Abstract

Laser-induced incandescence (LII) as a diagnostic technique is based on rapid heating of soot particles to temperatures of several thousand Kelvin and subsequent detection of the thermal radiation from the laser-heated particles. At such high temperatures, soot sublimation effects must be considered when estimating uncertainties in LII measurements. In this work we have investigated the use of various laser fluences in LII using a Nd:YAG laser at 1,064 nm. Using another Nd:YAG laser at 532 nm, the elastic light scattering (ELS) signal from soot particles heated by the 1,064-nm laser was monitored. This approach makes it possible to determine at which fluence of the LII laser soot sublimation starts to become visible as a decrease in the ELS signal. By performing the measurements at various heights in a premixed sooting flat ethylene/air flame, the fluence threshold above which the ELS signal decreased was found to be higher at the lower flame heights corresponding to younger, smaller and less aggregated particles. The results from this work indicate that the different fluence thresholds for sublimation may be explained by a lower absorption function E(m) for the younger soot particles.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Much effort has been spent on studying soot particles and their formation in combustion processes in order to gain knowledge about their characteristics (see e.g., [1, 2] and references therein). Both this knowledge and the measurement techniques used for soot diagnostics are of great use when optimizing combustion devices and minimizing their emissions of soot and also in the research fields dealing with environmental and health effects of soot particles. There are many different techniques for studying soot particles where some require probing and are often considered as intrusive techniques while others utilize optical interaction and can be considered as non-intrusive. The optical techniques also provide high spatial and temporal resolution and are therefore highly suitable for studying soot within the combustion process itself. One optical technique for measurements on soot particles is laser-induced incandescence (LII) [3, 4], providing soot volume fractions and soot particle sizes. For this technique, the soot particles are heated by a pulsed laser to (or close to) their sublimation temperature in the region 3,500–4,000 K after which the particles cool down to the ambient gas temperature. At these high temperatures, the particles radiate very strongly, and this radiation can be detected and analyzed to provide quantitative data on the soot, based on the fact that the signal intensity is approximately proportional to the soot volume fraction whereas the decay of the signal after the end of the laser pulse will be dependent on the particle size [3, 4].

One important step toward improving optical measurements of soot particles is to study the optical properties of soot, which describe the interaction with light. The optical properties are defined by the complex refractive index, m = n − ik, of the material. For LII, the absorption function, E(m) = −Im[(m 2 − 1)/(m 2 + 2)], will be of importance, as the predicted light absorption and emission from a soot particle scale linearly with the absorption function [5]. Previous studies on soot optical properties provide a quite broad range of values [4, 6], making the uncertainty in this parameter one of the most important ones, especially when applying the LII technique to a sooting environment where the nature of the soot is poorly known. One of the reasons for the large variation in reported values is likely the fact that soot is not an elemental, well-defined material and may have different properties dependent on fuel and burning characteristics, and when in the soot formation process the particles were targeted. The majority of previous studies consider mature soot particles, not nascent soot early in the soot formation process. There are studies indicating that nascent soot particles seem to have a more liquid-like structure than more mature soot, thereby differing substantially in structure [2, 7] and therefore potentially also in their optical properties.

To study soot particles during the growth process, there are burners, for example McKenna burners [8], producing flat premixed flames, in which the soot growth can be followed with height above burner (HAB). Recently, several groups have investigated this kind of flames and found signs of varying optical properties as a function of height and detection wavelength. In a recent study by Migliorini et al. [9], the variation in the relative E(m) with wavelength and HAB in an atmospheric premixed flat flame was studied by extinction. Their study showed strong dependence on both wavelength and position in the flame, indicating that the absorption properties of the nascent soot are different from those of the more mature. However, by using extinction, the results found could not be solely attributed to soot particles. Also, non-soot species such as polyaromatic hydrocarbons (PAH) might have contributed, an issue acknowledged by the authors in [9] and especially investigated in [10].

Cléon et al. [11] measured in a low-pressure flat premixed flame using a procedure based on LII excitation at 532 and 1,064 nm [12] and determined the ratio of E(m) at these wavelengths without interference from PAH. The results corroborate the findings in [9] that E(m) seems to vary with wavelength—an especially pronounced effect for nascent soot. Additionally, Cléon et al. reported LII fluence curves, that is, the peak LII signal as a function of laser fluence, at varying heights above burner, and the results clearly show different behaviors as a function of height. This could be explained by an increase in E(m) with height as the measurements go from the newly formed nascent soot particles to more mature. Similar fluence curves were also reported by Maffi et al. [13] in a flat flame at atmospheric pressure.

