7 and TE10. More light can be guided and laterally in-plane propagates along the rib waveguide as the waveguide width w increases. The guided light is finally diffracted into air at the waveguide output port. Therefore, the light intensity ratio at the waveguide output ports is thus improved, as illustrated in Fig. 9. It can be seen that the light power confined inside the rib waveguide is low when the rib height t r is smaller than 2 μm.

A suspended GaN-based nanostructure is implemented on a GaN-on-silicon platform, where silicon substrate is removed to achieve high optical confinement in epitaxial films and suspended epitaxial films are thinned by back wafer etching technique to improve optical performance. Escape cones parallel to the wafer surface are designed as different rib waveguides, which are equally spaced in angle and impinging on the circular disc. By optically pumping the central disc, the emitting device intrinsically provides its own light source, and different light intensities are observed at the waveguide output ports. The light intensity can be tuned by changing the rib waveguide structure, which is in consistent with FDTD simulation. Experimental and simulated results indicate the suspended GaN-based nanostructure is promising for the development of integrated optical circuits for planar visible light communication/sensing services.

References

M. Thompson, A. Politi, J. Matthews, J. O’Brien, Integrated waveguide circuits for optical quantum computing. IET Circuits Devices Syst. 5, 94 (2011)

J.L. O’Brien, G.J. Pryde, A.G. White, T.C. Ralph, D. Branning, Demonstration of an all-optical quantum controlled-NOT gate. Nature 426, 264 (2003)

Y. Zhang, L. McKnight, E. Engin, I.M. Watson, M.J. Cryan, E. Gu, M.G. Thompson, S. Calvez, J.L. O’Brien, M.D. Dawson, GaN directional couplers for integrated quantum photonics. Appl. Phys. Lett. 99(16), 161119 (2011)

Y.S. No, J.H. Choi, M.S. Hwang, H.G. Park, Investigation of light coupling between a semiconductor nanowire and a plasmonic waveguide. J. Korean Phys. Soc. 63(10), 1851–1854 (2013)

M. Tchernycheva, A. Messanvi, A. de Luna Bugallo, G. Jacopin, P. Lavenus, L. Rigutti, H. Zhang, Y. Halioua, F.H. Julien, J. Eymery, C. Durand, Integrated photonic platform based on InGaN/GaN nanowire emitters and detectors. Nano Lett. 14(6), 3515–3520 (2014)

M. Gromovyi, F. Semond, J.Y. Duboz, G. Feuillet, M.P. Demicheli, Low loss GaN waveguides for visible light on Si substrates. J. Eur. Opt. Soc. 9, 14050 (2014)

U. Dharanipathy, N. Vico Triviño, C. Yan, Z. Diao, J.-F. Carlin, N. Grandjean, R. Houdré, Near-infrared characterization of gallium nitride photonic-crystal waveguides and cavities. Opt. Lett. 37, 4588–4590 (2012)

I.-W. Feng, W.P. Zhao, J. Li, J.Y. Lin, H.X. Jiang, J. Zavada, Correlation between the optical loss and crystalline quality in erbium-doped GaN optical waveguides. Appl. Opt. 52, 5426–5429 (2013)

Y. Li, A. Bhattacharyya, C. Thomidis, T.D. Moustakas, R. Paiella, Ultrafast all-optical switching with low saturation energy via intersubband transitions in GaN/AlN quantum-well waveguides. Opt. Express 15, 17922–17927 (2007)

A. Krost, A. Dadgar, GaN-based optoelectronics on silicon substrates. Mater. Sci. Eng. B 93, 77–84 (2002)

J. Dadgar, A. Bläsing, A. Diez, A. Alam, M. Heuken, A. Krost, Metalorganic chemical vapor phase epitaxy of crack-free GaN on Si (111) exceeding 1 µm in thickness. Jpn. J. Appl. Phys. 39, L1183–L1185 (2000)

H. Hardtdegen, M. Hollfelder, R. Meyer, R. Carius, H. Münder, S. Frohnhoff, D. Szynka, H. Lüth, MOVPE growth of GaAs using a N2 carrier. J. Cryst. Growth 124, 420–426 (1992)

I.M.N. Duxbury, P. Dawson, U. Bangert, E.J. Thrush, W. Van Der Stricht, K. Jacobs, Effects of carrier gas on the properties of InGaN/GaN quantum well structures grown by MOCVD. Phys. Status Solidi 216, 355–360 (1999)

Y. Wang, J. Chen, Z. Shi, S. He, L.G. Martin, L.F. Chen, A.H. Nikolai, C. Martin, M. Zhang, H.B. Zhu, Suspended membrane GaN gratings for refractive index sensing. Appl. Phys. Express 7(5), 052201 (2014)

X. Li, Z. Shi, G. Zhu, M. Zhang, H. Zhu, Y. Wang, High efficiency membrane light emitting diode fabricated by back wafer thinning technique. Appl. Phys. Lett. 105(3), 031109 (2014)

Y. Wang, Z. Shi, X. Li, S. He, M. Zhang, H. Zhu, Surface-normal emission from subwavelength GaN membrane grating. Opt. Express 22, 667 (2014)

S.S. Choi, J.P. Donnelly, S.H. Groves, R.E. Reeder, R.J. Bailey, P.J. Taylor, W.D. Goodhue, All-active InGaAsP–InP optical tapered-amplifier 1 × N power splitters. IEEE Photon. Technol. Lett. 12, 974 (2000)

J.M. Heaton, R.M. Jenkins, D.R. Wight, J.T. Parker, J.C.H. Birbeck, K.P. Hilton, Novel 1-to-N way integrated optical beam splitters using symmetric mode mixing in GaAs/AlGaAs multimode waveguides. Appl. Phys. Lett. 105, 1754 (1992)

M. Mikulics, H. Hardtdegen, D. Gregušová, Z. Sofer, P. Šimek, S. Trellenkamp, D. Grützmacher, H. Lüth, P. Kordoš, M. Marso, Non-uniform distribution of induced strain in a gate-recessed AlGaN/GaN structure evaluated by micro-PL measurements. Semicond. Sci. Technol. 27, 105008–105011 (2012)

M. Mikulics, H. Hardtdegen, Nano-LED array fabrication suitable for future single photon lithography. Nanotechnology 26, 185302 (2015)

Acknowledgments

This work is jointly supported by NSFC (11104147, 61322112), research project (2014CB360507, RLD201204, BJ211026, SJZZ_0105).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bai, D., Wu, T., Li, X. et al. Suspended GaN-based nanostructure for integrated optics. Appl. Phys. B 122, 9 (2016). https://doi.org/10.1007/s00340-015-6293-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-015-6293-8