Abstract

We present an efficient, high-brightness laser at 1,112 nm by combining the direct pumping technique with an 885 nm laser diode and the composite crystal. Output power as high as 12.8 W at 1,112 nm is achieved under 22.2 W of absorbed pump power and it yields an optical-to-optical efficiency of 57.7 % and a slope efficiency of 64.0 % with respect to the absorbed pump power. To the best of our knowledge, both of these optical-to-optical and slope efficiencies with respect to the absorbed pump power are the highest values ever reported for 1,112 nm Nd:YAG lasers. Modeling of the temperature rise and stress induced in the laser crystals, with and without the undoped cap, and employing the pump at 808 and 885 nm are performed, respectively. Contributions of the composite crystal geometry and of the pump at 885 nm to lowering the threshold power, enhancing the optical-to-optical and the slope efficiencies with respect to the absorbed pump power are discussed, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past few years, lasers operating around 1.1 μm have increasingly attracted attention [1–3]. Such type of lasers have important applications in laser medical diagnosis, treatment, and therapy, owing to their lower scattering coefficient and a moderate absorption coefficient in blood as compared with the visible and the near-infrared spectral region (i.e., 0.8 to 1.0 μm); higher Lambert absorption coefficient in water; and a smaller extinction coefficient for melanin as compared with the visible spectral region [4–6]. The Nd:YAG single crystal is the most widely used laser gain medium because of its excellent combination of mechanical and thermo-optical properties. Generally, researchers focus on operating the 1,064, 1,319, and 946 nm line in an Nd:YAG crystal [7–9]. However, the 1,112 nm line is another important laser line. In addition, through frequency doubling, this spectral line can generate a yellow–green laser at 556 nm, which has numerous applications in the areas of illumination, display, biological medicine, and chemistry [10–12].

Different schemes have been employed to obtain an efficient laser operation at the 1,112 nm line and its frequency-doubled line. In 1978, Marling [13] first reported a 52 W continuous wave (cw) 1,112 nm laser by using a side-pumped architecture with a krypton arc lamp. The ratio of the output laser optical power to the electrical input power of the arc lamp was below 5 %. By using a diode-end-pumped scheme with an 808 nm laser diode (LD) and a conventional Nd:YAG single crystal, a multi-wavelength 1.1 μm laser with 1,112, 1,116, and 1,123 nm wavelengths was presented in 2006. This laser produced a maximum cw output power of 610 mW and an overall optical-to-optical efficiency (η o-o) of 38.1 % [10]. In 2009, the same group demonstrated a 556 nm laser, producing a 3.2 W output power with an η o-o of ~17.8 % and an M 2 of ~1.7 [11]. In 2010, by adopting a diode-side-pumped structure with an 808 nm LD and a conventional Nd:YAG rod, Li et al. achieved a maximum of 93.7 W cw output at 1,112 nm, with an η o-o of ~16.4 %, M 2 of ~17, and a slope efficiency (η s) of ~30.1 % [14]. In 2012, using acousto-optical Q-switching and intracavity frequency doubling with an LBO crystal, Wang et al. acquired an average output power as high as 83 W at 556 nm, having an η o-o of ~7.2 % and an M 2 of ~40 [12].

Efficient operations with high power and high brightness are difficult to realize. First, the stimulated-emission cross-section at 1,112 nm is only 3.6 × 10−20 cm2 [15]. This area leads to a high lasing threshold that requires a strong pump intensity, possibly resulting in a serious thermal lens effect, and consequently, severely deteriorating the beam quality. Second, the ratio between the stimulated-emission cross-sections at 1,112 nm and at 1,064 nm is ~0.08 [15]. This ratio indicates a serious mode competition, necessitating the introduction of high cavity losses at 1,064 nm to favor the emission at 1,112 nm. In addition, the 1,116 and 1,123 nm lines with equivalent gains would further deteriorate the mode competition, posing a significant challenge to the coating design [10–12].

