Abstract

We report the realization of a robust magnetic transport scheme to bring >3 × 108 ultracold 87Rb atoms into a cryostat. The sequence starts with standard laser cooling and trapping of 87Rb atoms, transporting first horizontally and then vertically through the radiation shields into a cryostat by a series of normal- and superconducting magnetic coils. Loading the atoms in a superconducting microtrap paves the way for studying the interaction of ultracold atoms with superconducting surfaces and quantum devices requiring cryogenic temperatures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

There has been growing interest in studying hybrid quantum systems [1–17]. Superconducting quantum devices are expected to be capable of fast quantum information processing but exhibit only short coherence times making them unsuitable for qubit storage [1]. Hybrid quantum systems promise that coupling to a different system with a long coherence time will allow for high fidelity storage of qubits. The hyperfine spin states in ultracold atoms are a promising candidate [6–12], which can be manipulated with great precision. For experiments with ultracold atoms and superconducting quantum devices, one must be able to efficiently trap ultracold atoms in a cryogenic environment.

Transport of ultracold atomic ensembles is a well established technique to separate the physical experiment from the initial preparation of an ultracold atomic ensemble. Since the first experiments with ultracold quantum gases aim for Bose–Einstein condensation, several transport mechanisms based on moving magnetic traps [18] and moving optical lattices [19] or optical tweezers [20] were developed. Transfer of atoms into a 4K cryogenic environment has been demonstrated with either a single moving magnetic quadrupole trap [21], by operating a MOT in the cryogenic environment [22–24], or using an optical tweezer [25]. We report a robust magnetic transport scheme for ultracold atoms from a room temperature MOT into a cryostat and successful loading into a superconducting atomchip microtrap.

2 Experimental details

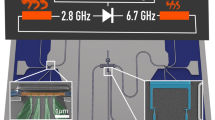

The experiment uses a combination of horizontal magnetic transport following [18] and vertical magnetic transport to enter the cryostat. Figure 1 shows a drawing of the entire setup. A 90 degree angle in the path of the transport efficiently blocks stray light from the MOT. The non-overlapping arrangement of the vertical coils allows efficient transition into the cryogenic environment. The MOT chamber is separated by a valve, allowing independent maintenance of the science chamber.

Cut through a CAD drawing of the setup with the MOT chamber on the bottom left and the copper cage holding the superconducting coils and the chip on the top right. The cryo chamber is made semi-transparent for clarity. The inset shows the currents used for the vertical transport. Currents for the normal conducting coils V1–V5 refer to the left axis, while the superconducting coils V6–V9 are driven with much lower currents (right axis)

The cryostat is an ultra-low vibration Gifford-McMahon closed cycle cryocooler [26, 27]. It provides a cooling power of about 800 mW at the 4 K stage. The cold finger rests in a CF200 vacuum chamber. An aluminum shield is connected to the 50 K stage. It has four anti-reflection coated windows for optical access and shields the inner part from thermal radiation [28]. To thermally isolate the 50 K shield, its outside is wrapped with several layers of aluminized Mylar foil. Radiation shielding is particularly important for the superconducting wires, therefore all of them are covered with reflective aluminum tape.

The MOT chamber is a pancake-shaped steel octagon that contains the Rb-dispenser. It provides optical access for a standard six beam vapor cell MOT. Following a ten second MOT phase, the atoms are sub-Doppler cooled and then optically pumped into the strongest low-field seeking state |2,2〉. The initial magnetic trap is loaded with typically 5 × 108 atoms at a temperature of about 300 μK.

2.1 Magnetic transport

To initiate the horizontal transport a so-called push coil shifts the quadrupole trap created by the MOT coils toward the magnetic conveyor belt. Currents for the horizontal section are calculated by defining the zero of the quadrupole field along the transport axis, a constant vertical trap gradient of 130 G/cm and a constant aspect ratio of 1.62.

The vertical transport section consists of nine coils in total, five normal- and four superconducting each with a vertical spacing of 30 mm. The normal conducting coils, which are mounted on water- cooled aluminum bodies, have 40 windings each and are operated up to 100 A. For the superconducting coils, a commercial Niobium–Titanium (NbTi) wire with a thickness of 127 μm is used [27]. Each coil has 3,000 windings and is wound on a copper mounting, consisting of four isolated segments in order to prevent eddy currents. The superconducting coils can be operated up to 3 A.