An increase in the absorption function, E(m), of soot with soot age was also found in a study by our group [5], where the methodology of Snelling et al. [14] was used to determine the peak temperature of laser-heated soot as a function of height in a premixed flat ethylene/air flame. The peak temperatures inferred from two-color pyrometry were found to increase with height, although the same laser fluence was used at all measurement positions. Accurate flame temperature measurements made it possible to determine the total internal energy change of the particles at each height and hence infer an effective E(m) at 1,064 nm from the data. The results show a monotonically increasing E(m) in the nascent soot region, stabilizing at values typical for mature soot higher up in the flame [5].

Several of the aforementioned studies [5, 11, 13] indicate that more laser energy is needed to heat the nascent soot to a specific temperature than the mature soot. There are, however, also other mechanisms than absorption that must be considered with regard to laser heating of soot. One of these is soot mass loss. If soot particles are heated to high enough temperatures, some fractions of the solid structure will be lost [15], which will change the LII signal behavior [15, 16]. It is a well-known fact that soot mass loss occurs above a certain threshold fluence. The mechanism by which the mass loss occurs is, however, still not known in detail and constitutes the dominating source of uncertainty in the models for the LII technique at high laser fluences [17]. With excitation sources in the visible or IR region, it is likely that most of the mass loss occurs from a thermal process, that is, sublimation of carbon material from the surface of the particles [15, 18]. Typically, flame soot has been found to sublime in the temperature region 3,500–4,000 K, close to the sublimation temperature of pure graphite [18]. Apart from this thermal desorption mechanism, other non-thermal desorption mechanisms should also be considered. These can potentially act in other temperature regions than the thermally driven mass loss mechanisms [15, 19]. It is beyond the scope of this study to investigate the mass loss mechanisms in detail, and as the sublimation most likely is the dominant one, we will from here on refer to all mass loss as sublimation. Given that many of the properties of nascent soot particles differ from the mature soot particles, possible variation also in the sublimation temperature of the soot should be considered—a variation that could be affecting the results in [5] as well as the fluence curves of [11, 13].

There have been a number of experimental studies over the years directed at understanding the sublimation process of soot after being heated by a strong nanosecond laser pulse. Many groups have investigated the products of sublimation, that is, detected the molecular species leaving the surface. Bengtsson and Aldén [20] used a dye laser at 512.9 and at 563.4 nm [21] to create C2 from laser-induced sublimation and, with the same pulse, excite the C2 radicals. In both studies the laser-induced fluorescence from the C2 radicals showed good correlation with the soot volume fraction measured by extinction measurements in premixed flat flames. Also, the spontaneous emission from laser-induced radicals in excited states has been studied, particularly noteworthy being the recent investigations of Goulay et al. [18, 22] regarding spontaneous emission from C2 and C3 originating from soot heated by a strong 532-nm pulse. Many studies have been focused on probing the soot itself. Dasch made pioneering work already in 1984 using a continuous-wave Argon ion laser at 488 nm to probe soot during the process of being exposed to strong heating laser pulses from a Q-switched Nd:YAG laser at 532 nm [23]. Probing was carried out using a combination of extinction and elastic light scattering (ELS), and it was found that the absorption and the scattering signals fall off exponentially as a function of laser fluence in the high-fluence regime. Vander Wal et al. [24] carried out double-pulse LII measurements and also high-resolution transmission electron microscopy (TEM) on laser-heated soot particles in order to investigate how the LII signal depends on changes made to the soot during the heating process. It was shown that structural changes with increased reordering of the graphitic planes (thermal annealing) were introduced already far below the sublimation threshold, resulting in an increase in the absorption and hence also in the LII signal detected from the second pulse. For higher fluences, mass loss induced from the first laser pulse decreased the LII signal from the second [24]. Similar effects have also been shown recently by de Iuliis et al. [25] where cold soot extracted from flames was exposed to multiple laser pulses. Witze et al. [26] made simultaneous LII and ELS in a propane/air diffusion flame using only one laser investigating both the low- and high-fluence regime behavior of the signals with sub-nanosecond time resolution. Yoder et al. [27, 28] carried out a pulse-probe experiment similar to that of Dasch [23]. A probe laser at 532 nm (pulsed Nd:YAG laser) was used to generate ELS from soot particles in a measurement volume which could be exposed to another laser beam at 1,064 nm providing the heating. By scanning the two pulses with respect to each other, a strong decrease in ELS signal could be detected after the heating pulse for laser fluences high enough to cause sublimation. Thomson et al. [29] made an extensive investigation targeting mainly the optical properties of cold soot during laser heating, including high-fluence conditions where mass loss due to sublimation is present. They used an extinction-based approach also similar to that of Dasch [23], but measured time-resolved, targeting all temporal domains in detail. They also included a scattering measurement from the 1,064-nm heating laser. These results clearly show effects of structural change already in the low-fluence regime, which are attributed to thermal annealing and particle swelling, and effects of mass loss due to sublimation at higher fluences [29].

