Abstract

In this work, we report the progressive formation of first nanoparticles, next fine ripples, and eventually coarse ripples during the irradiation of single-crystal 6H-SiC surfaces with increasing number of femtosecond laser pulses (λ = 515 nm, τ = 250 fs, repetition rate = 100 kHz). At laser fluences greater than the single-pulse ablation threshold, nanoparticles were produced on the surface by the first few pulses over which fine ripple patterns overlapped at increased pulse numbers. As the pulse number was further increased over ten, the surface was gradually transformed into a coarse ripple–covered one. At laser fluence below the threshold, however, only fine ripples were formed nonuniformly.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, the mechanism of ripple formation during ultrashort pulse laser irradiation of solids has received much attention by researchers due primarily to the uncertainty of the physical origin of those ripples [1–14] and also to the unique optical properties of rippled structures [15–19]. Laser ripples have been observed at variant pitches which are roughly classified into coarse and fine ripples depending on the spacing between adjacent ripples. For coarse ripples, the spacing between ripples is comparable to the wavelength of incident laser, whereas for fine ripples, it is much smaller than the laser wavelength. The fine ripples are especially of interest owing to their potential applicability for nanostructuring [1–10, 15–17, 20–23]. Also, ripples were mostly produced under multi-pulse laser irradiation conditions [2, 13, 22].

Despite the abundance of experimental observation of ripples, the mechanism of ripple formation still remains unclear, and several different explanations have been proposed [1–4, 6–8, 10–13]. The interference model in which the pitch (Λ) of ripples is related to the laser wavelength (λ) and incidence angle (θ) by the relation Λ = λ/(1 ± sin θ) [24–26] is widely accepted to explain the coarse ripples. However, it was also pointed out by several researchers that the pitch of coarse ripples observed in experiments was mostly shorter than the incident laser wavelength [5–9, 13], and thus, surface plasmonic waves could be the main reason of coarse ripple formation rather than interference [27, 28]. For fine ripples, no solid explanation about the mechanisms has been established. Fine ripples reported in earlier studies were produced over rather widely varying conditions and pitches, lacking consistency. For example, for femtosecond laser ablation with λ = 800 nm, coarse and fine ripples had been classified by spacings of 500 and 250 nm [29], respectively, or 700 and 200 nm [30]. The fine ripples of interest in recent studies are often characterized with a spacing within the range of λ/5–λ/3 [10, 31]. In addition, fine and coarse ripples were often observed simultaneously [1, 2, 7–9, 13, 15, 17, 21, 22]. Different mechanisms such as second harmonic generation [3], self-organization [32], excitation of surface plasmon polaritons [7], interference effects due to transient alteration in the optical properties during laser irradiation [33], etc. have been proposed to describe the fine ripples. Also, it has been reported that the spatial frequency of femtosecond laser ripples repeatedly decreased by a factor of two for increasing laser fluence rather than remaining constant [17].

SiC is an attractive material with high stiffness, mechanical strength, extreme chemical inertness, and wide band gap which are very useful for the fabrication of devices working at harsh environments [34]. Thus, the characteristics of femtosecond laser–nanostructured SiC have been investigated by many researchers. For example, Rudolph and Kautek [30] reported that three different regions were detectable, namely, middle of the crater with no texturing, coarse ripples of 700 nm size toward the edge, and followed fine ripples of 200 nm at the edge. Zhao et al. [15] reported that optical absorption and photocurrent of 6H-SiC nanostructured by femtosecond laser increased significantly. Buividas et al. [10] reported that ripple spacing also varies by (λ/n)/2 and suggested localized sub-surface nanoplasma formation as the mechanism.

In this study, based on the pulse-by-pulse observation of the surfaces of femtosecond laser–ablated single-crystal 6H-SiC, we report that the irradiated surface progressively changed from a surface covered with nanoparticles to fine ripples and eventually to coarse ripples as the pulse number increased at a laser fluence above the ablation threshold. When the laser energy was lowered below the threshold, however, only fine ripples were produced regardless of pulse number.