The last coil pair of the horizontal section also acts as the first two vertical transport coils. To maintain a constant aspect ratio of the trap during transport, four coils are used at the same time. In contrast to the horizontal section, transport along the coil axis in vertical direction requires bipolar operation of the respective currents. For simulating the magnetic field of each coil, the analytic solution is used [29]. The currents I i (z) for coil i and trap location z along the z-axis are obtained using four conditions |B(z)| = 0, |B z|′ = 130 G/cm, |B z |′′ = 0, and ∑ 4 i = 1 N i ·I i = 0 where N i is the number of windings per coil. The first three conditions imply a quadrupole trap with zero field at location z and a linear gradient of 130 G/cm. The last condition ensures smooth current over time. By specifying a position function z(t) that contains the desired acceleration and maximum velocity, transport currents I i(t) are obtained from I i (z) [30].

A maximum efficiency is achieved by using an acceleration of 0.4 m/s2 and a maximum velocity of 3 m/s for both horizontal and vertical transport, where the power supplies can accurately reproduce the desired currents. With these settings, the whole magnetic transport sequence takes about two seconds [31].

2.2 Cryogenic setup

The main experimental stage is mounted on the 4K stage of the cold finger. It consists of a copper-cage system that holds the coils and the chip mount. The cryostat contains eleven coils in total, four transport coils, one Ioffe coil, and three coils pairs for homogeneous offset (bias) fields. The upper stage of the coil setup is shown in Fig. 2a. As in most cryogenic experiments, proper anchoring of all wires connecting different temperature stages is crucial. A total of 24 copper wires with a length of 4 m and a diameter of 0.4 mm enter the cryostat. First, the wires are wound around the 50 K stage while minimizing thermal contact using plastic spacers. This increases the length between warm and cold side, hence minimizing heat conduction. Then, the wires are carefully anchored by winding them tightly to the 50 K stage. After entering the 20 K stage, the same scheme is applied: First plastic spacers are used before all wires are put in close contact with the 20 K stage of the cryostat. Commercial high-T c coated superconductors [27] directly connect the 20 K state and the 4 K stage. They have a smaller cross section than the copper wires, show no ohmic heating while in operation, and their flat structure allows much better thermal contact with the cold finger compared with the round copper wires. At the 4 K stage, the NbTi wires are soldered directly to the high-T c coated superconductors [27].

a Coil configuration and the chip mounting in the cryostat, showing the last two transport coils (blue), the vertical bias coils (yellow), the bias coils for the chip trap (green), the bias coils for the third direction (red) and the Ioffe coil (small, pink). b Photograph of the actual chip. Several aluminum bonds connect the Nb pads to the high-T c stripes

The chip mounting is made of single crystal quartz to prevent eddy currents and still have a high thermal conductivity. The chip is made of a Sapphire substrate with a 500-nm-thick sputtered niobium film (T c = 9.2 K). A 100-μm-wide Z-shaped wire with large contact pads is fabricated from this niobium layer with standard lithographic methods. To contact the niobium film, we use aluminum bonds between the contact pads and small pieces of the high-T c coated superconductors, which can then easily be soldered to the NbTi wires. A maximum current of 1.9 A can be driven through this niobium wire structure, which corresponds to a current density of 3.8 × 106 A/cm2. This is limited by the ohmic heating from the normal conducting Al bonds. Figure 2b shows the actual chip on the quartz mounting.

3 Results and discussion

At the end of the transport, up to 3 × 108 atoms at about 350 μK are held by the last two superconducting transport coils forming a quadrupole trap. This corresponds to a transport efficiency of about 60 %, which is limited by the background pressure (5 × 10−9 mbar) in the room temperature part of the setup. In principle, the atom number in the cryostat can be increased by upgrading the MOT optics or improving the background pressure in the lower chamber. In the cryostat, the atomic clouds exhibit lifetimes of up to five minutes due to the low pressure in the cryogenic environment. After transport, the atoms are loaded into an intermediate trap using the vertical bias coils in anti-Helmholtz configuration. This allows the quadrupole trap to be connected in series with the Ioffe coil. This forms a quadrupole-Ioffe configuration (QUIC) trap that minimizes heating due to current fluctuations [32]. After switching, the intermediate trap is ramped down, the QUIC trap is ramped up to \(I_{{\rm QUIC}}=1.2\,{\rm A}.\) The atoms are now in a macroscopic trap with trapping frequencies of \((\omega_{{\rm long}},\omega_{{\rm radial}})/2\pi=25,\,250\,{\rm Hz}\) and a trap bottom of 4 G. A slow radio frequency ramp from 30 to 5 MHz precools the atoms in the QUIC trap and increases the density of the cloud by evaporative cooling.