Most of the previous works above focused on the 808 nm pump line, whereas direct pumping remains rare in the 1,112 nm lasers. In this transition, pumping directly with an 885 nm LD enhances the quantum defect ratio between the pump and the laser wavelengths for the 1,112 nm laser emission by ~10 %, inducing a corresponding increase of η s and a decrease of the lasing threshold. A reduction in the absorbed power fraction transformed into heat by ~25 % is expected under an efficient laser emission [16, 17]. Therefore, our group first studied the diode-direct-pumped 1,112 nm laser. Employing a diode-end-pumped structure with an 885 nm LD and a conventional Nd:YAG single crystal, we achieved a maximum of 12.5 W infrared laser output, having an optical-to-optical efficiency with respect to the absorbed pump power (\( \eta_{o - o}^{a} \)) of ~46.6 %, a slope efficiency with respect to the absorbed pump power (\( \eta_{s}^{a} \)) of ~52.9 %, \( M_{x}^{2} \) of ~ 2.92, and \( M_{y}^{2} \) of ~2.87 [18].

In this paper, a compact, efficient 1,112 nm laser was developed. By combining the direct pumping technique with an 885 nm LD and the composite crystal, an output as high as 12.8 W at 1,112 nm was achieved under 22.2 W of absorbed pump power, yielding an \( \eta_{o - o}^{a} \) of 57.7 % and a \( \eta_{s}^{a} \) of 64.0 %. To the best of our knowledge, both these \( \eta_{o - o}^{a} \) and \( \eta_{s}^{a} \) values are the highest among those reported for 1,112 nm Nd:YAG lasers. The temperature and the stress intensity distributions of three different schemes for the 1,112 nm laser, including the conventional Nd:YAG crystal under 808 nm pumping (Scheme 1), the composite YAG/Nd:YAG crystal under 808 nm pumping (Scheme 2), and the composite YAG/Nd:YAG crystal under 885 nm pumping (Scheme 3), were simulated and analyzed. The contributions of the composite crystal and the 885 nm direct pumping to reducing the maximum temperature rise and the maximum stress intensity were evaluated. The equivalent thermal lens focal length (f T) was simulated and experimentally measured. The contributions of the composite crystal and the 885 nm direct pumping to increasing f T was examined. Finally, the characteristics of the cw output at 1,112 nm were demonstrated. Similarly evaluated were the contributions of the composite crystal and the 885 nm direct pumping to lowering the threshold power with respect to the absorbed pump power (\( P_{th}^{a} \)), enhancing \( \eta_{o - o}^{a} \) and \( \eta_{s}^{a} \).

2 Experimental setup

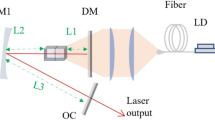

A compact, simple plano-concave cavity was employed to generate the 1,112 nm laser, as shown in Fig. 1. Compared with the 808 nm pump, the lower absorption coefficient of Nd:YAG at 885 nm necessitates a substantially higher pump power incident on the crystal (therefore more powerful LD) for the direct 885 nm pumping. In this case, a fiber-coupled laser diode array (LDA) purchased from DILAS Inc. served as the pump source, delivering a maximum output power of 40 W at 885 nm from the end of a fiber with a core diameter of 400 μm and a numerical aperture of 0.22. The line width was only 1.4 nm, which is beneficial to the overlap with the gain medium’s absorption spectra. The pump radiation was injected into the laser crystal through two coupling lenses with a waist spot diameter of ~600 μm. The doped portion of the composite YAG/Nd:YAG crystal was 3 × 3 × 8 mm and a Nd3+-doped concentration of 1.0 at. %. The undoped cap of the composite crystal was 4 mm long. The laser crystal was wrapped by an indium foil, mounted in a copper heat sink, and maintained at 20 °C ± 0.1 °C by a thermal electric cooler. Both surfaces of the crystal were well polished and coated for high transmission (HT) at 1,112 nm (T > 99.8 %) and the pump wavelengths (T > 99 %). A special coating was established to suppress the parasitic transitions with higher stimulated-emission cross-sections, including the transitions at 938, 946, 1,064, 1,318, and 1,338 nm as well as the 1,116 and 1,123 nm lines with equivalent gains. M1 was coated to be highly reflective at 1,112 nm (R > 99.8 %) and for HT at 885, 1,064, 938, and 946 nm with transmissions of ~95, 95, 70, and 70 %, respectively. M2, with a 200 mm radius of curvature, was coated for HT at 1318 and 1338 nm (T > 90 %) as well as partial transmission at 1,112, 1,116, and 1,123, nm with 2.2, 2.6, and 3.4 %, respectively. The geometric cavity length was ~27 mm. The laser output power was tested with a 30(150)A-SV power sensor and recorded with a NOVA II power meter (Ophir Inc.,).