Most of the previous work on soot sublimation has been made in diffusion flames on mature soot or cold soot sources, and little focus has been on potential differences between soot of varying age and history of formation. In this paper we present an investigation of laser-induced soot sublimation in a premixed flat ethylene/air flame at various heights probing both nascent and more mature soot particles. We have used a measurement methodology based on combining the approach of Yoder et al. [27] with our two-color LII system [5, 30] in order to provide detailed measurements of the influence of laser fluence on particle sublimation (detected by ELS) and particle temperatures (measured by two-color pyrometry).

2 Experiment

2.1 Setup

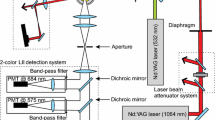

Two Nd:YAG lasers are combined in a pulse-probe setup, where flame-generated soot particles are heated by a 1,064-nm laser pulse. Effects of the heating on the particles are probed using ELS from a 532-nm laser. A sketch of the experimental setup is displayed in Fig. 1.

The laser used for heating of the soot particles was a Quantel Brilliant B pulsed Nd:YAG laser, at its fundamental wavelength 1,064 nm with a pulse duration of 8 ns. Choosing the wavelength 1,064 nm ensures that interferences from polyaromatic hydrocarbons (PAH) and C2 fluorescence on the measurements are minimized [4]. The 1,064-nm laser beam first passed an attenuator system so that the pulse energy could be easily adjusted. The attenuator consists of a thin-film polarizer (polarization ratio 1:200) and a half-wave plate, fastened in a rotational mount. After the attenuator, a diaphragm was used to cut out a 4-mm-diameter central part of the 9-mm-diameter beam. This part was then relay-imaged to the center of the flame, producing a top-hat profile with the diameter 2.6 mm at the flame center. A beam monitor system, consisting of an Ophir pyroelectric laser power meter and a beam profiler CCD camera (Gentec WinCamD), was used to monitor the pulse energies and to measure the area and intensity distribution of the spatial laser profile (standard deviation of 13.5 % in the region considered as top-hat). This was done by imaging the laser profile at the flame center onto the beam profiler sensor.

The laser used for the ELS measurements was a Quantel Brilliant B pulsed Nd:YAG laser, frequency doubled to 532 nm with a pulse duration of 5 ns and a vertical polarization. A spherical lens (f = 700 mm) was used to compress the 532-nm beam of 9 mm diameter. At flame center, the 532-nm laser beam was arranged to have a diameter of 1 mm (1/e2), easily positioned within the top-hat profile of the wider 1,064-nm beam so that the 532-nm laser light would scatter on soot particles equally affected by the laser heating. The resulting intersection of the two laser beams occurred at an angle of 6°, giving a 15-mm region of overlap between the beams.

A detection system with the ability to detect the ELS simultaneously with the LII at two different wavelengths, was set up at a 90° angle with respect to the 532-nm laser beam. The reason to use two wavelengths for LII detection was to be able to determine the peak temperature of the laser-heated soot particles by two-color pyrometry [14]. An achromatic lens was used for a 1:1 imaging of the center of the flame, where the two laser beams intersected, onto an aperture of the size 1 × 8 mm. Thus, the aperture determined the size of the measurement volume, providing a height resolution of 1 mm. To ensure that the top-hat spatial profile of the 1,064-nm laser was preserved throughout the probe volume width of 8 mm, the beam profiler was used by imaging the laser profile at the far ends of these 8 mm onto the beam profiler sensor. Behind the aperture in the detection path, an achromatic lens was used to collimate the transmitted light, which was then split up into three paths by a combination of two dichroic mirrors and one aluminum mirror. Three different filters were used to transmit only the desired wavelengths. For the LII detection at two wavelengths, two steep band-pass filters (Semrock, transmission >90 %) were used. One was centered at 684 nm (24 nm wide) and the other at 575 nm (25 nm wide). A 532-nm interference filter (2.5 nm wide, transmission >60 %) was used for the ELS detection. Each filter was followed by a lens collecting the transmitted light onto a photomultiplier tube (PMT, Hamamatsu H6780). A 1-GHz, 4-channel digital oscilloscope (LeCroy Waverunner 104MXI) was used to capture and store the ELS and LII signals from the PMTs. For calibration of the two-color pyrometry, a calibration lamp, Labsphere IES 1000, was utilized. The calibration lamp was aligned opposite to the detection system, across the burner, and directed straight into the detection system. A digital delay generator (Berkeley Nucleonics Corporation 575 4-C) was externally triggering the two lasers for synchronization of the laser pulses. This made it possible to adjust the time position of the laser pulses in steps down to 250 ps.

