Abstract

Tm3+/Al3+ co-doped silica glass with the composition of 0.08 Tm2O3–0.8 Al2O3–99.12 SiO2 (mol%) is prepared by combining the high-temperature plasma furnace sintering technology and the dried RE-doped granulates. Using the prepared Tm3+/Al3+ co-doped silica glass as the fiber core, the Tm3+/Al3+ co-doped air-cladding fiber is fabricated by the stack-and-draw technology. Optical and laser properties of Tm3+/Al3+ co-doped air-cladding fiber are studied. The experimental results show that the Tm3+/Al3+ co-doped air-cladding fiber can be used as the potential material for the high-power fiber laser operating at 2 μm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, thulium-doped (Tm3+-doped) fiber lasers have attracted much attention because of extensive applications in material processing, laser sensing, free-space optical communication, and biomedicine [1–6]. At present, lots of efforts have been directed toward high-power fiber laser [7–9] or pumped light source for generating the longer laser wavelength with the holmium-doped fiber [10, 11]. In 2010, Tm3+-doped fiber with 1 kW average power has been reported by Ehrenreich [12]. At present, Tm3+-doped fibers used for high-power fiber laser are mainly fabricated by the modified chemical vapor deposition (MCVD) method. However, it is difficult to make large-diameter fiber core using this method, especially for the fabrication of large-mode-area photonic crystal fiber (PCF). The studies have reported that the doping homogeneity of fiber is deteriorated because the MCVD method is multilayer deposition process [13–15]. So far, there have been several new alternative manufacturing methods to achieve rare-earth-doped fiber (RE-doped fiber) fabrication such as Repusil process [16, 17], powder sinter technology [18], atomic layer deposition [19], direct nanoparticle deposition [20], gas-phase doping technology [21], and sol–gel method [22–26]. Most of them is concentrated on the fabrication of ytterbium-doped (Yb3+-doped) traditional fiber or Yb3+-doped PCF [27, 28]. However, there are few reports on the fabrication of RE-doped fiber based on the high-temperature plasma furnace sintering technology and the dried RE-doped granulates [29–31], and, in particular, Tm3+-doped air-cladding fiber. Comparing with the traditional MCVD method, large-size glass samples with a broad composition can be prepared by the prepared technology for high-power special optical fiber laser.

In this paper, Tm3+/Al3+ co-doped silica glass with the composition of 0.08 Tm2O3–0.8 Al2O3–99.12 SiO2 (mol%) is prepared by combining the high-temperature plasma furnace sintering technology and the dried RE-doped granulates [29]. Using the prepared Tm3+/Al3+ co-doped silica glass as the fiber core, a Tm3+/Al3+ co-doped air-cladding fiber is fabricated by the stack-and-draw technology. Optical and laser properties of Tm3+/Al3+ co-doped air-cladding fiber are studied.

2 Fabrication of Tm3+ air-cladding fiber

The fabrication process of Tm3+ air-cladding fiber reported here is similar to the fabrication of RE-doped photonic crystal fiber (RE-doped PCF). Firstly, the core glass rod of Tm3+/Al3+ co-doped air-cladding fiber preform is prepared by combining the high-temperature plasma furnace sintering technology and the dried RE-doped granulates. This technology is selected due to its potential to provide large volume of high-concentration RE-doped silica glass [29]. In addition, the dried RE-doped granulates in this process is obtained by the hydrolysis of SiCl4 in the RE-doped and co-doped ions solution, which can provide the homogenous distribution of the core RE ions. Finally, a bulk Tm3+/Al3+ co-doped silica glass with free bubble with 0.08 Tm2O3–0.8 Al2O3–99.12 SiO2 (mol%) is prepared. Then, the bulk Tm3+/Al3+ co-doped silica glass is ground and polished to form the proper diameter Tm3+/Al3+ co-doped silica rod for Tm3+/Al3+ co-doped air-cladding fiber core.

Secondly, Tm3+/Al3+ co-doped air-cladding fiber preform is prepared by the stacking capillaries method. The central capillaries are replaced by the bulk Tm3+/Al3+ co-doped silica glass rod.

Thirdly, the prepared fiber preform is fixed onto the feeder of the drawing tower. Finally, the preform is drawn into the fiber under the temperature of 1800–2000 °C.