3 Analysis and simulations

The temperature and the stress intensity distributions were simulated according to the experimental boundary conditions by using the LASCAD software. The result was compared with that of Schemes 1 and 2 to evaluate the performance improvement of the composite YAG/Nd:YAG crystal under 885 nm pumping (Scheme 3). The total dimensions of the composite crystal were 3 × 3 × 12 mm (type 1), of which the undoped cap was 4 mm long. The dimensions of the conventional crystal were 3 × 3 × 8 mm (type 2). In the simulation, the spatial distribution function of the pump beam was.

where \( \omega {}_{p}(z) \) represents the spot radius of the pump beam, given by

where ω p0 is the pump beam waist, z and z 0 are the distances from the entrance surface of the crystal and the pump beam waist location, respectively, and θ is the beam divergence. Table 1 indicates the other main parameters [19–21]. Figure 2 depicts the simulated results; the highest temperatures in the laser crystal for Schemes 1, 2, and 3 are ~358, 346, and 325 K, respectively. Accordingly, the resulting maximum temperature increases in the laser crystal for Schemes 1, 2, and 3 are ~65, 53, and 32 K, respectively. Comparing the contributions of the composite crystal and the 885 nm direct pumping to reducing the maximum temperature rise is interesting. By comparing the reduction in the maximum temperature rise between Schemes 1 and 2, a reduction rate of ~19 % was determined and this value could be considered as the contribution of the composite crystal. Accordingly, by comparing the reduction in the maximum temperature increase between Schemes 2 and 3, a reduction rate of ~40 % was determined and this value can be considered as the contribution of the 885 nm direct pumping. In this case, the 885 nm direct pumping serves a more important role in reducing the maximum temperature rise in the laser crystal for the 1,112 nm laser operation. Furthermore, the highest temperature of the conventional Nd:YAG crystal in Scheme 1 lies on (0, 0, 0), whereas for the composite crystal in Schemes 2 and 3, the highest temperatures appear on (0, 0, 5) and (0, 0, 5.5), respectively. These coordinates are, respectively, about 1 and 1.5 mm away from the undoped–doped interface instead of the injected face of the gain medium. Moreover, the temperature homogeneity of the doped parts along the crystal length was enhanced remarkably when using Scheme 3.

f T was simulated and experimentally measured to evaluate the thermal lens effect induced by the optical pumping in the laser crystal. From Fig. 3, the simulated f T data for Schemes 1, 2, and 3 were obtained under the absorbed pump powers of ~10, 15, 20, and 22.2 W, respectively. The fitted solid lines indicate that f T is a function of the absorbed pump power (P abs), that is, f T = 1639×\( P_{\text{abs}}^{ - 1} \), 2033 × \( P_{\text{abs}}^{ - 1} \), and 3016 × \( P_{\text{abs}}^{ - 1} \) for Schemes 1, 2, and 3, respectively. In measuring f T in the 1,112 nm laser, the output mirror M2 was replaced with a plane one (T = 2.2 %). Under lasing conditions, the g 1 g 2 parameter of the cavity can be determined by considering the laser crystal as a thin lens. The cavity length was changed until the laser oscillation rapidly vanished [16]. At this point, f T becomes comparable with the cavity length. Figure 3 illustrates the experimental results. Considering that the experimentally measured data were in good agreements with the fitted solid lines resulting from the simulated data, the reliability of the LASCAD simulation was verified. Furthermore, based on the fitted lines, the contribution of the composite crystal and the 885 nm direct pumping to increasing f T was evaluated. The f T increasing rates were determined to be ~24 % and 48 % for the composite crystal and the 885 nm direct pumping, respectively. These rates indicate that the 885 nm direct pumping serves a more important role in increasing f T compared with the composite crystal. Therefore, the thermal lens effect can be effectively reduced when using Scheme 3 in the 1,112 nm laser. These results reveal that the composite crystal under 885 nm pumping endured a much lower heat load and weaker thermal lens effect; therefore, this scheme could enhance the laser’s efficiency with a better beam quality.