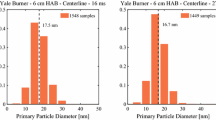

A premixed ethylene/air flame, burning on a McKenna burner with an equivalence ratio, Φ, of 2.1, was investigated (see Fig. 2). The burner has a center bronze porous plug of 60 mm diameter for the fuel mixture and a 20-mm-wide co-annular porous plug for a shielding co-flow. A stainless steel flame stabilizer (60 mm in diameter) was positioned 21 mm above the burner surface. The gas flow of the ethylene/air mixture through the center porous plug was 10 l/min (at 273 K and 1 atm), and the shielding co-flow of air was matched to the cold flow speed of the center gas mixture. To control the gas flow, mass flow controllers of the model Bronkhorst EL-FLOW F-201C were utilized.

2.2 Procedure

The measurements in this work were all taken at five different heights above burner: 8, 9, 10, 12 and 14 mm. As can be seen from the transmission electron microscope (TEM) images in Fig. 2, the ensemble of particles at 8 mm HAB mostly consists of small isolated particles, whereas at 14 mm the soot has aged to soot aggregates with larger primary particles. To simplify the discussion, from now on we will refer to the particles at 8 mm as nascent, whereas those at 14 mm will be called mature. Below 8 mm, measurements gave a weak and noisy signal; thus, the presented results start at 8 mm. All measurements in the same series were made within the same time frame of 3 h to minimize uncertainties due to systematic errors, and once every hour the flame was turned off and the soot layer that had been built up on the flame stabilizer was removed. The measurement series were repeated several times, ensuring the trends seen in the results.

To measure the peak temperature by two-color pyrometry of the laser-heated soot particles, the same procedure as in [14] was followed. This leads to the following expression for the experimentally determined temperature when detection is made at two different wavelengths:

where h is the Planck constant, c is the speed of light, k is the Boltzmann constant, λ is the detection wavelength, I is the detected signal intensity, m is the complex refractive index of the soot particles, and E(m) = −Im[(m 2 − 1)/(m 2 + 2)] is the absorption function. The indices 1 and 2 denote the two different detection wavelengths. When determining the temperature by using Eq. 1, the ratio of the absorption function values at these two λ is commonly approximated to 1. This is an approximation regarded as reasonable in this work, since the detection wavelengths are relatively close to each other spectrally and thus the variation in E(m) can be assumed small. Possible effects arising from this assumption are discussed in the “Results and discussion” section.

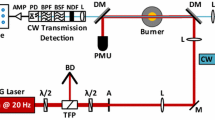

ELS at 532 nm was utilized as probing technique in the pulse-probe procedure where the heating effects on soot from a 1,064-nm laser pulse were studied. The digital delay generator controlled the delay between the two laser pulses and thus also controlled their position in time. By moving the scattering pulse (532 nm) in time, from before the heating pulse (1,064 nm) to after it, any changes in the soot induced by the laser heating could be studied via the scattering signal. This measurement procedure is graphically presented in Fig. 3a, and in Fig. 3b an example is given for the measurement point at 10 mm HAB and a fluence of 0.63 J/cm2 for the heating laser. At this high laser fluence, there is a rapid ELS signal decrease in time, and some hundred nanoseconds after the interaction, only 13 % remains. For the following results in this paper, we did not pursue full-time scans; instead, the ELS signal was measured at two time positions, one reference point prior to the heating pulse for unaffected soot and one point 200 ns after the heating laser pulse. By forming a ratio of the scattering and the reference signal, a measure of the change of scattering signal from the soot due to the laser heating was obtained.

a Sketch of the two laser pulses, in green is the ELS probe pulse (532 nm, varied in time) and in red is the heating pulse (1,064 nm), fixed in time. b ELS signal as a function of delay time at 10 mm HAB and 0.63 J/cm2 fluence of the heating laser. The x-axis displays the time position of the 532-nm pulse in relation to the 1,064-nm pulse

It was important to ensure that interferences induced by both the ELS laser and the heating laser were minimized. Since this study aimed at investigating heating effects induced by the 1,064-nm laser, it was vital to make sure that the ELS laser did not affect the soot particles by heating. This was achieved by keeping the 532-nm laser fluence as low as 8 mJ/cm2, which induced no detectable incandescence signal. However, the LII by the 1,064-nm laser introduced a small interference on the ELS detection at 532 nm for the two lowest studied heights, since at these lower heights the LII signal is relatively strong in comparison with ELS (up to about 1/5 of the ELS signal at 8 mm HAB). To minimize the effect of this incandescence interference, the interference signal was stored separately and subtracted together with the background from the detected signal at 532 nm.

