Abstract

Single-crystalline KY1−x−y−z GdxLuyYbz(WO4)2 layers are grown onto undoped KY(WO4)2 substrates by liquid-phase epitaxy. The purpose of co-doping the KY(WO4)2 layer with suitable fractions of Gd3+ and Lu3+ is to achieve lattice-matched layers that allow us to engineer a high refractive-index contrast between waveguiding layer and substrate for obtaining tight optical mode confinement and simultaneously accommodate a large range of Yb3+ doping concentrations by replacing Lu3+ ions of similar ionic radius for a variety of optical amplifier or laser applications. Crack-free layers, up to a maximum lattice mismatch of ~0.08 %, are grown with systematic variations of Y3+, Gd3+, Lu3+, and Yb3+ concentrations, their refractive indices are measured at several wavelengths, and Sellmeier dispersion curves are derived. The influence of co-doping on the spectroscopy of Yb3+ is investigated. As evidenced by the experimental results, the lattice constants, refractive indices, and transition cross-sections of Yb3+ in these co-doped layers can be approximated with good accuracy by weighted averages of data from the pure compounds. The obtained information is exploited to fabricate a twofold refractive-index-engineered sample consisting of a highly Yb3+-doped tapered channel waveguide embedded in a passive planar waveguide, and a cladding-side-pumped channel waveguide laser is demonstrated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The potassium double tungstates KY(WO4)2, KGd(WO4)2, and KLu(WO4)2 serve as excellent host materials for trivalent rare-earth-ion (RE3+) doped solid-state lasers [1] because of their high refractive indices of ~2.0−2.1 [2], the large transition cross-sections and broad line widths of optically active RE3+ ions doped into these hosts [3–5], and a long inter-ionic distance of >0.4 nm [6, 7], allowing for large doping concentrations without lifetime quenching [8]. In particular, KY(WO4)2:Yb3+ has an absorption maximum near 981 nm with a cross-section, for polarization parallel to the N m optical axis, about 15 times larger than that of Y3Al5O12:Yb3+ [5] and doping of high Yb3+ concentrations, up to the stoichiometric structure KYb(WO4)2 [6, 9, 10], results in extremely short absorption lengths down to <20 μm.

KY(WO4)2, KGd(WO4)2, and KLu(WO4)2 are strongly anisotropic biaxial crystals. The low-temperature α-KY(WO4)2 phase crystallizes in the monoclinic centrosymmetric space group C2/c or I2/c [11–14]. Both space groups belong to the 2/m point group and have Schönflies notation \( C_{2h}^{6} \), i.e., they describe the same crystal structure with different coordinates for the unit cell, see Fig. 1 [15]. Crystals of the low-temperature α-KY(WO4)2 structure cannot be grown from the stoichiometric melt but must be grown from solution, because a polymorphic phase transition occurs at ~1,010–1,025 °C [2, 16, 17], below the melting temperature of ~1,080° for KY(WO4)2 [2]. High-quality, single-crystalline thin layers of KY(WO4)2:RE3+ have been grown onto undoped KY(WO4)2 crystals by liquid-phase epitaxy (LPE) using the solvent K2W2O7 [18, 19], and highly efficient waveguide lasing was demonstrated in >10-μm-thick KY(WO4)2:(1.2–2.4 at.%)Yb3+ samples [19]. The choice of rather low dopant concentrations was governed by the requirements of lattice matching, to avoid structural stress and cracking of the layer, as well as optimizing the laser properties; it resulted in a low refractive-index contrast between layer and substrate of a few ×10−4 [19].

Orientation of crystallographic axes (black) of the low-temperature α-KYW crystal structure according to the C2/c space group (coordinate system without asterisk, recommended by the International Union of Crystallography as standard setting; a = 1.064 nm, b = 1.035 nm, c = 0.754 nm, β = 130.50°) and the I2/c space group (Hermann-Mauguin coordinate system, denoted by an asterisk; a* = 0.805 nm, b* = 1.035 nm, c* = 0.754 nm, β* = 94.0°) [15]. Optical ellipsoid of KYW (blue) [15]

A break-through toward the fabrication of integrated optical devices was achieved by co-doping the RE3+-activated KY(WO4)2 layer with optically inert Gd3+ and Lu3+ ions [20]. Both, Gd3+ and especially Lu3+ have higher electron densities than Y3+, thus increasing the refractive index contrast. Simultaneously, this approach provides the possibility for growing lattice-matched layers, as these two ions change the lattice constants of KY(WO4)2 in opposite directions. Furthermore, this approach facilitates the fabrication of microstructured channel waveguides [21], because the limited etch depth provides better horizontal confinement in case of a thinner layer. Finally, since the Lu3+ and Yb3+ ions have similar ionic radii, the former ion can gradually be replaced by the latter, thereby maintaining lattice matching, while simultaneously permitting independent control of the refractive-index contrast and Yb3+ dopant concentration up to ~50 at.% for specific amplifier or laser regimes. This approach has initialized a wealth of new investigations toward integrated amplifiers and lasers based on RE3+-doped KY1−x−y GdxLuy(WO4)2 thin films. Yb3+-doped planar waveguide lasers with 82.3 % slope efficiency [22] and microstructured channel waveguide lasers with 71 % slope efficiency and a record-low quantum defect of 0.7 % [23] were demonstrated. Exemplifying the enormous potential of RE3+-doped potassium double tungstate waveguides, ~1,000 dB/cm net gain was obtained with a high Yb3+ doping of 47.5 at.% [24].

In this paper, we report a systematic study on engineering lattice matching and simultaneously optimizing the refractive index and active dopant concentration in KY1−x–y−z GdxLuyYbz(WO4)2 epitaxial layers grown onto KY(WO4)2 substrates. The transition cross-sections and luminescence lifetime of Yb3+ are investigated. Exploiting the large absorption cross-section of Yb3+ in potassium double tungstates, the large Yb3+ concentrations attainable in the co-doped layers, as well as the passive guiding properties of a KY1−x–y GdxLuy(WO4)2 layer, we demonstrate lasing in a cladding-side-pumped tapered channel waveguide.

