Abstract

The paper presents a study of the effect of excitation conditions in a CuBr vapor brightness amplifier in a monostatic laser monitor on the radial non-uniformity of the radiation bearing the information about the object being visualized. A significant dependence of radial signal distribution on the concentrations of CuBr, HBr and pumping power has been demonstrated. In particular, an increase in CuBr vapor concentration causes the gain profile of the active medium to constrict and the axial gain to increase. The conditions for the most uniform radial distribution of the laser monitor signal are substantially different from those for the maximum radiated power. The paper demonstrates HBr doping to be usable as a tool to correct the non-uniformity of the radial distribution of laser monitor radiation. An addition of ~0.15 Torr HBr broadens and flattens the radiation profile, improving an important aspect of laser monitor image quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Active optical systems with brightness amplification (such as laser projection microscopes or laser monitors) present a significant practical interest for the observation of objects and processes masked from the observer by intense radiation [1–9]. The term “laser monitor” for a specific class of laser-based visualization instruments has been proposed by the authors of [2, 3]. A laser monitor is based on an active lasing medium used as a brightness amplifier. Gas discharge brightness amplifiers with copper or copper compound vapors as the active medium have become most popular in these systems due to their unique characteristics [10–12]. The use of CuBr vapor brightness amplifiers for monitoring such processes as self-propagating high-temperature synthesis, laser beam interaction with a glass surface, electrode surface structure changes in an arc discharge, or an onset of corona discharge in air has been demonstrated in [7, 8]. Due to an intense radiation, the progress of these processes and the dynamic changes in object properties cannot be visually observed by conventional methods. According to the estimates in [7], a laser monitor enables observation of objects with a brightness temperature of 40,000 °C or more. To the extent of our knowledge, the brightest objects actually observed through an active optical system with a metal vapor brightness amplifier are particles in plasma with a temperature of ~15,000 °C [9].

In the early implementations, the capabilities of laser projection microscopes and laser monitors were limited by the recording equipment. An image of the object was projected onto a screen [12–14] or photographed on film [15, 16], which did not allow rapid processes to be observed in real time. With the advent of high-speed CCD cameras, the functionality of laser monitors substantially improved, renewing the interest in their practical application.

To ensure a high quality of images produced by a laser projection microscope or a laser monitor, the means to control the gain characteristics of the active element are desirable. Gain characteristics largely depend on such active medium excitation conditions as pumping power, excitation pulse frequency, composition of the gaseous medium and ratios between its components. Principal components of gas mixtures used in the active elements of copper/copper bromide vapor lasers include the vapors of monoatomic copper or copper bromide, neon as a buffer gas, and molecular hydrogen or hydrogen halide (HCl, HBr) vapors.

The most concerning among the optical characteristics is the radial gain distribution of the active medium. This is related to the fact that individual rays of an image generated by a laser monitor or a laser projection microscope pass through different areas of the active medium [12, 17]. Accordingly, any spatiotemporal gain non-uniformity in some areas of the active medium would cause distortions in brightness transfer in the corresponding segments of the obtained image, i.e., image contrast errors.

Optical characteristics of brightness amplifiers are often studied using a so-called master-oscillator power-amplifier system (MOPA) [18–21] with a separate laser (the “master-oscillator”) used to probe the active medium of the amplifier. Thus, [18] presents a gain profile study of a CuBr vapor active element using a MOPA system with the active medium transversally scanned by a 3-mm beam.

The most popular design of a laser monitor is a monostatic scheme [22] with one and the same active element (the brightness amplifier) being used both for object illumination and for amplification of the reflected light. The profile of the illuminating beam (i.e., superluminescent radiation) also depends on the active medium gain profile. For this reason, studies of optical characteristics of brightness amplifiers in a MOPA system do not provide a complete picture of distortions in the transfer of object brightness. Therefore, studying the effect of excitation conditions on radial distribution of radiation in a CuBr vapor brightness amplifier using a setup approximating the standard monostatic design of a laser monitor becomes a high-priority topic in the studies of laser monitor image quality enhancement.

2 Experiment

The study was conducted on a sealed-off active element with external heating of the active volume of the discharge tube, similar to the ones described in [7, 18, 23–25]. The active element had an active volume (gain volume) 90 cm long and 5 cm in diameter. Copper bromide vapors were supplied to the active volume of the element from three heated containers with copper bromide powder equally spaced along the discharge tube. Container heating was provided independently of active volume heating. HBr (an active admixture) was introduced into the active volume at partial pressures up to 0.2 Torr from a HBr generator in the form of a dedicated heated container with HBr-saturated zeolite [26, 27]. Temperatures of all heaters were controlled by means of chromel–alumel thermocouple sensors and automatically stabilized at preset levels with an accuracy of ±5 °C. The active volume heater of the discharge tube was maintained at a constant temperature of 730 °C throughout the experiments; copper bromide container temperature was varied from 440 to 570 °C. Neon at a pressure of 30 Torr was used as a buffer gas.