In order to study the spectroscopic properties of core glass, the bulk Tm3+/Al3+ co-doped silica glass rod is cut and polished to a 5-mm-thick glass chip. The light source (DH-2000-BAL, ocean optics) is used, and the absorption spectra are recorded with a spectrophotometer (Maya 2000 and Nirquest 256, ocean optics) in the range of 200–2500 nm. The fluorescence spectrum of fiber fabricated by our PNCVD is detected by using the spectrophotometer (Maya 2000 and Nirquest 256, ocean optics) at 793 nm excitation. The pump source is a 793 nm laser diode (M793±3-16-F105/22-C1, HAN’STCS, China) with a laser spot diameter of 105 µm and NA of 0.22. All the measurements are taken at the room temperature.

3 Results and discussion

3.1 Spectral properties of Tm3+/Al3+ co-doped silica glass

Figure 1 shows the absorption and fluorescence of Tm3+/Al3+ co-doped silica glass chip prepared by combining the high-temperature plasma furnace sintering technology and the dried RE-doped granulates. The glass thickness used in the experiment is 5 mm. As seen from Fig. 1a, a significant absorption peaks centered at 785 nm is observed, corresponding to the 3H6–3H4 transition of Tm3+ ions. In addition, the relative weak absorption peaks centered at 681, 468, 352, 294, 280, and 272 nm are also observed, which ascribe to the level transition of Tm3+ ions from the ground state 3H6 to excited states 3F2,3, 1G4, 1D2,1I6, 3P0,1, and 3P2, respectively [32, 33]. As seen from Fig. 1b, a wide emission band around 1780 nm is observed when the Tm3+-doped glass chip is excited at 793 nm, corresponding to the 3F4–3H6 transition of Tm3+ ions [34]. The full width at half maximum (FWHM) of the emission spectrum is up to 400 nm, which suggests that Tm3+/Al3+ co-doped silica glass fabricated by the plasma non-chemical vapor deposition can be used as the potential material for the tunable Tm3+-doped fiber laser.

3.2 Tm3+/Al3+ co-doped air-cladding fiber

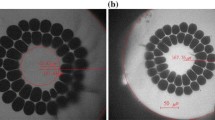

Figure 2 shows the cross section of Tm3+-doped air-cladding fiber fabricated by stack-and-draw technology. The outer and inner cladding diameters of the fiber are 255 and 93.5 μm, respectively. The air-cladding bridge width is 1.83 μm. Here, the air cladding can provide a high numerical aperture (NA) through controlling the width of silica bridges [35, 36]. The NA of the inner silica cladding with respect to air cladding is calculated. The NA of our Tm3+-doped air-cladding fiber is 0.35. In addition, NA is essential for efficient pump coupling into the small inner cladding [37]. To improve the absorption efficiency of doping core, the doping core is far away from the center region of fiber. In Fig. 2, the dotted line region is Tm3+-doped region. The doping core diameter is 25.7 μm, which suggest that the Tm3+-doped air-cladding fiber fabricated is a large area fiber [38].

3.3 Loss properties of Tm3+/Al3+ co-doped air-cladding fiber

Fiber loss is an important optical property of fiber, especially for the RE-doped fiber using the fiber laser. The loss spectrum of the drawn Tm3+-doped air-cladding fiber is depicted in Fig. 3, where the light source (400–2500 nm) is used. The loss of Tm3+-doped air-cladding fiber is determined by using the cutback method. As seen from the loss spectrum, there are several absorption loss peaks centered at 351, 465, 678, 786, 1198, 1389, 1604, and 2230 nm, respectively, and the loss peaks centered at 351, 465, 678, 786, 1198, and 1604 nm correspond to the absorptions from the ground state 3H6 to the excited states 1D2, 1G4, 3F2,3, 3H4, 3H5, and 3F4 [39]. The absorption loss at the wavelength of 786 nm is 24.696 dB/m, which is higher than that reported in Ref [40]. The absorption loss at 793 nm is 16.35 dB/m. The high absorption at 793 nm offers a platform for realizing the high-power fiber laser operating at 2 μm. Moreover, the optical loss at 1333 nm is 0.712 dB/m, which is lower than that of Tm3+ doped fiber prepared by sol–gel method [23] and could be ascribed to the existence of scattering sources as observed in doping core glass. The absorption loss at 1389 nm is mainly due to the existence of hydroxyl groups. In addition, a loss band around 2230 nm is also observed, which is resulted from the absorption of OH in the fused silica [41–43].