The transverse magnetic field of the Z-wire chip trap is rotated by 45° relative to the corresponding field in the QUIC trap, which is fixed by the axis of the vertical transport. This makes direct loading difficult. This is overcome by implementing a "swing-by maneuver." Figure 3a shows the whole loading sequence used to transfer the atoms from the QUIC trap into the superconducting Z-trap. The sequence starts by moving the QUIC trap closer to the chip with a vertical bias field, \(B_{{\rm vert}}\), while at the same time moving it off-center with the chip bias field in opposite polarity, \(-B_{{\rm bias}}\). The actual loading into the chip trap happens in the next step, when \(I_{{\rm QUIC}}\) is ramped to zero, \(I_{{\rm chip}}\) is ramped up and \(-B_{{\rm bias}}\) is ramped to the actual bias field \(+B_{{\rm bias}}\). This allows a smooth transition between the two rotated magnetic field configurations. The chip loading sequence was found to be optimal for a ramp time of 500 ms. Due to the high inductivity, the supply electronics do not reproduce faster ramps accurately. Figure 3b shows the atoms in the chip trap at different points during the transfer. The swing-by maneuver is best observed through the longitudinal direction, where the sideward motion of the trap is visible. At the end of the sequence, the superconducting microtrap holds around 2 × 106 atoms at 20 µK. Using a current of \(I_{{\rm chip}} = 1.12\,\hbox{A}\) in the Z-wire and a bias field of \(B_{{\rm bias}}=7.6\,\hbox{G}\) results in a trap around 350 μm from the chip surface. The measured trapping frequencies are \((\omega_{{\rm long}},\omega_{{\rm radial}})/2\pi=20,\,370{\rm Hz}\) with a trap bottom of 2 Gauss.

a Current sequence for loading, b absorption images of the atoms taken along the longitudinal (top) and transversal (bottom) axes of the chip trap. Here, four images corresponding to different points throughout the loading sequence are stacked. A initial QUIC trap, B −B Bias and vertical offset at maximum, C middle of the ramp and D final chip trap. The dashed line shows the trajectory of the atoms through the entire loading sequence

Bringing the trap closer than 2.5 times, the width of the superconducting wire (here 100 μm) opens it up toward the chip surface due to the Meissner effect [33]. In fact, the Meissner effect can be used to keep atoms close to the surface by applying a vertical bias field [34]. This "Meissner trap" has its minimum at the surface of the superconductor, where the atoms are lost quickly. It can easily be loaded directly from the QUIC trap. Figure 4 shows atoms in the "Meissner trap" along the superconducting surface of the Z-wire.

Meissner trap formation after ramping down \(I_{{\rm QUIC}}\) to zero while leaving only the vertical bias field on. Since the QUIC trap is not centered with respect to the Z-wire, the majority of the atoms are trapped on one of the Z-leads. The rest of the Z-structure is also weakly outlined by the Meissner trap

4 Summary and outlook

We have successfully transported thermal atoms into a cryogenic environment and trapped them on a superconducting atomchip. The magnetic conveyor belt shows high robustness due to the absence of alignment sensitive parts and avoids the operation of a MOT close to superconducting surfaces. Furthermore, the turnaround time for modifications in the science chamber is less than a day due to cryopumping. The transport scheme described here is fully compatible with a dilution refrigerator since they have similar cooling powers at the 4 K stage. This will enable experiments where ultracold atoms interact with superconducting quantum circuits. A superconducting microwave resonator can be integrated on the atomchip to study the coupling of ultracold atoms to microwave photons. Ultracold atoms near superconducting surfaces also open the possibility to use unique superconducting lattice traps [35]. Furthermore, being able to transport ultracold atoms into a cryostat allows sympathetic cooling of buffer gas cooled atoms or molecules [36], reduction of the blackbody radiation-induced light shifts in optical lattice clocks [37], and the usage of cold atoms to probe surfaces at cryogenic temperatures [38, 39].

References

R.J. Schoelkopf, S.M. Girvin, Wiring up quantum systems. Nature 451, 664–669 (2008)

M. Wallquist, K. Hammerer, P. Rabl, M. Lukin, P. Zoller, Hybrid quantum devices and quantum engineering. Phys. Scr. 2009(T137), 014001 (2009)

Z.-L. Xiang, J. Sahel Ashhab, Q. You, N. Franco, Hybrid quantum circuits: superconducting circuits interacting with other quantum systems. Rev. Mod. Phys. 85, 623–653 (2013)

P. Rabl, D. DeMille, J.M. Doyle, M.D. Lukin, R.J. Schoelkopf, P. Zoller, Hybrid quantum processors: molecular ensembles as quantum memory for solid state circuits. Phys. Rev. Lett. 97, 033003 (2006)