The active medium was excited by a circuit of pulse charging of the storage capacitor with its subsequent discharge directly through the discharge tube [24, 25]. The trigger switch between the storage capacitor and the discharge tube was based on a TGI1-1000/25 air-cooled thyratron capable of switching up to ~1.5 kW average power. Pumping pulse repetition rate was 20 kHz. A 500-pF storage capacitor was used.

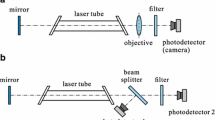

Radial distribution of radiation was registered in a standard monostatic laser monitor scheme shown in Fig. 1. Its principle of operation is as follows. The object to be visualized is illuminated with a superluminescent radiation generated by the active medium. A fraction of this radiation is reflected by the object and reintroduced into the active medium where it undergoes brightness amplification. A flat mirror of 80 % reflectance (Fig. 1) simulates a visualized object with a uniform reflectance throughout the entire visualization area, which allows the effect of object reflectance to be excluded from the analysis of gain characteristics of the active element of the laser monitor.

The study was dedicated to a detailed analysis of the laser monitor output radiation profile, i.e., the radiation emitted by the active medium, reflected off the mirror and amplified by the same active medium (Fig. 1). In our case of using the mirror as an object, radiation being measured is actually a double-pass amplified spontaneous emission. Radiation profiles were recorded by a Spiricon SP503U USB camera using BeamGage Standard 5.4 software. As the discharge tube has a diameter of 5 cm, while the dimensions of the active area of the camera sensor are only 6.5 × 4.8 mm2, optical matching elements were used to record the entire cross section of the beam: a SPZ17024 fourfold zoom optical lens installed on the camera and an Industar-51 photographic lens with 48 mm aperture and 210 mm focal length (Fig. 1). The radiation intensity was attenuated by gray light filters selected so as to prevent camera sensor saturation. Average power of radiation was measured by a L30C-SH optical power meter by Ophir Optronics Solutions Ltd. with its detector head installed at the output of the discharge tube during measurement cycles (without repositioning any optical elements of the setup). To reduce the possibility of parasitic lasing, filters were installed at an angle to the optical axis.

3 Experimental results and discussion

The study addressed the evolution of a laser monitor output radiation profile under variations in principal operating parameters of the active medium, including HBr-active admixture concentration, CuBr concentration and pumping power. Active element operation was initially optimized to achieve the maximum lasing power in a plane-parallel cavity. A maximum lasing power of 5 W without HBr additive at the pumping power of 1350 W (measured as mains power consumption of the high-voltage power supply) was achieved at the copper bromide container temperature of 570 °C. An average lasing power of 10 W was achieved at the HBr generator temperature of 110 °C (~0.2 Torr of the active admixture) and copper bromide container temperature of 530 °C.

A number of references [28–35] mention that doping the active medium with molecular hydrogen or hydrogen halide (HBr, HCl) tends to flatten out the gain and lasing profile, eliminating the intensity dip at the center of the beam typically occurring in copper/copper bromide vapor lasers. Conversely, no intensity dip at the center of the beam was observed in [18] even at low copper bromide vapor concentrations. However, an addition of HBr admixture drove the gain profile toward the Gaussian shape. A Gaussian beam profile was also observed in [36] in a CuBr vapor laser with capacitive pumping both with and without HBr doping.

Figure 2 shows the profiles of laser monitor output radiation at different HBr admixture concentrations. Measurements were taken at a constant pumping power of 1350 W and copper bromide container temperature of 490 °C. The arrangement of the optical components also remained unchanged throughout the experiment. The effect of HBr doping on discharge characteristics occurs in the HBr partial pressure interval from 0.1 to 0.2 Torr [26], which in our case corresponded to the HBr generator temperature range of 90–110 °C. As the temperature stabilization system only supported several fixed settings, the following approach was used for the measurement. The HBr generator temperature was set to 100 °C, which corresponded to the HBr partial pressure of ~0.15 Torr and 8 W average power output in a plane-parallel cavity. A series of laser monitor output radiation profiles were progressively recorded in the course of HBr diffusion into the active medium. Once the radiation profile stopped evolving (curve 5 on Fig. 2c), the HBr generator temperature setting was raised to 110 °C. Curve 7 on Fig. 2c corresponds to a steady state with a concentration of HBr admixture in the discharge medium corresponding to the HBr generator temperature of 110 °C. Any further temperature increases led to discharge contraction and unstable lasing. Only one profile (curve 8 on Fig. 2c) was recorded for HBr generator temperatures above 110 °C. One can notice a significant contraction of the laser monitor output radiation profile.

