Abstract

Results of a GaAs/AlGaAs-based phase modulator designed for an operating wavelength of 780 nm are presented for the first time. The modulator is based on a P-p-i-n-N double heterostructure and features a waveguide with a vertical W-shaped index profile optimized for low propagation losses and a ridge waveguide for lateral index-guiding. A phase modulation efficiency of 12°/V mm is reported. The propagation losses are determined to about 1.4 dB/cm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, there has been increasing interest in building micro-integrated laser systems and integrated optical devices operating at the wavelength of 780 nm for atomic spectroscopy applications like atom interferometry [1]. Phase modulators, for example, are required for frequency modulation spectroscopy applications as well as for ultra-fast phase control in optical phase-locked loops. Chip-based modulators provide the means to micro-integrate phase control and modulation into hybrid laser and spectroscopy modules in a very compact and robust way. The realization of phase modulators based on GaAs/AlGaAs double heterostructures (DH) has been motivated by the unique properties of III–V compound semiconductors as they promise excellent integration with electronic devices [2, 3].

Semiconductors offer several advantages compared to other materials that can be used in phase modulators. The refractive index in a semiconductor depends on the free carrier concentrations as well as on an internal quasi-static electric field and can be easily changed in a pn-junction, for example, by applying an external bias voltage. The spatial distribution of the refractive index in semiconductor devices can be tailored so that photonic integrated circuits, including modulators, combiners, splitters, and interferometers can be realized.

Besides a high phase modulation efficiency (phase change per Volt per mm), phase modulators should provide high speed modulation and low propagation losses [4]. So far, phase modulators based on P-p-n-N GaAs/AlGaAs double heterostructure have been demonstrated by various authors [5, 6] with high modulation efficiency. However, such structures have the disadvantage of high absorption losses and large capacitance, the latter of which limits the high-speed modulation capability.

Other concepts introduced an intrinsic (not intentionally doped) layer to form a P-i-N junction [7, 8]. The free carriers in the intrinsic layer are depleted so that most of the electric field is confined inside of it. This creates an optimum overlap between the optical field and the static electric field [7]. The introduction of an intrinsic layer decreases the junction capacitance but is accompanied by a reduction in the modulation efficiency due to the decreased carrier effect.

A phase modulator with a P-p-i-n-N-DH where a part of the waveguide core is doped was demonstrated in [4]. This structure showed high modulation efficiency (34°/V mm for transverse electric (TE) polarized light at 1.31 μm) and low propagation losses (less than 0.6 dB/cm) due to a W-shaped refractive index profile.

In this paper, we present a P-p-i-n-N-DH phase modulator similar to the structure described in [4] but optimized for operation at 780 nm. In the first part of the Sect. 2, we briefly describe the different effects responsible for phase modulation in GaAs/AlGaAs DHs. Next, the design of the multilayer structure is described, and results of waveguide simulations are presented. Details related to the fabrication and experimental electro-optical characterizations are addressed in the Sect. 3.

2 Design and simulation

2.1 Electro-optic effects in GaAs/AlGaAs double heterostructures

The electro-optic effects resulting in a phase modulation are the linear electro-optic (LEO) effect, the quadratic electro-optic (QEO) effect caused by the Franz–Keldysh effect, and carrier-density-related effects [3]. Equations (1) and (2) describe the modification of the refractive index of a semiconductor of the zinc-blende class \(\overline{4} 3_{m}\) by means of the LEO coefficient r 41 and QEO coefficients R 11 = R 12 = R,

for a mode with the electrical field polarized perpendicular to the [001] direction (TE mode in a waveguide), and

for a mode with the electrical field polarized parallel to the [001] direction (transverse magnetic mode). Here, E j is the strength of the junction electric field, n is the refractive index, and V is the modulation voltage. The negative sign in the first term of (2) corresponds to modes propagating in the \([1\overline{1} 0]\) direction, and the positive sign corresponds to the propagation along the [110] direction [3]. For TM polarization, only the QEO contributes to the electric field effect.

For the modulator under investigation, the demand for modulation of light with a wavelength of 0.78 μm enforces to use an intrinsic layer and waveguide core made from AlGaAs instead of GaAs as in [3] in order to avoid strong interband absorption. We chose an Al mol fraction of 35 %. In order to estimate the expected phase modulation, the electro-optic constants for Al0.35Ga0.65As at a wavelength of 0.78 μm must be known. Due to the fact that for this material and wavelength, no values of the electro-optic effects have been published, we used the following procedure to estimate the corresponding LEO and QEO coefficients.