A. Andre, D. DeMille, J.M. Doyle, M.D. Lukin, S.E. Maxwell, P. Rabl, R.J. Schoelkopf, P. Zoller, Wiring up quantum systems. Nat. Phys. 2, 636–642 (2008)

A.S. Sørensen, C.H. van der Wal, L.I. Childress, M.D. Lukin, Capacitive coupling of atomic systems to mesoscopic conductors. Phys. Rev. Lett. 92, 063601 (2004)

D. Petrosyan, M. Fleischhauer, Quantum information processing with single photons and atomic ensembles in microwave coplanar waveguide resonators. Phys. Rev. Lett. 100, 170501 (2008)

D. Petrosyan, G. Bensky, G. Kurizki, I. Mazets, J. Majer, J. Schmiedmayer, Reversible state transfer between superconducting qubits and atomic ensembles. Phys. Rev. A 79, 040304 (2009)

J. Verdú, H. Zoubi, Ch. Koller, J. Majer, H. Ritsch, J. Schmiedmayer, Strong magnetic coupling of an ultracold gas to a superconducting waveguide cavity. Phys. Rev. Lett. 103, 043603 (2009)

K. Henschel, J. Majer, J. Schmiedmayer, H. Ritsch, Cavity QED with an ultracold ensemble on a chip: prospects for strong magnetic coupling at finite temperatures. Phys. Rev. A 82, 033810 (2010)

M. Hafezi, Z. Kim, S.L. Rolston, L.A. Orozco, B.L. Lev, J.M. Taylor, Atomic interface between microwave and optical photons. Phys. Rev. A 85, 020302 (2012)

S. Bernon, H. Hattermann, D. Bothner, M. Knufinke, P. Weiss, F. Jessen, D. Cano, M. Kemmler, R. Kleiner, D. Koelle, J. Fortágh, Manipulation and coherence of ultra-cold atoms on a superconducting atom chip. Nat. Commun. 4, 2380 (2013)

R. Amsüss, Ch. Koller, T. Nöbauer, S. Putz, S. Rotter, K. Sandner, S. Schneider, M. Schramböck, G. Steinhauser, H. Ritsch, J. Schmiedmayer, J. Majer, Cavity qed with magnetically coupled collective spin states. Phys. Rev. Lett. 107, 060502 (2011)

H. Wu, R.E. George, J.H. Wesenberg, K. Mølmer, D.I. Schuster, R.J. Schoelkopf, K.M. Itoh, A. Ardavan, J.L. Morton, G. Briggs, D. Andrew, Storage of multiple coherent microwave excitations in an electron spin ensemble. Phys. Rev. Lett. 105, 140503 (2010)

D.I. Schuster, A.P. Sears, E. Ginossar, L. DiCarlo, L. Frunzio, J.J.L. Morton, H. Wu, G.A.D. Briggs, B.B. Buckley, D.D. Awschalom, R.J. Schoelkopf, High-cooperativity coupling of electron-spin ensembles to superconducting cavities. Phys. Rev. Lett. 105, 140501 (2010)

Y. Kubo, F.R. Ong, P. Bertet, D. Vion, V. Jacques, D. Zheng, A. Dréau, J.F. Roch, A. Auffeves, F. Jelezko, J. Wrachtrup, M.F. Barthe, P. Bergonzo, D. Esteve, Strong coupling of a spin ensemble to a superconducting resonator. Phys. Rev. Lett. 105, 140502 (2010)

A. Imamoğlu, Cavity QED based on collective magnetic dipole coupling: spin ensembles as hybrid two-level systems. Phys. Rev. Lett. 102, 083602 (2009)

M. Greiner, I. Bloch, T.W. Hänsch, T. Esslinger, Magnetic transport of trapped cold atoms over a large distance. Phys. Rev. A 63, 031401 (2001)

S. Schmid, G. Thalhammer, K. Winkler, F. Lang, J.H. Denschlag, Long distance transport of ultracold atoms using a 1d optical lattice. New J. Phys. 8(8), 159 (2006)

A.P. Chikkatur, Y. Shin, A.E. Leanhardt, D. Kielpinski, E. Tsikata, T.L. Gustavson, D.E. Pritchard, W. Ketterle, A continuous source of Bose–Einstein condensed atoms. Science 296(5576), 2193–2195 (2002)

T. Mukai, C. Hufnagel, A. Kasper, T. Meno, A. Tsukada, K. Semba, F. Shimizu, Persistent supercurrent atom chip. Phys. Rev. Lett. 98, 260407 (2007)

C. Roux, A. Emmert, A. Lupascu, T. Nirrengarten, G. Nogues, T. Brune, J.M. Raimond, S. Haroche, Bose–Einstein condensation on a superconducting atom chip. Eur. Phys. Lett. 81, 81 (2008)