2.3 Theory

To aid interpretation of the results, some theoretical considerations for the particle heat-up will be needed. The results can be analyzed using the full heat and mass transfer model for LII [31], but this approach is considered beyond the scope of the work. Instead, we will focus on the low-fluence regime and derive a simplified relationship between the E(m), the laser fluence F, and the temperature difference ΔT = T max − T gas. In the presence of the laser pulse and for low fluences where sublimation can be neglected, the absorption rate will be approximately equal to the internal energy change, as sublimation is absent and heat conduction and radiation will be orders of magnitude smaller. If we assume all parameters except the temporal distribution of laser energy, g(t), and the particle temperature, T, as constants and integrate both rate terms over the time period covering particle heat-up, we get a total absorption at time t max:

where d p is the particle size, λ the laser wavelength, and G(t) a primitive function of g(t). The internal energy of the particle at time t max can be written as:

where it has been assumed that the soot density and heat capacity, ρ s and c s, are independent of temperature. As verified using the model for LII, the time position of the peak LII signal (and hence peak temperature), t max, will be located after or at the very end of the laser pulse for all fluences below the sublimation threshold. This means that G(t) ≈ 1. Using this fact, and putting Eq. (2) and (3) equal, we may write the temperature increase of the particles as:

Equation 4 will be approximately true for fluences below the sublimation threshold fluence and may therefore be used at the threshold fluence to examine the relationship between the experimentally obtained quantities. We further note that

provided that we make the assumption that the soot density and heat capacity do not vary with height above burner.

3 Results and discussion

LII fluence curves measured at the five different heights above burner are presented in Fig. 4, where they are normalized at the highest laser fluence. The incandescence signals were detected at 575 and 684 nm, as a function of laser fluence of the heating laser at 1,064 nm. The presented fluence curves are evaluated from the detected signal at 684 nm with a standard deviation of the single shots in each measurement point of about 5 %. In studying Fig. 4, all the fluence curves can be seen to start off low for the lowest fluences, thereafter increase rapidly for increasing laser fluence and then level off. For heights from 10 mm and above, the signal reaches a peak value after which a slight decrease is seen for the highest fluences. That the curves for the peak LII signal level off is a sign of significant sublimation of the soot particles [17]. The fluence curves were measured to get a first indication on differences in response to the laser heating between newly formed soot particles and more mature ones. By comparison of the fluence curves at the different HAB, a clear difference can be seen between the fluence values where the curves start to level off. The lower in the flame the measurement is made, the higher laser energy is required for the signal to level off, indicating that higher laser energy is required for sublimation at the lower heights in the flame. Thus, the fluence curves hint that higher laser energy is required for sublimation of the younger soot particles than what is required for the more mature ones. The typical appearance of the fluence curves is similar to those found in premixed flames by other groups [11, 13].

In Fig. 5 the ratio of the ELS signal 200 ns after the heating laser pulse and the reference ELS signal before the heating pulse is plotted for the five studied HAB as a function of laser fluence. The measurement points typically have a standard deviation of about 7 %. For all heights and for fluences below ~0.18 J/cm2, the ratios appear around unity. For higher laser fluence, the ratio starts to decrease, as a result of lower scattering signal from the laser-heated soot. By looking at the curves for the different heights, a clear disparity can be seen as to where this decrease begins. Higher laser fluence is required for the ratio to fall off the lower in the flame the measurement is made. Thus, this is in line with the results presented in Fig. 4, where the fluence curves level off at higher laser fluences for the lower flame heights. It is established that the decrease in ELS signal is related to sublimation effects through numerous studies (see e.g., [21, 23]). However, there may be other effects as well that may contribute to the observed decrease, and these are discussed later in this paper.

Ratio of the ELS signal from the soot 200 ns after the heating laser pulse, and the reference ELS signal from soot particles unaffected by the heating laser, plotted as a function of laser fluence of the heating laser for five different HAB. Both signal and background were averaged over 400 single shots at all measurement points

For the reasons of comparison of the results at different HAB, a sublimation threshold was defined at each height according to the following procedure. In the fluence region just above where the sublimation sets in, the ELS signal falls off almost linearly with fluence and a line could be fitted to the slope. In the same manner, a line could be fitted to the data points below the sublimation threshold, resulting in a line almost parallel to the horizontal axis. The crossing point of these two lines for each height is distinct, and the laser fluence at this crossing point is defined as the sublimation fluence threshold. These sublimation thresholds are displayed in Table 1, and remarkably, there is a decrease with increasing height by nearly a factor of 1.7 from 8 to 14 mm. An interesting observation is that the fluence threshold appears close to the inflection point (steepest slope) for each of the fluence curves shown in Fig. 4. The soot particle peak temperatures at these laser fluences, from here on referred to as the sublimation temperatures, were evaluated for each of the five heights and are presented in Table 1 together with the flame temperatures evaluated by coherent anti-Stokes Raman spectroscopy (CARS) [5]. The extracted peak temperatures are relatively constant (3,550–3,690 K) at heights from 9 to 14 mm, except for the value at 8 mm which is around 200 K higher, which may be a result of the lower signal-to-noise ratio for this measurement point. Here we must, however, also consider the ratio between the absorption function at the two detection wavelengths, E(m)575/E(m)684, which has been assumed to be unity in the temperature evaluations. The results of previous investigations indicate that this assumption may not be valid [9, 11]. To illustrate the uncertainty in the estimated temperatures, calculations were performed assuming an E(m) which is 5 % higher at the shorter wavelength 575 nm in comparison with 684 nm. The result was that evaluated temperatures at around 3,500 K were ~4 % lower, that is, ~140 K.