For GaAs with a band gap wavelength λ 1g = 0.872 μm, the LEO coefficient has been given in [9] in the wavelengths range between 1.05 and 1.32 μm. For Al0.35Ga0.65As with a band gap wavelength λ 2g = 0.651 μm, the electro-optic coefficients are requested for λ 2 = 0.78 μm. The difference between both wavelengths is δλ = λ 2 − λ 2g = 0.129 μm. We assume that the coefficients are determined by the spacing between a given wavelength and gap wavelength independently of the Al-content in Al x Ga1−x As. Therefore, we add δλ to the gap wavelength λ 1g = 0.872 μm of GaAs obtaining λ 1 = 1.001 μm. The electro-optic coefficients of GaAs at this wavelength are assumed to correspond to the values for Al0.35Ga0.65As at the wavelength λ 2 = 0.78 μm. The linear electro-optic (LEO) effect of GaAs can be linearly extrapolated from the values given in [9] to the wavelength λ 1 = 1.001 μm so that r 41(1.001 μm) = 1.84 × 10−12 m/V. This value is then considered to describe the LEO coefficient for Al0.35Ga0.65As at λ 2 = 0.78 μm.

The quadratic electro-optic coefficient of GaAs according to [3] is given by the expression

with E pg being the gap energy, E p the photon energy, and A a constant. We suppose that this constant is equal for GaAs and Al0.35Ga0.65As and can be eliminated by referring R 12 for Al0.3Ga0.65As at the requested wavelength λ 2 to the same coefficient for GaAs at a wavelength λ 1 for which its value is known

with λ 1 = 1.15 μm (the wavelength where experimental results have been published in [3]), λ 1g = 0.872 μm, λ 2 = 0.78 μm, λ 2g = 0.651 μm, n(λ 1) = 3.4496, n(λ 2) = 3.4265, R 12(λ 1) = −1.7 × 10−20 m2/V2 (given in [3] for GaAs) and with R 12(λ 2) = −2.3 × 10−20 m2/V2 for Al0.35Ga0.65As.

The carrier effects are caused by the dependence of the refractive index on transitions of the carriers within the bands (so-called plasma effect) and by transitions between the valence and conduction bands (inter-band transitions). The interband contribution is composed of band filling and band gap shrinkage (a many-body effect) [2, 3] and is strongly wavelength dependent, similar as the QEO effect. Free carrier effects contribute to the index change, if the hole and electron densities are modulated in dependence on the bias voltage. Typically, the carrier density is reduced at the edges of the space charge region of a pn-junction if applying a reverse bias voltage, thus increasing the refractive index there.

In a waveguide, the phase shift is proportional to the change in the propagation constant β of the mode when the modulation voltage V is applied,

where L is the length of the phase modulator.

The change Δn mod in the mode index n mod can be either calculated by solving the waveguide equation for two different refractive index distributions, or perturbationally by using the intensity distribution I(x, y) of the mode of a reference waveguide with refractive index distribution n(x, y),

The expression will be used below in Sect. 2.2 to estimate the magnitude of the LEO, QEO, and carrier effects in the layer structure under investigation.

2.2 Vertical structure

When optimizing the vertical layer structure for the guiding region, one has to compromise the interband absorption against the electro-optic coefficients because both increase as the photon energy approaches the band gap energy. For the modulator under investigation, Al0.35Ga0.65As was selected for the waveguide core with a band gap energy of 1.90 eV, which is sufficiently larger than the photon energy of 1.59 eV.

The layer structure of the phase modulator is summarized in Table 1. The corresponding refractive index profile and the calculated intensity profile of the fundamental TE mode are displayed in Fig. 1. In order to obtain low internal optical losses, we chose a W-shape refractive index profile similar to as used in [4]. The waveguide core has a total thickness of 1.9 μm resulting in a full width at half maximum of the intensity profile of the far field of only 22.5°, which facilitates the hybrid integration of the modulator with active and passive optical elements.

Refractive index profile of the vertical multilayer structure described in Table 1 (between the substrate and the upper contact), and the intensity profile of the fundamental TE mode

The low-index layers adjacent to the waveguide core have a high Al mol fraction of 70 %, which results in an index step of 0.233. This causes a strong confinement of the mode to the waveguide core, with a confinement factor of 99.6 %. The Al mol fraction of the outer cladding layers is only 2 % higher than that of the waveguide core, which results in an index step of only 0.014. This leads to a suppression of higher-order vertical modes. Another requirement to the cladding layers is that their thickness should be large enough to prevent a coupling of the fundamental mode to the upper contact layer and to the substrate.

