Abstract

A planar optical waveguide in MgAl2O4 crystal sample was fabricated using 6.0 MeV oxygen ion implantation at a fluence of 1.5 × 1015 ions/cm2 at room temperature. The optical modes were measured at a wavelength of 633 nm using a model 2010 prism coupler. The near-field intensity files in the visible band were measured and simulated with end-face coupling and FD-BPM methods, respectively. The absorption spectra show that the implantation process has almost no effect on the visible and near-infrared band absorption.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Magnesium aluminate spinels are mixed oxide compounds that are attracting interest because of their many remarkable properties such as their high melting point (2135 °C), high radiation resistance, high mechanical strength at elevated temperatures, chemical inertness, high hardness and low electrical loss [1, 2]. Because of these remarkable properties, magnesium aluminate spinels can be easily activated using transition metal ions such as chromium (Cr3+) or cobalt (Co2+) for optical devices; the Cr3+-doped stoichiometric or non-stoichiometric MgAl2O4 spinel has been studied for tunable solid-state laser applications [3], and Co2+-doped MgAl2O4 crystal is used as a medium for the passive Q-switch of lasers with saturable absorption in the eye-safe spectral range, which is 1.3–1.6 μm, such as 1.54 μm erbium glass lasers and 1.32 μm Nd:YAG [4]. Cr3+-doped MgAl2O4 is a potentially powerful material for a fiber-optic thermometer with high temperature sensitivity because of the large temperature coefficient [5]. Some properties of MgAl2O4 were investigated for some applications such as substrates and microelectronic packages in microwave and millimeter-wave communication systems [6]. Considering its advantages, MgAl2O4 has potential value for integrated optical devices.

Optical waveguides are the basic elements of integrated photonic systems, which implies that the high-refractive-index media are surrounded by low-index regions. A planar or slab waveguide can confine light propagation in one dimension, and a channel or ridge geometry can confine light propagation in two dimensions [7, 8]. The ion implantation technique has become increasingly popular since the 1960s as a fairly effective method to fabricate waveguides in more than 100 optical materials such as glasses, semiconductors, crystals and polymers [9–15].

Recently, the studies of MgAl2O4 spinels have concentrated on the structural properties, optical absorption, thermoluminescence, etc. [16–20]. To our knowledge, this study is the first investigation of the planar waveguide in MgAl2O4 spinel crystal that was fabricated using O ion implantation. The waveguide properties were measured and analyzed with the corresponding methods.

2 Experimental details

An x-cut MgAl2O4 crystal sample with dimensions of 10 × 8×1 mm3 was optically polished and cleaned before the ion implantation. The sample was implanted with 6.0 MeV O ions at a fluence of 1.5 × 1015 ions/cm2 at room temperature, and the implantation was performed using a 1.7-MV tandem accelerator at Peking University. To minimize the channeling effect during the implantation, the sample was tilted 7° off the incident beam. The ion beam was electrically scanned to guarantee uniform implantation over the targets during the ion implantation process. A planar waveguide structure formed after the implantation.

The effective refractive indices of the dark modes were measured using a Metricon 2010 prism coupler (Metricon Corporation, USA). An He–Ne laser beam with a wavelength of 633 nm struck the base of the prism. Using a silicon photodetector, the intensity of the reflected light was measured. The incident angle could be continuously changed because the sample, prism and photodetector were mounted on a small rotary table.

The end-face coupling method was used to measure the near-field intensity distribution. During the measurement, two objective lenses and the sample were located on different adjustable optical stages to control their positions. A 633 nm laser light was injected into and ejected out of the sample through two 25× microscope objective lenses; then, a CCD (charge coupled device) camera was used to capture the coupling image of the light that was coupled out of the planar waveguide. We calculated the electronic and nuclear power losses in the oxygen implantation process using the software package stopping and range of ions in matter (SRIM) 2010, which is known to be a notably effective method for calculating the instance of ion implantation [21].

