Abstract

Electro-optically tunable transmission grating was imprinted in potassium lithium tantalate niobate by irreversible spatial patterning of the dielectric constant. While embedded into waveguided architecture, it provides a reliable and versatile building block for opto-electronic circuitry, capable of both active switching and multiplexing. Realization of such a block is critical for the fabrication of integrated photonic circuits in electro-optic substrates by means of Refractive Index Engineering by fast ion implantation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Sub-micron structuring of ferroelectric perovskites [1–5] is a promising pathway toward low-loss [6] GHz-operated [7] integrated photonic circuits. Potassium lithium tantalate niobate (KLTN) is of a particular interest as a substrate material for high-end complexity functional photonic circuits, due to its controllable dispersion [8], operational scalability [9] and sub-nanosecond switching times [10, 11].

However, the extreme chemical inertness of KLTN, specific to densely packed perovskite stoichiometry, constitutes a central technological hurdle on the way toward realizing circuits of complexity, comparable to those achieved in the Silicon Photonics realm [12] by employing standard lithography using chemical etching techniques.

In the course of the past few years, a significant progress toward overcoming this hurdle has been made, beginning with the emergence of the so-called Refractive Index Engineering (RI-Eng) approach [13]. RI-Eng by the implantations of fast ions is a generic method for constructing thermally stabilized integrated photonic circuits in electro-optical substrates [14]. RI-Eng exploits the fact that light ions incident on a substrate of oxygen perovskites form an amorphous layer within the depth of the substrate, with reduced refractive index (RI). The depth of this layer is defined by a longitudinal penetration of the implanted ions, which is a variable of the energy imparted to the ions at the acceleration stage [15].

In addition to the control over the longitudinal location of the amorphization, in order to construct 3D structures, a technique for controlling the implantation process in the lateral dimension was required. This was accomplished by introducing the concept of the stopping mask [16, 17]. The stopping mask is a film of varying thickness and topology, designed to selectively retard the penetration of the implanted ions. The amorphous layer, resulting from the accumulation of the Frenkel defects created by the implantation, replicates the contour of the mask topography multiplied by its spatial density distribution, while the average depth of the layer is set by adjusting the initial energy of the implanted ions [18]. Hence, a combination of a series of implantation sessions, at different initial energies, through a respective set of stopping masks can be used to form complex multi-level 3D structures, with sub-micron features within the depth of a substrate. In addition to the RI reduction induced by the amorphization, the implantation of protons at high fluences creates an absorbing sub-micron thick layer, which exhibits both electrical conductivity and photoconductivity [19, 20].

The current article describes the fabrication process and investigates the performance of a volume grating embedded in a slab waveguide. The grating was designed and fabricated by implementing a complete process flow based on RI-Eng technique in an electro-optical KLTN crystal [21, 22]. This study aims to combine both the transmission behavior of the waveguide and the unique features of the volume grating comprising the aforementioned device. In particular, this study examines the current device operated in the Bragg regime [23] from a practical perspective, as a diffraction efficiency–modulated spectrally selective waveguided volume grating (WVG).

2 Fabrication

The fabrication process was done in a KLTN:Cu substrate with a phase transition at T c = 2.4 °C. The copper doping does not affects the IR absorption spectrum of the substrate [21] and therefore had no effect on the results presented in this study. A plate of 4.5 × 5.1 × 1.1 mm3 was cut from the grown crystal along the crystallographic [100] axes. One of the substrate 4.5 × 5.1 mm2 faces was polished to an optical grade and subjected to the implantations protocol described below. After completing the implantations, the 5.1 × 1.1 mm2 faces of the crystal were polished to an optical grade, and gold electrodes were deposited on the 4.5 × 1.1 mm2 faces.

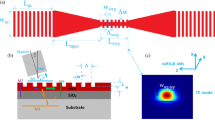

The WVG was fabricated by an implantation of protons with an initial energy of 0.85 MeV and a fluence of 6.4 × 1016 ions/cm2 through a comb-like stopping mask. The stopping mask used was a density pulse-wave grating, made of alternating stripes of gold and SU8 polymer on the polished 4.5 × 5.1 mm2 face of the substrate, as shown in Fig. 1. The mask was 2.9 μm thick. The grating period was 3.5 μm. The gold-to-SU8 widths ratio in each period was ≈5:2. After the fabrication of the WVG, the stopping mask was removed, and He+ ions with an initial energy of 2.2 MeV and a fluence of 1.3 × 1016 ions/cm2 were directly implanted into the bare KLTN substrate, to clad the implanted grating, restricting it to a waveguided configuration.