2 Experimental

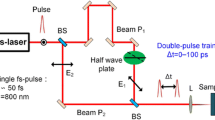

The ablation experiments were carried out using a Yb:KGW laser system (Light Conversion, PHAROS; maximum repetition rate = 100 kHz, pulse width = 250 fs, wavelength = 515 nm, linear polarization) under normal atmospheric pressure and room temperature with single-crystal 6H-SiC targets (CREE Inc.; n type, thickness = 270.5 μm, surface roughness <20 nm). The incident laser pulse energy (E p) was adjusted using a half-wave plate and a linear polarizer. The laser beam was normally incident to the target surface and focused with an objective lens (Mitutoyo; 10×, numerical aperture = 0.26). The laser spot had an elliptical shape, but for the estimation of spot radius (ω) and threshold laser fluence (F = E p/πω 2), it was converted into a circular spot of equivalent size so that the relation between laser fluence and squared crater diameter of a Gaussian laser beam could be applied [35]. The accordingly estimated single-pulse ablation threshold fluence (F th) and equivalent spot radius (ω 0) were 1.07 J/cm2 and about 8.4 μm, respectively.

The laser system utilized in experiments had the function for single-shot emission. Using this function, the number of laser pulse irradiated on each test surface was controlled pulse by pulse so that the changes on target surface with each increasing pulse number could be examined. After laser ablation, the samples were cleaned using an ultrasonic cleaner with water for 5 min and then rinsed with ethanol. The ablated surface and ripples were examined using a scanning electron microscope (SEM, Hitach S-4700).

3 Results and discussion

Prior to laser irradiation, the 6H-SiC sample had a clear surface. Figure 1 shows the SEM images of 6H-SiC surfaces irradiated from two to nineteen laser pulses along with magnified views of the middle (′) and edge (″) of laser spots. For the ablation of these spots, a fixed laser fluence of F = 1.17 J/cm2, slightly higher than the single-pulse ablation threshold (1.07 J/cm2), was utilized. Note that each figure in Fig. 1a–r represents a different laser spot irradiated with increasing number of pulses (N). As shown in Fig. 1a and its magnified view, the sample surface was covered by many nanoparticles of approximately 50 nm size after being irradiated twice. At N = 3 and 4, faint ripple-like patterns started to appear over the nanoparticle-covered surface as shown in Fig. 1b, c. As the pulse number increased to 6 or 7, fine ripples were clearly observed over the entire laser spot, and nanoparticles seemed to be buried within these ripples (Fig. 1e, f). The spacing of these fine ripples measured from the SEM images lies in the range of roughly 120–155 nm (λ/4.3–λ/3.3). These fine ripples remained on the surface until the pulse number increased up to about 11 or 12. At these pulse numbers, however, coarse ripple patterns with a spacing varying within the range of about 420–520 nm started to appear over the existing fine ripples and became apparent at N = 12 and 13 as shown in Fig. 1k, l. In other words, a transition from the fine ripple–covered surface to a coarse ripple–covered surface occurred between N = 8 and 13. For N > 14, although remnant fine ripple patterns were locally observable, the laser spot was almost fully covered by coarse ripples as shown in Fig. 1m–r. During the increase of pulse number from 14 to 19, the pitch of coarse ripples did not vary appreciably, whereas the depth of grooves appeared to increase gradually as examined from the SEM images. Both the fine and coarse ripples in Fig. 1 were aligned in the direction perpendicular to the laser polarization. The variation of ripple spacing with respect to increasing pulse number at the center and edge of craters explained above is summarized in Fig. 2.