The central part of the waveguide core is not intentionally doped, whereas 200 nm on either side of the core is moderately doped with N a = 3×1017 cm−3 and N d = 3×1017 cm−3. The low-index and cladding layers are more strongly doped in order to achieve a large overlap between the electric field and the optical field. Due to the strong confinement of the mode in the waveguide core, the calculated modal losses amount to only α mod = 0.1 cm−1, assuming electron and hole cross-sections of 3 × 10−18 and 7 × 10−18 cm2 [10], respectively, for absorption by free carriers (intraband absorption). The p-i-n waveguide core establishes a compromise between a best overlap of optical field and internal electric field on one hand, and low capacitance enabling high speed operation and high modulation efficiency [4, 11, 12] on the other hand.

To estimate the expected phase modulation due to the LEO, QEO, and carrier effects for the layer structure given in Table 1, one has to calculate Δn mod for those effects separately. For this purpose, a commercial program has been used to simulate the distributions of the optical field, the junction electric field, and the carrier densities. Using the simulation results, the refractive index change Δn due to the LEO and QEO effects can be calculated by means of (1). For the carrier effect, we used the expressions given in [3] and performed a similar procedure as in the utilization of Eq. (3). The modal index change caused by the different effects is finally computed by means of Eq. (5). Table 2 compares in the first row below the heading the order of magnitude of the three contributions to Δn mod for an electric field of 1 V and a modulator length of 1 mm and in the second row the result of the corresponding modulation efficiencies.

The LEO is the dominant effect, whereas the QEO and the carrier effects are negligible. This is because of (1) the thick intrinsic core limiting the strength of the junction electric field, (2) the small overlap of the optical field with the regions of varying carrier density at the boundary of the intrinsic core, and (3) the large difference between band gap energy of the i-core layer and the photon energy.

The QEO effect could be increased either by decreasing the spacing between the band gap and the photon energy (i.e. reducing the Al composition) or by employing a multiquantum well structure [13] in the guiding region. Although this makes the phase modulation more efficient, it has the drawback to increase the absorption losses.

2.3 Lateral structure

The lateral optical confinement is provided by a ridge waveguide (RW), realized by etching trenches along the propagation direction. To ensure a well-defined phase shift, the RW should support only the fundamental quasi-TE mode. Figure 2 shows the simulated single-mode regime as a function of the waveguide width and the etch depth at the wavelength of 780 nm. The simulations were carried out with a commercial tool utilizing the finite element method [14].

For example, for a ridge width of 2 μm, the etch depth should be less than 2.14 μm. Otherwise, the first-order lateral mode will also be confined under the ridge. Figure 3 shows calculated 2D distributions of the fundamental mode and the first-order lateral mode when the etching depth is larger than the limit given in Fig. 2. Both the TE00 and the TE10 can be confined even though the TE10 shows about 100 times larger loss coefficient.

A wider ridge is favored to ease coupling of the laser beam into the ridge and requires a smaller etching depth, resulting in a smaller effective index step of the fundamental mode in the lateral direction. Although this is not critical for phase modulators, it may be relevant for more complex waveguide structures such as Mach–Zehnder interferometers (MZIs) for intensity modulation, for which bent waveguides are needed. If the lateral effective index step becomes too small, the waveguide will experience radiation losses at the bends [15]. Hence, if phase modulators are used as part of more complex photonic circuits, a compromise between the ridge width and the etch depth has to be found.

3 Experiment

3.1 Fabrication

The epitaxial layer structure was grown on a 3-inch (001) n-GaAs substrate using metal–organic vapor phase epitaxy (MOVPE). The grown vertical structure consists of a lower 1.5 μm N-Al0.37Ga0.63As cladding layer, a 0.19 μm N-Al0.7Ga0.3As confinement layer, a 0.2 μm n-Al0.35Ga0.65As guiding layer, a 1.5 μm unintentionally doped (intrinsic) p-Al0.35Ga0.65As guiding layer, an upper p-Al0.35Ga0.65As guiding layer, a 0.19 μm P-Al0.7Ga0.3As confinement layer, an upper 1 μm P-Al0.37Ga0.63As cladding layer, and a 0.27 μm p+-GaAs electrode. Si and C were used as n- and p-type dopants, respectively. A full description of the structure with the corresponding doping concentration of each layer is given in Table 1.