2 Growth of co-doped potassium double tungstate layers

LPE was performed in a resistance-heated oven (Carbolite) with a single-zone vertical temperature profile at ambient atmosphere. A micro-mechanical unit on top of the oven allowed for precise control of substrate translation and rotation. Starting from 5 N raw materials (Alfa Aesar), thin layers of KY1−x−y−z GdxLuyYbz(WO4)2 were grown onto 1-mm-thick KY(WO4)2 substrates (Altechna) with laser-grade-polished (010) faces of 1.0 × 1.0 cm2 size and orientation shown in Fig. 2 in a K2W2O7 solvent contained within a 25-ml-volume platinum crucible. The substrate was fixed to a platinum wire and vertically immersed by >80 % into the solution. Complete immersion is not desirable, since overgrowth of the platinum wire results in fractured layers. In addition, the non-overgrown surface of the substrate was subsequently exploited for alignment of the sample during surface polishing of the grown layer. Computer-controlled, fully automated growth routines were developed, controlling the substrate rotation, growth duration, growth temperature, heating and cooling rates to ensure reproducible layer growth. The solute/solvent ratio was 10.5–89.5 mol%.

a Photographs of lattice-matched samples of KGd0.492Lu0.492Tm0.015(WO4)2 (left-hand side) and KGd0.447Lu0.078Yb0.475(WO4)2 (right-hand side). b Photographs of samples with two different fracture patterns observed in non-lattice matched layers. c Photographs of KGd0.425Yb0.575(WO4)2 samples without (left-hand side) and with (right-hand side) cracks. The crystal orientations are indicated

During the LPE growth from an open crucible, a small fraction of the solution evaporates. The solvent K2W2O7 is significantly more volatile than the solute KY1−x−y−z GdxLuyREz(WO4)2, therefore mostly it is a part of the solvent that evaporates. On the other hand, part of the solute is lost to the growing layer. Since the relative loss of solute is larger than that of the solvent, the net result is a decrease in the solute concentration and, thus, in the level of super-saturation during growth. In standard LPE experiments, this effect is counterbalanced and the level of super-saturation is maintained by slowly lowering the growth temperature. However, in a simple oven like the one used in our experiments, with a single-zone vertical temperature profile and a temperature stability of ±0.1 °C, any adjustment of the growth temperature would lead to discontinuous cooling which induces growth instabilities. Therefore, the growth was performed at a constant elevated growth temperature in the range of 920–925 °C, with a level of super-saturation high enough at the beginning of the growth process to accommodate the decrease in solute concentration and maintain an acceptable level of super-saturation throughout the growth process. This procedure leads to slow growth rates of 15–18 μm/h and results in crack-free layers of thicknesses ranging between 10 and 50 μm, see Fig. 2a. The layers were surface polished parallel to the substrate–layer interface with 1.5-nm (rms) roughness to the thickness desired for the specific investigation or application.

X-ray diffraction investigations confirmed the single-crystalline nature of such a grown layer [22]. Its Y3+, Gd3+, Lu3+, and Yb3+ concentrations were determined by laser-ablation inductively coupled plasma mass spectrometry [22], indicating that the layer composition is close to that of the initial solution, therefore, suggesting that the segregation coefficients of all incorporated ions are close to unity.

3 Lattice mismatch between co-doped layers and substrate

We performed several studies, comprising samples of the compositions (a) KY1−x−y−0.025GdxLuyYb0.025(WO4)2 with a systematic variation of the fraction 1−x−y−0.025 of Y3+ ions and (b) KGdxLuyYb1−x−y (WO4)2 with a systematic variation of the fraction 1−x−y of Yb3+ ions. In the former variation, the gradual replacement of Y3+ ions by Gd3+ and Lu3+ ions, at a constant Yb3+ concentration of typically a few at.% that is suitable for operating planar [19, 22] and channel [21, 23, 25] waveguide lasers, allows us to optimize the refractive index contrast, hence, the optical mode size, for the intended laser wavelength. In this manner, excellent confinement of pump and laser light and efficient fundamental-mode lasing are obtained. In the latter variation, while maintaining lattice matching and the desired refractive index contrast, the concentration of the active RE3+ ion can be significantly increased to allow for ultra-high optical gain in a RE3+-doped waveguide amplifier [24]. The optimum dopant concentration can vary significantly, depending on the RE3+ ion, targeted emission transition, and potential concentration-dependent spectroscopic quenching mechanisms.

The known lattice parameters of the stoichiometric compounds KY(WO4)2, KGd(WO4)2, KLu(WO4)2, and KYb(WO4)2 are summarized in Table 1. Prior to layer growth, these parameters were used to predict—by assuming a linear change of lattice parameters when gradually replacing ions of one stoichiometric compound by ions of another, known as Vegard’s law [29]—the amounts of Y3+, Gd3+, Lu3+, and Yb3+ ions in the layer that lead to minimum lattice mismatch with the KY(WO4)2 substrate. Because of the thermal expansion, it is important that values for the different compounds are measured at the same temperature; therefore, the data sets denoted by an asterisk in Table 1 were chosen as a basis for our investigation.

The diagrams of Fig. 3 display the calculated lattice mismatch (color code) versus Gd3+ and Lu3+ fraction independently along the crystal a-axis (left-hand side) and c-axis (right-hand side) for (a) non-activated KY1−x–yGdxLuy(WO4)2, (b) KY1−x–y−0.025GdxLuyYb0.025(WO4)2, and (c) KGdxLuyYb1−x–y (WO4)2. The black diagonal lines indicate the remaining fraction of Y3+ ions or, for the completely Y3+-free compositions of part (c), the fraction of Yb3+ doping. The compositions for which perfect lattice matching—averaged over the statistical incorporation of Y3+, Gd3+, Lu3+, and Yb3+ ions, i.e., over a few lattice constants—is obtained along the crystal a- or c-axis are indicated by the blue lines.

