Abstract

The response of non-premixed swirling flames to acoustic perturbations at various frequencies (0–350 Hz) and the impact of imposed air inlet velocity oscillations on the formation and oxidation of soot are investigated. The results obtained from these flames are of special interest for “rich-quenched-lean” (RQL) combustion concepts applied in modern gas turbines. In RQL combustion, the fuel is initially oxidized by air under fuel-rich conditions in a first stage followed by a fuel-lean combustion step in a second stage. To mimic soot formation and oxidation in RQL combustion, soot particle measurements in highly turbulent, non-premixed swirling natural gas/ethylene-confined flames at imposed air inlet velocity oscillations are performed using simultaneous 2-Colour-Time-Resolved-Laser-Induced Incandescence (simultaneous 2-Colour-TIRE-LII). The latter technique is combined with line-of-sight averaged OH*-chemiluminescence imaging, measurements of the velocity field by high-speed particle imaging velocimetry under reactive combustion conditions and measurements of the mean temperature field obtained by a thermocouple. A natural gas/ethylene mixture (Φ = 1.56, 42 % C2H4, 58 % natural gas, P th = 17.6 kW at atmospheric pressure) is used as a fuel, which is oxidized by air under fuel-rich conditions in the first combustion chamber.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Combustion in modern gas turbines, e.g. in “rich-quenched-lean” (RQL) concepts, is taking place sequentially in partially premixed or diffusion flames under fuel-rich and fuel-lean conditions to decrease the combustion temperature and, as a consequence, the NOX emission of the engines. Unfortunately, these combustion conditions are accompanied by the formation of soot [1, 2]. The particles originally formed during the fuel-rich (diffusion controlled) stage have to be completely oxidized in the subsequent fuel-lean stage in order to avoid the emission of soot particles into the ambient air with the exhaust gas of the engine.

The basic concept of RQL is to split the combustion into two stages. In a first stage, the combustion is initiated under fuel-rich conditions, followed by a rapid admixing of secondary air which leads to fuel-lean combustion during the second stage. During non-stationary operating conditions of the gas turbine, flow instabilities may occur, which are the source of combustion instabilities or combustion oscillations. These oscillations are an additional challenge when trying to predict the soot emission from gas turbines. In spite of the significant progress being made with respect to the development and validation of soot models during the last decades, the understanding of the formation and oxidation of soot especially under highly turbulent—gas turbine like—conditions is still incomplete [1–3]. This situation is getting even worse in the presence of combustion oscillations, whose influence on the formation and oxidation of soot is more or less unknown.

Investigations of the impact of imposed air inlet velocity oscillations on laminar and turbulent flames are reported in the literature [see, e.g., 4–6]. However, the majority of existing flame-response literature is not dedicated to the analysis of the impact on the formation and oxidation of soot.

The main goal of this work was to investigate experimentally (1) the response of non-premixed swirling flames to acoustic perturbations at various frequencies (0–350 Hz) and (2) to derive the impact of imposed air inlet velocity oscillations on the formation and burnout of soot. The oscillations were realized with four loudspeakers at the air inlet of a two-stage model combustor. A natural gas/ethylene mixture (Φ = 1.56, 42 % C2H4, 58 % natural gas, P th = 17.6 kW at atmospheric pressure) is used as a fuel which is oxidized by air under fuel-rich conditions in the first combustion chamber. An additional second combustion chamber enables the oxidation of the remaining HC, CO and soot, simulating a RQL combustion concept.

Soot detection and soot particle sizing in the highly turbulent swirl diffusion flames with imposed air inlet velocity oscillations are performed using simultaneous 2-Colour-Time-Resolved-Laser-Induced Incandescence (2-Colour-TIRE-LII). The latter method is described in detail in Ref. [7]. This technique is a non-intrusive diagnostic method based on the simultaneous detection of the time-resolved LII signals at two different wavelengths. These measurements are combined with line-of-sight averaged imaging of OH*-chemiluminescence, measurements of the velocity field by high-speed particle imaging velocimetry (PIV) under reactive conditions and measurements of the mean temperature field. The experimental set-up allows the qualitative determination of the soot volume fractions. The work aims at a detailed and well-documented databases for this standard configuration given for those who are interested in the development and validation of soot models.