In conjunction with Table 1, the consequence of the decreasing flame temperature with height should also be discussed. As can be seen, the flame temperature decreases about 130 K from 8 to 14 mm HAB. In terms of laser fluence required to heat the soot particles to a certain temperature, this means that higher laser fluence is required to heat the soot particles at the higher HAB due to a lower initial temperature. According to Eq. 5 the temperature increase in the heated soot particles will be approximately proportional to the laser fluence. Applying this proportionality, we predict an estimated fluence of about 0.011 J/cm2 to heat the soot particles to 130 K at 14 mm HAB. Looking at the values in Table 1, it can be seen that this is about 5 % of the total fluence required to heat the soot at 14 mm HAB to its sublimation temperature. Thus, if the flame temperature had been constant with the same value from 8 to 14 mm, that is, 1,728 K, then the sublimation threshold at 14 mm had decreased from ~0.159 to ~0.148 J/cm2, that is, the difference in sublimation fluence threshold had increased for the investigated heights.

The results presented in this work provide new information with regard to the interpretation of the results of previous studies. The fluence curves as a function of HAB reported by Cléon et al. [11] and Maffi et al. [13] and indeed also Fig. 4 in this work show variations as a function of height. As the characteristics of the experimental setup are the same for all heights when performing these kinds of measurements, the explanation for the different shapes must be sought for in the properties of the soot. Considering the presented results, the explanation is likely to be found in variations in the absorption function, E(m). This quantity may be dependent on the type of soot probed (in this work related to the height above burner) but also on the soot temperature via reversible (e.g., particle swelling effects) and irreversible (e.g., thermal annealing) changes in the particle matter during heat-up [29]. This means that interpretation is not straightforward. We may, however, use Eq. 5 to estimate the inferred effective E(m) at 1,064 nm from the data in Table 1. The results show that the E(m) appears to increase by a factor of ~1.5 from 8 to 14 mm HAB, which is in agreement with what we reported earlier, from studies of the same flame [5]. We note that these values should be treated with caution as they rely on a number of simplifications in the underlying theory, some of which will be discussed later.

When further studying Fig. 5, it becomes clear that the changes between the curves at the different HAB are largest at the lower heights and above 10 mm the curves are more closely spaced and have a similar shape. This indicates that the soot particle properties high in the flame are more similar to each other than at the lower HAB. In the previous studies [2, 7], it has been suggested that there is a significant difference between the structure of young and mature soot particles, where the younger soot seems more liquid like. This could provide an explanation both for the difference in laser energy required for sublimation and for the larger variation seen at the lower HAB. It can be reasoned that a change in soot internal structure would also imply a change in optical properties, in this case the E(m). Hence, the mature soot particles needing lower laser fluence to reach the sublimation temperature could be explained by an increasing E(m) with HAB, a trend also seen in [5]. The larger difference between the measurements low in the flame could be attributable to nascent soot particles undergoing significant change in their internal structure with height, while mature soot particles are not altered as much with height. Apart from the internal structure, also aggregation must be considered for heights above ~10 mm [5, 25], a change that is believed to have minor influence on values of E(m) evaluated using the present approach, where the Rayleigh–Debye–Gans theory is assumed for the absorption [32].

When inferring properties of soot from signals dependent on multiple mechanisms and parameters, it is especially important to consider the uncertainties involved. This can be understood by studying the energy terms given in Eqs. 2 and 3. It is clear that values of E(m) may be inferred from the data, but any violation of the assumptions may introduce errors in the evaluation. Of importance when it comes to the determination of optical properties from the soot particle heat-up behavior is the internal energy change (Eq. 3). As discussed in our previous work [5], assuming that the particle characteristics vary with soot age, it is not farfetched to expect variations also in the soot density, ρ s, and specific heat, c s, with age. These parameters, or actually the product of them, must be known (or assumed) in order to infer E(m) from this kind of measurements (see Eq. 4). Previous studies suggest that the density of the nascent soot particles is less (~1.2 g/cm3) than that of the more mature soot (~1.9 g/cm3) [33, 34]. To the authors’ knowledge, there are no available data on the specific heat as a function of soot age. It is, however, possible that the product of the soot density and specific heat, ρ s c s, shows variations with soot age and that the variation in E(m) may be somewhat different than inferred in this work. Further work using alternative methods or approaches will be needed in order to clarify this issue.

