Abstract

Polarization holographic gratings were formed in liquid crystal (LC) cells fabricated from a mixture of low molecular weight nematic LC and a photoreactive liquid crystalline polymer (PLCP) with 4-(4-methoxycinnamoyloxy)biphenyl side groups. The diffraction properties of the gratings were analyzed using theoretical models which were determined based on the polarization patterns of the polarization holography. The results demonstrated that vector gratings comprised of periodic orientation distributions of the LC molecule were induced in the cells based on the axis-selective photoreaction of the PLCP. The vector gratings were erased by applying a sufficiently high voltage to the cells and then were reformed with no hysteresis after the voltage was removed. This phenomenon suggested that the PLCP molecules were stabilized based on the axis-selective photocrosslink reaction and that the LC molecules were aligned by the photocrosslinked PLCP. This LC composite with axis-selective photoreactivity is useful for various optical applications, because of their stability, transparency, and response to applied voltage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Low molecular weight liquid crystals (LCs) are excellent media in various optical applications due to their large optical anisotropy and transparency in the visible region [1]. Functional active optical elements, including variable focal length lenses, switchable diffraction gratings, and tunable mirrors, are realized by using LCs, because orientation of LC molecules can be controlled by applying external fields [2–9]. In optical elements using LCs, highly sophisticated control technologies for molecular alignment are required. To date, various patterning methods, including photoalignment, microrubbing, and imprinting, have been studied [10–14]. In particular, photoalignment using polarized light has received considerable attention for many years [15]. By using alignment layers photoregulated by means of polarization holographic recording, we can easily obtain LC cells with periodic orientation distributions. Azobenzene-containing materials are typical media for polarization holographic recording [16, 17]. Azobenzene molecules reorient when exposed to linearly polarized (LP) light, through a trans–cis–trans photoisomerization reaction. Therefore, vector gratings consisting of periodic molecular orientation can be formed by polarization holographic recording in azobenzene-containing materials, such as azopolymer films. Azopolymer films with molecular orientation are applicable in alignment layers for LCs [15]. Gibbons et al. [13] demonstrated photopatterning of LC cells using azopolymer films as alignment layers. Choi et al. [18] studied twisted nematic LC gratings fabricated by polarization holographic recording in azopolymer films. Photoalignment is also realized in azobenzene-dispersed LCs. Chen and Brady reported holographic gratings formed by a green laser polarized parallel to the molecular director in an azo-dye-doped LC [19]. We also reported that multidimensional periodic alignment can be achieved by three-dimensional vector holographic recording in azo-dye-doped LCs with initial alignment [20, 21]. These studies demonstrated that azobenzene-dispersed LCs are suitable media for photoalignment, because they do not require photoalignment layers and bonding processes of photoregulated substrates. However, azobenzene-containing materials absorb in the visible region, which can be problematic for optical applications [22].

We have intensively studied LC cell gratings fabricated by using thin films of photoreactive liquid crystalline polymer (PLCP) with cinnamate side groups [23–29]. In these PLCP films, the side groups of the PLCP are cross-linked by irradiating them with polarized ultraviolet (UV) light, and molecular reorientation is induced through subsequent annealing at LC temperature [30]. PLCP films with uniaxial orientation are also applicable in alignment layers of LCs. PLCP films are transparent in the visible region and thermally stable, and their anchoring strength is relatively high [25]. Therefore, PLCPs are suitable media for photoalignment of LCs. We previously reported that various LC cell gratings were obtained by using PLCP films photoregulated by photomasking method, polarization holographic recording, or polarizer-rotation exposure [23–29]. However, photoalignment effects of PLCP-dispersed LCs (i.e., composites of low molecular weight LCs and PLCPs) have not been investigated differently from the case of azobenzene. If the LC composites are aligned by irradiation with polarized UV light, various optical applications are expected due to their transparency. Therefore, to investigate photoalignment properties of the LC composites is very important.

In the present study, we formed polarization holographic gratings in planar LC cells that were fabricated using a nematic LC doped with a PLCP. We discussed the photoalignment effect of the LC composite based on the diffraction properties of the gratings. The polarization dependence of the diffraction efficiencies and the polarization conversion properties of the gratings demonstrated that the axis-selective photoalignment was realized in the LC cells. In addition, the response to applied voltage showed that the orientation distributions in the LC cells were stabilized due to the axis-selective photocrosslink of the PLCP.