A pre-condition for achieving significant diffraction efficiency is a sufficient quantity of grating periods [23]. However, the absorption induced by the proton implantation [19] has limited the propagation distance in the waveguide. Therefore, an annealing process has been applied to the implanted crystal in order to diffuse the protons outside the active region. The absorption decreased dramatically after annealing the sample, in a furnace at 450 °C for 10 h, while the wave guiding properties of the structure remained almost undamaged [14].

The amorphization profile for a given energy and a given implantation fluence can be simulated by TRIM [24]. In addition, the semi-empirical formula [15] provides a prediction of the RI for a given amorphization profile. Therefore, by using the combination of both methods, the RI profile can be calculated for a set of implantations’ parameters (i.e., energy, fluence, ion type, etc.). Based on the RI profile, which is presented in Fig. 2a–c, the effective RIs of the TE modes were calculated using the modified method of Chandler and Lama [25], fully described in [26], while an infinite slab approximation [17] was assumed. Effective RI of (n TE)1 = 2.14 and (n TE)2 = 2.16 were calculated for the Au-covered and the SU8-covered half-periods, respectively. Thus, the effective RI contrast of the grating for the fundamental mode is 0.9 %. The bottom cladding of the whole structure (i.e., the uniform amorphized layer beneath the grating) is expected to be minimal at a RI of 1.994 at the depth of 4.8 μm.

3 Measurement setup

Considering the radiation restricted to the waveguide area, we notice that the propagation of the waveguide-coupled beam is predefined by its wave-vector location in a two-dimensional angular space, spanned by two orthogonal angles: the mode angle denoted by θ—the angle between the surface plane of the waveguide and the beam wave vector—and the Bragg angle denoted by ϕ—the angle between the projection of the beam wave vector on the plain of the waveguide and the grating vector. θ is translated into the effective RI of the waveguide as n eff = n 0sin θ where n0 is the RI of the waveguide core.

The propagating beam is coupled into the structure using the prism coupler configuration [27, 28]. Using Snell transformations, the internal angles (i.e., θ and ϕ) can be calculated from the external angles (i.e., θ′—the angle that the beam wave vector makes relatively to the prism surface normal—and ϕ′—the angle that the wave vector makes with respect to the triangular side facet of the prism). The beam coupled into the waveguide, referenced as the direct beam, once satisfying the Bragg condition at angle ϕ B, is constructively diffracted by the grating, as shown in Fig. 3., building up a diffracting beam.

Given the appropriate angle combination, both the direct beam and the diffracting beam are observable at the exit plane of the WVG structure. The internal angles (i.e., θ and ϕ) are individually dependent on both external angles (i.e., θ′ and ϕ′). Therefore, in order to track the Bragg condition compliance while preserving the mode coupling, it is required to scan both external angles simultaneously. Thus, the prism coupler measurement setup [27, 28] was upgraded by an additional rotational degree of freedom (i.e., has two rotational degrees of freedom relative to the prism entrance plane).

4 Diffraction measurements

Diffraction measurements were taken at λ = 1,556 nm using a distributed feedback (DFB) laser. The substrate temperature was set to 13 °C (i.e., at 10.6 °C above T c ), for which the substrate’s relative dielectric constant is ε r = 1.4 × 104 and RI of 2.191 ± 0.002. The intensity measurements of the direct beam and the diffracting beam are presented in Fig. 4a, b, respectively. It can be seen that when ∆ϕ = ϕ − ϕ B is small, the intensity is coupled into the structure only for specific n eff, i.e., the coupled beam wave vector lies within the narrow numerical aperture of the waveguide mode. For large ∆ϕ, the incident beam is not coupled into the structure, due to geometric limitation of the prism coupling method.

When ∆ϕ is close to zero, a diagonal dark band in the intensity of the direct beam appears, as can be clearly seen in Fig. 4a. This band corresponds to the Bragg condition compliance. Moreover, Fig. 4b reveals the complementary nature of the diffracting beam with respect to the direct beam upon the Bragg condition compliance. The propagation through a grating thickness (defined at [29]) of 1.5 ± 0.25 mm resulted in diffraction efficiency of 78 %, at the Bragg condition, while n eff (or θ) is corresponding to the maximized basic mode coupling.

The mode spectrum of the RI structure and the Bragg condition are both wavelength dependent. In order to substantiate this statement, diffraction measurements of the RI structure were taken at λ = 1,480 nm and at λ = 1,580 nm, using a tunable laser. These measurements are shown in Fig. 5a, b, respectively. It should be mentioned that for these measurements, Δϕ was calibrated in the same way as for the measurement presented in Fig. 4, i.e., Δϕ = 0 referred to the Bragg condition of the first mode at λ = 1,556 nm. It can be seen that both the Bragg angle and the mode’s n eff are shifted relatively to the measurement at λ = 1,556 nm (Fig. 4).

