Abstract

A physical model is established to demonstrate the mechanism and the kinetic process of a diode transverse-pumped cesium vapor laser. The distribution of pump laser power is described, and the effects of parameters such as the temperature, the cell length and the output coupler reflectivity on the output performance of a cesium vapor laser are simulated and analyzed. The simulation results agree well with the experiment data which shows the validity of this model. A set of optimization parameters is achieved for improving the output characteristics of a diode transverse-pumped Cs vapor laser.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

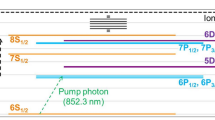

Since the first end-pumped rubidium vapor laser was reported by Krupke et al. in 2003 [1], diode pumped alkali vapor lasers (DPALs) have attracted gaining attention and made significant progress during the past decades [2–8]. Compared with other high-power lasers, DPALs have notable advantages such as the high quantum efficiency, which is important for minimizing the thermal effect, the good optical quality of gain medium and the narrow line-width, all these are desirable for applications in laser cooling, material processing and energy transmission [9].

A series of experiments on DPALs have been conducted with promising results in recent years. Laser diode arrays or stacks of diode arrays were used as multiple laser diode pump sources in order to scale alkali lasers to high-power application. By using longitudinal pumping method with multiple laser diode arrays, a Rb laser of 17-W [5] (with two laser diode arrays) and a Cs laser of 48-W [6] (with four laser diode arrays) output power were reported. However, it is difficult if more than four beams are to be coupled into the alkali vapor cell for the longitudinal pumping way. This problem can be solved with the side-pumped configuration proposed by Zhdanov et al. As the separation between the pump and the laser beams can simplify the optics arrangement, decrease the power burden on laser windows and make the gain along the laser path to be much more uniform, the power of side-pumped DPAL is more scalable [10]. The first transversely pumped Cs vapor laser with 28-W output power and 15 % slope efficiency was reported by Zhdanov et al. [7]. Then, its output performance was improved to 49-W output power and 43 % slope efficiency with unstable resonator [8]. Recently, by analyzing the kinetic process, Yang et al. [10, 12] established physical models to describe the laser characteristics of side-pumped alkali vapor lasers.

In this paper, we present a physical model to demonstrate the mechanism and the kinetic process of a diode transverse-pumped Cs vapor laser. According to relative experiment parameters in [7], the results from numerical simulation study agree well with those of the experiment. The pump power distribution in Cs vapor cell is calculated and analyzed on this basis. Then, the influence of parameters such as the temperature, the output coupler reflectivity and the cell length on the output characteristics of the Cs vapor laser is analyzed. A set of optimization parameters is obtained for designing an efficient diode transverse-pumped Cs vapor laser.

2 Description of the model

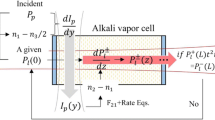

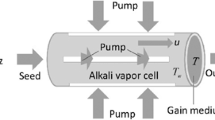

The simplified schematic diagram of the transverse-pumped DPAL used in this model is shown in Fig. 1. The 5-cm-long and 3-mm-inner-diameter Cs vapor cell is placed inside a cylindrical white diffuse reflector with a 2 mm × 50 mm slit on its side where the pump light is coupled in transversely. The pump sources are fifteen laser diode arrays with total pump power of 200 W. In our model, only the pump beams that have entered the Cs vapor cell were concerned. As shown in Fig. 1, pump beams that enter into the vapor cell through the slit along the y axis are reflected by the inner surface of the diffuse reflector. For simplification, the pump beam is assumed to travel through the Cs vapor cell only once. Along the x axis, the pump beam is collimated by beam-shaping optics and is assumed to be in Gaussian profile in the incident plane. In the z-axis direction, the pump intensity is considered as a uniform distribution due to the overlapping of multiple laser diode arrays.

A two-dimension division of the alkali gain medium along x and y axes was made. Each divided volume element has dimensions of \(\Updelta x \times \Updelta y \times L\)that meet the condition of \(\Updelta x,\Updelta y \ll L\). In the longitudinal (z) direction, the dynamic process is described in the literature [13]. Considering the assumption that the pump intensity is homogenous along the z-axis direction, the rate equations of Cs atomic levels in each volume element can be described as below:

where \(n_{1} (x,y)\), \(n_{2} (x,y)\)and \(n_{3} (x,y)\)are the number density of Cs atomic energy levels \(6{}^{2}S_{1/2}\), \(6{}^{2}P_{1/2}\)and \(6{}^{2}P_{3/2}\), respectively. \(\tau_{D1}\) \(\left( {\tau_{D2} } \right)\)is the lifetime of level \(6{}^{2}P_{1/2}\) \(\left( {6{}^{2}P_{3/2} } \right)\). \(\Updelta E\)is the energy difference between the \(6{}^{2}P_{1/2}\)and \(6{}^{2}P_{3/2}\)levels. T is cell temperature in Kelvin. \(\gamma_{32}\)is the fine-structure mixing rate which can be written as:

where \(n_{{{\text{C}}_{2} {\text{H}}_{6} }}\)and \(n_{\text{He}}\)are the number densities of ethane and helium in the vapor cell, respectively. \(\sigma_{{{\text{C}}_{2} {\text{H}}_{6} }}\)and \(\sigma_{\text{He}}\)are the fine-structure mixing cross-sections, and \(V_{\text{r}}\)is the rms thermally averaged relative velocity between alkali atoms and ethane (or helium) molecules. \(\Upgamma_{\text{p}} \left( {x,y} \right)\)and \(\Upgamma_{\text{l}} (x,y)\)are the respective pump absorption and the laser emission rates. According to the simplification that the pump beam travels through the cell only once, \(\Upgamma_{\text{p}} (x,y)\)is expressed as follows:

where \(P_{\text{p}} \left( {x,y} \right)\)is the total pump power, c is the speed of the light, \(\lambda\)is the pump wavelength, \(\sigma_{13} \left( \lambda \right)\)is the absorption cross-section, and \(V_{\text{p}} = \Updelta x \times \Updelta y \times L\)is the pump volume of each element.

\(\Upgamma_{\text{l}} (x,y)\)is given by:

where \(P_{\text{l}} (x,y)\)is the output laser power in each volume element, and \(h\upsilon_{\text{l}}\)is the laser photon energy. \(\sigma_{21}\)is the emission cross-section. \(R_{\text{OC}}\)is the reflectivity of the output coupler; t is the one-way cavity transmission. L is the gain cell length. \(\eta_{\text{mode}} = {{V_{\text{l}} } \mathord{\left/ {\vphantom {{V_{\text{l}} } {(V_{\text{p}} + }}} \right. \kern-0pt} {(V_{\text{p}} + }}V_{\text{l}} )\)is the mode match factor, where \(V_{\text{l}}\)is the element volume of cavity mode. Taking the experiment results into consideration, the overlapping factor between the output laser and the pump beams was estimated and the supposed value of \(\eta_{\text{mode}}\)is 0.22.

In the transverse (y) dimension, the iterative algorithm is used to calculate the simulated results. The propagation equation of \(P_{\text{p}} \left( {x,y,\lambda } \right)\)is similar to that in [10] and is given by

Combining with the equations in the longitudinal model above and Eq. (7), and taking \(P_{\text{p}} (x,0,\lambda )\)as the initial value, we can solve for the transverse population distribution n i (x,y) with the method of iterative algorithm in MATLAB. Together with the main parameters cited from the literature [13] and the numerical method with MATLAB, the influences of parameters on the laser output performances can be analyzed to get the optimized parameters for designing an efficient transverse-pumped alkali vapor laser.

3 Simulation results

3.1 Influence of division numbers along x and y axes

The division numbers along x and y axes are important to our model, and the influence of division numbers on the calculated output performance has been analyzed. The dependences of the optical efficiency on the division numbers along x and y axes with 10 division numbers of y and x axes are displayed in Fig. 2a, b, respectively. The results reveal that the optical–optical efficiency is not sensitive to division numbers both along x and y axes. Therefore, only a few division numbers were set for a fast calculation to get the simulated results in our model.

3.2 Distribution of pump power

To simplify the calculation, the spectral dependence of the pump light absorption is described as an effective cross-section, which is calculated by the convolution of D2 transition Lorentzian line shape and the LDA Gaussian spectral shape [11]. So the spectral dependences in the rate equations above can be ignored. Together with the assumption that the pump beam travel through the cell only once and using the numerical method in MATLAB, the distribution of pump power along x and y axes in the vapor cell was obtained as shown in Fig. 3. As a result of nonlinear absorption, we can see the attenuation curve of pump power along y axis. Along x axis, the distribution of pump power is in Gaussian profile, which agrees well with the previous assumption that the pump beam is in Gaussian profile in the incident plane.

3.3 Influence of the temperature

The cell temperature determines the alkali vapor density, which is important for optimizing the laser output power. According to the experimental results [7] and relative parameters, we calculate the relationship between the one-way cavity transmission t and the temperature (T) which can be described as follows:

As displayed in Fig. 4, both the results of simulation and experiment show that the laser output power increases rapidly from the threshold temperature of ~360 K to a maximum value and then starts falling slowly or keeps stabilization. The simulated optimal temperature is about 390 K, which is almost the same with the experimental data of 393 K [7]. The calculated threshold temperature of 360 K is a little lower than the experimental value of 365 K. The higher threshold temperature in experiment is caused by the lower gain in the gain medium. The higher optimal temperature can be explained by the shorter absorbing gain medium along the cell length [7]. Higher temperature will provide higher vapor density, which can cause the reabsorption of the laser emission and the chemical reaction between the cesium vapor and the ethane buffer gas, so the laser output power rolls over at high temperature as shown in Fig. 4. In general, the simulation results have a good agreement with the experiments. Therefore, this model can provide an effective way for further improving the laser efficiency of the transverse-pumped alkali vapor laser.