Lattice mismatch (color bar) and refractive index contrast (white lines) of KY1−x–y−z GdxLuyREz(WO4)2 thin layers with the undoped KY(WO4)2 substrate versus Gd3+ and Lu3+ fractions, calculated independently along the crystal a-axis (left-hand side) and c-axis (right-hand side). The blue lines indicate the compositions for which lattice matching is achieved individually along each crystal axis, while the red lines (identical position for a- and c-axes) indicate the compositions for which minimum mismatch is obtained when considering both, the a- and c-axes. Displayed are the data for a KY1−x–y GdxLuy(WO4)2, as well as the investigated samples (red dots) of b KY1−x–y−0.025GdxLuyYb0.025(WO4)2, and c KGdxLuyYb1−x–y (WO4)2. In a and b, the black lines indicate the remaining Y3+ fraction, while in c, they represent the doped Yb3+ fraction

Since the lattice parameters vary differently along the crystal a- and c-axis from one stoichiometric compound to another, perfect lattice matching between the grown layer and the KY(WO4)2 substrate cannot be obtained simultaneously along both axes. Therefore, for a Yb3+ fraction z that is predefined by the spectroscopic properties required for the intended application and an Y3+ fraction 1−x−y−z that serves to realize the desired refractive index contrast, the overall lattice mismatch in the a-c-plane was minimized by selecting the Gd3+ and Lu3+ fractions x and y, respectively, that lead to equal lattice mismatch Δa and Δc along the a- and c-axis, respectively, according to the equations

The results are indicated in the diagrams of Fig. 3 by the red lines. Obviously, as a direct consequence of the chosen procedure, the red lines are identical for a- and c-axis. The compositions of the investigated samples with minimum lattice mismatch in the a-c-plane are indicated by the red circles, and their compositions and calculated lattice mismatch along the a- and c-axis are summarized in Table 2. The sample with the composition KY0.0Gd0.491Lu0.484Yb0.025(WO4)2 appears in both, the KY1−x–y−0.025GdxLuyYb0.025(WO4)2 and KGdxLuyYb1−x–y (WO4)2 systematic variations. Since we adjusted the compositions only to an accuracy of 10−3, while the lattice parameters in Table 1 have a higher accuracy, the lattice mismatch presented in Table 2 exhibits small deviations between a- and c-axis.

Inspection of the grown samples, the exemplary photographs of two of which are shown in Fig. 2a, demonstrates that sufficiently small lattice mismatch along the a- and c-axis can be obtained with this procedure, such that crack-free layers are grown onto KY(WO4)2 substrates for any composition up to the complete replacement of Y3+ by Gd3+ and Lu3+ ions. The Y3+-free composition that leads to minimum lattice mismatch includes approximately 49 at.% of Gd3+ ions and 51 at.% of Lu3+ ions. Since the optically active Yb3+ ion has a similar ion radius as the Lu3+ ion, it can replace the Lu3+ ion without significantly changing the lattice constants. Consequently, with only small adjustments to the fraction of Gd3+ ions to compensate for the small difference between the ion radii of Lu3+ and the active Yb3+ dopant, crack-free layers with optically active dopant concentrations up to ~50 at.% can be grown. According to Table 2, the maximum lattice mismatch encountered in all the compositions investigated in this study amounts to 0.07378 % for the KGd0.447Lu0.078Yb0.475(WO4)2 sample along the crystal a-axis, a value which is still small enough to allow for the growth of crack-free layers.

In contrast, layer compositions whose lattice constants do not closely match those of the pure KY(WO4)2 substrate, exhibit (usually systematic) crack patterns. Two examples are shown in Fig. 2b. The ~30-μm-thick grown layer of sample A has the composition KY0.600Gd0.130Lu0.246Yb0.024(WO4)2, thus exhibiting a calculated lattice mismatch of −0.0323 and −0.1214 % along the a- and c-axis, respectively, whereas the ~35-μm-thick layer of sample B with composition KGd0.720Lu0.263Yb0.017(WO4)2 has a larger lattice mismatch of −0.4163 and −0.4479 % along the a- and c-axis, respectively. Consequently, in both layers the resulting tensile stress is largest in the direction of the c-axis, although the difference between mismatch in a- and c-axis is rather small in sample B. Depending on its magnitude, the stress can be released via elastic deformation, growth defects, cracks, or fracture. Crack patterns in both layers are clearly visible in Fig. 2b. Evidently, the larger mismatch between layer and substrate of sample B results in a denser crack pattern which, as expected, is oriented along the crystal a*-axis, i.e., almost perpendicular to the c-axis. In the layer of sample A, however, the crack pattern is oriented at a small angle with respect to the a-axis and, thus, not perpendicular to the direction of the largest stress. We have not been able to determine whether the crack patterns occur during LPE or when cooling the sample down to room temperature.

Finally, in an attempt to further increase the Yb3+ dopant concentration, we grew layers of the composition KGd0.425Yb0.575(WO4)2, thereby exceeding the maximum fraction of Yb3+ ions of 53.5 % that can be compensated by Gd3+ ions to achieve the minimum possible lattice mismatch. The calculated lattice mismatch for this composition amounts to 0.06330 and −0.09017 % along the a- and c-axes. As long as the grown layer thickness did not exceed 10 μm, some of the grown layers turned out to be crack-free, while others showed a typical crack pattern, see Fig. 2c.

Taking all these results into account, the lattice mismatch at which crack-free layers can reproducibly be grown is smaller than ~0.08 %.

4 Refractive indices of co-doped layers

Conventionally, the N g , N m , and N p principal axes of the optical indicatrix correspond to the maximum, intermediate, and minimum refractive indices n g , n m , and n p , respectively. In the investigated potassium double tungstates, N p is parallel to the crystal b-axis, which corresponds to the layer growth direction, while N g and N m are located in the a-c-plane, which is the plane of the grown layer (Fig. 1).

Using published Sellmeier coefficients for KY(WO4)2, KGd(WO4)2, KLu(WO4)2, and KYb(WO4)2, which are provided in Table 3, we calculated the dispersion curves of n g, n m, and n p in the pure compounds for the wavelength range 400–1,600 nm (Fig. 4) using the different Sellmeier equations applied by the authors and displayed in Table 3. Gd3+ has a larger electron number but also a larger ion radius than Y3+. The latter effect partially compensates the former, resulting in a rather small enhancement in the electron density of Gd3+ compared to Y3+ and the refractive indices of KGd(WO4)2 compared to KY(WO4)2. Despite their even larger electron numbers, due to the lanthanide contraction, Yb3+ and Lu3+ have smaller ion radii, thereby significantly increasing their electron densities and, hence, the refractive indices of KYb(WO4)2 and KLu(WO4)2.

For layer compositions with a combination of Y3+, Gd3+, Lu3+, and Yb3+ ions, one can estimate the refractive index values n g,m,p in the co-doped layer by the linear approximation

f i are the fractions 1−x−y−z, x, y, and z of the constituent ions i = Y3+, Gd3+, Lu3+, and Yb3+, respectively, in the layer and n g,m,p (i) are the wavelength-dependent refractive indices of the corresponding pure compounds. The sum of fractions f i equals unity. Alternatively, one can apply the Bruggeman effective medium approximation [31]

ε g,m,p (i) ≈ \( {\it{n}}_{\it{g,m,p}}^{2} ({\it{i}}) \) are the wavelength-dependent dielectric constants of the pure compounds and ε g,m,p ≈ \( {\it{n}}_{\it{g,m,p}}^{2} \) are the wavelength-dependent dielectric constants of the co-doped layer. The difference between the results obtained from Eqs. (4) and (5) is less than 1 × 10−5. The refractive index contrast between the co-doped layer, as calculated from Eq. (4), and the undoped KY(WO4)2 substrate is indicated by the white lines in Fig. 3.