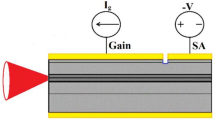

A standard RW process was applied with the orientation of the waveguides parallel to the \([1\overline{1} 0]\) crystallographic direction in order to make use of the linear electro-optic effect. The RWs with a ridge width of 2 μm and an etch depth of 1.7 μm were defined by reactive ion etching (RIE) and encapsulated with a 100-nm-thick SiN x layer. The isolation layer was opened on top of the waveguides for lateral carrier confinement. Ti/Pt/Au layers were deposited for p-side contacts, and before evaporation of the n-metallization, the wafer was thinned to 150 μm. Devices were cleaved and mounted p-side up on C-mount. Figure 4 shows a cross-sectional scanning electron microscope picture of the fabricated device. As shown by the simulation, see Fig. 2, the ridge width and etching depth are consistent with single-mode guiding.

For operation of the phase modulator, the reverse bias voltage must not exceed the break-down voltage. As Fig. 5 reveals, no break-down is observed for a reverse bias voltage as large as −20 V. The capacitance of a 2-mm-long modulator has been estimated to be about 250 pF at 0 V. The capacitance could be reduced by adding a benzocyclobutene polymer (BCB) passivation layer between the p-metallization and the upper cladding instead of the thin SiNx layer. Note that the pin junction capacitance for a waveguide length of 2 mm, a ridge width of 2 μm, and a depletion width of 1.5 μm is 0.28 pF.

3.2 Phase shift measurements

The phase shift was measured using the Fabry–Perot (FP) interference technique [4]. The measurement setup is shown in Fig. 6. The radiation of a DFB laser emitting at 780 nm is sent through an optical isolator and a polarization controller, before it is coupled into a polarization-maintaining (PM), AR-coated lensed fiber that provides a focal spot diameter of 2.5–3 μm. The axial direction at the front end of the fiber was set to the required polarization. The fiber output is then coupled into the waveguide of the modulator, which has uncoated facets. The output of the waveguide is collimated using a microscope objective, and its intensity was measured using a Ge photodetector. A second objective together with a CCD camera is used to record the intensity profile. Modulators with 1, 2, and 4 mm length have been characterized.

To scan the fringes of the FP resonator formed by the uncoated facets of the modulator chip, a 1 kHz sawtooth on top of 10 V DC reverse bias voltage signal is swept from 0 to −20 V. The voltage V π corresponding to a phase shift of π along the modulator length L was determined from the voltage difference between two maxima (or two minima) of the transmitted power. Figure 7 shows the measurement of a 2-mm-long phase modulator. A voltage V π of 7.5 V is obtained, which corresponds to a phase shift efficiency of \(\Updelta \phi /(\Updelta V \cdot L) = 12^{^\circ } /({\text{V}}\,{\text{mm}})\) which agrees quite will with the modulation efficiency 11.8°/(V mm) calculated in Sect. 2.2. The agreement confirms our assumption made in Sect. 2.1 regarding the calculation of the LEO coefficient.

Further improvement of the modulation efficiency is possible by optimizing the doping profile to increase the electric field strength and the impact of the variation in the carrier density.

3.3 Waveguide losses

Low propagation loss is an important requirement for waveguide phase modulators. Due to the relatively thick intrinsic layer and the large optical field confinement inside the guiding region, propagation losses in the waveguide are expected to be small. The FP technique is also suitable to perform a loss measurement. To this end, transmission losses are recorded for different chip length.

The propagation loss can be determined from transmission loss measurements carried out on waveguides with different lengths according to [16],

where L is the length of the cavity, i.e., the chip length, R is the reflectivity of the FP cavity, and K = (I max − I min)/(I max + I min) is the contrast of the Fabry–Perot resonances [16, 17], where I max and I min are the maximum and minimum transmitted intensities, respectively.

In [4], the phase of the optical signal was thermally tuned, and the fringes of the waveguide and its facets were measured. The propagation losses as a function of the applied reversed bias voltage were then estimated by repeating the measurement at different reverse bias voltages [4]. The full description of this method is given in [16, 17].

We have used a slightly different method to verify the propagation losses. Instead of thermally tuning the phase, we electrically tuned the phase in the FP setup. Chips with 3 different lengths were characterized: 1, 2, and 4 mm. We applied a 1 kHz modulation signal with an amplitude of 10 V and an offset of 10 V and recorded the output signal of the photodetector by means of an oscilloscope.

This method for loss measurement is based on the assumption that the propagation loss does not depend on the reverse bias voltage. To confirm this assumption, we replaced the DFB laser by a tunable external cavity diode laser (ECDL) in the experimental setup shown in Fig. 6. By tuning the ECDL by 0.1 nm around 780 nm and measuring the transmitted intensity through the 4-mm-long uncoated modulator chip, 8 FP fringes were observed. For different values of the reverse bias between 0 and 20 V, the maxima and minima of the FP fringes remained unchanged indicating constant propagation losses, which is in agreement with the fact that according to Table 2, the QEO and carrier effects are negligible.