The KLTN shows a strong electro-optical effect [22], and, thus it is expected that the diffraction efficiency can be governed by applying an external electric field. Therefore, after both setup angles were fixed to the Bragg condition, the diffraction efficiency was measured while changing the bias voltage between the electrodes deposited on the substrate. The results are presented in Fig. 6. The diffraction efficiency for a volume grating, defined by η = I diffracting/I direct at the Bragg condition, is given by [15]:

where λ is the wavelength, ϕ B is the Bragg angle, Δn is the RI modulation, d is the grating thickness, and α is the average absorption coefficient. The RI modulation due to the electro-optic effect can be described as follows [22]:

where Δn 0 = n a − n b , n is the RI, g is the quadratic electro-optic coefficient, ε is the relative dielectric constant, and the lower indices a and b refer to the implanted grating half-periods (i.e., a is the original KLTN and b is the amorphous KLTN). Therefore, by plugging (2) into (1), the diffraction efficiency is a function of the electrical field, namely:

where η 0 is the diffraction efficiency at E = 0, and B = sinh2(Δαd/2 cos(ϕ B)).

Assuming g a = g11 = 0.14 m4/C2, n a = 2.191 and ε a = 1.4 × 104, the ratio between the electro-optic effect in the amorphous half-periods b, and half-periods a that were unperturbed by the implantation, was found to be g b n 3 b ε 2 b /g a n 3 a ε 2 a = 0.36 ± 0.07. This ratio was found by fitting Eq. (3) to the experimental data of the grating’s electro-optic tunability shown in Fig. 6, while the RI contrast (Δn) of the grating was set as a free parameter. Note that the relatively large error of the grating thickness does not affect the results due to the direct measurement of η 0 at E = 0. It should be mentioned that from the semi-empirical formula, the ratio between the RIs is n 3 b /n 3 a = 0.97. Therefore, most of the reduction in the electro-optic effect in the amorphous half-periods is attributed to the amorphization-induced reduction in the electro-optic coefficient or the dielectric permittivity. In addition, the fitting of the parameter B indicates that the contribution of the absorption of the amorphous half-periods to the diffraction can be neglected in Eqs. (1, 3), with respect to the contribution of the RI contrast. Therefore, it indicates that the annealing process has succeeded to diffuse the majority of the absorbing proton complexes.

5 Conclusions

An electro-optical Bragg grating with significant refractive index contrast, embedded in a slab waveguide, was designed and fabricated using RI-Eng by fast ion implantation. The fabrication of such a device in waveguided architecture provides a switching and multiplexing building block, critical to the fabrication of integrated photonic circuits in electro-optic substrates.

Moreover, the successful demonstration of this device solidly establishes the feasibility of photonic circuitry realization in the oxygen perovskite KLTN using RI-Eng. RI-Eng by fast ion implantations per se enables the construction of 3D structures with sub-micron features in which the refractive index is significantly reduced in comparison with the surrounding crystalline material. The implanted regions were also found to be three orders of magnitude more soluble than the surrounding crystalline material [13]. This can be the basis for a selective etching technique that can be used for the construction of grooves, trenches with steep aspect ratio and suspended structures for constructing devices cladded by air [13]. In addition, recent investigations of structures formed by the implantation of a high fluence of protons were shown these to be electrically conductive and photoconductive [19].

Thus, fast ion implantations can be the basis for a comprehensive fabrication methodology for constructing complex electro-optical integrated circuits in oxygen perovskites substrates. The essence of this fabrication methodology is to design a complete process flow for the entire circuit that consists of a series different of implantations sessions. The properties and spatial distribution of the amorphized region created in each session are determined by setting the type of the implanted ions, their energy, the dosage of the implantation and by the topography of the stopping mask. This enables the simultaneous construction of an integrated circuit that consists of different types of devices, components and structures with complex topology that are pre-aligned interconnected by a mesh of waveguides. In this respect, RI-Eng imports the essence of very large integration of silicon electronic circuits to the electro-optic arena. Such circuits can include an ensemble of electro-optic devices, optical components and nano photonic structures that are interconnected by a mesh of waveguides and will operate in unison.

Finally, circuits that are constructed by RI-Eng in substrates of KLTN manifest additional advantages: (1) The structures that are constructed by the implantations are thermally stable; (2) the strong electro-optical effect in KLTN enables the operation of electro-optic devices constructed by RI-Eng to be operated with moderate voltages; and (3) KLTN is paraelectric at the working temperature. This inhibits the formation of optical damage and enables operation at the entire visible-IR spectral range (0.38–6 μm).