Refractive index measurements on a pure KY(WO4)2 substrate, as well as on all co-doped layers of compositions KY1−x−y−0.025GdxLuyYb0.025(WO4)2 and KGdxLuyYb1−x−y (WO4)2, listed in parts (a) and (b) of Table 2, respectively, on KY(WO4)2 substrates were carried out with a Metricon 2010M film prism coupler by dark-m-line spectroscopy [32]. The measurements were performed at different wavelengths of 633, 830, 1,300, and 1,550 nm. For characterization of the in-plane optical axes N g and N m cross polarizers were utilized to approximately pre-orient the substrates. The refractive index n p along the N p optical axis was characterized with transverse-magnetic-polarized light propagating along either the N m or the N g optical axis, in both cases providing identical values for n p . By means of a least-squares fit, from the obtained data we calculated the coefficients of the single-term Sellmeier equation,

with λ in units of μm. The Sellmeier coefficients obtained for the KY(WO4)2 substrate and all investigated co-doped layers are summarized in Table 4.

The measured refractive indices n g , n m , and n p of the KY1−x−y−0.025GdxLuyYb0.025(WO4)2 and KGdxLuyYb1−x−y (WO4)2 layers at the investigated wavelengths are displayed in Fig. 5a, b, respectively, along with the fitted dispersion curves. As a reference, the measured refractive indices and fitted dispersion curves of the KY(WO4)2 substrate were added to each figure. In Fig. 5a, the refractive indices of the co-doped layer gradually increase when replacing Y3+ by a lattice-matching combination of Gd3+ and Lu3+, while in all compositions, the Yb3+ concentration remains fixed at 2.5 at.%. The observed increase in refractive index is mainly due to the partial replacement of Y3+ by Lu3+, as can be seen from Fig. 4: the refractive indices of KLu(WO4)2 are significantly higher than those of KY(WO4)2 and KGd(WO4)2. In Fig. 5b, Lu3+ is gradually replaced by Yb3+, while the Gd3+ fraction changes only slightly to compensate for the small difference in the ionic radii of Lu3+ and Yb3+. Since KLu(WO4)2 and KYb(WO4)2 have similar refractive indices, the observed increase in the refractive index is much less pronounced in this variation.

When comparing the dispersion curves obtained experimentally (Table 4 and Fig. 5) with those estimated from the data of the pure compounds (Table 3 and Fig. 4) by the linear approximation of Eq. (4), we find that especially at the longer wavelengths, from 1,300 to 1,550 nm, the difference between the measured and calculated refractive indices can be as high as 1 × 10−2. Likely, this difference arises because several of the dispersion curves previously presented in the literature (Table 3 and Fig. 4) were obtained from measurements at wavelengths not exceeding 1,200 nm, which leads to extrapolation errors when estimating the refractive indices of the pure compounds and, thus, also the co-doped compounds at longer wavelengths.

Figure 6a, b visualizes the corresponding refractive index contrast with the undoped KY(WO4)2 substrate for the series KY1−x−y−0.025GdxLuyYb0.025(WO4)2 and KGdxLuyYb1−x−y (WO4)2, respectively. The refractive index contrast monotonically increases as Y3+ is replaced by Gd3+, Lu3+, and/or Yb3+ and reaches a maximum of 2 × 10−2 for the N p optical axis when entirely replacing Y3+ by Gd3+ and Yb3+.

Refractive index contrast Δn between the KY(WO4)2 substrate and layers of a KY1−x–y−0.025GdxLuyYb0.025(WO4)2 versus Y3+ content and b KGdxLuyYb1−x–y (WO4)2 versus Yb3+ content, measured at 830 nm wavelength. The green, red, and blue lines represent the N p , N g , and N m optical axes, respectively. The data points in a at 97.5 at.% yttrium content are reference points calculated from Eq. (4) with the data of Table 3

The motivation for investigating the growth of KY1−x−y−z GdxLuyYbz(WO4)2 layers is the quest for a large refractive index contrast between layer and substrate and/or large active dopant concentration. The larger the refractive index contrast between layer and substrate, the smaller is the layer thickness that leads to guiding of only the fundamental optical mode in this layer and the tighter is the confinement of this mode [20, 22]. To confine guided light also in the horizontal direction, a channel waveguide geometry is required. Therefore, grown layers were microstructured by Ar+ beam etching [21], resulting in channel ridge waveguides of typically 2–6 μm height and 4–10 μm width. Growth of a pure KY(WO4)2 cladding layer on top of the microstructured channel waveguide further improves the mode overlap with the channel waveguide region [21].

5 Spectral properties of Yb3+ in co-doped layers

Generally, the positions of energy levels for the trivalent rare-earth ions in the potassium double tungstates do not differ significantly from those in other oxide crystals because of the electronic shielding of the 4f sub-shell by the outer 5s and 5p sub-shells. The two energy states of the Yb3+ ion, the 2F5/2 excited state and 2F7/2 ground state, are split due to the presence of the ligand crystal field into three and four crystal-field levels, respectively. Due to the splitting of only a few hundred cm−1, the partial population distribution within each crystal-field multiplet obeys a Boltzmann distribution. Data for the energy levels in KY(WO4)2 are presented in Fig. 7.

Energy level scheme, including energies [5] and Boltzmann factors of the individual crystal-field levels at a temperature of 300 K, of the Yb3+ ion in the KY(WO4)2 host

On the other hand, the transition cross-sections of RE3+ ions are strongly influenced by the host material. RE3+ ions exhibit higher transition cross-sections in potassium double tungstates than in most other dielectric host materials. Besides, the strongly anisotropic crystal field in these crystals significantly enhances the absorption and emission cross-sections for E||N m polarized light. These cross-sections are altered by the composite materials investigated here. Therefore, an evaluation of the absorption and emission spectra of Yb3+ in KY1−x–y GdxLuy(WO4)2 samples with different compositions was performed, based on the spectra of the KY(WO4)2:Yb3+, KGd(WO4)2:Yb3+, KLu(WO4)2:Yb3+, and KYb(WO4)2 compounds.