2 Experiment

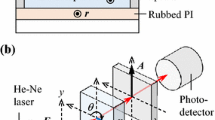

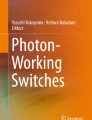

The LC composite was obtained by mixing a nematic LC (4-pentyl-4′-cyanobiphenyl; 5CB) and a PLCP with 4-(4-methoxycinnamoyloxy)biphenyl side groups. The chemical structure of the PLCP is shown in Fig. 1. The synthetic procedure of the PLCP and properties of PLCP films are described elsewhere [30]. The mixture ratio was 5CB/PLCP = 99:1 by weight. The mixture was stirred at 180 °C, until a homogeneous solution was obtained, and then was slowly cooled at room temperature. The LC composite was injected to planar glass cells, fabricated using ITO substrates inner coated with polyvinyl alcohol (PVA) films, by capillary method at room temperature. In this study, we prepared two LC cells. The one was fabricated using rubbed PVA films to obtain homogeneous alignment, and the other one was prepared using rubbing-free PVA films to obtain random alignment in the substrate plane. The cell thicknesses were adjusted to be 5 μm by using spacers. For polarization holographic recording, an LP He–Cd laser with an operating wavelength of 325 nm was used as the light source. The laser beam was divided into two beams with intensities of 0.37 mW/cm2, and these two beams were crossed in the LC cell. Their incident angles were ±0.75°, respectively, which produced an estimated grating pitch of 12 μm. The exposure time used was 90 s. The gratings were formed by orthogonal circularly polarized beams (OC recording) in the rubbing-free cell or parallel LP beams (PL recording) in the rubbing cell. The polarization states of the two beams were controlled using half- and quarter-wave plates. For the PL recording, the two beams were s-polarized and the rubbing direction of the cell was set as being perpendicular to the plane of incidence of the two beams. The experimental geometry is schematically illustrated in Fig. 2. The diffraction properties of the formed gratings were probed using an LP He–Ne laser with an operating wavelength of 633 nm, incident normal to the film plane through a half-wave plate and/or a quarter-wave plate. The intensities and polarization states of the plus and minus first (±1st)-order diffraction beams were measured using an optical power meter and a polarimeter. In the measurements, square-wave voltage with the amplitude of V 0 and the frequency of 1 kHz was applied to the LC cells. The recording and measurements were conducted at room temperature.

3 Results and discussion

3.1 OC recording

Figure 3 shows the measured diffraction properties at V 0 = 0 for the grating formed by OC recording in the rubbing-free cell. In interference light for OC recording, the light intensity is spatially constant and the polarization state is linear polarization whose azimuth angle is linearly rotated for the grating vector direction [17]. When uniaxial optical anisotropy is induced by OC recording and the optical axis is parallel or perpendicular to the polarization azimuth, the phase distribution of the grating is written using the Jones matrix method as

where \( {\varvec{R}} \) is the rotation matrix in the film plane (the xy-plane), \( \xi = 2\pi x/\varLambda \), \( \varLambda \) is the grating pitch, Δn is the photoinduced optical anisotropy, d is the cell thickness, and λ is the wavelength of the probe beam [17]. Here, the grating vector is defined being parallel to the x-axis. From Eq. (1), we can write the Jones matrix determining the ±1st-order diffraction as

where \( \gamma = \pi\Delta {nd}/\lambda \). By defining the normalized Jones vector of the polarized probe beam as \( \varvec{E}_{\text{in}} = (E_{x} ,\,E_{y} ) \), we can obtain the Jones vectors of the ±1st-order diffraction beams as

Equation (3) shows that the +1st-order diffraction beam is left-hand circularly polarized (LCP), and the −1st-order diffraction beam is right-hand circularly polarized (RCP). From Eq. (3), the ±1st-order diffraction efficiencies are given by \( \eta_{ \pm 1} = \left| {\varvec{E}_{ \pm 1} } \right|^{2} \). For example, when the probe beam is RCP, i.e., \( \tfrac{1}{\sqrt 2 }(1,\, - i) \), we obtain \( \eta_{ + 1} = 0 \) and \( \eta_{ - 1} = \sin^{2} \gamma \). These theoretical diffraction properties are consistent with the experimental results shown in Fig. 3. This fact demonstrates that the axis-selective photoreaction was induced in the LC composite, and the orientation distribution given by Eq. (1) was formed due to the photoreaction. From the −1st-order diffraction efficiency for the LCP probe beam, the photoinduced optical anisotropy was estimated as \( \Delta n \cong 4 \times 10^{ - 3} \). Figure 4 shows the dependence of the −1st-order diffraction efficiency for the LCP probe beam on the applied voltage. As shown in Fig. 4, the vector grating (i.e., the orientation distribution) was erased after a sufficiently high voltage was applied. This is because the alignment varied from planar orientation to perpendicular orientation. Figure 4 also shows that the vector grating was reformed after the voltage was removed. This indicates that the photocrosslinked PLCP molecules were stabilized in the cell and that they aligned the LC molecules. The dependence of the diffraction efficiency on the applied voltage is similar to that for the grating fabricated from photoalignment layers [31]. This agreement supports the axis-selective molecular reorientation in the LC composite.