2 Methods and experimental set-up

2.1 Simultaneous 2-Colour-Time-Resolved-Laser-Induced Incandescence

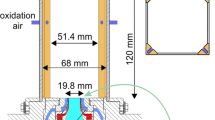

The simultaneous 2-Colour-TIRE-LII is a non-intrusive, diagnostic technique to determine the size distribution of a particle ensemble [7]. It is based on the simultaneous one-dimensional detection of the time-resolved LII signal at two different detection wavelengths along the propagation direction of an unfocussed laser beam. A schematic drawing of the set-up is shown in Fig. 1 [7]. A pulsed frequency-doubled Nd:YAG laser (injection seeded, λ = 532 nm, t pulse = 10 ns, full beam diameter = 8 mm, laser fluence 0.275 J/cm2) induces the LII signal within the measuring volume. The thermal radiation emitted from the particle ensemble is collected by a spherical lens L1, and afterwards the signal is separated by a dichroic plate (DP) into two wavelength regimes: λ 1 > 500 nm and λ 2 < 500 nm. The thermal radiation signals at both wavelengths are imaged onto the entrance slit (slit width = 1250 µm) of a streak camera (Hamamatsu C7700, temporal resolution 3.9 ns/pixel) one aside each other with the help of the lenses L2 and L3, respectively. In the employed modification of 2-Colour-TIRE-LII, the LII signals from a narrow region of the laser beam have been collected, so that finally pointwise measurements were performed. Because of the low soot concentration and consequently low LII signal intensities in the flame under investigation, it was necessary to use a comparatively large detection volume. Therefore, the thermal radiation of the soot particles is accumulated over the total Gaussian laser beam profile. In the vertical direction, the size of the probe volume (1838 μm) is limited by the slit width of the streak camera, taking the magnification ratio 220/150 = 1.47 into account. The spatial resolution in horizontal direction is 1380 µm.

Experimental set-up of the simultaneous 2-Colour-TIRE-LII technique [7]

In front of the entrance slit of the streak camera, appropriate interference filters (IFs) are positioned to further restrict both detection wavelength regimes. The centre wavelength of the filter in the straight optical path is λ 1 = 650 nm (full width at half maximum (FWHM) 40 nm) and λ 2 = 450 nm (FWHM 40 nm) in the folded beam path, respectively. Unfortunately, the experimental set-up is not designed to allow phase-correlated measurements of the soot distributions, because the maximum repetition rates of the CCD camera (Hamamatsu C4880) recording the LII signals from the streak unit (0.5 frames per second) as well as the Nd:YAG laser (10 Hz) are limited.

By applying Planck’s law (assuming grey properties of the soot particles), the temporal evolution of the particle-ensemble temperature can be calculated from the measured ratio of the time-resolved LII signals obtained at two different wavelengths [7–14]:

with T the temperature, h Planck’s constant, k B Boltzmann’s constant, c speed of light, K cal calibration constant, λ detection wavelength, ε spectral emissivity of soot layer and I LII signal intensity (see also “Appendix”). For the estimation of T, the relation ε 2/ε 1 = λ 1/λ 2 is used [7–10, 13]. The latter simplification is entitled in the investigated low-sooting flames, because E(m) was assumed as wavelength independent in the narrow wavelength-interval, ranging from 450 to 650 nm [7–19]. This assumption seems to be reasonable in a diffusion flame, even though some restrictions are found in recent investigations in sooting premixed laminar ethylene/air flames at lower heights above the burner [20, 21].

One of the major advantages of the simultaneous 2-Colour-TIRE-LII experiments is that modelling of laser absorption is not necessary, because the particle temperatures after the laser pulse are experimentally determined. Particle size distributions are obtained by fitting the simulated particle temperature decay onto the measured one by varying fit parameters [7–10, 13]. In the case of a particle system dominated by coagulation, the particle size distribution can be approximated by a log-normal distribution, where two fit parameters (medium size r m and the width of the distribution σ) are needed to describe the size distribution. A multidimensional nonlinear regression method delivers these two parameters [7–10, 13]. Soot volume fractions are obtained from the LII signals at 450 nm, assuming the linearity between LII signal and f V. Relative particle number densities (N T ) are derived from the relative soot volume fractions and the measured (absolute) log-normal particle size distribution according to [7–10, 13]

In order to avoid possible contributions to the LII signal from laser-induced fluorescence originating from polycyclic aromatic hydrocarbons (PAHs), the data for the evaluation of soot properties and the particle temperatures were taken 39 ns after the maximum of the LII signal. For the calculation of the soot particle sizes, locally resolved background flame temperatures T 0 have to be known. Therefore, temporal mean values of T 0 are determined spatially resolved by thermocouple measurements. In a next step, the particle sizes were calculated on the basis of averaged LII signal decays obtained from 40 individual decays and the averaged T 0. The spectral response of the streak camera was calibrated using a wolfram band lamp with known temperature. A more detailed description of LII and the simultaneous 2-Colour-TIRE-LII method applied in this work is given in refs [7–10].