As one can see from the profile set in Fig. 2c, an addition of HBr broadens and flattens the laser monitor output radiation profile. The radiation profile without the admixture has a marked axial dip (Fig. 2a). A “flat top” profile, which corresponds to the most uniform radial gain distribution, is observed at the HBr generator temperature of 100 °C (Fig. 2b). However, a significant increase in HBr concentration causes the profile to sharpen with the gain peaking along the axis.

An increase in half-magnitude profile width (but not in bottom width) with molecular hydrogen doping was experimentally observed in [30] in a CuBr laser discharge tube with a diameter of 2 cm. A similar effect of hydrogen doping was noted in a model of a monoatomic copper vapor laser with a 2.5-cm discharge tube [32]. According to the same calculations, doping with hydrogen chloride (HCl) would cause beam broadening at the bottom level and sharpening at the peak. One can also mention an experimental paper [31] where an addition of HBr led to beam profile narrowing, which may have been caused by an excessive concentration of the admixture. Generally, the results of the above papers are in good agreement with the data obtained in our study.

Figure 3 presents the average power of superluminescent beam and output radiation from a brightness amplifier versus the temperature of copper bromide containers. For the HBr admixture to achieve a boosting effect on lasing power, the active medium pumping power is to exceed a certain threshold, e.g., about 1000 W for the discharge tube in question [24]. In the present study, all measurements were taken at a constant pumping power of 1350 W, which exceeds this threshold. For this reason, the addition of admixture has a boosting effect—that is, laser monitor output radiation power in the presence of HBr admixture exceeds that without the admixture (Fig. 3).

Average laser monitor output radiation power and average superluminescent beam power curves with and without HBr admixture. 1 Superluminescent radiation without HBr, 2 laser monitor output radiation without HBr, 3 superluminescent radiation with HBr and 4 laser monitor output radiation with HBr. Pumping power: 1350 W

Figure 4 presents laser monitor output radiation profiles at different temperatures of copper bromide containers without and with HBr admixture (HBr generator temperature 110 °C). In the presence of the HBr admixture and at copper bromide container temperatures over 530 °C, the discharge contracts and becomes unstable. One can see from Fig. 4 that an increase in copper bromide vapor concentration (which, as can be seen from Fig. 3, leads to an increase in average emissive power in the stable discharge region) causes the radiation profile to contract and become flatter. The flattest top of the radiation profile is observed at copper bromide container temperatures of 515–530 °C.

A distribution of superluminescent beam intensity for copper bromide container temperatures of 450 and 480 °C is presented in [30]. The paper notes a half-magnitude narrowing of the superluminescent beam profile as the copper bromide concentration in the active medium decreases, whether with or without hydrogen doping. This is consistent with the laser monitor output radiation profile contraction observed in the present study.

An analysis of curves in Fig. 3 shows that HBr doping of the active medium of CuBr lasers introduced to improve frequency and power characteristics does also slightly increase the single-pass gain (the ratio of laser monitor output radiation power to superluminescent radiation power). Furthermore, an addition of the admixture flattens the radiation profile at low concentrations of copper bromide vapors (T ≤ 500 °C), and the axial dip in radiation intensity disappears. At higher temperatures of copper bromide containers, an addition of the admixture makes the radiation profile sharper. One should emphasize that HBr doping in a concentration corresponding to the HBr generator temperature of 100 °C is optimal for the use of this active element in a laser monitor setup, as it ensures the most uniform radiation profile. High concentrations of the HBr admixture cause the radiation profile and the discharge to contract.

In the discharge tube at hand (5 cm in diameter), optimal conditions correspond to the average laser monitor output radiation power of 1–1.8 W without HBr or 2.5–3 W doped with HBr, which is less than maximum achievable emissive power. These values correspond to CuBr powder container temperatures of 515–530 °C without HBr or 475–500 °C with HBr, which is substantially below the temperatures for the maximum average emissive power in the plane-parallel cavity lasing mode.