In summary, the electro-optical Bragg grating embedded in a slab waveguide presented in this paper demonstrates the potential of RI-Eng by fast ion implantations as the basis for a generic and comprehensive fabrication methodology for constructing complex electro-optical integrated circuits operating in the visible and IR spectral range.

References

D. Kip, Appl. Phys. B Laser Opt. 67, 131–150 (1998)

P.M. Rørvik, T. Grande, M. Einarsrud, Adv. Mater. 23, 4007–4034 (2011)

X. Zhu, Recent Pat. Nanotechnol. 3, 42–52 (2009)

F. Chen, X.L. Wang, K.M. Wang, Opt. Mater. 29, 1523 (2007)

V. Ionela, A. Marin, H. Dietrich, G. Ulrich, J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 27(1), 498–503 (2009)

M. Majd, B. Schuppert, K. Petermann, J. Lightwave Technol. 8, 2 (1990)

P. Tang, D.J. Towner, T. Hamano, A.L. Meier, B.W. Wessels, Opt. Express 12(24), 5962–5967 (2004)

E. DelRe, M. Tamburrini, M. Segev, E. Refaeli, A.J. Agranat, Appl. Phys. Lett. 73, 16 (1998)

E. Del Re, E. Spinozzi, A.J. Agranat, C. Conti, Nat. Photonics 5(1), 39–42 (2011)

A.J. Agranat, L. Secundo, N. Golshani, M. Razvag, Opt. Mater. 18(1), 195–197 (2001)

N. Sapiens, A. Weissbrod, A.J. Agranat, Opt. Lett. 34(3), 353–355 (2009)

Y. Okawachi, A.L. Gaeta, M. Lipson, Breakthroughs in nonlinear silicon photonics 2011 (in Breakthroughs in Photonics 2011). IEEE Photonics J. 4, 2 (2012)

A.J. Agranat, A. Gumennik, H. Ilan, Proc. SPIE 7604, 76040Y (2010)

A. Gumennik, A.J. Agranat, I. Shachar, M. Hass, Appl. Phys. Lett. 87, 251917 (2005)

A. Gumennik, H. Ilan, R. Fathei, A. Israel, A.J. Agranat, I. Shachar, M. Hass, Appl. Opt. 46, 4132 (2007)

H. Ilan, A. Gumennik, G. Perepelitsa, A. Israel, A.J. Agranat, Appl. Phys. Lett. 92, 191101 (2008)

A. Gumennik, G. Perepelitsa, A. Israel, A.J. Agranat, Opt. Express 17, 6166 (2009)

H. Ilan, A. Gumennik, R. Fathei, A.J. Agranat, I. Shachar, M. Hass, Appl. Phys. Lett. 89, 241130 (2006)

H. Siman-Tov, A. Gumennik, H. Ilan, N. Mazursky, A.J. Agranat, Appl. Phys. A 102, 45–48 (2011)

H. Ilan, S. Frishman, A.J. Agranat, Appl. Phys. Lett. 101, 141111 (2012)

A.J. Agranat, R. Hofmeister, A. Yariv, Opt. Lett. 17, 713 (1992)

R. Hofmeister, S. Yagi, A. Yariv, A.J. Agranat, J. Cryst. Growth 131, 486–494 (1993)

M.G. Moharam, L. Young, Appl. Opt. 17(11), 1757–1759 (1978)

J.F. Ziegler, J.P. Biersack, U. Littmark, The Stopping and Range of Ions in Solids (Pergamon, New York, 1985). http://srim.org/

P.J. Chandler, F.L. Lama, Optica Acta 33, 127–143 (1986)

A. Gumennik, PhD thesis, Hebrew University, Jerusalem, Israel, 2010, p. 40

J. Seligson, Appl. Opt. 26, 2609 (1987)

R. Ulrich, R. Torge, Appl. Opt. 12, 2901 (1973)

H. Kogelnik, Bell Syst. Tech. J. 48(9), 2909–2947 (1969)

Acknowledgments

We acknowledge the support of the Israeli Ministry of Science Grant No. 3-6473 and the Eshkol Fellowships Foundation, Grant No. 3-6435.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Frishman, S., Gumennik, A., Ilan, H. et al. A Bragg grating embedded in a slab waveguide fabricated by the implantation of high-energy light ions in KLTN substrate. Appl. Phys. B 115, 143–147 (2014). https://doi.org/10.1007/s00340-013-5585-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5585-0