Abstract

In this paper, an effective substrate for surface-enhanced fluorescence, which consists of dendritic silver nanostructure on copper surface, was fabricated by modified galvanic displacement reaction at room temperature. It was found that the fluorescence efficiency of Rh6G probe molecules on the substrate depended on the period of the nanostructure growth. And it increased with the enrichment of fine-branches of the dendritic silver nanostructure. The experimental results indicated that the fine nanostructure with dendritic distribution can produce better fluorescence enhancement with the help of proper control over the reaction condition. It is important for studying the mechanism and the potential applications of enhanced fluorescence effect.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Surface-enhanced fluorescence (SEF), a phenomenon where the quantum yield and photostability of weakly fluorescing species are dramatically increased, is becoming a powerful technique for the fluorescence-based applications, such as in optical devices, biological and chemical sensing and diagnosis, protein–protein detection and so on [1–3]. It is widely accepted that the locally enhanced electromagnetic (EM) field formed at a nanostructure surface is mostly responsible for SEF effect [4, 5]. So many efforts in the fabrication of effective SEF substrate with high local EM field or “hot spots” have been made for producing strong fluorescence signals with higher contrast level. In the past few years, various shapes of metallic nanostructures have been developed and investigated as SFE-active substrates, including metallic island films, metallic nanograting, metallic nanohole arrays, metal nanorods, nanoparticles arrays and fractal-like nanostructure [6–12]. However, to the best of our knowledge, few studies on the metal dendrites with random atom distribution as SEF-active substrate were reported [13, 14]. Here, we present SEF results from dendritic silver nanostructure and highlight the applicability of such nanodendritic substrate for fluorescence-based biological sensing.

In this paper, a simple method for the synthesis of unique heterogeneous dendritic silver nanostructure, acted as SEF substrate, is developed in a reliable way. The synthesis is based on a galvanic displacement reaction between AgNO3 aqueous solution and copper substrate. Comparing with the physically polished copper surface and clean glass slide, we found that the heterogeneous dendritic silver nanostructures, fabricated with proper control over the experimental conditions, such as reaction time and solution concentration, exhibit very good fluorescence enhancement capabilities.

2 Experimental setup

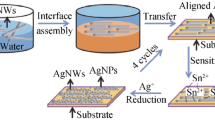

AgNO3 was purchased from Beijing Chemical Plant and used without purification. Copper foils (99.999 %, General Research Institute for Nonferrous Metals, Beijing, China) were first physically polished with 4,000 grid sand paper to remove surface oxides, then rinsed with deionized water and followed by drying with N2. The copper plate was then immersed into AgNO3 solution (10−3 m/L). Silver nanostructures with different morphologies were obtained by controlling over the immersion time. The nanostructure products were cleaned for several times using deionized water to remove excessive chemicals like Cu2+ and NO3 −. Finally, the prepared substrates were dried by a gentle flow of N2 (Fig. 1).

Characterizations of the substrate samples were performed by scanning electron microscope (SEM). The film of Rh6G molecules was prepared with the method described by Wang and Hu [15]. In this method, the dye (10−7 mol/L Rh6G in water) was deposited on the substrate by immersing the prepared SEF substrate into the dye solution for about 20 min. After that, the sample was rinsed thoroughly with deionized water and dried with gentle nitrogen blow. Fluorescence measurements were conducted at room temperature. SP2750i Spectrometer (Acton Research Corporation, USA) and PIXIS100 CCD system (Acton Research Corporation, USA) were employed for fluorescence collection and detection. The wavelength of the excitation laser was 532 nm. A properly selected notch filter was used to eliminate the scattered light in spectroscopic measurements.

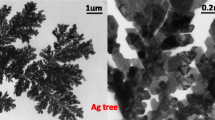

Figure 2 shows the SEM images of silver nanostructure formed in the solution of AgNO3 (10−3 mol/L) for 5, 40, 70, and 120 min, respectively. After copper plate was immersed into AgNO3 solution for 5 min, silver aggregates consisted of silver nanoparticles with non-uniform distribution were formed on the copper plate. When the immersion time is about 40 min, a dendritic silver nanostructure was formed. The fabricated nanostructure was composed of silver nanoparticles. The nanoparticles formed symmetrical leaves on branches by connecting with each other, which looked like metasequoia leaves with multilevel nanostructures. The length of each individual dendrite varies from 1 to 10 μm. It was found that the silver ion concentration also played a significant role in the formation and growth of the silver nanostructure, such as the morphology, size and production amount of the silver dendrites. It was showed that after the copper plate was immersed into the 10−3 mol/L AgNO3 solution for 80 min, a perfect dendritic structure with well-crystallized separate hexagonal plates was formed. As reported in Ref. [16, 17], the diffusion-limited aggregation model is widely used to explain the growth of silver dendrites. The evolution of the silver aggregates to a thermodynamically stable dendritic nanostructure attributed to strong anisotropic growth. If the concentration is too high, the formed silver nanostructure on copper plate will be too thick and fragile to handle. Therefore, an optimum reaction time of 80 min and the concentration of 10−3 mol/L are chosen in current work to get sufficient amount of silver dendrites.

