Abstract

An all-fiber, single-frequency, linearly polarized, high peak-power, pulsed laser at 1,540 nm for Doppler wind lidar is presented. This laser is composed of a single-frequency, narrow-linewidth external cavity diode laser, and multistage fiber amplifiers. A peak power of 1.08 kW and a pulse width of 500 ns at 10 kHz repetition rate are achieved, which is the highest peak power with a linewidth of 800 kHz in erbium-doped silica fiber to our knowledge. The beam quality of M 2 < 1.3 and a polarization extinction ratio over 16 dB are obtained. This laser will be employed in a compact long-range coherent Doppler wind lidar.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

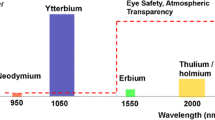

Coherent Doppler lidar (CDL) has been proved to be a powerful tool for monitoring atmospheric wind-velocity and aircraft wake-vortex hazard detection [1, 2]. All-fiber, eye-safe, single-frequency laser is paid attention to be an important candidate for CDL owing to maturity of robustness, flexible installation, and reliability [3]. Mitsubishi Electric Corporation developed a series prototype CDL for turbulence prediction and the laser output reached 179 μJ in the latest model [4]. ONERA obtained pulses with 940 W peak power and laser linewidth of 1 MHz by employing an erbium/ytterbium (Er/Yb) co-doped multifilament-core (MFC) fiber as the gain fiber of power stage [5]. Fibertek demonstrated a 1.55-μm fiber-optic coherent lidar system up to 700 watt peak power with a ~1.5 MHz linewidth by utilizing proprietary technology [6]. A highly Er/Yb co-doped phosphate fiber was used by NP photonics Inc., to achieve a 2.02 kW peak power for 105 ns pulses at 1,530 nm [7]. For multi-kilometer CDL, all-fiber laser with high peak power, several hundred nanoseconds pulse width, narrow-linewidth, and near-diffraction limited beam quality is required [8]. In our developing CDL, the range resolution is designed to be 75 m and pulse duration of 500 ns with Fourier-limited linewidth of about 1 MHz is preferred. However, the peak power of sub-microsecond-pulsed fiber lasers is limited by nonlinear effects, primarily by the stimulated Brillouin scattering (SBS) [9]. Many methods have been proposed to overcome this limitation: some special fibers were designed to reduce the overlap of optical and acoustic fields in the fiber [10, 11]. Phosphate-based fibers [7] and MFC fibers [5] were also used to raise the SBS threshold (SBST). However, these kinds of fiber were difficult to fabricate and splice to other commercial fiber components. Temperature [12] and strain gradient [13] were also applied to broaden the SBS gain spectrum.

In this paper, we demonstrate an eye-safe, narrow-linewidth, polarized, pulsed, fiber laser based on master oscillator power amplifier (MOPA) configuration. Pulse energy of 540 μJ at 10 kHz repetition (corresponding to 1.08 kW peak power) and laser linewidth of 800 kHz have been obtained with beam quality M 2 < 1.3 and a polarization extinction ratio over 16 dB. This is, to the best of our knowledge, the highest peak power of narrow line linewidth (<1 MHz) in erbium-doped silica fiber.

2 Experiment and discussion

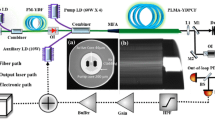

The experiment setup of all-fiber, single-frequency, polarized, pulsed laser is illustrated in Fig. 1.

A commercial diode laser (RIO Inc.) with 10 kHz linewidth and relative intensity noise (RIN) of less than −110 dB/Hz (@ >1 kHz) is used as the seed laser. It is a wavelength-locked laser with low sensitivity versus temperature and bias current. The center wavelength of seed is chosen to be 1,540 nm due to eye-safe and mature components technology from telecommunication industry’s concern. What is more, it is the transmission window of atmosphere. An isolator is added to protect the seed laser from backscattering light of the adjacent amplifier stages. Divided by an optical coupler, a small portion of seed light is used as the local laser of heterodyne detection. Then, the seed is amplified by three preamplifier stages and a power amplifier stage, which are built with all-fiber polarization-maintaining (PM) components. Both the first and second preamplifiers use single-mode (SM) Er-doped 7/125 as gain fiber and are core pumped by a 976 nm SM laser diode (LD) via wavelength division multiplexers (WDM). Between adjacent amplifier stages, there is an isolator and a 1-nm band-pass filter to prevent parasitic oscillation and to block out-of-band amplified spontaneous emission (ASE) generated by the amplifier, respectively. The first preamplifier is operated in CW mode, which is useful to improve energy extraction efficiency and to get higher optical signal-to-noise ratio (SNR). An acousto-optic modulator (AOM) inserted between the first and second preamplifier stage is used to modulate the optical pulse shape with high on/off extinction ratio and acts as the frequency shifter for heterodyne Doppler detection simultaneously. It is feasible to adjust the pulse repetition rate, pulse width, and pulse shape within a certain range for the lidar applications. The front edge of optical pulses is tailored to be slow and smooth (the modulated signal employed on the AOM is shown in Fig. 2a) by an arbitrary waveform generator. After the second amplification stage, an electronic optic switch (EOS) is added as a pulse picker. The signal applied on EOS is time-synchronized to the AOM and as short as possible to cut the AOM signal (as can be seen in Fig. 2a). We can see from the optical spectrum after third amplification stage in Fig. 2b that the ASE in band is suppressed, and thus, a higher on/off extinction ratio, which is critical for pulsed CDL system, can be obtained.