T. Nirrengarten, A. Qarry, C. Roux, A. Emmert, G. Nogues, M. Brune, J.M. Raimond, S. Haroche, Realization of a superconducting atom chip. Phys. Rev. Lett. 97, 200405 (2006)

F. Jessen, M. Knufinke, S. C. Bell, P. Vergien, H. Hattermann, P. Weiss, M. Rudolph, M. Reinschmidt, K. Meyer, T. Gaber, D. Cano, A. Günther, S. Bernon, D. Koelle, R. Kleiner, J. Fortágh. Trapping of ultracold atoms in a 3He/4He dilution refrigerator. Appl. Phys. B 1–7 (2013). doi:10.1007/s00340-013-5750-5

M.A. Naides, R.W. Turner, R.A. Lai, J.M. DiSciacca, B.L. Lev, Trapping ultracold gases near cryogenic materials with rapid reconfigurability. Appl. Phys. Lett. 103(25), 251112 (2013)

P.B. Antohi, D. Schuster, G.M. Akselrod, J. Labaziewicz, Y. Ge, Z. Lin, W.S. Bakr, I.L. Chuang, Cryogenic ion trapping systems with surface-electrode traps. Rev. Sci. Instrum. 80(1), 013103 (2009)

Cryostat: Advanced Research Systems (arscryo.com), Type ARS CS210*F-GMX-20, high-Tc wires: Superpower Inc. (http://www.superpower-inc.com), Type SCS4050, Niobium–Titanium wires: Supercon Inc.(superconinc.com), Type 54S43

T. McMillan, P. Taborek, J.E. Rutledge, A low drift high resolution cryogenic null ellipsometer. Rev. Sci. Instrum. 75(11), 5005 (2004)

J. Simpsons, J. Lane, C. Immer, R. Youngquist, Simple analytic expressions for the magnetic field of a circular current loop. NASA technical documents, 2001

N. Lippok, A magnetic transport for ultracold atoms. Master’s thesis, Atominstitut TU Wien, Austria, 2008

S. Haslinger, Cold atoms in a cryogenic environment. PhD thesis, Atominstitut TU Wien, Austria, 2011

T. Esslinger, I. Bloch, T.W. Hänsch, Bose–Einstein condensation in a quadrupole-Ioffe-configuration trap. Phys. Rev. A 58, R2664–R2667 (1998)

V. Dikovsky, V. Sokolovsky, B. Zhang, C. Henkel, R. Folman, Superconducting atom chips: advantages and challenges. Eur. J. Phys. D 51(2), 247–259 (2008)

C. Hufnagel, Superconducting microtraps for ultracold atoms. PhD thesis, Atominstitut TU Wien / NTT Japan, 2011

O. Romero-Isart, C. Navau, A. Sanchez, P. Zoller, J.I. Cirac, Superconducting vortex lattices for ultracold atoms. Phys. Rev. Lett. 111, 145304 (2013)

S. Doret, C. Colin, K. Wolfgang, D. John, Buffer-gas cooled Bose–Einstein condensate. Phys. Rev. Lett. 103(10), 103005 (2009)

J.A. Sherman, N.D. Lemke, N. Hinkley, M. Pizzocaro, R.W. Fox, A.D. Ludlow, C.W. Oates, High-accuracy measurement of atomic polarizability in an optical lattice clock. Phys. Rev. Lett. 108(15), 153002 (2012)

S. Wildermuth, S. Hofferberth, I. Lesanovsky, S. Groth, P. Krüger, J. Schmiedmayer, I. Bar-Joseph, Sensing electric and magnetic fields with Bose–Einstein condensates. Appl. Phys. Lett. 88(26), 264103 (2006)

A. Emmert, A. Lupacu, G. Nogues, M. Brune, J.M. Raimond, S. Haroche, Measurement of the trapping lifetime close to a cold metallic surface on a cryogenic atom-chip. Eur. J. Phys. D 51(2), 173–177 (2009)

Acknowledgments

SM and FD would like to acknowledge the support of the COQUS doctoral program. This work was funded through the European Union Integrated Project SIQS and the Austrian Science Fund FWF (Wittgenstein Prize, SFB FOQUS).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Stefan Minniberger and Fritz Diorico have contributed equally to the efforts leading to this paper.

Rights and permissions

About this article

Cite this article

Minniberger, S., Diorico, F., Haslinger, S. et al. Magnetic conveyor belt transport of ultracold atoms to a superconducting atomchip. Appl. Phys. B 116, 1017–1021 (2014). https://doi.org/10.1007/s00340-014-5790-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-014-5790-5