The ion implantation cross section was observed using a metallographic microscope (Axio Imager, Carl Zeiss) with reflective polarized light. The obtained image showed us the depth of the implanted region. The absorption spectra on the implanted spinel crystals were measured using a Jasco U570 spectrophotometer at room temperature. The optical absorption spectrum of the sample was measured before and after implantation with a wavelength range of 200–2000 nm.

3 Results and discussion

The effective refractive index profiles of the O-ion-implanted MgAl2O4 waveguide were measured at a wavelength of 633 nm using the prism-coupling method. Figure 1 shows the TM (transverse magnetic) dark-mode spectra of the O-ion-implanted waveguide at the wavelength of 633 nm. The refractive index of the MgAl2O4 substrate is also shown in Fig. 1 with a red dash line for comparison. In the prism-coupling measurement process, the light laser was coupled to the waveguide region, and a lack of reflected light subsequently produced a dip in the dark-mode spectrum, which corresponds to a propagation mode. As shown in Fig. 1, one sharp dip, which corresponds to the fundamental mode (TM0 mode), was detected; the surface refractive index (n sur) and the effective refractive index (n eff) of the TM0 mode of the O-ion-implanted MgAl2O4 planar waveguide are larger than the substrate refractive index of the virgin MgAl2O4 sample (n sub = 1.7122). The other residual spectral dip might arise from leaky modes because multiple optical reflections occurred at the interfaces between the MgAl2O4 substrate and the waveguide.

As shown in Fig. 2(a), the end facet photograph of the O-ion-implanted MgAl2O4 spinel sample was collected using a 50× magnification of a metallographic microscope with reflected polarized light. The thickness of the modified layer is approximately 3.1 μm. We also simulated the physical process of ion implantation using SRIM 2010, which provided a good method to understand the formation mechanism of the waveguide. Figure 2(b) shows the nuclear energy loss (S n ) and electronic energy loss (S e ) of 6.0 MeV O ions in the MgAl2O4 crystal. In the implantation process, the O ions lose energy through elastic collisions (nuclear stopping power) and inelastic collisions of the target electrons (electronic stopping power) because of the electronic ionizations along their trajectories inside the spinel sample. Elastic collisions between the incoming ions and the atoms of the material and the electronic excitation process, which is associated with ion and electron interactions, are the two main mechanisms for energy loss. As shown in Fig. 2(b), the S n curves of the oxygen ion show that the peaks of S n are at 3.1 μm depth. The O ion implantation in MgAl2O4 crystal creates an optical barrier layer with a low refractive index, which is buried at the end of the track by the nuclear damage and forms a typical barrier that confines the waveguide structure with the cladding air. The electronic collision at the sample surface formed the color center and damage in this region.

a A photograph of the end face of an O-ion-implanted MgAl2O4 crystal, which was collected using a metallographic microscope with 50× magnification using reflected polarized light; b the nuclear and electronic energy losses (S n and S e ) as functions of the penetration depth for 6.0 MeV O ions in the MgAl2O4 crystal based on the SRIM 2010 code