When SBS occurs, any increase in the signal power will be transferred into the Brillouin wave and the Brillouin wave is downshifted in frequency and propagates in the opposite direction of the signal wave, so a 2 × 2 tap coupler is placed after the EOS to monitor the backscattered optical power and the spectrum. We use a double-cladding Er/Yb fiber with a core diameter of 10 μm as the gain fiber of third stage. The signal light is combined with the pump light by a PM (2 + 1) × 1 combiner and the pump light is provided by a 976-nm multimode (MM) LD. It should be noted that the experiment result shows that the SBST of main amplifier will be higher on a suitable input signal power [14]. In this experiment, we find the output peak power of less than 30 W is beneficial for increasing SBST of power amplifier. Some similar phenomenon can be found in Raman fiber amplifier system [15]. The power here is high enough to depress the influence of ASE in the power amplifier. Therefore, the 1-nm band-pass filter after the third preamplifier is removed to reduce the system fiber length and to get a higher SBST.

The simplified SBST formula can be expressed as:

where A eff is the optical effective mode area, g B is the SBS gain coefficient, L eff is the effective fiber length, and α is the absorption. It is found that a larger-mode aperture fiber should be used to get a higher A eff. What is more, the fiber must also have low core numerical aperture (NA) to maintain single-mode operation, which is helpful to lidar efficiency. In our experiment, a length of 1.4 m 25/250 PM large mode area (LMA) Er/Yb co-doped fiber is taken as the gain fiber of power amplifier stage. The large core diameter (25 μm) with a low NA (0.09) makes a trade-off between minimizing deleterious SBS effects and avoiding multimode operation. The high NA (0.46) 250 μm cladding waveguide allows for efficient coupling of high pump powers, and the gain fiber is pumped by several 976-nm MM-LD via a customized PM (6 + 1) × 1 combiner. The fiber is coiled on a metal drum cylinder with a diameter of 10 cm for better beam quality [16] and thermal dissipation. Another influencing factor of the SBST is L eff, which is proportional to the fiber length. All fiber components used in the system, especially in the final stage, are cut as short as possible to decrease L eff. Furthermore, a designed strain gradient [17] over the length coordinate z of the fiber is applied to the Er/Yb co-doped silica fiber and the strain distribution is showed in Fig. 3.

The strain increases progressively along the fiber but the final segment is free of strain for easy splicing. The SBST is enhanced because the SBS gain spectra of different fiber segments are shifted by applying different strain. An angle-cleaved end cap is spliced with the active fiber to minimize the end feedback and to avoid fiber facet damage. We recoat the spliced region with high-index gel to filter the unabsorbed pump light in the inner cladding of the active fiber. A dichroic mirror is inserted to further separate the signal light from the pump light.

In pulsed fiber amplifiers, the pulse often becomes steep at the leading edge due to the dynamic gain saturation [18], which increases the peak power significantly. Therefore, we design a special initial pulse to mitigate pulse steepening during amplifications. Figure 4 shows that the pulse shape, as compared with the initial pulse shape, exhibits quasi-Gaussian shape after the final power amplifier stage. This is useful in enhancing the pulse energy when the peak power is limited by the SBS effect.

When the variably strained fiber is utilized, the averaged output power at 10 kHz is shown in Fig. 5, up to 5.5 W power at 1,540 nm is obtained with an optical conversion efficiency of 16.7 %, where SBS reaches threshold and starts to increase quickly. The output power shows good stability with fluctuations less than 5 ‰ over 7 min. An optical spectrum analyzer (AQ6370B) is used to measure the spectral purity of the output laser. Figure 6 shows the forward (left) and backward (right) optical spectrum at maximum output power demonstrating that the SBS light at the highest laser output is still lower than the Rayleigh scattering. The optical signal-to-noise ratio is found to be as high as 40 dB, implying the ASE is effectively suppressed. This is primarily due to the use of EOS. The power within 40 dB is calculated to be 5.4 W, corresponding to a pulse energy of 540 μJ.