For KY(WO4)2:Yb3+, the only spectroscopic data available in the literature are for E||a*, whereas our samples were investigated and devices operated with polarization E||N m . The angular difference of 13.5° between these two polarization directions [2, 11] leads to some deviation in the spectral behavior, as was also observed for the emission cross-sections of KGd(WO4)2:Yb3+ in E||a* and E||N m polarization [33, 34]. We chose the absorption spectrum of KY(WO4)2:Yb3+ from Ref. [5], displayed in Fig. 8a. It exhibits a peak absorption cross-section on the zero-phonon line at 981 nm of 1.33 × 10−19 cm2, which may be more reliable than the other available data [33, 35], because it was measured for a lower dopant concentration of 5 at.%, resulting in a sufficiently large amount of transmitted signal light. On the other hand, for the emission, we chose the spectrum provided in Refs. [33, 35], because it agrees well with the spectral behavior of our measured emission spectrum and can be well reproduced from the measured absorption spectrum of Ref. [5] by the reciprocal method [36] or McCumber theory [37], whereas the emission cross-sections published in Ref. [5] deviate significantly and may have been miscalculated, see Fig. 8a. Furthermore, we used the absorption spectra reported in the literature for KGd(WO4)2:Yb3+ [38], KLu(WO4)2:Yb3+ [39], and KYb(WO4)2 [9], together with their emission spectra calculated with the McCumber theory [37]. We then approximated the absorption and emission cross-sections of KY1−x−y−z GdxLuyYbz(WO4)2 samples with different compositions as the weighted averages of the above-mentioned spectra.

a Comparison of the absorption and emission cross-sections of KY(WO4)2:Yb3+ from Ref. [5] versus Refs. [33, 35] (identical, only one displayed) with polarization E||a*. The measured absorption cross-sections are very similar. The emission cross-sections of Refs. [33, 35] and recalculated from the absorption spectrum of Ref. [5] are also very similar, whereas the emission cross-section presented in Ref. [5] deviates significantly and has possibly been miscalculated. b Comparison of a spontaneous emission spectrum measured in a KY0.60Gd0.13Lu0.253Yb0.017(WO4)2 channel waveguide with the emission spectrum calculated as the weighted average of the emission spectra of the compounds KY(WO4)2:Yb3+, KGd(WO4)2:Yb3+, KLu(WO4)2:Yb3+, and KYb(WO4)2

As an example, the emission spectrum of a KY0.600Gd0.130Lu0.253Yb0.017(WO4)2 layer was recorded for E||N m . The Yb3+ ions were excited by end-coupling to the waveguide the continuous-wave irradiation of a Ti:Sapphire laser at a wavelength of 932 nm. The luminescence emitted in E||N m polarization was collected perpendicular to the surface using a liquid fiber with a polarization filter fixed to its collection end and the spectra were recorded by a spectrophotometer. Figure 8b presents the measured spontaneous emission spectrum from the co-doped waveguide, in direct comparison with the calculated emission spectrum for this composite host material, as described above. The measured intensity spectrum was calibrated to the peak cross-section of the calculated spectrum. Good agreement is found between the two spectra.

When assuming that the spectral data of KY(WO4)2:Yb3+ also hold for the grown composite layers, we were unable to explain the laser and amplifier behavior observed in these layers. In contrast, with the absorption and emission cross-sections calculated as weighted averages in the way described above, we could well reproduce the wavelength-dependent laser performance of KY0.40Gd0.433Lu0.150Yb0.017(WO4)2 channel waveguides [25] and amplifier performance of KGd0.447Lu0.078Yb0.475(WO4)2 channel waveguides [24]. When fitting the measured luminescence peaks at 981 nm of a KY0.983Yb0.017(WO4)2 and a KY0.600Gd0.130Lu0.253Yb0.017(WO4)2 layer to a Lorentzian curve, a full width at half maximum of the emission peak in the co-doped film of 3.6 and 3.8 nm, respectively, was derived [22], indicating that the emission line width is not significantly broadened by co-doping the layer with Gd3+ and Lu3+ ions.

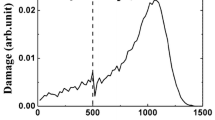

The influence of concentration quenching on Yb3+ luminescence lifetime was measured by pumping the KY1−x−y−z GdxLuyYbz(WO4)2 layers with a switched diode laser operating at 976 nm. Luminescence light at 1,020 nm was collected normal to the sample surface by a multimode glass fiber (NA = 0.24), diffracted by a monochromator, and detected by an amplified InGaAs detector. The measured lifetime values were elongated from 261 to 292 μs for various Yb3+ concentrations increasing from 1.2 to 57.5 at.%, respectively, as presented in Fig. 9a. In order to minimize the lifetime elongation that is typically observed at higher Yb3+ concentrations due to reabsorption of luminescence light [8], we decreased the area of observation by collecting the luminescence with a 50-μm-core fiber positioned directly on top of each thin film. The concentration dependence of the measured Yb3+ luminescence lifetime (squares) is displayed in Fig. 9b. We fitted the equation [40]

to our experimental results, as indicated by the solid line in Fig. 9b. In Eq. (7), τ w = 261 μs is the lifetime at low concentration, σ = 2.92 × 10−21 cm2 is the absorption cross-section taken from Fig. 8a, and N is the dopant concentration, where 1 at.% equals 0.63 × 1020 cm−3. The average absorption length, l ≈ 140 μm, and the critical concentration for concentration quenching, N 0 ≈ 2 × 1022 cm−3, are used as free parameters to fit the concentration dependence of Fig. 9b. The denominator describes the concentration quenching effect, while the numerator accounts for the reabsorption of light. The de-convolution of concentration quenching from reabsorption is performed by applying Eq. (7) without the term σNl, resulting in the dashed line in Fig. 9b. Due to the two-multiplet electronic level scheme of Yb3+, which avoids parasitic spectroscopic processes, and the rather large distance between neighboring Yb3+ ions, which diminishes energy migration within the Yb3+ system and energy transfer to other impurities, the observed lifetime quenching is rather weak, thus allowing for the utilization of large doping concentrations.