3 Results and discussion

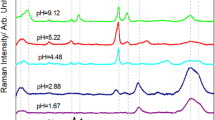

To investigate the enhancement of fluorescence intensity from the dendritic silver nanostructure, typical fluorescence spectra of Rh6G molecule film on the prepared nanostructure substrate with 120 min reaction time (Curve e), 70 min (Curve d), 40 min reaction time (Curve c), 5 min reaction time (Curve b) and reference substrate (Curve a) are shown in Fig. 3a. We can find that the enhancement in SEF on the dendritic silver nanostructure is remarkable. Comparing to the physically polished copper substrate, we can see that the dendritic silver nanostructure provides a good reproducible SEF substrate with relatively high enhancement.

Fluorescence measurements of Rh6G molecules on the dendritic silver nanostructure and other reference surfaces have been carried out and the corresponding results are presented in Fig. 3a. By comparing the peak at 558 nm from the prepared metal substrates with that from the clean glass substrate, we find that the greatest enhancement factor (\( E_{\text{f}} \)) is about 12.4 based on the Eq. (1).

where \( I_{\text{sample}} \) is the fluorescence intensity of Rh6G monolayer on the dendritic silver substrate, \( I_{\text{reference}} \) is the fluorescence intensity of Rh6G monolayer on the clean glass substrate and \( I_{\text{background}} \) is the background intensity of the spectra.

We also note that the peak fluorescence intensity varies with silver reaction time of substrate preparation and reaches the highest value at 70 min reaction time. At 70 min growth time, the SEF intensity was 12.4 times higher than that on the reference substrate, as shown in Fig. 3b. Then, it subsequently decreases to 9.8-fold and 1.9-fold at 40 and 5 min reaction time, respectively. With further increase of the reaction time, the enhancement decreases, as shown in curve e in Fig. 3a.

The dendritic silver nanostructures can be regarded as aggregates of Ag nanoparticles with three dimensional distributions, which are different from other nanostructures such as compact or periodic geometries. With the increase in the reaction time, the dendrites of the formed silver nanostructure are becoming complete gradually. They are symmetrical distribution with fractal-like characteristic. When excited by external EM field, the excited surface plasmon wave will be located in a small region, so the locally enhanced EM field will be obtained. However, if the reaction time is too long, the morphology of the dendritic nanostructure will be destroyed, and the fractal-like and symmetrical properties will be disappeared. It is not benefit to the formation of locally enhanced EM field [18]. It is considered that the EM theory that relies upon the excitation of localized surface plasmons dominates the SEF response in current nanostructures. And the locally enhanced field strongly depends on the interaction process of incident light and the metallic nanostructure with nanoscale surface roughness [19, 20]. Dendritic nanostructure, with highly curved sharp surface features, creates locally enhanced EM field at their numerous corners and edges and tends to be localized in plasmonic “hot spots” [18, 21, 22]. The increase of the fluorescence intensity with the reaction time changing can be attributed to the formation and growth of dendritic silver nanostructure, which is supported by the experimental observation. However, if the reaction time is too long, the formed silver nanostructure on copper plate will be too thick and fragile to handle (as shown in Fig. 2d).

The enhanced EM field in the dendritic silver nanostructure leads to the enhancement of the EM field and fluorescence emission of dye molecules. Excited surface plasmon on the tip of dendritic nanostructures is associated with collective electron oscillations, which create a localized EM field with much higher intensity than that of other substrates [23]. In a sense, the nonplanar surface structure acts as a nanoantenna for the enhancement of the incident and radiate EM fields [24, 25]. Therefore, the dendritic silver nanostructure formed on copper surface is suitable for the SEF application, which exploits a potential way for fluorescence analysis and imaging.

4 Conclusion

We have demonstrated the fabrication of an effective and stable SEF substrate with galvanic displacement method. The SEF observation exhibits a controlled EM coupling among nanoparticles in the dendritic silver nanostructure. The enhanced fluorescence effect mainly depends on the reaction time of the nanostructure formation, which could be attributed to the locally enhanced EM field formed in the multidimensional nanostructure. The simplicity and the cost of overall process make the procedure an excellent candidate for ultrasensitive bioassays with improved detectability of bimolecular.