As depicted in Fig. 7, The linewidth is measured to be 800 kHz by the self-heterodyne method [19] with a 50-km-long fiber delay line. The approximately Gaussian pulse shape indicates that the amplified pulses are very close to transform-limited. The far-field beam profile is also measured using a CCD camera (see inset in Fig. 7). The beam quality factors of laser at highest output power are calculated to be \(M_{x}^{2} = 1.23,M_{y}^{2} = 1.08\) by measuring the beam size around the waist position and the far-field diameters of the focused propagation beam. The pulses are linearly polarized and the PER is measured to be over 16 dB.

3 Conclusion

In conclusion, we have successfully implemented an all-fiber pulsed single-frequency laser in MOPA configuration at 1,540 nm with 1.08 kW peak power and 500 ns pulse width by using stress distributed fibers for the first time. Pulses with 540 μJ at 10 kHz repetition frequency and ~800 kHz transform-limited linewidth have been obtained with beam quality of M 2 < 1.3 and PER >16 dB. It has the potential for being the transmitter of long-range coherent Doppler wind lidar.

References

S.M. Hannon, J.A. Thomson, S.W. Henderson, R.M. Huffaker, Proc. SPIE 2464, 94 (1995)

Y. Liu, J.Q. Liu, W.B. Chen, Chin. Opt. Lett. 9, 090604 (2011)

S. Kameyama, T. Ando, K. Asaka, Y. Hirano, S. Wadaka, Appl. Opt. 46, 1953 (2007)

H. Inokuchi, H. Tanaka, T. Ando, in Proceedings of 27th Congress of International Council of the Aeronautical Sciences, ICAS (2010). http://www.icas.org/ICAS_ARCHIVE/ICAS2010/PAPERS/179.PDF

G. Canat, S. Jetschke, S. Unger, L. Lombard, P. Bourdon, J. Kirchhof, V. Jolivet, A. Dolfi, O. Vasseur, Opt. Lett. 33, 2701 (2008)

M. Akbulut, J. Hwang, F. Kimpel, S. Gupta, H. Verdun, Pulsed coherent fiber lider transceiver for aircraft in-flight tubulence and wake-vortex hazard detection. Proc. SPIE 8037, 80370R (2011). doi:10.1117/12.883990

W. Shi, N. Moor, E.B. Petersen, D.T. Nguyen, Z.D. Yao, M.A. Stephen, A. Chavez-Pirson, N. Peyghambarian, in International Symposium on Lidar and Radar Mapping 2011: Technologies and Applications, ed. by X. He, J. Xu, V.G. Ferreira, vol. 8286, 828602 (2011). doi:10.1117/12.912548

J.-P. Cariou, B. Augere, M. Valla, C.R. Phys. 7, 213 (2006)

A. Kobyakov, M. Sauer, D. Chowdhury, Adv. Opt. Photon. 2, 1 (2010)

M.J. Li, X. Chen, J. Wang, S. Gray, A.P. Liu, J.A. Demeritt, A.B. Ruffin, A.M. Crowley, D.T. Walton, L.A. Zenteno, Opt. Express 15, 8290 (2007)

S. Gray, D.T. Walton, X. Chen, J. Wang, M.J. Li, A.P. Liu, A.B. Ruffin, J.A. Demeritt, L.A. Zenteno, IEEE J. Sel. Top. Quantum Electron. 15, 37 (2009)

V.I. Kovalev, R.G. Harrison, Opt. Lett. 31, 161 (2006)

L. Zhang, J.M. Hu, J.H. Wang, Y. Feng, Opt. Lett. 37, 4796 (2012)

X. He, H. Hou, L. Feng, B. Wu, Q. Shen, T. Hou, G. Lan, D. Zhou, Laser Technol. 35, 145 (2011). (in Chinese)

C. Vergien, I. Dajani, C. Zeringue, Opt. Express 18, 26214 (2010)

J.P. Koplow, D.A.V. Kliner, L. Goldberg, Opt. Lett. 25, 442 (2000)

L. Zhang, S. Cui, C. Liu, J. Zhou, Y. Feng, Opt. Express 21, 5456 (2013)

G. Sobon, P. Kaczmarek, A. Antonczak, J. Sotor, A. Waz, K. Abramski, Appl. Phys. B 105, 721 (2011)

L. Richter, H. Mandelberg, M. Kruger, P. McGrath, IEEE J. Quant. Electron. 22, 2070 (1986)

Acknowledgments

We would like to thank Zhang Lei and Hu Jinmeng for their help, and the work is supported by the National Natural Science Foundation of China under Grant No. 60908036.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Diao, W., Liu, Y. et al. Single-frequency polarized eye-safe all-fiber laser with peak power over kilowatt. Appl. Phys. B 115, 123–127 (2014). https://doi.org/10.1007/s00340-013-5582-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5582-3