Measured lifetimes in KY1−x−y−z GdxLuyYbz(WO4)2 for Yb3+ concentrations ranging from 1.2 to 57.5 at.%. a Luminescence decay curves at 1,020 nm. b Yb3+ lifetime as a function of concentration (squares). Equation (7) with or without the term σNl, respectively, describes the combined effect of concentration quenching and reabsorption (solid line) or solely the concentration quenching (dashed line)

6 Application to a cladding-side-pumped channel waveguide laser

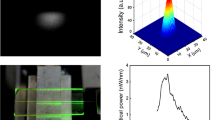

We exploited the information obtained in the previous sections to create a device requiring twofold refractive-index engineering as well as high Yb3+ doping concentration. We fabricated a multi-layer sample, see Fig. 10, comprising a lattice-matched, highly activated KGdxLuyYb1−x−y (WO4)2 channel waveguide on a KY(WO4)2 substrate, according to the investigations presented in Figs. 3c, 5b, and 6b, which was surrounded by a lattice-matched, passive KY1−x−y GdxLuy(WO4)2 planar waveguide, according to the investigations of Fig. 3a and similar to those of Figs. 3b, 5a, and 6a. The chosen compositions were KGd0.447Lu0.078Yb0.475(WO4)2 and KY0.770Gd0.114Lu0.116(WO4)2, resulting in refractive index contrasts of 1.73 × 10−2 and 3.3 × 10−3 with the KY(WO4)2 substrate (in E||N m polarization, at 800 nm), see Fig. 3a, c, respectively, thus ensuring simultaneously channel as well as planar waveguiding. As an application we demonstrated a cladding-side-pumped channel waveguide laser.

Micrographs of the microstructured, horizontally tapered channel waveguide embedded in the planar waveguide, showing a top view of the shape of the taper structure etched into the active layer (top) and end views of the device output (bottom left) and input (bottom right) cross-sections after end-face polishing. The schematic (bottom center) indicates the various material compositions providing a twofold refractive-index-engineered structure. Diode pump light whose propagation direction is indicated by the red arrows is coupled into the passive planar section from the side of the taper structure

The channel waveguide geometry provides compact size to rare-earth-ion-activated solid-state lasers, thereby enabling their integration on a microchip. This approach combines the advantage of tight light confinement and excellent laser mode control achieved in fiber lasers with the significantly larger dopant concentrations and accordingly shorter pump-absorption lengths that are typical of bulk solid-state lasers. Unfortunately, the desired fundamental-mode structure sets clear limitations to the power scaling of channel waveguide lasers: end-pumping schemes require high-brightness fundamental-mode pump sources, however, compact fundamental-mode diode lasers deliver only low optical power. Side-pumping schemes fundamentally solve this problem, but usually replace it by another. On the one hand, in this configuration, the whole length of the active medium becomes available for pump-light coupling, such that high-power diode stripes or bars can be utilized for pumping, allowing for much higher pump powers to be launched into the active medium. On the other hand, the length over which this pump light can be absorbed is drastically reduced—from the length of the active medium in end-pumped configuration—to the diameter of the oscillating laser mode.

In the approach presented here, pump light from a high-power multi-mode diode bar was side-coupled to the passive planar waveguide and guided to the active channel waveguide (Fig. 10). The channel waveguide had a 50-μm-wide multi-mode region that allowed us to increase the pump absorption, connected by a waveguide taper to a fundamental-mode region that acted as a lasing-mode selector in the horizontal direction. To further enhance pump absorption, we chose a high Yb3+ concentration of 47.5 at.%. According to Eq. (7) and Fig. 9b, at this high concentration, the Yb3+ lifetime is only slightly quenched from 261 to 253 μs. The channel waveguide was oriented along the N m optical axis to ensure efficient absorption of N m -polarized pump light; the resulting absorption length at the absorption peak near 981 nm, see Fig. 8a, is ~30 μm. Such short absorption lengths can also be exploited for side pumping in a bulk configuration [41]. Our approach overcomes the limitations of previously demonstrated diode-side-pumped planar waveguide lasers which produced a strongly asymmetric inversion distribution and, therefore, may require an astigmatic external resonator to enable a high-quality laser-beam profile [42].

The diode bar was mounted on a water-cooled chuck without active temperature control. Consequently, the temperature of the cooling chuck varied from 25 °C at low power to 30 °C at maximum power, thereby changing the pump wavelength from 976 to 982.5 nm, respectively (Fig. 11). The pump power was modulated with a frequency of 16 Hz and 2.9 % duty cycle, side-coupled via a set of plan-convex cylindrical lenses to the passive planar waveguide, and propagated over a distance of 0.6 mm in the direction perpendicular to the channel waveguide, until it reached the latter. Owing to polishing non-parallel to the substrate–waveguide interface, the planar waveguide varied in height between 2.5 and 5 μm. The active channel waveguide was 5-mm long and 0.6–1.7-μm high, which ensured fundamental-mode operation in the vertical direction, and was horizontally tapered down from 50 to 5 μm over a length of 2 mm, according to the design presented in Ref. [43]. By use of a fluorinated oil, mirrors with a reflection of 99.8 and 90 % at 1,038 nm were butt-coupled to the polished end-facets of the wide and narrow channel waveguide part, respectively. The laser output was collected from the narrow waveguide end with a ×16 objective lens (NA = 0.32).

After relaxation oscillations, a maximum quasi-continuous-wave laser power of 8 mW was measured. The laser wavelength was slightly shifted from the typical 1,022–1,029 nm [19, 21–23] to a wavelength of 1,038 nm, at which losses owing to reabsorption were diminished, thereby indicating a low population inversion that was caused by non-optimal excitation of the Yb3+ ions in the active waveguide. Nevertheless, the laser wavelength was significantly shorter than the 1,070 nm previously observed in a KYb(WO4)2 bulk sample [10]. Besides the fundamental laser mode, two weaker horizontal side lobes were observed, which originated from the non-adiabatic taper. Since the diode pump wavelength walked off the ideal absorption wavelength, an additional measurement was performed by quickly switching on the diode bar to 30 W. The fairly cold diode bar operated close to the preferred absorption wavelength near 981 nm, resulting in a peak emission of 10 mW over a period of ~20 s, as indicated by the additional measurement point in Fig. 11.

Significant improvement in laser output power can be achieved by addressing a number of issues. (1) The coupling efficiency of pump light into the passive waveguide can be optimized by applying a more suitable lens configuration and an anti-reflection coating. (2) Pump-light coupling from the passive to the active waveguide can be improved by placing the active waveguide at the center height of the passive waveguide and/or increasing its height. (3) A double-pass pump absorption scheme can be realized by placing an additional mirror that reflects the unabsorbed pump light back into the active waveguide section, and simultaneously reducing the width of the active channel waveguide. (4) Diode bars with higher output powers per unit length of several 100 W/cm can be utilized, such that a larger average pump intensity and excitation density can be reached over the entire device length. (5) Improving the surface polishing, thereby obtaining better thickness uniformity of both, the active and passive waveguide, will result in a decreased round-trip loss and laser threshold, hence (6) allowing for larger outcoupling degrees and slope efficiencies.

