Abstract

We report on a Q-switched \(\hbox {Ho}^{3+}\):YAG laser resonantly pumped by fiber-coupled high-spectral-brightness laser diodes emitting at \(1.91~\upmu {\hbox {m}}\). Using a 75-mm-long composite crystal pumped by two fiber-coupled diode modules, 18 W was obtained at a wavelength of 2121 nm for 53 W of injected power with a slope efficiency of 51 % with respect to absorbed power. The beam propagation factor \((M^{2})\) was measured to be 1.2 at the maximum output power. The laser performance in Q-switched operation was recorded for different repetition rates between 100 Hz and 20 kHz. A maximum output energy of 8.7 mJ was measured at 1 kHz repetition rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

High-energy laser sources emitting in the \(2{\hbox {-}}\upmu {\hbox {m}}\) region find their interest in different domains such as medicine, atmospheric monitoring and optical parametric oscillator (OPO) pumping for mid-infrared generation [1]. In this region of the spectrum, thulium-based lasers are widely used owing to two great advantages: First, they are pumped at wavelengths around 800 nm with highly efficient diodes; second, they benefit from the so-called two-for-one process which leads to high conversion efficiency. However, in some applications, holmium-based lasers are preferred due to their longer operating wavelength, increasing the atmospheric transmission and lowering the absorption in nonlinear crystals such as \(\hbox {ZnGeP}_{2}\) (ZGP). Depending on the host material, the maximum absorption cross section of holmium lasers is around 1.9 µm. Thulium fiber lasers turn out to be good candidates for holmium laser pumping because of high power and high beam quality available at this wavelength. But this cascading scheme reduces significantly the compactness, simplicity and the overall efficiency of the source. To overcome this issue, \(1.9{\hbox {-}}\upmu {\hbox {m}}\) diodes could replace thulium lasers advantageously. The first attempt on direct diode pumping of \(\hbox {Ho}^{3+}\):YAG was performed with six diodes emitting each 0.7 W at \(1.91~\upmu {\hbox {m}}\) [2]. In addition to the relatively low emitting power of these diodes, the setup was complex because diodes were angle-multiplexed and polarization-coupled. At cryogenic temperature, only 0.7 W of laser average power was extracted. With the development of diode stacks at \(1.9~\upmu {\hbox {m}}\), 55 W of output power has been generated in continuous-wave regime with a \(\hbox {Ho}^{3+}\):YAG laser pumped with 160 W [3]. By adapting the laser cavity for Q-switched regime, 33 mJ in 100 ns pulse duration at 100 Hz pulse repetition rate was produced at a wavelength of \(2.09~\upmu {\hbox {m}}\) [4]. These results are excellent, but the optical-to-optical efficiency is only 2 % in Q-switched regime and the beam exhibits a multimode behavior. In this study, we describe a compact source with good beam quality together with good optical-to-optical efficiency.

2 Experimental setup

2.1 Cavity arrangement

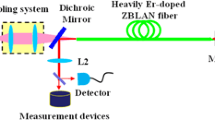

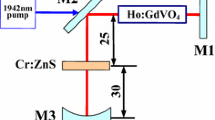

The experimental setup is shown in Fig. 1. The laser crystal is a composite \(\hbox {YAG/Ho}^{3+}\):YAG/YAG material rod. It is 5/65/5 mm long and 2 mm in diameter. The holmium doping concentration is 0.75 at.%. Its faces are uncoated. During laser operation, it is cooled down to 293 K with a temperature-controlled water flow. In order to avoid inhomogeneous cooling of the doped part of the crystal, which could reduce the beam quality, we use undoped endcaps to allow for complete cooling of the doped section. Due to the length of the crystal and the beam propagation factor of the pump beam \((M^{2}\approx 110)\), the cylindrical surface of the crystal is polished for total internal reflection pump propagation. It ensures a better overlap between the pump and the laser beams over the longitudinal crystal dimension. The laser crystal is pumped from both ends with two fiber-coupled diode modules. Each pump beam is focused inside the crystal with a 1:1 telescope and a dichroic mirror. This mirror is highly reflective for the pump beam and antireflection-coated for the laser beam. For this work, we tested two different cavity configurations because the crystal was damaged during laser pulse operation with the first cavity. The two laser cavities are composed of a flat highly reflective mirror and a flat output coupler of different reflectivities. Two antireflection-coated intracavity lenses, with a focal length of 120 mm for the first cavity and 360 mm for the second cavity, are inserted in the cavity to expand the beam in order to avoid damage on the acousto-optic modulator (AOM) and on cavity mirrors. The lengths of the resonators are 735 and 1485 mm, respectively. In order to evaluate the beam waist, we take into account the thermal lens inside the crystal. It is approximated to be of 200 mm focal length. The beam waist in the crystal is calculated to be \(350~\upmu {\hbox {m}}\) for the first configuration and \(630~\upmu {\hbox {m}}\) for the second one. The maximum possible beam radius is \(630~\upmu {\hbox {m}}\) in order to prevent diffraction losses on the edge of the crystal.