References

M. Moskovits, Surface-enhanced spectroscopy. Rev. Mod. Phys. 57(3), 783–826 (1985)

E. Fort, S. Gresillon, Surface enhanced fluorescence. J. Phys. D Appl. Phys. 41, 013001 (2008). (1–31)

H.X. Xu, X.H. Wang, M. Persson, H. Xu, M. Käll, P. Johansson, Unified treatment of fluorescence and raman scattering processes near metal surfaces. Phys. Rev. Lett. 93, 243002 (2004). (1–4)

G.C. Schatz, R.P. Van, Electromagnetic mechanism of surface-enhanced spectroscopy, Handbook of Vibrational Spectroscopy (Wiley, Chichester, 2002)

K.A. WilElets, R.P. Van Duyne, Localized surface plasmon resonance spectroscopy and sensing. Annu. Rev. Phys. Chem. 58(1), 267–297 (2007)

X.Q. Cui, K. Tawa, H. Hori, J. Nishii, Tailored plasmonic gratings for enhanced fluorescence detection and microscopic imaging. Adv. Funct. Mater. 20(4), 546–553 (2010)

A.G. Brolo, S.C. Kwok, M.G. Moffitt, R. Gordon, J. Riordon, K.L. Kavanagh, Enhanced fluorescence from arrays of nanoholes in a gold film. J. Am. Chem. Soc. 127(42), 14936–14941 (2005)

Z. Yang, W.H. Ni, X.S. Kou, S.Z. Zhang, Z.H. Sun, L.D. Sun, J.F. Wang, C.H. Yan, Incorporation of gold nanorods and their enhancement of fluorescence in mesostructured silica thin films. J. Phys. Chem. C 112, 18895–18903 (2008)

J. Dong, H.R. Zheng, X.Q. Yan, Z.L. Zhang, Fabrication of flower-like silver nanostructure on the Al substrate for surface enhanced fluorescence. Appl. Phys. Lett. 100, 051112 (2012)

K. Aslan, P. Holley, C.D. Geddes, Metal-enhanced fluorescence from silver nanoparticle-deposited polycarbonate substrates. J. Mater. Chem. 16, 2846–2852 (2006)

K. Drozdowicz-Tomsia, F. Xie, E.M. Goldys, Deposition of silver dentritic nanostructures on silicon for enhanced fluorescence. J. Phys. Chem. C 114(3), 1562–1569 (2010)

J. Dong, J.M. Gong, J.H. Liu, M. Chen, X.W. Yan, The decoration of silver fractal-like nanostructure with Ag nanoparticles on the plastic slide for surface enhanced fluorescence. Electrochim. Acta 60, 264–268 (2012)

X.Z. Sun, L.H. Li, Z.C. Li, Z.J. Zhang, J.Y. Feng, Novel Ag–Cu substrates for surface-enhanced Raman scattering. Mater. Lett. 63, 2306–2308 (2009)

N. Ma, F. Tang, X.Y. Wang, F. He, L.D. Li, Metal-enhanced Fluorescence by Stimuli-responsive Polyelectrolyte Interlayer Films[J]. Macromol. Rapid Commun. 32, 587–592 (2011)

Y. Wang, C. Hu, Layer-by-layer self-assembly of dye-polyoxometalate multilayer composite films and their fluorescent properties. Thin Solid Films 476, 84–91 (2005)

C. Gu, T. Zhang, Electrochemical synthesis of silver polyhedrons and dendritic films with superhydrophobic surfaces. Langmuir 24, 12010–12016 (2008)

J.X. Fang, H.J. You, P. Kong, Y. Yi, X.P. Song, B.J. Ding, Dendritic silver nanostructure growth and evolution in replacement reaction. Cryst. Growth Des. 7(5), 864–867 (2007)

V.M. Shalaev, Optical properties of nanostructured random media. Top. Appl. Phys. 82, 93–114 (2002)

H. Raether, Surface plasmons on smooth and rough surfaces and on gratings (Springer, Berlin, 1988)

W.L. Barnes, A. Dereux, T.W. Ebbesen, Surface plasmon subwavelength optics. Nature 424, 824–830 (2003)

M.I. Stockman, L.N. Pandey, L.S. Muratov, T.F. George, Giant fluctuations of local optical fields in fractal clusters. Phys. Rev. Lett. 72, 2486–2489 (1994)

T. Qiu, Y.J. Zhou, J.Q. Li, W.J. Zhang, X.Z. Lang, T.J. Cui, P.K. Chu, Hot spots in highly Raman-enhancing silver nano-dendrites. J. Phys. D Appl. Phys. 42(17), 175403 (2009). (1–5)

E. Hutter, J.H. Fendler, Exploitation of localized surface plasmon resonance. Adv. Mater. 16(19), 1685–1706 (2004)

P. Bruno, Surface enhanced Raman scattering-physics and application. Top. Appl. Phys. 103, 217–242 (2006)

Z.P. Li, T. Shegai, G. Haran, H.X. Xu, Multiple-particle nanoantennas for enormous enhancement and polarization control of light emission. ACS Nano 3, 637–642 (2009)

Acknowledgments

This work was supported by the National Science Foundation of China (Grant No. 11174190), the Fundamental Research Funds for the Central Universities (Grant No. GK201101022) and the Foundation of Xi’an University of Posts and Telecommunications (Grant No. ZL2011-08).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, J., Zheng, H. Self-assembled synthesis of SEF-active silver dendrites by galvanic displacement on copper substrate. Appl. Phys. B 111, 523–526 (2013). https://doi.org/10.1007/s00340-013-5367-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5367-8