Another consideration is the uncertainties in the interpretation of scattering data. In this work it has been assumed that the decrease in scattering intensity with fluence is related to soot mass loss. Due to the small size of soot particles, they can often be approximated as Rayleigh scatterers [35], meaning that there is a strong size dependence (sixth power of particle diameter) of the scattered intensity from the soot, and thereby also a high sensitivity to changes in particle volume. However, for heights above ~10 mm, aggregate size must also be considered and the scattering signal scales through the square of the number of primary particles per aggregate [36]. This means that a reduction in scattering signal may also occur due to laser-induced aggregate breakup. Indeed, studies on laser-heated soot [24, 25, 37] have indicated that laser heating of soot aggregates can lead to fragmentation of the aggregates. Therefore, the decrease in the ELS ratios in Fig. 5 at the heights where the soot particles are aggregated may not be solely attributable to a decreasing size of the soot particles due to sublimation. Consequently, it is fair to assume that the decrease in the ELS ratio seen for the ratios above 10 mm HAB could be a combined effect of sublimation and fragmentation of the soot aggregates. An interesting observation is that the slopes of the curves are much steeper for the higher flame heights where aggregates are found, which may be a result of laser-induced breakup of aggregates being present. Also, the internal structure of the soot is of importance with respect to scattering as the signal is linearly dependent on the refractive index function for scattering [36], \(F(m) = \left| {(m^{2} - 1)/(m^{2} + 2)} \right|^{2}\). As previously discussed, the different properties of nascent and more mature soot are likely to result in a varying refractive index and thus, potentially, varying F(m) as a function of height. Also, the heat-up process with the reversible (particle swelling) and irreversible (thermal annealing) change to the particles may affect the scattering. Indeed, some results suggest a slight increase in the amount of scattered light with graphitization [6]. However, recent results from Thomson et al. [29] could not detect such changes. Future work will include studies of a variation in F(m) with laser fluence.

It can also be reasoned that heating of the soot particles should result in heating of the surrounding gas due to conduction when the soot particles cool down, as noted in [38]. Such gas heating would then lead to an expansion of the surrounding gas and thus a lower concentration of soot particles and thereby a lower scattering signal. This decrease in scattering signal can be estimated, for example, using the data from [38], in which laser heating of soot at a volume fraction of 4 ppm was estimated to lead to a temperature increase of up to 400 K. Since the volume fractions in our most sooting condition at 14 mm HAB are around a factor of 50 lower, the estimated temperature increase is lower than 10 K due to this potential effect. This would lead to a scattering signal decrease of around 0.5 %, which is of negligible importance in the present work.

4 Conclusions

Soot sublimation effects related to LII measurements have been studied in a flat premixed sooting flame. The interaction between laser light at 1,064 nm and soot was examined using both two-color LII to retrieve particle peak temperatures and ELS to probe optical and structural changes of the soot.

Through measurements at different heights in the flame (corresponding to different soot age), further indications were found that the optical soot properties change during the soot growth and aggregation process. Especially, the results showed that higher laser fluence is needed at lower flame heights for the fluence curves to level off (and start to decrease for heights above 10 mm HAB) and also that higher laser fluence is required of the heating laser (at 1,064 nm) to get a decrease in the ELS signal at lower heights. The strong decrease in the ELS signal with increasing laser fluence can be related to sublimation of carbon material from the soot, although other effects such as fragmentation of aggregates may influence the ELS signal as well.

Two-color pyrometry was utilized to determine the sublimation temperature, that is, peak temperature of the laser-heated particles at the sublimation fluence threshold at all heights. The evaluated sublimation temperature was found to be relatively constant with temperatures in the range 3,500–3,700 K at heights 9–14 mm when assuming a wavelength-independent absorption function, E(m).

The results from this study show that the laser fluence required for sublimation decreases with HAB while the sublimation temperature shows only a slight decrease, indicating an increase in E(m) with height, thus more mature soot particles have higher E(m) than nascent soot particles. These results, together with the results from previous work, demonstrate that there are differences between nascent soot particles found at low heights above burner in flat premixed flames and more mature soot particles higher up in the flame regarding both structure and optical properties.