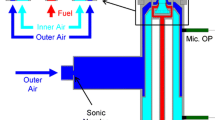

2.2 High-speed particle image velocimetry

The state-of-the-art non-intrusive flow velocity measurement technique is the particle image velocimetry (PIV) using small tracer particles. The particles follow the flow and, therefore, are used for the determination of the fluid velocity. In the present investigation, as shown in Fig. 2, micrometer-sized MgO particles were illuminated by a laserlight sheet of an Ar+-ion laser (INNOVA 70C-5, all lines laser power 4 W, sheet height 60 mm, sheet thickness 0.8 mm) defining the measurement plane. A CMOS camera (High Speed Star 5.1) captures the light scattered by the particles. Two pictures (double-frame mode) were taken within an adjustable time gap of 20 µs at a repetition rate of 8 kHz. The exposure times for both frames are 62 µs. The imaging resolution of the PIV measurements is 115 µm/pixel. Because a 24 × 24 pixel interrogation window with 75 % overlap is chosen to increase the number of vectors, a resulting final spatial resolution of 6 × 115 µm < 0.7 mm is obtained. The two images captured at time t and t’ are stored on two frames of the CMOS sensor. This allows us to cross-correlate the two particle image distributions in small interrogation areas in order to determine their displacement at several positions of the observation field. The principle of the PIV measurement technique relies on the physical definition of velocity as a differential quotient determined by the spatial displacement per time between the frames.

Based on the ±0.07 pixel uncertainty of the peak-finding algorithm (adaptive PIV using Gaussian weighting function, multipass 24 × 24 pixel interrogation window, 75 % overlap), the maximum random uncertainty of in-plane instantaneous velocities is ±0.4 m/s. In order to enhance the measurement accuracy and to reduce the exposure time, it was necessary to take the images separately in three sections above the nozzle (section 1 from 0 to 35 mm height above burner (HAB), section 2 from 35 to 65 mm HAB and section 3 from 66 to 103 mm HAB) instead of one image for the entire combustion chamber. Before the PIV system was applied to the swirled non-premixed flames described above, it was validated against a known and well-investigated velocity field [25]. Several tests reveal quantitative agreement with respect to the absolute values as well as the structures of the latter flow configuration with the a priori known data. Therefore, despite the relatively low-power laser, the chosen evaluation procedure allows us to extract the needed information of the velocity calculation in the present investigation. A detailed description and the variety of PIV measurement techniques are given in refs [22–24].

2.3 Other techniques

The temperature measurements at various oscillation frequencies are carried out by the use of a thermocouple (type B (Pt 30 %–Rh 70 % and Pt 6 %–Rh 94 %) error = 5 %, two thermocouples probe for radiation corrections, d 1 = 0.2 mm and d 2 = 0.4 mm). The two-dimensional temperature field was determined by interpolation of the measured results, obtained at various points at seven HABs, starting at 18 mm HAB with 14 mm step size in axial direction and 2.5 mm step size at radial direction.

Additional information about the combustion process is obtained by line-of-sight averaged OH*-chemiluminescence imaging at a detection wavelength of 309 nm. The OH*-images are phase-locked time-averaged; in other words, the time-averaged values are obtained within the same phase intervals of the oscillation cycles. Measurements were taken at various excitation frequencies using the high-speed camera (High Speed Star 5.1 CMOS) at 8 kHz repetition rate. The measured chemiluminescence distributions depicted in the figures are not Abel-inverted. This is not a problem for the further use of the data in numerical simulations, because in the latter, the line-of-sight averaging can be easily carried out numerically.