2.2 Pump source investigation

The electrical-to-optical efficiency of one diode module is presented in Fig. 2. At the maximum of the curve, the efficiency is approximately 11.5 %. At maximum output power, the efficiency of this diode module is close to 8.5 %. It is comparable to a commercial Tm fiber laser emitting at this wavelength that we have in our laboratory.

As can be seen in Fig. 3, holmium-doped YAG material has a peak absorption around 1907 nm. This wavelength can be addressed by a Tm:YLF laser or a Tm-doped fiber laser. It can also be addressed with diode modules with the advantage of reducing the complexity of the overall system. However, the wavelength shift being a function of the driving current is a drawback when using diode modules. The emitting spectrum of one diode module is represented in Fig. 4, for three different driving currents. The pump beam wavelength is approximately centered at 1910 nm at full output power (50 A driving current) with a linewidth lower than 2 nm (FWHM). We can observe a shift of approximately 6 nm from threshold to maximum output power. Therefore, the overlap between the pump spectrum and the absorption profile of the crystal is not always optimal. This will affect the laser efficiency for different driving currents. For some driving currents, we can observe dips in the diode spectrum which correspond to water absorption lines. For that reason, the laser must run in dry air environment to keep it stable.

We have measured the relative absorption of the pump beam as a function of its center wavelength for nine different driving currents (see Fig. 3). During these measurements, the \(\hbox {Ho}^{3+}\):YAG laser was off and the crystal was pumped from one side. The pump beam absorption varied between 90.7 and 98.7 %. The crystal bleaching at high pump power (high driving current) explains the lower absorption measured at 50 A as compared to 10 A.

3 First laser cavity

In the following section, we describe the results of the first cavity arrangement, i.e., with \(350~\upmu {\hbox {m}}\) beam waist in the crystal.

3.1 Continuous-wave operation

The output power, in continuous-wave regime, as a function of the absorbed pump power was recorded for seven output coupler reflectivities (see Fig. 5). The lowest reflectivity was 40 % and the highest 95 %. The highest slope efficiency (51 %) was obtained with an output coupler reflectivity of \(R_{\text {OC}}=60~\%\). In the literature, \(\hbox {Ho}^{3+}\):YAG lasers with a slope efficiency up to 74 % can be found [5]. This difference arises from the total internal reflection pumping scheme which is less efficient than mode-matched pumping [6]. In our setup, the laser beam diameter is calculated to be \(700~\upmu {\hbox {m}}\) in the crystal while the pump beam fills out the crystal which has a diameter of 2 mm; therefore, a part of the pump power is not efficiently converted. With an output coupler of \(R_{\text {OC}}=80~\%\), a maximum of 18 W at 52 W of absorbed pump power was produced. The emitted wavelength was measured at 2121 nm with a linewidth of 1 nm (FWHM) regardless of the output power and the output coupler reflectivity. Comparing the product of the crystal length and its doping concentration with the cavity losses (intrinsic and output coupler transmission), it is possible to predict the laser wavelength [7]. Using a Caird analysis [8], we measured our intrinsic cavity loss to 3 %. This relatively low loss compared to the length–doping product explains that the laser emits at \(2.12~\upmu {\hbox {m}}\) even with low output coupler reflectivity.

We measured the beam propagation factor at the maximum output power. As can be seen in Fig. 6, the beam was symmetric and the beam propagation factor \(M^{2}\) was approximately 1.3. The beam was not perfectly diffraction-limited at high output power due to the thermal lens distortion in the crystal at high pump power [9]. The fact that the pump area is larger than the cavity mode may also have an impact on the beam quality.

3.2 Q-switched regime

We have measured the performance of the laser in Q-switched regime. In order to reduce the intracavity energy, the reflectivity of the output coupler was set to \(R_{\text {OC}}=50~\%\). The output energy was recorded as a function of the absorbed pump power for four different repetition rates (see Fig. 7). At 2 kHz (respectively, 3 kHz) repetition rate, a maximum of 6.8 mJ (respectively, 4.6 mJ) was obtained. For repetition rates of 1 kHz and 100 Hz, the output energy was limited by the damage threshold of the crystal. The maximum output energy obtained, before the crystal was damaged, was 7 mJ at 1 kHz repetition rate. We estimate the damage threshold of this crystal under these experimental conditions (wavelength, pulse width, and repetition rate) to be \(F_{\rm th}=2*E_{\rm ic}/(\omega _0^{2}*\pi ) = 7~{\rm J cm^{-2}}\), where \(E_{\rm ic}\) is the intracavity pulse energy and \(\omega _{0}\) the \(1/e^{2}\) beam radius. This damage threshold is relatively low for a \(\hbox {Ho}^{3+}\):YAG crystal and is comparable to the damage threshold of the coating of the \(\hbox {Ho}^{3+}\):YAG crystal in [4]. It may be due to contamination of the crystal surface by dust.