References

A. D’Anna, Proc. Combust. Inst. 32, 593 (2009)

H. Wang, Proc. Combust. Inst. 33, 41 (2011)

R.J. Santoro, C.R. Shaddix, in Applied Combustion Diagnostics (Taylor and Francis, New York, 2002), p. 252

C. Schulz, B.F. Kock, M. Hofmann, H.A. Michelsen, S. Will, B. Bougie, R. Suntz, G. Smallwood, Appl. Phys. B 83, 333 (2006)

H. Bladh, J. Johnsson, N.-E. Olofsson, A. Bohlin, P.-E. Bengtsson, Proc. Combust. Inst. 33, 641 (2011)

T.C. Bond, R.W. Bergstrom, Aerosol Sci. Technol. 40, 27 (2006)

S. De Iuliis, S. Maffi, F. Cignoli, G. Zizak, Appl. Phys. B 102, 891 (2011)

Holthuis and Associates, www.flatflame.com

F. Migliorini, K.A. Thomson, G.J. Smallwood, Appl. Phys. B 104, 273 (2011)

J. Zerbs, K.P. Geigle, O. Lammel, J. Hader, R. Stirn, R. Hadef, W. Meier, Appl. Phys. B 96, 683 (2009)

G. Cléon, T. Amodeo, A. Faccinetto, P. Desgroux, Appl. Phys. B 104, 297 (2011)

E. Therssen, Y. Bouvier, C. Schoemaecker-Moreau, X. Mercier, P. Desgroux, M. Ziskind, C. Focsa, Appl. Phys. B 89, 417 (2007)

S. Maffi, S. De Iuliis, F. Cignoli, G. Zizak, Appl. Phys. B 104, 357 (2011)

D.R. Snelling, F. Liu, G.J. Smallwood, Ö.L. Gülder, Combust. Flame. 136, 180 (2004)

H.A. Michelsen, J. Chem. Phys. 118, 7012 (2003)

H. Bladh, P.-E. Bengtsson, Appl. Phys. B 78, 241 (2004)

H.A. Michelsen, F. Liu, B.F. Kock, H. Bladh, A. Boiarciuc, M. Charwath, T. Dreier, R. Hadef, M. Hofmann, J. Reimann, S. Will, P.-E. Bengtsson, H. Bockhorn, F. Foucher, K.P. Geigle, C. Mounaïm-Rousselle, C. Schulz, R. Stirn, B. Tribalet, R. Suntz, Appl. Phys. B 87, 503 (2007)

F. Goulay, L. Nemes, P.E. Schrader, H.A. Michelsen, Mol. Phys. 108, 1013 (2010)

H.A. Michelsen, P.O. Witze, D. Kayes, S. Hochgreb, Appl. Opt. 42, 5577 (2003)

P.-E. Bengtsson, M. Aldén, Combust. Sci. Technol. 77, 307 (1991)

P.-E. Bengtsson, M. Aldén, Appl. Phys. B 60, 51 (1995)

F. Goulay, P.E. Schrader, L. Nemes, M.A. Dansson, H.A. Michelsen, Proc. Combust. Inst. 32, 963 (2009)

C.J. Dasch, Appl. Opt. 23, 2209 (1984)

R.L. Vander Wal, T.M. Ticich, A.B. Stephens, Appl. Phys. B 67, 115 (1998)

S. De Iuliis, F. Cignoli, S. Maffi, G. Zizak, Appl. Phys. B 104, 321 (2011)

P.O. Witze, S. Hochgreb, D. Kayes, H.A. Michelsen, C.R. Shaddix, Appl. Opt. 40, 2443 (2001)

G.D. Yoder, P.K. Diwakar, D.W. Hahn, Appl. Opt. 44, 4211 (2005)

G.D. Yoder, Master Thesis, University of Florida, 2003

K.A. Thomson, K.P. Geigle, M. Köhler, G.J. Smallwood, D.R. Snelling, Appl. Phys. B 104, 307 (2011)

H. Bladh, J. Johnsson, P.-E. Bengtsson, Appl. Phys. B 96, 645 (2009)

H. Bladh, J. Johnsson, P.-E. Bengtsson, Appl. Phys. B 90, 109 (2008)

F. Liu, G.J. Smallwood, J. Quant. Spectrosc. Radiat. Transf. 111, 302 (2010)

R.A. Dobbins, Combust. Flame 130, 204 (2002)

T.S. Totton, D. Chakrabarti, A.J. Misquitta, M. Sander, D.J. Wales, M. Kraft, Combust. Flame 157, 909 (2010)

R.B. Miles, W.R. Lempert, J.N. Forkey, Meas. Sci. Technol. 12, R33 (2001)

C.M. Sorensen, Aerosol Sci. Technol. 35, 648 (2001)

R.L. Vander Wal, M.Y. Choi, Carbon 37, 231 (1999)

D.R. Snelling, K.A. Thomson, F. Liu, G.J. Smallwood, Appl. Phys. B 96, 657 (2009)

Acknowledgments

This work is financially supported by the Swedish Research Council, Centre of Combustion Science and Technology (CECOST), through the Strategic Science Foundation, and the Linnaeus program within the Lund Laser Centre.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Olofsson, NE., Johnsson, J., Bladh, H. et al. Soot sublimation studies in a premixed flat flame using laser-induced incandescence (LII) and elastic light scattering (ELS). Appl. Phys. B 112, 333–342 (2013). https://doi.org/10.1007/s00340-013-5509-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5509-z