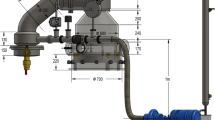

2.4 Model combustor

For the present investigations, a model combustor for gaseous fuels with good optical access was designed and manufactured to apply advanced optical measurement techniques (Fig. 3). For the stabilization of the flame, a double swirl nozzle for gaseous fuels was designed. The air is supplied to both swirl generators individually. A second burning chamber allows the implementation of RQL operating conditions. All measurements are taken in the first combustion chamber (cross-section 89 mm × 89 mm, height 114 mm). As depicted in Fig. 3, optical access is achieved by four quartz glass windows (width × height 74 mm × 112 mm) mounted by steel frames. The measurements were performed in a plane through the nozzle axis. A natural gas/ethylene mixture is used as a fuel which is oxidized by air under rich conditions in the first combustion chamber (Φ = 1.56, 42 % C2H4, 58 % natural gas, P th = 17.6 kW at atmospheric pressure). The air flow ratio (L = Vair,sec/Vair,pri) between the outer and the inner swirl nozzle is L = 1.85, with a total air flow rate Vair = 171 lN/min. In order to perform acoustic perturbations, four loudspeakers were mounted in both separated air inlets (two per air inlet). The response of the confined flame at several acoustic excitation frequencies between 0 and 350 Hz was investigated.

In order to quantify the intensity of the imposed flow oscillations, a sound pressure level was calculated from microphone measurements in the outer and the inner air supply. The comparison between acoustic unexcited and excited case shows an increase in the sound pressure level due to the air inlet perturbations by approximately 19 dB.

3 Results and discussion

In the following, the reacting flow field inside the combustion chamber at various air inlet perturbation frequencies is presented. Figure 4 gives the two-dimensional velocity field for section 1 (5–35 mm HAB) of the primary combustion chamber of the non-excited case. For a better comparability of the results with the excited cases, 50-shot averaged images with 2 ms spacing are displayed. As expected, the flow field remains unchanged with time and shows the same structure and value of the velocity in every time step. The typical inner and outer recirculation zone for a swirl stabilized flame can be observed.

In Figs. 5 and 6, the velocity fields under reactive conditions at 50 and 100 Hz excitation are displayed for section 1 (5–35 mm HAB) and in Figs. 8 and 9 for section 2 (35–65 mm HAB), respectively. As for Fig. 4, the results displayed in Figs. 5, 6, 7, 8 and 9 are averaged values of the same phase intervals of the oscillation cycles. The averaged exposures are taken in the phase-locked mode for a period of 20 ms with 2 ms spacing (50 Hz) and 10 ms with 1 ms spacing (100 Hz), respectively. The flow field in the two cases is strongly influenced by the imposed air inlet oscillations. At 50 Hz, during one period, the flow field varies strongly and the inner recirculation zone (IRZ) moves further downstream at some phase-angles. Additionally, the region of maximal axial velocity shifts and varies its position in every single phase. Also for air inlet oscillation of 100 Hz, the velocity field is influenced. The IRZ exists at all phase-points over one complete 100 Hz oscillation cycle, and the change in the value and position of the maximal and minimal axial velocity is very pronounced. The outer recirculation zone is also affected, and the outer vortex cores are shifted from 10 mm HAB and 25 mm radial position to 25 mm HAB and 35 mm radial position.

The flow response to the air inlet perturbations is strongly frequency-dependent. This can be recognized comparing the results in Figs. 5 and 6 with Fig. 7, where the phase-locked velocity field under reactive conditions over one oscillation cycle with 0.28 ms spacing at 350 Hz excitation frequency is given. In contrast to the 50 and 100 Hz cases, the velocity field remains almost completely unaffected by the acoustic oscillation. At 350 Hz, phase-locked exposures for section 2 are not shown, because they are identical with the results depicted in Fig. 10. The flow field remains unchanged in every single phase at 350 Hz excitation frequency and is similar to the unexcited case. This behaviour of the flow can be attributed to an obviously frequency-depending change in the impedance of the oscillating system under investigation. The latter is influenced by several factors, among others the geometry of the combustion chamber, the shape of the nozzle and the plenum, the interaction between flow and combustion reaction, the thermal load. Depending on the impedance of the system, there is a high-frequency limit, where the flow cannot follow the fluctuations [6]. As a consequence, the response of the flow field to different oscillation frequencies affects crucially the mixing conditions between the fuel and the air, the reaction progress and the temperature field in the combustion zone of the primary combustion chamber and, hence, causes changes in the soot formation and oxidation conditions.