In Fig. 8, the term on the left-hand side of (6) is plotted as a function of the cavity length. The loss coefficient α = 0.33 cm−1 (which corresponds to 1.4 dB/cm) can be extracted from the slope of the fitted straight line. This value is consistent with the value of 0.1 cm−1 calculated above, which only accounts for the free carrier absorption losses. The deviation could be attributed to additional losses introduced by the etched planes of the RW. The reflectivity of the facets extracted from the interception with the ordinate is R = 0.278, which is slightly smaller than the theoretical value of 0.305.

Transmission losses: left-hand side of Eq. (6) as a function of the cavity length. The slope of the linear fit corresponds to the propagation loss coefficient in 1/mm

4 Conclusions

In this paper, the design, fabrication, and the electro-optical characterization of a double-heterostructure GaAs/AlGaAs phase modulator for operation at 780 nm have been presented. The guiding region consists of a p-i-n multilayer epitaxial structure that maximizes the overlap of the optical and electrical field. Arguments have been presented that suggest that the phase modulation is dominated by the linear electro-optic effect rather than by the QEO and the carrier effects. A modulation efficiency of 12°/(V mm) and a propagation loss coefficient of 1.4 dB/cm have been demonstrated. The total modulator capacitance was estimated to be 250 pF at 0 V, limiting direct modulation with a 50 Ω source to 13 MHz. The reduction in the modulator capacitance by one to two orders of magnitude seems feasible in the future so that GaAs/AlGaAs-based modulators could provide access to modulation frequencies beyond 1 GHz with direct driving. This paper has shown that GaAs/AlGAs-based phase modulators constitute a compact and robust alternative to crystal-based modulators.

References

E. Luvsandamdin, S. Spießberger, M. Schiemangk, A. Sahm, G. Mura, A. Wicht, A. Peters, G. Erbert, G. Tränkle, Appl. Phys. B. (2013). doi:10.1007/s00340-012-5327-8

S.S. Lee, R.V. Ramaswamy, V.S. Sundaram, IEEE J. Quantum Electron. 27, 726 (1991)

J. Faist, F.-K. Reinhart, J. Appl. Phys. 67, 6998–7012 (1990)

Y.T. Byun, K.H. Park, S.H. Kim, S.S. Choi, J.C. Yi, Appl. Opt. 37, 496 (1998)

J.G. Mendoza-Alvarez, L.A. Coldren, A. Alping, R.H. Yan, T. Hausken, K. Lee, K. Pedrotti, J. Lightwave Technol. 6, 793 (1988)

J.-F. Vinchant, J.A. Cavailles, M. Erman, P. Jarry, M. Renaud, J. Lightwave Technol. 10, 63 (1992)

W.K. Marshall, J. Katz, Appl. Opt. 24, 1996 (1985)

A. Bandyopadhyay, P.K. Basu, J. Lightwave Technol. 10, 1438 (1992)

Y.T. Byun, S.J. Kim, S.H. Kim, J. Korean Phys. Soc. 45, 1162 (2004)

J. Shin, Y.-C. Chang, N. Dagli, Appl. Phys. Lett. 92, 201103 (2008)

H.C. Panish Jr, M.B. Casey, Heterostructure Lasers: Part A: Fundamental Principles (Academic Press, San Diego, 1978), p. 175

J. Faist, F.K. Reinhart, D. Martin, Electron. Lett. 23, 1391 (1987)

S.S. Lee, Y.S. Kim, R.V. Ramaswamy, V.S. Sundaram, Appl. Phys. Lett. 55, 1865 (1989)

B.M.A. Rahman, B.J. Davies, IEEE Trans. Microw. Theory Tech. 32, 20 (1984)

R.J. Deri, E. Kapron, L.M. Schiavone, Electron. Lett. 23, 845 (1987)

R. Regener, W. Sohler, Appl. Phys. B 36, 143 (1985)

Y.T. Byun, K.H. Park, S.H. Kim, S.S. Choi, T.K. Lim, Appl. Opt. 35, 928 (1996)

Acknowledgments

This work is supported by the German Space Agency DLR with funds provided by the Federal Ministry of Economics and Technology (BMWi) under Grant Number 50WM1141.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arar, B., Wenzel, H., Güther, R. et al. Double-heterostructure ridge-waveguide GaAs/AlGaAs phase modulator for 780 nm lasers. Appl. Phys. B 116, 175–181 (2014). https://doi.org/10.1007/s00340-013-5671-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5671-3