7 Conclusions

Our systematic study of crystalline layers of the compositions KY1−x−y−0.025GdxLuyYb0.025(WO4)2 and KGdxLuyYb1−x−y (WO4)2 grown onto KY(WO4)2 substrates has shown that, with an appropriate choice of co-dopants, compositions up to the complete replacement of the Y3+ ions can be grown crack-free with high optical quality. A maximum lattice mismatch in the a- and c-axis of 0.07378 % and a maximum refractive-index contrast between layer and substrate of 2 × 10−2, resulting in tight optical mode confinement in planar and channel waveguides, are found. Optically active doping with Yb3+ ions up to ~50 at.% becomes possible. The absorption and emission cross-sections of Yb3+ in these layers can be approximated by weighted averages of the spectra in the compounds KY(WO4)2:Yb3+, KGd(WO4)2:Yb3+, KLu(WO4)2:Yb3+, and KYb(WO4)2. As a result of large rare-earth interionic distances, luminescence lifetime quenching is insignificant even at high doping levels. As an application, a twofold refractive-index-engineered sample combining a highly activated channel and passive planar waveguide was fabricated, and a cladding-side-pumped channel waveguide laser was demonstrated.

References

M. Pollnau, Y.E. Romanyuk, F. Gardillou, C.N. Borca, U. Griebner, S. Rivier, V. Petrov, Double tungstate lasers: from bulk toward on-chip integrated waveguide devices. IEEE J. Sel. Top. Quantum Electron. 13, 661–671 (2007)

A.A. Kaminskii, A.F. Konstantinova, V.P. Orekhova, A.V. Butashin, R.F. Klevtsova, A.A. Pavlyuk, Optical and nonlinear laser properties of the χ(3)-active monoclinic α-KY(WO4)2 crystals. Crystallogr. Rep. 46, 665–672 (2001)

A.A. Lagatsky, N.V. Kuleshov, V.P. Mikhailov, Diode-pumped CW lasing of Yb:KYW and Yb:KGW. Opt. Commun. 165, 71–75 (1999)

N.V. Kuleshov, A.A. Lagatsky, V.G. Shcherbitsky, V.P. Mikhailov, E. Heumann, T. Jensen, A. Diening, G. Huber, CW laser performance of Yb and Er, Yb doped tungstates. Appl. Phys. B 64, 409–413 (1997)

N.V. Kuleshov, A.A. Lagatsky, A.V. Podlipensky, V.P. Mikhailov, G. Huber, Pulsed laser operation of Yb-doped KY(WO4)2 and KGd(WO4)2. Opt. Lett. 22, 1317–1319 (1997)

M.C. Pujol, X. Mateos, R. Solé, J. Massons, J. Gavaldà, X. Solans, F. Díaz, M. Aguiló, Structure, crystal growth and physical anisotropy of KYb(WO4)2, a new laser matrix. J. Appl. Crystallogr. 35, 108–112 (2002)

I.M. Krygin, A.D. Prokhorov, V.P. D’yakonov, M.T. Borowiec, H. Szymczak, Spin-spin interaction of Dy3+ ions in KY(WO4)2. Phys. Solid State 44, 1587–1596 (2002)

K. Petermann, D. Fagundes-Peters, J. Johannsen, M. Mond, V. Peters, J.J. Romero, S. Kutovoi, J. Speiser, A. Giesen, Highly Yb-doped oxides for thin-disc lasers. J. Cryst. Growth 275, 135–140 (2005)

M.C. Pujol, M.A. Bursukova, F. Güell, X. Mateos, R. Solé, J. Gavaldà, M. Aguiló, J. Massons, F. Díaz, P. Klopp, U. Griebner, V. Petrov, Growth, optical characterization, and laser operation of a stoichiometric crystal KYb(WO4)2. Phys. Rev. B 65, 165121 (2002)

P. Klopp, U. Griebner, V. Petrov, X. Mateos, M.A. Bursukova, M.C. Pujol, R. Solé, J. Gavaldà, M. Aguiló, F. Güell, J. Massons, T. Kirilov, F. Díaz, Laser operation of the new stoichiometric crystal KYb(WO4)2. Appl. Phys. B 74, 185–189 (2002)

S.V. Borisov, R.F. Klevtsova, Crystal structure of KY(WO4)2. Sov. Phys. Crystallogr. 13, 420–421 (1968). (Transl.: Kristallografiya 13, 517-519 (1968))

P.V. Klevtsov, L.P. Kozeeva, Synthesis X-ray and thermographic study of potassium rare-earth tungstates, KLn(WO4)2, Ln = rare-earth elements. Sov. Phys. Doklady 14, 185–187 (1969). (Transl.: Doklady Akademii Nauk SSSR 185, 571-574 (1969))

M.C. Pujol, M. Aguiló, F. Díaz, C. Zaldo, Growth and characterisation of monoclinic KGd1-xREx(WO4)2 single crystals. Opt. Mater. 13, 33–40 (1999)

G. Métrat, M. Boudeulle, N. Muhlstein, A. Brenier, G. Boulon, Nucleation, morphology and spectroscopic properties of Yb3+-doped KY(WO4)2 crystals grown by the top nucleated floating crystal method. J. Cryst. Growth 197, 883–888 (1999)

Y.E. Romanyuk, Liquid-phase epitaxy of doped KY(WO4)2 layers for waveguide lasers. Ph.D. thesis, Ecole Polytechnique Fédérale de Lausanne, Lausanne, Switzerland (2006)

P.V. Klevtsov, L.P. Kozeeva, R.F. Klevtsova, Crystallographic study of potassium-yttrium tungstate and molybdate. Izv. Akad. Nauk SSSR Neorgan. Mater. 4, 1147–1151 (1968)

E. Gallucci, C. Goutaudier, G. Boulon, M.T. Cohen-Adad, Growth of KY(WO4)2 single crystal: investigation of the WO3 rich region in the K2O–Y2O3-WO3 ternary system. 2. The KY(WO4)2 crystallization field. Eur. J. Solid State Inorg. Chem. 35, 433–445 (1998)