More information about the impact of the air inlet perturbations on the flow field, especially on the inner and outer recirculation zone, is given in Fig. 10, where phase-unresolved averaged velocity fields under reactive conditions for section 1 (5–35 mm HAB) and section 2 (35–65 mm HAB) at various imposed acoustic oscillation frequencies are displayed. The strongly affected cases at 50 and 100 Hz exhibit an enlargement of the inner recirculation zone compared to the unexcited flow. In the case of 100 Hz, in section 2 this enlargement is most significant (see also the phase-locked results in Fig. 9). This leads to increased recirculation of hot gases from the flame regions, carrying radicals and intensifying the fuel decomposition and the homogenization of the mixture and the temperature field. In the 350 Hz case, the averaged velocity field is similar to the unexcited case. However, the extension of the inner recirculation zone decreases. This behaviour causes less intensive homogenization.

The phase-locked fluctuations (RMS) of the velocity field under reactive conditions at various imposed acoustic oscillation frequencies are shown in Figs. 11, 12, 13 and 14. At 0 and 350 Hz, the highest fluctuations are typically located in the shear layer between the inner and the outer recirculation zone. Consequently, the position of the zones of highest velocity fluctuations is similar between the 0 and the 350 Hz case. Therefore, these structures remain unchanged at the different phases. The observation demonstrates once again the frequency-depending flame response on the acoustic perturbations: at 50 and 100 Hz, the region with the highest values of the velocity fluctuations is shifted in every single phase and the value of the velocity (RMS) additionally changes strongly over the oscillation. All this implies a temporal instability of the inner recirculation zone. The enlargement of the IRZ and the zone of high velocity fluctuation due to the imposed acoustic oscillation might cause an improvement of mixing in the combustion chamber in the 50 Hz, especially 100 Hz, excitation cases. The intensification of the mixing between fuel/oxidator and between the radicals on the one hand, and unburned hydrocarbons (UHCs) and soot particles on the other hand, may possibly lead to smaller gradients in the concentration and the temperature field. Thus, combustion is taking place in more premixed- and preheated-like conditions in these cases. This behaviour of the flow and its coupling the combustion reactions and soot formation and oxidation have a strong impact on the sooting tendencies of the non-premixed flame.

From Fig. 15, the strong impact of acoustic oscillations on the phase-unlocked time-averaged, relative soot volume fractions, averaged mean particle sizes and averaged, relative particle number densities (avg_fV, avg_rm, avg_NT) is obvious. The images show an interpolated field of the measured points at seven HABs, starting at 18 mm HAB with 14 mm step in axial direction and 2.5 mm step at radial direction. For the averaging, 40 frames were used at every point. The soot volume fractions as well as the particle number densities are normalized to the maximal values, respectively. Unfortunately, for the reason mentioned in Sect. 2.1, phase-locked investigations of the soot distributions cannot be carried out with our set-up, because of the limited repetition rates of the Nd:YAG laser (10 Hz) as well as the CCD chip (0.5 fps) of the streak camera. It can be seen that depending on the oscillation frequency, a reduction in the averaged soot volume fractions and soot particle sizes occurs. Between 50 and 200 Hz, the region with the highest soot volume fraction in the flame is stable and not shifted by the oscillations. This zone is located at about 60 mm height above the burner (HAB) and 8 mm radial distance. At 0 and 350 Hz, a different distribution is observed. In this case, the highest soot volume fraction is detected at somewhat lower HAB and 8 mm radial distance. From Fig. 15, it can further be seen that the soot volume fraction decreases in all regions by approximately 50 %, if the frequency is increased from 50 to 100 Hz. At higher frequencies (200 Hz), the response of the system is weaker, whereas at 350 Hz fV is even higher than without acoustic excitation. This especially is obvious at HAB > 70 mm and in the outer regions of the combustion chamber.

The averaged mean particle size is also reduced at 50, 100 and 200 Hz, whereas at 350 Hz no significant change in the size of the soot particles is observed. Further, a strong reduction in NT occurs at 100 Hz, in the outer regions of the flame. At 350 Hz, even an increase in the particle number density caused by applied oscillations is observed. The particle inception and coagulation-dominated zone, which is indicated in the figure with the help of a black ellipse, at 100 Hz are reduced in size, whereas they are enlarged at 50, at 200 and mainly at 350 Hz. From Fig. 15, it is obvious for the unexcited case that the region near to the nozzle axis is the most important zone with respect to soot particle inception and coagulation (highest soot volume fractions, soot particle sizes and number densities). This near nozzle axis region and the connected inner recirculation zone are strongly influenced by the imposed oscillations of the flow field, especially at 100 Hz, thereby affecting soot inception and coagulation.