3.2 PL recording

For the grating fabricated by PL recording in the rubbing cell, the ±1st-order diffraction efficiencies were measured by varying the polarization azimuth angle of the LP probe beam. For this grating, the ±1st-order diffraction efficiencies were almost the same. Figure 5 shows the +1st-order diffraction efficiency. At V 0 = 0, the diffraction efficiency significantly depended on the polarization azimuth angle of the LP probe beam. By assuming that the order parameter of the LC composite increased based on the axis-selective photoreaction, we characterized the diffraction efficiency of the grating. For PL recording, the intensity of interference light is given by \( I(x) \propto \cos^{2} (\xi /2) \). Using the light intensity, we write the ordinary and extraordinary refractive indices of the exposed LC composite as \( \tilde{n}_{\text{o}} (x) = n_{\text{o}} -\Delta n_{\text{o}} \cos (\xi /2) \) and \( \tilde{n}_{\text{e}} (x) = n_{\text{e}} +\Delta n_{\text{e}} \cos (\xi /2) \), where n o and n e are the ordinary and extraordinary refractive indices of the LC composite at I = 0 and Δn o and Δn e are the positive proportionality constants. Using these equations, the Jones matrix of the grating is written as

Equation (4) shows that the state of polarization of diffracted beams depend on the input polarization, Δn o and Δn e, and is not defined uniquely unlike for OC recording. We estimated Δn o and Δn e by fitting the theoretical diffraction efficiency calculated from Eq. (4) to the experimental data. The parameters used in the calculation are d = 5.0 μm, λ = 633 nm, n o = 1.53, and n e = 1.69. Here, the ordinary and extraordinary refractive indices are values of 5CB [32]. As shown in Fig. 5, the measured diffraction efficiency was described based on the theoretical model. The values of Δn o and Δn o were determined as 4.8 × 10−3 and 7.0 × 10−3, respectively. This result indicates that the order parameter or refractive indices of the LC composite were spatially modulated by the recording. The vector grating formed in the rubbing cell was also erased when the applied voltage was sufficiently high. This phenomenon indicates that the alignment varied to perpendicular orientation and that the refractive indices were made constant spatially, by applying the voltage. The mechanism of the grating formation should be studied in more detail, but the photoreactive LC composite with axis selectivity is useful for various optical applications, because of their stability, transparency, and response to applied voltage. Figure 6 shows the switching property of the grating in the rubbing cell. For orientation transition in typical LC cells with homogeneous alignment, the switching-on time \( \tau_{\text{on}} \) is substantially shorter than the switching-off time \( \tau_{\text{off}} \), when the applied voltage was sufficiently high. This is because the ratio of \( \tau_{\text{off}} \) and \( \tau_{\text{on}} \) is given by \( {{\tau_{\text{off}} } \mathord{\left/ {\vphantom {{\tau_{\text{off}} } {\tau_{\text{on}} }}} \right. \kern-0pt} {\tau_{\text{on}} }} \cong (V/V_{\text{c}} )^{2} - 1 \), where V is the applied voltage and V c is the threshold voltage [33, 34]. As shown in Fig. 6, the switching-on time was also shorter than the switching-off time.

Figure 7 shows SEM images of the substrates of the LC cells. The substrates were washed using hexane to rinse 5CB. As seen in Fig. 7a–c, aggregates were observed on the substrates of the exposed cells in contrast to an unexposed cell (Fig. 7d). However, there were no clear grating patterns with Λ = 12 μm for the exposed cell. The degree of the aggregation was almost the same for the front and rear substrates (Fig. 7a, b) and for the polarization state of the recording beams (Fig. 7a, c). We also analyzed the substrates using time-of-flight secondary ion mass spectrometry. As a result, the signals originating in C4H5O2, C10H9O3, C12H8O2, and C22H17O4 were observed, i.e., we observed the PLCP at the substrate surface. The peak intensities of the signals were the same degree for the exposed and unexposed cells. Therefore, we guess that the aggregates probably do not contribute the formation of periodic patterns and that the non-aggregated PLCP molecules in the exposed LC cells align 5CB based on the axis-selective photocrosslink reaction.

4 Conclusions

We formed holographic vector gratings in LC cells fabricated from a PLCP-doped LC and investigated their diffraction properties. The polarization dependence of the diffraction efficiencies and the polarization conversion property of the grating formed in the rubbing-free cell indicated that a spatial distribution of optical anisotropy was induced in the LC composite. The vector grating was erased by applying a sufficiently high voltage to the cell and was reformed after the voltage was removed. Namely, the photoreacted PLCP molecules were stabilized in the cell and affected the orientation of the LC composite. The axis-selective photoreaction was also induced in the rubbing cell. By assuming that the order parameter of the LC composite changed due to the axis-selective photoreaction, we described the polarization dependence of the diffraction efficiency based on a theoretical model. We think that these LC composites with axis-selective photoreactivity are useful for various optical applications, because of their stability, transparency, and response to applied voltage.