3.4 Laser performance of Tm3+/Al3+ co-doped air-cladding fiber

To evaluate the laser performance of the prepared Tm3+/Al3+ co-doped air-cladding fiber, the laser experiment is carried out. Figure 4 shows the experimental setup of Tm3+/Al3+ co-doped air-cladding fiber. The resonator cavity is formed by using two dichroic mirrors at the input and output ends of fiber. One is fixed on the incident end of the fiber, which has high reflectivity within the wavelength range from 1850 to 2053 nm and high transmittance at 793 nm. The other is fixed on the output end of fiber, which has high reflectivity at 793 nm and high transmittance at 2053 (~85 %). The pump light source used is 793 nm LD diode with a spot diameter of 105 nm and NA of 0.22. The pump light is collimated and focused by a couple of 10× lenses. A filter is used to separate the residual pump power and the generated laser power. The output power is measured by a power meter. The fiber length used in the experiment is 0.9 m.

The spectral variation in the Tm3+-doped air-cladding fiber laser with the increase in pump power is shown in Fig. 5. The pump power is chosen as 100, 200, 600, and 1000 mW, respectively. The emission intensity is increased obviously with the increase in pump power, as shown in Fig. 5a–d. As seen from Fig. 5c, when the pump power is close or over the laser threshold, an intense and sharp emission peak is observed. The centered wavelength is centered at 1968 nm. With the further increase in pump power, a more intense and sharp emission band will be observed. According to the analysis, this spectrum (Fig. 5d) is a laser spectrum. The FWHM is up to 46 nm, which provides a platform to realize the wavelength tunable fiber laser.

Figure 6 shows the laser output power versus incident pump power. The maximum output power is limited to 1.02 W by available pumping power. To the best of our knowledge, this is the highest laser output power report on Tm3+/Al3+ co-doped air-cladding fiber fabricated by plasma non-chemical vapor deposition method. According to the linear fit of measured value, the slope efficiency is 48.2 %. The slope efficiency is lower than that of fiber prepared by using other methods [38], which is mainly ascribed to the fiber un-cleaved end in our experiment. The fiber end in our experiment is cleaved with a ruby–diamond–pencil. If the fiber end is cleaved perpendicularly, the slope efficiency will be further improved. In addition, the slope efficiency with the fiber length is experimentally studied, as shown in Fig. 7. The slope efficiency for the different fiber length (0.6, 0.9, 1.2, and 1.6 m) are 42.5, 48.2, 35.7, and 26.2 %, respectively. According to the above experimental result, the optimum fiber length is 0.9 m. The maximum slope efficiency is higher than that reported in Ref. [1], which suggests that the Tm3+-doped air-cladding fibers prepared by our PNCVD method are suitable for the high-power fiber laser operating at 2 μm. In addition, the output power and slope efficiency will be further improved when the fiber end is clearly cleaved and the coupling loss is reduced. Therefore, further work will be focused on reducing the coupling loss of fiber laser and improving the slope efficiency of Tm3+-doped air-cladding fiber. For example, the fiber end is cleaved by a distinct fiber cleaver or by reducing the background loss of the fiber by optimizing the preparation process of the fiber.

4 Conclusion

In summary, Tm3+/Al3+ co-doped silica glass with the composition of 0.08 Tm2O3–0.8 Al2O3–99.12 SiO2 (mol%) is prepared by combining the high-temperature plasma furnace sintering technology and the dried RE-doped granulates. Using the prepared Tm3+/Al3+ co-doped silica glass as the fiber core, the Tm3+/Al3+ co-doped air-cladding fiber is fabricated by the stack-and-draw technology. The FWHM of emission spectrum is up to 400 nm. The absorption loss at a wavelength of 789 nm is up to 16.9 dB/m. The laser output power of over 1 W limited by available pumping power is obtained in the Tm3+/Al3+ co-doped air-cladding fiber. To the best of our knowledge, this is the highest laser output power in Tm3+/Al3+ co-doped air-cladding fiber fabricated by plasma non-chemical vapor deposition method. The maximum slope efficiency is up to 48.2 %. The FWHM of laser spectrum is up to 46 nm, which provide a platform to realize wavelength tunable fiber laser using our fiber. The experimental results show that the Tm3+/Al3+ co-doped air-cladding fiber can be used as the potential material for the high-power fiber laser operating at 2 μm.