For the observed sooting tendencies of the investigated flames, also variations in the “oxidation regions” of the flame, indicated in the figure with the help of a red ellipse, are significantly affecting soot oxidation. Soot oxidation is correlated with a reduction in the soot particle number density and larger mean soot particle sizes. The extent and location of the “oxidation regions” are strongly affected by the air inlet perturbations, especially at 100 Hz, where the zone dominated by oxidation reactions is the largest one for all cases (0–350 Hz). This zone can be observed for all HABs at r > 24 mm. Taking the results from the averaged soot volume fraction and the normalized particle number density into account, we are able to interpret the vertical patterns on the mean soot particle size plot. These patterns reveal a narrow zone in the combustion chamber, where a small number of big soot particles are still remaining and “surviving” the oxidation processes in this outer flame zone in contrast to the small-sized particulate matter, which is completely oxidized.

Figure 16 shows the fluctuations of the soot volume fractions (RMS) at various excitation frequencies. Comparing the unexcited case, the regions of high soot volume fraction fluctuations at 50 and 100 Hz are shifted towards the nozzle axis. The comparatively weak impact on the sooting tendencies in the flame excited at 350 Hz is obviously related to the weak response of the flow to this “high” oscillation frequency.

Additional important information about the impact of the acoustic oscillations on the formation and oxidation of soot is obtained by phase-locked line-of-sight averaged OH*-chemiluminescence measurements at various excitation frequencies, as shown in Fig. 17 (50 Hz), Fig. 18 (100 Hz) and Fig. 19 (0 and 350 Hz). It can be seen that the region of highest OH*-concentration is strongly affected by the acoustic oscillation at 50 and 100 Hz. The position of this high OH*-concentration is shifted during every cycle of the oscillation, showing the strong impact on the flame and its fluctuations. The acoustic excitation leads to changes in the position of the flame as well as to changes in the intensity of the OH*-concentration, respectively. Significant fluctuations of the chemiluminescence of OH* and—as a consequence—of the heat release during every single period is observed, especially in the case of 100 Hz. In addition, the size of the region of high OH*-concentration is clearly increased in some of the phases. The OH*-concentration fields of the non-excited and 350 Hz case are pretty similar, comparing Fig. 19. Thus, no change in the position and size of the OH*-concentration field or in the intensity occurs. Particularly at 100 Hz, the influence of perturbations on the flame becomes also evident by the enlargement of the zone exhibiting high OH*-concentration. Zones of high soot concentrations are reduced in the flame because of the extension of zones with high OH*-concentrations leading to an intensification of soot oxidation. Additionally, from the OH*-chemiluminescence measurements, it can be seen that the lift-off height of the flames (50 and 100 Hz) is decreased by the acoustic oscillations.

In Fig. 20, temperature field measurements at various oscillation frequencies are plotted. The images show an interpolated field of the measured points at seven HABs, starting at 18 mm HAB with 14 mm step in axial direction and 2.5 mm step at radial direction. The mean temperature fields measured at 50 and 100 Hz are much more homogeneous. Particularly, at 100 Hz, regions of “low” temperatures are significantly reduced compared to the unexcited case. In the latter case, a large area of “low” temperature (<1200°K) occurs, located from HAB = 0 mm to HAB = 102 mm. In the region near the axis of the nozzle at HAB = 45 mm, the temperature is even less than 1000°K. At 350 Hz air inlet excitation frequency, the temperature field is pretty similar to the non-oscillating case.

Comparing the results from the OH*-chemiluminescence and the temperature fields, it can be seen that the lift-off height of the flames at 50 Hz, especially at 100 Hz, is decreased by the acoustic oscillations, which corresponds very well with the shift in the region of high temperatures near to the nozzle in these cases. It implies a preheating of the fuel and the combustion air, intensifying the mixing (higher diffusion coefficients) which leads to smaller gradients.

If all results are taken into account, the following hypothesis can be derived: the observed frequency-dependent impact of imposed air inlet velocity oscillations on the formation and oxidation of soot went along with a significant change in the velocity, the temperature and the OH*-concentration fields.