3.4 Influence of the pump power

According to the experiment [7] and relative parameters, we simulate the dependences of the output laser power on the pump power with different cell lengths at the optimal cell temperature of 390 K. As shown in Fig. 5, the output power increases with the pump power for each cell length and the saturation effect is not reached when the pump power is 200 W. Through linear fit, with 5-cm cell length, we get the slope efficiency of 14 % and the maximum optical efficiency of 13 % which agree well with the experiment results [7]. The lower slope and optical efficiencies can be explained by the mismatch between the pump beam and the laser cavity mode in such transverse-pump way. So a proper inner size of the laser cavity should be designed to match the illuminated gain medium inside the reflector to get higher pump coupling efficiency. Besides, the figure also shows that it is not the longer cells can bring higher output power when the pump power is <200 W, this is because a shorter cell has a higher pump power density, which can pump more cesium atoms from the ground state to the excited state and leading to higher output power. This result can also be seen in the following calculations. Thus, an optimized length should be determined for different situations in the experiment.

3.5 Influence of the cell length

Figure 6 shows the dependences of the output power on the cell length with different pump powers from 100 to 500 W, 390-K optimal cell temperature and 20 % output coupler reflectivity. It can be seen that the output power decreases with the increase in cell length when the pump power is <200 W. It can be explained by the lower pump power density in the vapor cell. When the pump power exceeds 200 W, the output power increases obviously with the cell length till its optimal value, and then it keeps stabilization or decreases slowly with the increase in the cell length. The optimal cell length increases a little with enhancing the pump power, from 3.5 cm at 200 W to 6 cm at 500 W. This agrees well with other result [14] that it is not the longer cells can bring higher output power, because the gain medium absorption is nonlinear and the fine-structure mixing rate is limited.

3.6 Influence of the output coupler reflectivity

The output coupler reflectivity has an important effect on the output laser power. Figure 7 describes the laser output power as a function of the pump power under different output coupler reflectivity with 390-K temperature and 5-cm cell length. It can be seen from the figure that the laser power is almost the same when the pump power is <60 W, then it increases a little with the decrease in the output coupler reflectivity. With the same parameters of 0.2 output coupler reflectivity, 200-W pump power and 5-cm cell length as described in experiment [7], we calculate the laser output power of 26 W. This result is also consistent with the experiment.

4 Conclusion

The transverse-pumped alkali vapor laser is very promising to achieve high output power in the development of DPALs. In this paper, by analyzing the mechanism and kinetic process in transverse-pumped alkali vapor lasers, we established a physical model to simulate the output characteristics of a transverse-pumped Cs vapor laser. According to the data from the literature, the effects of factors such as the temperature, the cell length and the output coupler reflectivity on the output performance of Cs vapor laser have been simulated and analyzed. The simulated results have a good agreement with the experiment data, which shows the validity of our model. It is concluded that this model can provide an effective way for designing an efficient transverse-pumped alkali vapor laser in experiment.

References

W.F. Krupke, R.J. Beach, V.K. Kanz, S.A. Payne, Opt. Lett. 28, 2336–2338 (2003)

T. Ehrenreich, B. Zhdanov, T. Takekoshi, S. Phiopps, R.J. Knize, Electron. Lett. 41, 47 (2005)

B. Zhdanov, T. Ehrenreich, R. Knize, Opt. Commun. 260, 696–698 (2006)

B. Zhdanov, C. Maes, T. Ehrenreich, A. Havko, N. Koval, T. Meeker, B. Worker, B. Flusche, R. Knize, Opt. Commun. 270, 353–355 (2007)

B.V. Zhdanov, A. Stooke, G. Boyadjian, A. Voci, R. Knize, Opt. Lett. 33, 414–415 (2008)

B. Zhdanov, J. Sell, R. Knize, Electron. Lett. 44, 582–583 (2008)

B. Zhdanov, M. Shaffer, J. Sell, R. Knize, Opt. Commun. 281, 5862–5863 (2008)

B. Zhdanov, M. Shaffer, R. Knize, Opt. Express 17, 14767–14770 (2009)

B. Zhdanov, R. Knize, Proc. SPIE 8187, 818707–818713 (2011)

Z. Yang, H. Wang, Q. Lu, Y. Li, W. Hua, X. Xu, J. Chen, J. Opt. Soc. Am. B 28, 1353–1364 (2011)

A.M. Komashko, J. Zweiback, Proc. SPIE 7581, 75810H-1–75810H-9 (2010)

Z. Yang, H. Wang, Q. Lu, W. Hua, X. Xu, Opt. Express 19, 23118–23131 (2011)

R.J. Beach, W.F. Krupke, V.K. Kanz, S.A. Payne, M.A. Dubinskii, L.D. Merkle, J. Opt. Soc. Am. B 21, 2151–2163 (2004)

P. Bai-Liang, W. Ya-Juan, Z. Qi, Y. Jing, Opt. Commun. 284, 1963–1966 (2011)

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Grant No. 10974176.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, J., Yang, Y., Luo, J. et al. Modeling of a diode transverse-pumped cesium vapor laser. Appl. Phys. B 115, 571–576 (2014). https://doi.org/10.1007/s00340-013-5638-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5638-4