Pumping power is an important variable in optimizing the operation of a brightness amplifier. The study analyzed the dependence of laser monitor output radiation profile on pumping power for the active medium without and with HBr admixture (with the HBr generator temperature of 110 °C). Measurements were taken at a constant copper bromide container temperature of 490 °C and pumping power (measured as mains power consumption of the high-voltage power supply) varying from 430 to 1560 W. The resulting laser monitor output radiation profiles are presented in Fig. 5. As can be seen from the curves, an increase in pumping power causes the radiation profile to broaden, both with and without HBr admixture. A distinctive abrupt contraction of the laser monitor output beam profile along with an increase in beam intensity was observed at pumping power of 920 W in the presence of HBr or 600 W without HBr. This operating mode is obviously undesirable for a laser monitor, as it may cause narrowing of the field of view. At pumping power levels below 700 W in the presence of HBr or below 400 W without HBr, the study was complicated by the instability of the discharge.

The optimum pumping power to obtain the flattest profile of laser monitor output radiation in the discharge tube at hand was ~1000 W (without HBr admixture). The axial output beam intensity dip increases at higher pumping power levels. For operation with doping, the optimal pumping power appears to be above the limit of the laboratory setup.

The axial dip in beam intensity in large-diameter lasers may be caused by such effect as gas overheating in the axial region, radial electric field, or skin effect [37–39]. As noted in [28], even at a higher pumping power, an addition of hydrogen would reduce the axial beam intensity dip similarly to hydrogen bromide in our study. Modeling results in [39] do also confirm the addition of small quantities of hydrogen to the active medium to improve the situation with the axial dip.

4 Conclusions

The study has demonstrated the operating conditions of CuBr vapor active element to obtain the maximum diameter of a laser monitor output beam and the most uniform radial distribution of its intensity in the brightness amplifier mode in a monostatic laser monitor scheme to be different from the conditions for the maximum average emissive power in a plane-parallel cavity lasing mode. The optimal concentrations of copper bromide vapors and HBr admixture are lower for the brightness amplifier operation.

In the discharge tube at hand, the flattest gain distribution across the active medium corresponded to an average laser monitor output radiation power 40–60 % below the maximum value achieved. For this operating mode, the temperature of CuBr powder containers was 515–530 °C without HBr admixture, or 475–500 °C in the presence of HBr.

Doping the active medium with HBr not only increased the emissive power and gain, but also flattened the gain profile, bringing it closer to the Gaussian shape. However, high concentrations of the HBr admixture caused the radiation profile and the discharge to contract. Thus, HBr as an admixture turns out to be an efficient tool to manipulate the gain profile of the active medium.

The experiments also revealed a strong dependence of the radiation profile on the concentration of copper bromide vapors (as a function of temperature of CuBr powder containers). An increase in CuBr vapor concentration causes the gain profile of the active medium to contract and the gain in the axial region of the discharge tube to increase. This effect occurs both with and without the HBr admixture. It should also be noted that obtaining the maximum bottom width of the gain profile requires a sufficiently high pumping power.

References

K.I. Zemskov, M.A. Kazaryan, V.M. Matveev, G.G. Petrash, M.P. Samsonova, A.S. Skripnichenko, Sov. J. Quantum Electron. 14, 288 (1984)

V.M. Batenin, I.I. Klimovsky, L.A. Selezneva, Sov. Phys. Dokl. 33, 949 (1988)

D.V. Abramov, S.M. Arakelyan, A.F. Galkin, I.I. Klimovskii, A.O. Kucherik, V.G. Prokoshev, Quantum Electron. 36, 569 (2006)

R.O. Buzhinsky, V.V. Savransky, K.I. Zemskov, A.A. Isaev, O.I. Buzhinsky, Plasma Phys. Rep. 36, 1269 (2010)

V.M. Yermachenko, A.P. Kuznetsov, V.N. Petrovskiy, N.M. Prokopova, A.P. Streltsov, S.A. Uspenskiy, Laser Phys. 21, 1530 (2011)

M.V. Trigub, N.A. Agapov, G.S. Evtushenko, F.A. Gubarev, Russ. Phys. J. 56, 588 (2013)

G.S. Evtushenko, M.V. Trigub, F.A. Gubarev, T.G. Evtushenko, S.N. Torgaev, D.V. Shiyanov, Rev. Sci. Instrum. 85, 033111 (2014)

D.V. Rybka, M.V. Trigub, D.A. Sorokin, G.S. Evtushenko, V.F. Tarasenko, Atmos. Ocean. Opt. 27, 582 (2014)

F.B.J. Buchkremer, A.J. Andrews, D.W. Coutts, C.E. Webb, Technical Digest of Papers Presented at The Thirteenth UK National Quantum Electronics Conference (University of Wales, Cardiff, 1997), p. 116

C.E. Little, N.V. Sabotinov (eds.), Pulsed Metal Vapour Lasers (Kluwer Academic Publishers, Dordrecht, 1996)

C.E. Little (ed.), Metal Vapor Lasers: Physics, Engineering and Applications (Willey, Chichester, 1998)