These correlations are most pronounced within timescales relevant for soot formation (~50 ms). Due to the excitation, the concentration gradients are reduced resulting in a better mixing of fuel and air. Therefore, more premixed-like combustion conditions in the chamber exist, which consequently reduce the number of local rich regions. These conditions strongly inhibit an excessive formation of soot precursor molecules which leads to a decrease in soot inception. The reduced temperature gradients observed in the moderate excitation cases also decrease soot particle inception (less quenching). The observed very strong fluctuations of the OH*-concentration field (position and intensity) went along with a reduced lift-off height of the flame at moderate oscillation frequencies. The enlargement of the averaged OH*-field causes an intensification of the soot oxidation processes by OH-radicals, which is further promoted by an increased temperature observed in some phases. At the same time, the enlargement of the IRZ accelerates the secondary oxidation of the initially formed soot particles by an increase in the residence time in the region of high OH*-concentration.

It can be concluded that imposed acoustic oscillations at 50 Hz, especially at 100 Hz, coherently influences the sub-processes of the formation and oxidation of soot towards lower soot levels.

4 Conclusions

The response of non-premixed swirling flames to acoustic perturbations at various frequencies (0–350 Hz) and the impact of imposed air inlet velocity oscillations on the formation and oxidation of soot were investigated. Soot particle sizing and soot detection measurements in highly turbulent flames at imposed air inlet velocity oscillations were performed using simultaneous 2-Colour-TIRE-LII. These measurements are combined with line-of-sight averaged OH*-chemiluminescence imaging, measurements of the mean temperature and measurements of the velocity field under reactive conditions using high-speed PIV.

The experimental results give first insights in the interaction mechanisms of the formation and oxidation of soot with acoustic oscillations in swirled non-premixed flames. A frequency- and amplitude-dependent decrease in the soot volume fraction, soot particle size and number density was observed. These variations were attributed to changes in the velocity field, temperature and OH*-radical distribution. Variations in the mixing conditions between fuel and oxidizer, smaller temperature gradients, enlargement of the zone of high OH*-concentration (intensification of the soot oxidation) and smaller lift-off heights of the flame were observed. As a consequence, a significant impact of the air inlet velocity oscillations on the formation and oxidation of soot was found in our investigations.

The results of the high-speed PIV measurements reveal a strong influence of the air inlet acoustic perturbations at 50 and 100 Hz on the flow field in the combustion chamber. A shift in the maximal velocities (axial and radial) in radial direction was found. This observation leads to the conclusion that, especially in the case of 100 Hz, the mixing conditions in the chamber are improved due to an increased radial exchange of the fluid. Consequently, the conditions in the combustion chamber are more homogenous and the flame behaviour is more similar to premixed combustion with respect to the formation and burnout of the soot particles.

The velocity measurements show a significant enlargement of the inner recirculation zone and its temporal stability at 100 Hz excitation. At about 100 Hz, the highest decrease in soot volume fraction (~50 %) and mean soot particle sizes (~30 %) as well as number density (outer region) was observed. Furthermore, the shift in the region of maximum particle number density was more pronounced at 100 Hz compared to other frequencies.

References

H. Bockhorn, A. D’Anna, A.F. Sarofim, H. Wang, Combustion Generated Fine Carbonaceous Particles, Proceedings of an International Workshop, Villa Orlandi, Anacapri (2007)

H. Bockhorn, Soot Formation in Combustion: Mechanism and Models (Springer, Berlin, 1994)

C.S. McEnally, L.D. Pfefferle, B. Atakan, K. Kohse-Höinghaus, Studies of aromatic hydrocarbon formation mechanisms in flames: Progress towards closing the fuel gap. Prog. Energy Combust. Sci. 32(3), 247–294 (2006). doi:10.1016/j.pecs.2005.11.003

R. Balachandran, B.O. Ayoola, C.F. Kaminski, A.P. Dowling, E. Mastorakos, Combust. Flame 143, 37–55 (2005)

O.A. Ezekoye, K.M. Martin, F. Bisetti, Proc. Combust. Inst. 30, 1485–1492 (2005)

Uyi Idahosa, Abhishek Saha, Xu Chengying, Saptarshi Basu, Combust. Flame 157, 1800–1814 (2010)

Th. Lehre, R. Suntz, H. Bockhorn, Time-resolved two-color LII: size distributions of nano-particles from gas-to-particle synthesis, in 30th Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, 2585 (2005)

T. Lehre, B. Jungfleisch, R. Suntz, H. Bockhorn, Appl. Opt. 42, 2021 (2003)

T. Lehre, H. Bockhorn, B. Jungfleisch, R. Suntz, Chemosphere 51, 1055 (2003)

M. Charwath, Experimentelle Untersuchung und numerische Simulation der Rußbildung in laminaren Methan/Luft Diffusionsflammen, Dissertation, Karlsruhe Institute of Technology (KIT), (2011)