R. Solé, V. Nikolov, X. Ruiz, J. Gavaldà, X. Solans, M. Aguiló, F. Díaz, Growth of β-KGd1-xNdx(WO4)2 single crystals in K2W2O7 solvents. J. Cryst. Growth 169, 600–603 (1996)

Y.E. Romanyuk, C.N. Borca, M. Pollnau, S. Rivier, V. Petrov, U. Griebner, Yb-doped KY(WO4)2 planar waveguide laser. Opt. Lett. 31, 53–55 (2006)

F. Gardillou, Y.E. Romanyuk, C.N. Borca, R.P. Salathé, M. Pollnau, Lu, Gd co-doped KY(WO4)2:Yb epitaxial layers: towards integrated optics based on KY(WO4)2. Opt. Lett. 32, 488–490 (2007)

D. Geskus, S. Aravazhi, C. Grivas, K. Wörhoff, M. Pollnau, Microstructured KY(WO4)2:Gd3+, Lu3+, Yb3+ channel waveguide laser. Opt. Express 18, 8853–8858 (2010)

D. Geskus, S. Aravazhi, E.H. Bernhardi, C. Grivas, S. Harkema, K. Hametner, D. Günther, K. Wörhoff, M. Pollnau, Low-threshold, highly efficient Gd3+, Lu3+ co-doped KY(WO4)2:Yb3+ planar waveguide lasers. Laser Phys. Lett. 6, 800–805 (2009)

D. Geskus, S. Aravazhi, K. Wörhoff, M. Pollnau, High-power, broadly tunable, and low-quantum-defect KGd1-xLux(WO4)2:Yb3+ channel waveguide lasers. Opt. Express 18, 26107–26112 (2010)

D. Geskus, S. Aravazhi, S.M. García-Blanco, M. Pollnau, Giant optical gain in a rare-earth-ion-doped microstructure. Adv. Mater. 24, OP19–OP22 (2012)

D. Geskus et al. Highly efficient channel waveguide laser at the 981-nm zero-line of Yb3+. (are preparing a manuscript)

M.C. Pujol, R. Solé, J. Massons, J. Gavaldà, X. Solans, C. Zaldo, F. Díaz, M. Aguiló, Structural study of monoclinic KGd(WO4)2 and effects of lanthanide substitution. J. Appl. Crystallogr. 34, 1–6 (2001)

M.C. Pujol, X. Mateos, R. Solé, J. Massons, J. Gavaldà, F. Díaz, M. Aguiló, Linear thermal expansion tensor in KRE(WO4)2 (RE = Gd, Y, Er, Yb) monoclinic crystals. Mater. Sci. Forum 378, 710–717 (2001)

M.C. Pujol, X. Mateos, A. Aznar, X. Solans, S. Surinach, J. Massons, F. Díaz, M. Aguiló, Structural redetermination, thermal expansion and refractive indices of KLu(WO4)2. J. Appl. Crystallogr. 39, 230–236 (2006)

L. Vegard, Die Konstitution der Mischkristalle und die Raumfüllung der Atome. Z. Phys. 5, 17–26 (1921)

M.C. Pujol, M. Rico, C. Zaldo, R. Solé, V. Nikonov, X. Solans, M. Aguiló, F. Díaz, Crystalline structure and optical spectroscopy of Er3+-doped KGd(WO4)2 single crystals. Appl. Phys. B 68, 187–197 (1999)

R. Jansson, H. Arwin, Selection of the physically correct solution in the n-media Bruggeman effective medium approximation. Opt. Commun. 106, 133–138 (1994)

R. Ulrich, R. Torge, Measurement of thin-film parameters with a prism coupler. Appl. Opt. 12, 2901–2908 (1973)

S. Biswal, S.P. O’Connor, S.R. Bowman, Thermo-optical parameters measured in ytterbium-doped potassium gadolinium tungstate. Appl. Opt. 44, 3093–3097 (2005)

H. Liu, J. Nees, G. Mourou, Diode-pumped Kerr-lens mode-locked Yb:KY(WO4)2 laser. Opt. Lett. 26, 1723–1725 (2001)

B.F. Aull, H.P. Jenssen, Vibronic interactions in Nd:YAG resulting in nonreciprocity of absorption and stimulated emission cross sections. IEEE J. Quantum Electron. 18, 925–930 (1982)

D.E. McCumber, Einstein relations connecting broadband emission and absorption spectra. Phys. Rev. 136, A954–A957 (1964)

A. Major, I. Nikolakakos, J.S. Aitchison, A.I. Ferguson, N. Langford, P.W.E. Smith, Characterization of the nonlinear refractive index of the laser crystal Yb:KGd(WO4)2. Appl. Phys. B 77, 433–436 (2003)

X. Mateos, R. Solé, J. Gavaldà, M. Aguiló, J. Massons, F. Díaz, V. Petrov, U. Griebner, Crystal growth, spectroscopic studies and laser operation of Yb3+-doped potassium lutetium tungstate. Opt. Mater. 28, 519–523 (2006)

F. Auzel, G. Baldacchini, L. Laversenne, G. Boulon, Radiation trapping and self-quenching analysis in Yb3+, Er3+, and Ho3+ doped Y2O3. Opt. Mater. 24, 103–109 (2003)

L.J. McKnight, S. Calvez, Gain-guided KYb(WO4)2 laser, in Digest of Europhoton Conference 2010, Europhysics Conference Abstract Vol. 34C (European Physical Society, Mulhouse, 2010), p. 24, paper WeP19

U. Griebner, R. Grunwald, H. Schönnagel, Thermally bonded Yb:YAG planar waveguide laser. Opt. Commun. 164, 185–190 (1999)

R.P. Soon, O. Beom-Hoan, Novel design concept of waveguide mode adapter for low-loss mode conversion. IEEE Photon. Technol. Lett. 13, 675–677 (2001)

Acknowledgments

The authors thank A. Hollink for technical assistance with the growth setup, Yaroslav E. Romanyuk for helpful discussions, and Martin Krejci from Oclaro Inc. for providing the diode bar. This project was financially supported by The Netherlands Organization for Scientific Research (NWO) through the VICI Grant no. 07207 “Photonic integrated structures”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aravazhi, S., Geskus, D., van Dalfsen, K. et al. Engineering lattice matching, doping level, and optical properties of KY(WO4)2:Gd, Lu, Yb layers for a cladding-side-pumped channel waveguide laser. Appl. Phys. B 111, 433–446 (2013). https://doi.org/10.1007/s00340-013-5353-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5353-1