The RIP (refractive index profile) of the O-ion-implanted MgAl2O4 crystal waveguide structure plays an important role in investigating the waveguide properties. The Wentzel–Kramers–Brillouin method [22] and the refractivity calculation method [23] are two important methods to accurately reconstruct the refractive index profile. As shown in Fig. 1, because only one dark mode was observed at the wavelength of 633 nm, considering the reported data of ion implantation waveguides, we can assume the refractive index distribution. The refractive index profile was an index-enhanced well and an index-decreased barrier in the waveguide region and at the end of the ion track, respectively [13, 24]. Thus, the refractive index profile can be depicted using two half Gaussian curves. According to this case, it appears reasonable to assume that the O-ion-implanted MgAl2O4 spinel waveguide has similar index behaviors. In the assumption process, there are five different parameters relative to the refractive index profile: implanted depths, refractive index of the sample surface, height of the optical barrier and the FWHMs of two half Gaussian curves. The depth can be determined from the TRIM calculation, and the prism-coupling method can estimate the refractive index of the sample surface. Thus, by adjusting certain parameters to match the experimental ones within a satisfactory error, we can obtain the refractive index profile. In this work, we used a method of finite difference (FD) based on the effective refractive index to reconstruct the index. The reconstructed refractive index profile of the O-ion-implanted MgAl2O4 crystal waveguide at 633 nm is shown in Fig. 3(a). The refractive index of the substrate (n sub) is also marked with a red dash line. It is found that the refractive index profile of the waveguide is the “well” + “barrier” type. To simulate the process of light propagation in the planar waveguide, we reconstructed the two-dimensional RIP of the planar waveguide cross section at 633 nm as shown in Fig. 3(b). Moreover, we found that the depth of the optical barrier position, which corresponds to the depth of the implanted region, was approximately 3.1 μm, which is consistent with the measured thickness of the waveguide layer in Fig. 2(a) and the position of the optical barrier in Fig. 2(b).

The end-face coupling experiment was performed to directly observe the light intensity profile that was transmitted through the planar waveguide. We simulated the near-field intensity profiles of the O-ion-implanted waveguide at 633 nm using the finite-difference beam propagation method (FD-BPM), as shown in Fig. 4(a) and (c). As shown in Fig. 4(b), the two-dimensional near-field optical intensity profiles, which were measured using a CCD camera at the output face of the MgAl2O4 spinel planar waveguide, were obtained at 633 nm. The light is continuous and homogeneous, which indicates a better confinement of light between the surface and the optical barrier. The width of the waveguide was approximately 3.1 μm, which was consistent with the depth of the optical barrier in Fig. 2(a). We concluded that the measured near-field intensity distributions were consistent with the reconstructed ones. Therefore, the light is well confined in the waveguide layer, and it is possible to construct designable waveguide devices in MgAl2O4 spinel using O ion implantation. The propagation loss of the planar waveguide at 633 nm was estimated by directly measuring the powers of the incident and output light through the waveguide. The propagation loss of the MgAl2O4 planar waveguide is ~2.38 dB/cm which is low enough to make the O-ion-implanted MgAl2O4 alternative material for radiation transmission.

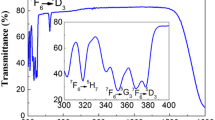

The absorption spectra of the waveguide before and after the ion implantation treatments were measured using a Jasco U570 spectrophotometer. Before the absorption measurement, the upper and lower faces of the sample were optically polished to guarantee accurate results. However, the transmitted light that was detected in the optical absorption experiments must pass through both the implanted layer and the un-implanted substrate. We detected the absorption spectrum that was obtained from a prism to understand the defects in the implanted layer. Figure 5 shows the absorption spectra of the O-ion-implanted MgAl2O4 waveguide region and the virgin MgAl2O4. The two absorption spectra have almost identical shapes. The position of the absorption edge does not vary. The lattice defects and color center that were created in the ion implantation process may be responsible for the slight optical absorption. Thus, the implantation process does not contribute to the absorption in the visible and near-infrared regions.

4 Conclusions

A planar waveguide was fabricated using 6.0 MeV O ion implantation at the dose of 1.5 × 1015 ions/cm2 at room temperature in the MgAl2O4 spinel crystal, which could carry one mode at 633 nm. The prism-coupling method measured the waveguide modes and the reconstructed refractive index profile at 633 nm, which induced a non-leaky guiding region that could efficiently confine light. It is shown that a typical “well + barrier” optical waveguide was formed in the MgAl2O4 spinel crystal. The measured and reconstructed near-field optical intensity profiles of the planar waveguide at 633 nm using the FD-BPM were consistent with each other, which demonstrated that it was possible to construct designable waveguide devices using an O-ion-implanted MgAl2O4 spinel. The O ion implantation processes had almost no contribution to the absorption in the visible and near-infrared regions of the measured optical absorption. This result demonstrates that O ion implantation is an appropriate method to fabricate waveguide structures in magnesium aluminate spinel crystals.