E. Therssen, Y. Bouvier, C. Schoemaecker-Moreau, X. Mercier, P. Desgroux, M. Ziskind, C. Focsa, Determination of the ratio of soot refractive index function E(m) at the two wavelengths 532 and 1064 nm by laser induced incandescense. Appl. Phys. B 89, 417–427 (2007)

M.H. de Andrade Oliveira, N.-E. Olofsson, J. Johnsson, H. Bladh, A. Lantz, B. Li, Z.S. Li, M. Alden, P.-E. Bengtsson, C.C.M. Luijten, L.P.H. de Goey, Soot, PAH and OH measurements in vaporized liquid fuel flames. Fuel 112, 145–152 (2013)

C. Schulz, B.F. Kock, M. Hofmann, H. Michelsen, S. Will, B. Bougie, R. Suntz, G. Smallwood, Appl. Phys. B 83, 333–354 (2006)

D.R. Snelling, G.J. Smallwood, F. Liu, Ö.L. Gülder, W.D. Bachalo, A calibration-independent laser-induced incandescence technique for soot measurement by detecting absolute light intensity. Appl. Opt. 44, 6773–6785 (2005)

T.P. Jenkins, R.K. Hanson, Combust. Flame 126, 1669 (2001)

M. Kerker, The Scattering of Light and other Electromagnetic Radiation (Academic Press, New York, 1969)

W.H. Dalzell, A.F. Sarofim, J. Heat Transf. 91, 161 (1969)

S. C. Lee, C. L. Tien, in 18th Symposium (Int.) on Combustion, The Combustion Inst., Pittsburgh (1981), pp. 1159–1166

B.J. Stagg, T.T. Charalampopoulos, Combust. Flame 94, 381 (1993)

J. Simonsson, N.-E. Olofsson, S. Török, P.-E. Bengtsson, H. Bladh, Wavelength dependence of extinction in sooting flat premixed flames in the visible and near-infrared regimes. Appl. Phys. B (2015). doi:10.1007/s00340-015-6079-z

N.-E. Olofsson, J. Simonsson, S. Török, H. Bladh, P.-E. Bengtsson, Evolution of properties for aging soot in premixed flat flames studied by laser-induced incandescence and elastic light scattering. Appl. Phys. B (2015). doi:10.1007/s00340-015-6067-3

M. Raffael, Chris E. Willert, Steve T. Wereley, J. Kompenhans, Particle Image Velocimetry: A Practical Guide (Springer, Berlin, 1998 /2007 2nd ed.)

W. Merzkirch, Flow Visualization (Academic Press, Orlando, 1987)

J. Westerweel, Digital particle image velocimetry—theory and application, PhD Dissertation, Delft University Press, Delft (1993)

C. M. Arndt, M. Severin, C. Dem, M. Stöhr, A. M. Steinberg, W. Meier, Experimental analysis of thermo-acoustic instabilities in a generic gas turbine combustor by phase-correlated PIV, chemiluminescence and laser Raman scattering measurements, in Experiments in Fluids, Experimental Methods and their Applications to Fluid Flow (Springer, Berlin, 2015). doi:10.1007/s00348-015-1929-3

Author information

Authors and Affiliations

Corresponding author

Appendix: Nomenclature

Appendix: Nomenclature

Latin symbols

- c:

-

Speed of light 3 × 108 (m/s)

- E(m):

-

Complex refractive index function for absorption (–)

- f v :

-

Soot particle volume fraction (–)

- h :

-

Planck’s constant 6.6256 × 10−34 (J s)

- I :

-

LII signal intensity (W/m3)

- k B :

-

Boltzmann’s constant 1.3806 × 10−23 (J/K)

- K cal :

-

Calibration constant (–)

- L :

-

Length (m)

- m :

-

Refractive index of soot (–)

Greek letters

- ε :

-

Spectral emissivity of soot layer (–)

- λ :

-

Wavelength (m)

Rights and permissions

About this article

Cite this article

Aleksandrov, A., Suntz, R. & Bockhorn, H. Investigation of the impact of imposed air inlet velocity oscillations on the formation and oxidation of soot using simultaneous 2-Colour-TIRE-LII. Appl. Phys. B 119, 777–795 (2015). https://doi.org/10.1007/s00340-015-6117-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-015-6117-x