G.G. Petrash (ed.), Optical Systems with Brightness Amplifiers (Nauka, Moscow, 1991)

Z. Xiao, G. Zhang, X. Song, G. Chen, F. Lin, Chin. J. Lasers 19, 712 (1992)

Z. Meng, G. Zhang, X. Song, J. Jiang, F. Lin, Chin. J. Lasers B 6, 91 (1997)

Z. Xiao, G. Zhang, F. Lin, Appl. Opt. 31, 3395 (1992)

F. Lin, Proc. SPIE 2513, 499 (1995)

M.A. Kazaryan, Optical systems with image brightness amplifiers. Dissertation ScD, P.N. Lebedev Physical Institute, 1987

F.A. Gubarev, V.O. Troitskiy, M.V. Trigub, V.B. Sukhanov, Opt. Commun. 284, 2565 (2011)

G.N. Tiwari, R.K. Mishra, R. Khare, S.V. Nakhe, Pramana J. Phys. 82, 217 (2014)

D.J.W. Brown, M.J. Withford, J.A. Piper, IEEE J. Quantum Electron. 37, 518 (2001)

D.N. Astadjov, S.V. Nakhe, J. Phys: Conf. Ser. 253, 012076 (2010)

A.P. Kuznetsov, R.O. Buzhinskij, K.L. Gubskii, A.S. Savjolov, S.A. Sarantsev, A.N. Terekhin, Plasma Phys. Rep. 36, 428 (2010)

S.N. Torgaev, F.A. Gubarev, A.M. Boichenko, G.S. Evtushenko, O.V. Zhdaneev, Russ. Phys. J. 54, 221 (2011)

F.A. Gubarev, G.S. Evtushenko, N.K. Vuchkov, V.B. Sukhanov, D.V. Shiyanov, Rev. Sci. Instrum. 83, 055111 (2012)

V.A. Dimaki, V.B. Sukhanov, V.O. Troitskii, A.G. Filonov, Instrum. Exp. Tech. 55, 696 (2012)

D.V. Shiyanov, V.B. Sukhanov, G.S. Evtushenko, O.S. Andrienko, Quantum Electron. 34, 625 (2004)

A.G. Filonov, D.V. Shiyanov, Instrum. Exp. Tech. 56, 349 (2013)

D.N. Astadjov, N.V. Sabotinov, N.K. Vuchkov, Opt. Commun. 56, 279 (1985)

M.J. Withford, D.J.W. Brown, J.A. Piper, Opt. Commun. 110, 699 (1994)

D.N. Astadjov, N.K. Vuchkov, K.I. Zemskov, A.A. Isaev, M.A. Kazaryan, G.G. Petrash, N.V. Sabotinov, Sov. J. Quantum Electron. 15, 457 (1988)

M.J. Withford, D.J.W. Brown, R.J. Carman, J.A. Piper, Opt. Commun. 135, 164 (1997)

R.J. Carman, M.J. Withford, D.J.W. Brown, J.A. Piper, Opt. Commun. 157, 99 (1998)

M.J. Withford, D.J.W. Brown, R.P. Mildren, R.J. Carman, G.D. Marshall, J.A. Piper, Prog. Quantum Electron. 28, 165 (2004)

M.J. Withford, D.J.W. Brown, R.J. Carman, J.A. Piper, Opt. Commun. 154, 160 (1998)

M. Kocik, M. Mohamed-Seghir, J. Mizeraczyk, Proc. SPIE 3571, 135 (1999)

F.A. Gubarev, V.B. Sukhanov, G.S. Evtushenko, V.F. Fedorov, D.V. Shiyanov, IEEE J. Quantum Electron. 45, 171 (2009)

R.J. Carman, R.P. Mildren, M.J. Withford, D.J.W. Brown, J.A. Piper, IEEE J. Quantum Electron. 36, 438 (2000)

R.J. Carman, J. Appl. Phys. 82, 71 (1997)

C. Cheng, S. Wei, Opt. Quantum Electron. 28, 405 (1996)

Acknowledgments

The authors are grateful to M. E. Levitskii for the technical support. The author, Miron Klenovskii, is expressing his gratitude to the Tomsk Polytechnic University for the opportunity to conduct scientific research in the TPU postdoctoral program. The work was supported by the Russian Science Foundation, Project No. 14-19-00175.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gubarev, F.A., Trigub, M.V., Klenovskii, M.S. et al. Radial distribution of radiation in a CuBr vapor brightness amplifier used in laser monitors. Appl. Phys. B 122, 2 (2016). https://doi.org/10.1007/s00340-015-6288-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-015-6288-5