References

P. Shukla, A. Chernatynskiy, J.C. Nino, S.B. Sinnott, S.R. Phillpot, J. Mater. Sci. 46(1), 55 (2011)

F. Naum, C. Shahar, M. Shay, K. Aergei, P.D. Moshe, J. Mater. Sci. 42(9), 3273 (2007)

W. Mikenda, A. Preisinger, J. Lumin. 26, 53 (1981)

K.V. Yumashev, I.A. Denisov, N.N. Posnov, P.V. Prokoshin, V.P. Mikhailov, Appl. Phys. B 70, 179 (2000)

H. Aizawa, N. Ohishi, S. Ogawa, E. Watanabe, T. Katsumata, S. Komur, T. Morikawa, E. Toba, Rev. Sci. Instrum. 73, 3089 (2002)

K.P. Surendran, P.V. Bijumon, P. Mohanan, M.T. Sebastian, Appl. Phys. A 81, 823 (2005)

K. Lizuka, Elements of Photonics, Volume II: For Fiber and Integrated Optics (Wiley, New York, 2002)

G. Lifante, Integrated Photonics: Fundamentals (Wiley, Atrium, 2003)

P.D. Townsend, Nucl. Instrum. Methods Phys. Res. Sect. B 46(1–4), 18–25 (1990)

E.R. Schineller, R.P. Flam, D.W. Wilmot, J. Opt. Soc. Am. 58, 1171 (1968)

S. Bourzeix, J.M. Moison, F. Mignard, F. Barthe, A.C. Boccara, C. Licoppe, B. Mersali, M. Allovon, A. Bruno, Appl. Phys. Lett. 73, 1035 (1998)

D. Jaque, F. Chen, Appl. Phys. Lett. 94, 011109 (2009)

F. Chen, X.L. Wang, K.M. Wang, Opt. Mater. 29, 1523 (2007)

Y. Tan, F. Chen, D. Jaque, W.L. Gao, H.J. Zhang, G. Solé Jose, H.J. MA, Opt. Lett. 34, 1438 (2009)

K.S. Chiang, J. Lightwave Technol. 3(2), 385 (1985)

P. Nadia, D.E. Catherine, M. Valérie, B. Michel, M. Dominique, J. Phys. Chem B 111, 12707 (2007)

I.V. Afanasyev-Charkin, V.T. Gritsyna, D.W. Cooke, B.L. Bennett, C.R. Evans, M.G. Hollander, K.E. Sickafus, Nucl. Instrum. Methods Phys. Res. Sect. B 148, 787–792 (1999)

N. Yu, K.E. Sickafus, M. Nastasi, Mayer. Chem. Phys. 46, 161 (1996)

J. Salmones, J.A. Galicia, J.A. Wang, M.A. Valenzuela, G. Aguilar-Rios, J. Mater. Sci. Lett. 19, 1033 (2000)

P. Fu, W.Z. Lu, W. Lei, K. Wu, Y. Xu, J.M. Wu, Mater. Res. 16(4), 844 (2013)

J.F. Ziegler, Computer Code SRIM, http://www.srim.org

P. Hertel, H.P. Menzler, Appl. Phys. B 44, 75 (1987)

P.J. Chandler, F.L. Lama, Opt. Acta. 33, 27 (1986)

F. Chen, H. Hu, X.L. Wang, F. Lu, K.M. Wang, J. Appl. Phys. 98(4), 044507 (2005)

Acknowledgments

This work is supported by the National Science Foundation of China (Grant No. 11275117), and the State Key Laboratory of Nuclear Physics and Technology at Peking University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, HL., Yu, XF., Zhang, L. et al. Optical planar waveguide in magnesium aluminate spinel crystal using oxygen ion implantation. Appl. Phys. B 120, 25–29 (2015). https://doi.org/10.1007/s00340-015-6089-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-015-6089-x