References

N. Modsching, P. Kadwani, R. Andrew Sims, L. Leick, J. Broeng, L. Shah, M. Richardson, Opt. Lett. 36, 3873 (2011)

D. Creeden, B.R. Johnson, S.D. Setzler, E.P. Chicklis, Opt. Lett. 39, 470 (2014)

Y.L. Tang, L. Xu, Y. Yang, J.Q. Xu, Opt. Express 18, 22964 (2010)

Y. Zhang, B.Q. Yao, Y.L. Ju, Y.Z. Wang, Opt. Express 13, 1085 (2005)

C. Liu, C.C. Ye, Z.Q. Luo, H.H. Cheng, D.D. Wu, Y.L. Zheng, Z. Liu, B. Qu, Opt. Express 21, 204 (2013)

X. He, S.H. Xu, C. Li, C.S. Yang, Q. Yang, S.P. Mo, D.D. Chen, Z.M. Yang, Opt. Express 21, 20800 (2013)

G.D. Goodno, L.D. Book, J.E. Rothenberg, Proc. SPIE 7195, 71950Y-1 (2009)

M. Schellhorn, S. Ngcobo, C. Bollig, M. Esser, D. Preussler, K. Nyangaza, in Lasers and Electro-Optics 2009 and the European Quantum Electronics Conference. CLEO Europe—EQEC, pp. 1–1

A. Hemming, S. Bennetts, N. Simakov, A. Davidson, J. Haub, A. Carter, Opt. Express 21, 4560 (2013)

J.W. Kim, A. Boyland, J.K. Sahu, W.A. Clarkson, in CLEO/Europe and EQEC 2009 Conference Digest, (Optical Society of America, 2009) paper CJ6_5

T. Ehrenreich, et al., SPIE Photonics West 2010, LASE Fiber Lasers VII: Technology, Systems, and Applications, Conference 7580, January 2010, Session 16: Late-Breaking News, San Francisco, CA

F.G. Lou, P.W. Kuan, L. Zhang, S.K. Wang, Q.L. Zhou, M. Wang, S.Y. Feng, K.F. Li, C.L. Yu, L.L. Hu, Opt. Mater. Express 4, 1267 (2014)

U. Pedrazza, V. Romano, W. Luthy, Opt. Mater. 29, 905 (2007)

A. Dhar, M.C. Paul, M. Pal, A.K. Mondal, S. Sen, H.S. Maiti, R. Sen, Opt. Express 14, 9006 (2006)

A. Langner, G. Schotz, M. Such, T. Kayser, V. Reichel, S. Grimm, J. Kirchhof, V. Krause, G. Rehmann, Proc. SPIE 6873, 687311 (2008)

A. Langner, M. Such, G. Schotz, F. Just, M. Leich, A. Schwuchow, S. Grimm, H. Zimer, M. Kozak, B. Wedel, 2012. xv, 22, 138, 139, 140, 143

M. Leich, F. Just, A. Langner, M. Such, G. Schötz, T. Eschrich, S. Grimm, Opt. Lett. 36, 1557 (2011)

I. Montiel, J.J. Ponsoda, L. Norin, C. Ye, M. Bonsund, M.J. Soderland, A. Tervonen, S. Honkanen, Opt. Express 20, 25085 (2012)

J.J. Koponen, L. Petit, T. Kokki, V. Aallos, J. Paul, H. Ihalainen, Opt. Eng. 50, 111605 (2011)

S. Unger, F. Lindner, C. Aichele, M. Leich, A. Schwuchow, J. Kobelke, J. Dellith, K. Schuster, H. Bartelt, Laser Phys. 24, 035103 (2014)

V. Romano, L.D. Labio, R. Renner-Erny, F. Sandoz, Lüthy Wand Feurer T 2007 The International Quantum Electronics Conference

H.E. Hamzaoui, L. Bigot, G. Bouwmans, I. Razdobreev, M. Bouazaoui, B. Capoen, Opt. Mater. Express 1, 234 (2011)