We have recorded the pulse width (FWHM) as a function of the pulse energy for the different repetition rates. As expected, the pulse width depends only on the pulse energy and not on the repetition rate. In Fig. 8, one can see that the pulse width is as short as 100 ns at 7 mJ pulse energy, when the laser was running at 1 kHz, corresponding to a peak power of 70 kW.

4 Second laser cavity

4.1 Continuous-wave operation

In order to reduce the risk of damaging the crystal, we increased the diameter of the laser beam by changing the intracavity lenses to 360 mm focal length. We recorded the output power in continuous-wave regime as a function of the absorbed power for an output coupler of \(R_{\text {OC}}=50~\%\) (see Fig. 9). As expected, the laser threshold increased, as compared to the previous cavity, to 24 W of absorbed pump power. However, the slope efficiency remained at 48 %. The maximum output power was 16 W at 58 W of absorbed pump power. We measured the beam propagation factor when the laser was operated in continuous wave at 14 W of output power. The parameter \(M^{2}\) was approximately 1.2 for the two orthogonal directions (see Fig. 10).

The wavelength of the laser was recorded for an output power of 14 W. It is centered at approximately 2122 nm as can be seen in Fig. 11. The spectrum is composed out of two peaks separated by 0.2 nm. The laser spectral width is 0.3 nm (FWHM), which is narrow enough for efficiently pump a nonlinear crystal like ZGP.

4.2 Q-switched regime

We measured the performance of this laser in Q-switched regime. The repetition frequency was set from 20 kHz down to 1 kHz. We recorded the output energy as a function of the absorbed pump power. The results are reported in Fig. 12. The maximum output energy was 8.7 mJ at 1 kHz repetition rate which corresponds to an optical-to-optical efficiency of 20 %. The output energy was limited by the damage threshold of the crystal which was estimated to be less than \(3~{\rm J cm^{-2}}\). This relatively low damage threshold as compared to the damage threshold measured with the first cavity is attributed to crystal surface contamination. The rollover behavior that can be seen at 2 kHz repetition rate is attributed to lower pump absorption at high driving current (see Fig. 3). The pulse width was measured for every output energy and every repetition rate. In Fig. 13, one can see that the minimum pulse width was approximately 115 ns (FWHM) at maximum output energy, which corresponds to a peak power of 75 kW.

5 Conclusion

In conclusion, we have demonstrated direct diode pumping of a \(\hbox {Ho}^{3+}\):YAG crystal with \(1.9{\hbox {-}}\upmu {\hbox {m}}\) high-brightness fiber-coupled diodes. In continuous-wave regime, 18 W was produced at a wavelength of \(2.12~\upmu {\hbox {m}}\) with a slope efficiency of 51 %. The beam quality at maximum output power was excellent with \(M^{2}\sim 1.2.\) Q-switching was performed at repetition rates between 20 kHz and 100 Hz. Almost 9 mJ was produced at 1 kHz.

References

M. Eichhorn, Appl. Phys. B 93, 269 (2008)

C.D. Nabors, J. Ochoa, T.Y. Fan, A. Sanchez, H.K. Choi, G.W. Turner, IEEE J. Quantum Electron. 31, 1603 (1995)

S. Lamrini, P. Koopmann, M. Schäfer, K. Scholle, P. Fuhrberg, Appl. Phys. B 106, 315 (2012)

S. Lamrini, P. Koopmann, M. Schäfer, K. Scholle, P. Fuhrberg, Opt. Lett. 37, 515 (2012)

E. Lippert, S. Nicolas, G. Arisholm, K. Stenersen, G. Rustad, Appl. Opt. 45, 3839 (2006)

M. Eichhorn, Appl. Phys. B 93, 773 (2008)

N. Barnes, F. Amzajerdian, D. Reichle, W. Carrion, G. Busch, P. Leisher, Appl. Phys. B 103, 57 (2010)

J.A. Caird, S.A. Payne, P.R. Staver, A.J. Ramponi, L.L. Chase, W.F. Krupke, IEEE J. Quantum Electron. 24, 1077 (1988)

M. Eichhorn, Appl. Phys. B 94, 451 (2009)

Acknowledgments

The research leading to these results has received funding from French la Direction Générale de l’Armement (DGA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Berrou, A., Ibach, T. & Eichhorn, M. High-energy resonantly diode-pumped Q-switched \(\hbox {Ho}^{3+}\):YAG laser. Appl. Phys. B 120, 105–110 (2015). https://doi.org/10.1007/s00340-015-6108-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-015-6108-y