References

T. Scharf, Polarized Light in Liquid Crystals and Polymers (Wiley, Hoboken, 2007)

S. Sato, Jpn. J. Appl. Phys. 18, 1679 (1979)

L.-C. Lin, H.-C. Jau, T.-H. Lin, A.Y.-G. Fuh, Opt. Express 15, 2900 (2007)

K.-C. Lo, J.-D. Wang, C.-R. Lee, T.-S. Mo, Appl. Phys. Lett. 91, 181104 (2007)

X.-Q. Wang, A.K. Srivastava, V.G. Chigrinov, H.-S. Kwok, Opt. Lett. 38, 1775 (2013)

W.M. Gibbons, S.T. Sun, Appl. Phys. Lett. 65, 2542 (1994)

J. Chen, P.J. Bos, H. Vithana, D.L. Johnson, Appl. Phys. Lett. 67, 2588 (1995)

M. Honma, T. Nose, Opt. Express 20, 18449 (2012)

R.A.M. Hikmet, H. Kemperman, Nature 392, 476 (1998)

M. Honma, T. Nose, Appl. Opt. 43, 5193 (2004)

S. Park, C. Padeste, H. Schift, J. Gobrecht, T. Scharf, Adv. Mater. 17, 1390 (2005)

R. Lin, J.A. Rogers, Nano Lett. 7, 1613 (2007)

W.M. Gibbons, P.J. Shannon, S.-T. Sun, B.J. Swetlin, Nature 351, 49 (1991)

M. Schadt, K. Schmitt, V. Kozinkov, V. Chigrinov, Jpn. J. Appl. Phys. 31, 2155 (1992)

K. Ichimura, Chem. Rev. 100, 1847 (2000)

T. Todorov, L. Nikolova, N. Tomova, Appl. Opt. 23, 4309 (1984)

L. Nikolova, P.S. Ramanujam, Polarization Holography (Cambridge University Press, Cambridge, 2009)

H. Choi, J.W. Wu, H.J. Chang, B. Park, Appl. Phys. Lett. 88, 021905 (2006)

A.G.-S. Chen, D.J. Brady, Opt. Lett. 17, 1231 (1992)

T. Sasaki, H. Ono, N. Kawatsuki, Jpn. J. Appl. Phys. 46, 1579 (2007)

T. Sasaki, H. Ono, N. Kawatsuki, J. Appl. Phys. 104, 043524 (2008)

G.S. Kumar, D.C. Neckers, Chem. Rev. 89, 1915 (1989)

T. Sasaki, H. Ono, N. Kawatsuki, M. Kuwabara, Appl. Phys. Lett. 87, 161112 (2005)

T. Sasaki, H. Ono, N. Kawatsuki, M. Kuwabara, Jpn. J. Appl. Phys. 46, 698 (2007)

H. Ono, S. Oikawa, N. Kawatsuki, J. Appl. Phys. 101, 123523 (2007)

H. Ono, T. Shinmachi, A. Emoto, T. Shioda, N. Kawatsuki, Appl. Opt. 48, 309 (2009)

H. Ono, M. Hishida, A. Emoto, T. Shioda, N. Kawatsuki, J. Opt. Soc. Am. B 26, 1151 (2009)

M. Kuzuwata, T. Sasaki, N. Kawatsuki, H. Ono, Opt. Lett. 37, 1115 (2012)

T. Sasaki, M. Kuzuwata, K. Noda, N. Kawatsuki, H. Ono, Jpn. J. Appl. Phys. 52, 042503 (2013)

N. Kawatsuki, K. Goto, T. Kawakami, T. Yamamoto, Macromolecules 35, 706 (2002)

G.P. Crawford, J.N. Eakin, M.D. Radcliffe, A.C. Jones, R.A. Pelcovits, J. Appl. Phys. 98, 123102 (2005)

P. Yeh, G. Gu, Optics of Liquid Crystal Displays (Wiley, Hoboken, 1999)

E. Jakeman, E.P. Raynes, Phys. Lett. 39A, 69 (1972)

X. Nie, R. Lu, H. Xianyu, T.X. Wu, S.-T. Wu, J. Appl. Phys. 101, 103110 (2007)

Acknowledgments

This work was partially supported by JSPS KAKENHI Grant Number 24760265.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sasaki, T., Shoho, T., Goto, K. et al. Photoalignment and resulting holographic vector grating formation in composites of low molecular weight liquid crystals and photoreactive liquid crystalline polymers. Appl. Phys. B 120, 217–222 (2015). https://doi.org/10.1007/s00340-015-6124-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-015-6124-y