The observed changes in surface morphology from nanoparticle formation to coarse ripples with increasing pulse number are inexplicable yet. However, to verify whether the observed transition from nanoparticles to coarse ripples holds for all laser energy conditions above the single-pulse ablation threshold, the same experiments were repeated at different laser fluences. Figure 3 shows the images of laser spots irradiated with a fixed pulse number of N = 20 at increased laser fluences. Despite the variation of laser fluence, the irradiated surfaces showed coarse ripples of almost the same pitch. At elevated laser fluences, however, the middle of laser spot showed distorted ripples, (Fig. 3c–e), which should be due to thermal damage at the relatively high fluences. The experimental results in Figs. 1 and 3 for laser fluences over the single-pulse ablation threshold are summarized as follow. First, a thin layer of material near the surface was ablated by the initial one or two pulses producing nanoparticles over the irradiated surface. Subsequent laser pulses (N = 3–7) then transformed the nanoparticle-covered surface into fine ripples. These fine ripples were then overwritten by coarse ripples as the pulse number increased up to about 13 over which the entire surface was basically covered with coarse ripples. It is unknown yet how these nanoparticles were produced, although many possibilities such as material inhomogeneity, crystalline property of the target, scattering of laser light at the surface, etc. could be considered. In most ripple studies, the ripples were produced by multi-pulse irradiation from tens to hundreds of pulses or more [4, 12, 22]. Therefore, it would be difficult to find useful information about detailed changes of ripples and mechanisms by an examination of the final surfaces produced by such a large number of pulses. On the other hand, there have been studies that investigated the effects of pulse number on ripple pitch. For example, several researchers [2, 22, 36] reported that coarse ripples produced at lower number of pulses were transformed into fine ripples at increased pulse number due possibly to nonlinear response of the coarse-rippled surface. Conversely, Tomita et al. [29] reported from femtosecond laser irradiation of 4H-SiC surface that fine ripples were formed with preexisting scratches at N = 10. As N was increased to 50, coarse ripples were observed in the middle of crater, whereas fine ripples were in the peripheral region. They suggested the differences in transient material phase and the effects of sample temperature, but could not elucidate the mechanism of fine ripple formation. Alternatively, Miyaji and Miyazaki [37] reported the pulse number dependence of periodicity of ripples produced on diamond-like carbon (DLC) film (500 nm thickness) during femtosecond laser ablation (λ = 800 nm, 100 fs, 10 Hz) for N = 10–1,000. They showed that line-like traces appeared at N = 30 with a spacing of 40–60 nm that grew into broader and deeper periodic structures at increased N, to about 140–170 for N = 500–1,000. They explained that the bonding structure change for DLC to glass carbon produced a random distribution of nanometer-size roughness in the initial stage of ablation. This surface roughness then allowed the incident electric field to coherently couple with the collective oscillation of free electrons to excite surface plasmon polaritons (SPPs) in the surface layer, and the SPP had a periodic change resulting local field amplitude to periodically initiate nanoscale ablation. The authors consider that the experimental observations reported in [37] have some similarity to the progressive changes on 6H-SiC observed in the present study. The inhomogeneity of material or crystalline property in 6H-SiC may have lead to the formation of randomly distributed nanoparticles followed by the excitation of SPPs.

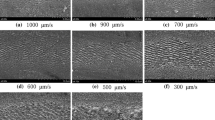

Next, the ablation experiments were repeated at a fluence below the single-pulse ablation threshold. Figure 4 shows the surfaces irradiated by increasing number of pulses at F = 0.9 J/cm2, slightly below the single-pulse ablation threshold. First, it was found that only fine ripples were formed on the surface at this sub-threshold condition regardless of pulse number. Because of the low laser energy, ripples were hardly observed until the pulse number reached 20 at which crack-like fine ripples started to appear at different locations of the laser spot as shown in Fig. 4a. As the pulse number increased, the isolated fine ripple patterns expanded and coalesced into others to form a larger connected pattern, Fig. 4b, c, and eventually covered nearly the entire laser spot (Fig. 4d–f). The pitch of these fine ripples was similar to that of the fine ripples in Fig. 2 for N = 6–10 and remained almost constant during the expansion. Note that the rippled surfaces show uneven depth and the fine ripples formed at varying layers of material.

4 Summary

From the experimental study of femtosecond laser ablation of single-crystal 6H-SiC, it was found that there existed a progressive change on the irradiated surface with respect to increasing pulse number when laser fluence was above the single-pulse ablation threshold. First, nanoparticles were produced on the irradiated surface during the initial two or three pulses; then, fine ripples started to appear over the nanoparticle-covered surface, and eventually, the fine ripples transformed into coarse ripples as the pulse number increased approximately over ten. This was true only for a laser fluence greater than the single-pulse ablation threshold. If the laser fluence was below single-pulse ablation threshold, only fine ripples were produced regardless of pulse number. These results also reconfirmed the known importance of laser energy in determining ripple spacing.

References

A. Borowiec, H.K. Haugen, Appl. Phys. Lett. 82, 4462 (2003)

J. Bonse, M. Munz, H. Sturm, J. Appl. Phys. 97, 013538 (2005)

T.Q. Jia, H.X. Chen, M. Haung, F.L. Zhao, J.R. Qiu, R.X. Li, Z.Z. Xu, X.K. He, J. Zhang, H. Kuroda, Phys. Rev. B 72, 125429 (2005)

X.J. Wu, T.Q. Jia, F.L. Zhao, M. Huang, N.S. Xu, H. Kuroda, Z.Z. Xu, Appl. Phys. A Mater. Sci. Process. 86, 491 (2007)

A.Y. Vorobyev, C. Guo, J. Appl. Phys. 104, 63523 (2008)