S.K. Wang, Z.L. Li, C.L. Yu, M. Wang, S.Y. Feng, Q.L. Zhou, D.P. Chen, L.L. Hu, Opt. Mater. 35, 1752 (2013)

S.K. Wang, S.Y. Feng, M. Wang, C.L. Yu, Q.L. Zhou, H.Y. Li, Y.X. Tang, D.P. Chen, L.L. Hu, Laser Phys. Lett. 10, 115802 (2013)

A. Baz, H. Hamzaoui, I. Fsaifes, G. Bouwmans, M. Bouazaoui, L. Bigot, Laser Phys. Lett. 10, 5106 (2013)

P.G. Yan, G.L. Zhang, H.F. Wei, S.C. Ruan, IEEE J. Lightwave Technol. 31, 3658 (2013)

H.F. Wei, H.W. Chen, S.P. Chen, P.G. Yan, T. Liu, L. Guo, Y. Lei, Z.L. Chen, J. Li, X.B. Zhang, G.L. Zhang, Laser Phys. Lett. 10, 045101 (2013)

C. Xia, G. Zhou, J. Liu, C. Wang, Y. Han, J. Yuan, Appl. Phys. A 118, 523 (2015)

C.M. Xia, G.Y. Zhou, W. Zhang, Y. Han, C. Wang, J.H. Yuan, Opto-Electron. Adv. Mater. Rapid Commun. 9, 619 (2015)

C.M. Xia, G.Y. Zhou, W. Zhang, Y. Han, C. Wang, J.H. Yuan, Opt. Fiber Technol. 25, 20 (2015)

S.D. Jackson, S. Mossman, Appl. Opt. 42, 2702 (2003)

J.T. Thomas, M. Tonelli, S. Veronesi, E. Cavalli, X. Mateos, V. Petrov, U. Griebner, J. Li, Y. Pan, J. Guo, J. Phys. D Appl. Phys. 46, 375301 (2013)

D.J. Lee, J. Heo, S.H. Park, J. Non-Cryst. Solids 331, 184 (2003)

D. Ghosh, A. Halder, M. Pal, M.C. Paul, H. Bookey, S.K. Bhadra, A.K. Kar, Appl. Opt. 50(25), E1 (2011)

K.P. Hansen, J. Broeng, P.M. Skovgaard, J.R. Folkenberg, M.D. Nielsen, A. Petersson, F. Salin, in Lasers and Applications in Science and Engineering (International Society for Optics and Photonics, 2005)

V. Prosentsov, E. Sherman, A. Patlakh, Y. et Ariel, D. Eger, et al., in High-Power Lasers and Applications. (International Society for Optics and Photonics, vol. 193, 2003)

J. Limpert, T. Schreiber, S. Nolte, H. Zellmer, T. Tunnermann, R. Iliew, F. Lederer, J. Broeng, G. Vienne, A. Petersson, C. Jakobsen, Opt. Express 11, 818 (2003)

Z.L. Li, S.K. Wang, X. Wang, P.W. Kuan, L.L. Hu, Chin. J. Lasers 40, 6003 (2013)

F. Jansen, F. Stutzki, C. Jauregui, J. Limpert, A. Tünnermann, Opt. Lett. 37, 4546 (2012)

A.H. Rose, T.J. Bruno, J. Non-Cryst. Solids 231, 280 (1998)

G.F. Schotz, J. Vydra, G. Lu, D. Fabricant, Fiber Opt. Astron. III. 152, 20 (1998)

C.M. Petrie, D.P. Hawn, W. Windl, T.E. Blue, J. Non-Cryst. Solids 409, 88 (2015)

Acknowledgments

This work was supported by National Natural Science Foundation of China under Grants 61377100 and 61205084, Guangdong Natural Science Foundation under Grant S2013040015665, Specialized Research Fund for the Doctoral Program of Higher Education under Grant 20134407120014, and colleges and universities in Hebei Province science and technology research project under Grant QN20131044.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, C., Zhou, G., Liu, J. et al. Optical and laser properties of Tm3+-doped air-cladding fiber fabricated by plasma non-chemical vapor deposition. Appl. Phys. B 121, 25–30 (2015). https://doi.org/10.1007/s00340-015-6197-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-015-6197-7