M. Huang, F.L. Zhao, Y. Cheng, N.S. Xu, Z.Z. Xu, Phys. Rev. B 79, 125436 (2009)

S. Sakabe, M. Hashida, S. Tokita, S. Namba, K. Okamuro, Phys. Rev. B 79, 33409 (2009)

Y. Yang, J. Yang, L. Xue, Y. Guo, Appl. Phys. Lett. 97, 141101 (2010)

M. Huang, F. Zhao, Y. Cheng, N. Xu, Z. Xu, ACS Nano 3, 4062 (2010)

R. Buividas, L. Rosa, R. Sliupas, T. Kudrius, G. Slekys, V. Datsyuk, S. Juodkazis, Nanotechnology 22, 055304 (2011)

B.R. Tull, J.E. Carey, E. Mazur, J.P. McDonald, MRS Bull. 31, 626 (2006)

T.Q. Jia, F.L. Zhao, M. Haung, H.X. Chen, J.R. Qiu, R.X. Li, Z.Z. Xu, H. Kuroda, Appl. Phys. Lett. 88, 111117 (2006)

J. Bonse, A. Rosenfeld, J. Kruger, J. Appl. Phys. 106, 104910 (2009)

Y. Dong, P. Molian, Appl. Phys. Lett. 84, 10 (2004)

Q.Z. Zhao, F. Ciobanu, S. Malzer, L.J. Wang, Appl. Phys. Lett. 91, 121107 (2007)

A.Y. Vorobyev, V.S. Makin, C.L. Guo, Phys. Rev. Lett. 102, 234301 (2009)

M. Huang, F. Zhao, Y. Cheng, N. Xu, Z. Xu, Opt. Express 18, A600 (2010)

Y. Yang, J. Yang, C. Liang, H. Wang, Opt. Express 16, 11259 (2008)

Y. Yang, J. Yang, C. Liang, H. Wang, X. Zhu, N. Zhang, Opt. Express 17, 21124 (2009)

M. Shinoda, R.R. Gattass, E. Mazur, J. Appl. Phys. 105, 053102 (2009)

M. Huang, F.L. Zhao, Y. Cheng, N.S. Xu, Z.Z. Xu, Opt. Express 16, 19354 (2008)

X. Jia, T.Q. Jia, Y. Zhang, P.X. Xiong, D.H. Feng, Z.R. Sun, J.R. Qiu, Z.Z. Xu, Opt. Lett. 35, 1248 (2010)

S.H. Kim, I.B. Son, S.H. Jeong, Appl. Phys. A Mater. Sci. Process. 102, 55 (2011)

D.C. Emmony, R.P. Howson, L.J. Willis, Appl. Phys. Lett. 23, 598 (1973)

Z. Guosheng, P.M. Fauchet, A.E. Siegman, Phys. Rev. B 26, 5366 (1982)

E. Sipe, J.E. Young, J.S. Preston, H.M. van Driel, Phys. Rev. B 27, 1141 (1983)

W.L. Barnes, A. Dereux, T.W. Ebbesen, Nature 424, 824 (2003)

H. Raether, Surface Plasmons on Smooth and Rough Surfaces and on Gratings (Springer, Berlin, 1988)

T. Tomita, K. Kinoshita, S. Matuso, S. Hashimoto, Jpn. J. Appl. Phys. 45, L444 (2006)

P. Rudolph, W. Kautek, Thin Solid Films 453–454, 537 (2004)

R.A. Ganeev, Opt. Spectrosc. 106, 142 (2009)

J. Reif, F. Costache, M. Henyk, S.V. Pandelov, Appl. Surf. Sci. 891, 197 (2002)

Q. Wu, Y. Ma, R. Fang, Y. Liao, Q. Yu, X. Chen, K. Wang, Appl. Phys. Lett. 82, 1703 (2003)

Y. Dong, C. Zorman, P. Molian, J. Micromech. Microeng. 13, 680 (2003)

S.H. Kim, I.B. Son, S.H. Jeong, Appl. Surf. Sci. 255, 9717 (2009)

W. Zhang, G. Cheng, Q. Feng, L. Cao, F. Wang, R. Hui, Appl. Surf. Sci. 257, 4321 (2011)

G. Miyaji, K. Miyazaki, Opt. Express 16, 16265 (2008)

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) (No. 2011-0029850).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.H., Byun, K.H., Sohn, I.B. et al. Progressive formation of fine and coarse ripples on SiC surface by repeated irradiation of femtosecond laser pulses. Appl. Phys. B 113, 395–402 (2013). https://doi.org/10.1007/s00340-013-5476-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5476-4