Figure 4 indicates the simulated results of the stress intensity distributions for all three schemes. The maximum stress intensity of the conventional crystal in Scheme 1 is ~77 N/mm2, which lies in the injected face of the crystal. The peak value appears on (1.5, 0, 0), which is the periphery of the crystal instead of the center of the xoy plane. This location corresponds with Chen’s [22] experimental results in fiber-coupled diode-end-pumped solid-state lasers, indicating that the thermal fracture is most likely initiated at the periphery of the front face for a conventional crystal. By contrast, the maximum stress intensities of the composite crystal in Schemes 2 and 3 appear on (0, 0, 5.5) and (0, 0, 6), that is, the center of the xoy plane is 68 and 45 N/mm2, respectively. This result indicates that, for the composite crystal, the thermal fracture is most likely initiated at the center of the xoy plane, and the location along the z axis may vary with the pump beam waist location (z 0 ) and the pump line in the diode-end-pumped solid-state lasers. Similar to the comparison in reducing the maximum temperature increase, we evaluated the contribution of the composite crystal and the 885 nm direct pumping to the reduction in the maximum stress intensity, the rates of which were determined as ~12 and 34 % for the composite crystal and the 885 nm direct pumping, respectively. Likewise, the 885 nm direct pumping serves a more important role in reducing the maximum stress intensity in the laser crystal for the 1,112 nm laser operation. These results indicate that, when employing Scheme 3, the gain medium suffers less thermal stress, which is beneficial to extending the fracture-limited pump power and scaling the diode-end-pumped lasers to a high output power [23].

Under the above-mentioned experimental conditions, the radius of the laser mode in the middle of the laser crystal (ω 1) and the g 1 g 2 parameter associated with the stability of the laser cavity are shown in Fig. 5. These values were calculated by using an ABCD matrix formalism including M 2 (assuming 2) with the approximation of a thin lens in the middle of the laser crystal [24]. In Fig. 5, both ω 1 and g 1 g 2 are nearly constant within a broad region of f T from 200 to 1,000 mm. Therefore, to a large extent, such a cavity is insensitive to the thermal lens effect. Furthermore, the resonator remains in the stability zone when f T is 50 mm, that is, the laser can maintain stable operations even under high pump power and intense focusing conditions.

4 Experimental results and discussions

The optical power of the pump beam was measured before and after it passes through the laser crystal under different LDA currents to determine the absorbed pump power. The maximum pump power directly incident on the crystal was ~38.0 W, and the maximum absorbed pump power was ~22.2 W. Figure 6 depicts the characteristics of the cw output at 1,112 nm versus the absorbed pump power. Under Scheme 1, a maximum output power of 7.6 W at 1,112 nm was obtained for the absorbed pump power of 22.2 W. \( \eta_{o - o}^{a} \) was 34.2 %, \( \eta_{s}^{a} \) was 39.9 %, and \( P_{th}^{a} \) was ~3.2 W. Under Scheme 2, using the composite crystal as the laser crystal, a maximum output power of 9.5 W at 1,112 nm was obtained for the absorbed pump power of 22.2 W, having an \( \eta_{o - o}^{a} \) of ~42.8 %, \( \eta_{s}^{a} \) of ~49.8 %, and \( P_{th}^{a} \) of ~3.1 W. Under Scheme 3, the 4 F 3/2 emitting level in the composite crystal was pumped at 885 nm. 12.8 W of output power at 1,112 nm was achieved for the absorbed pump power of 22.2 W, yielding \( P_{th}^{a} \) of ~ 2.1 W. \( \eta_{o - o}^{a} \) and \( \eta_{s}^{a} \) were ~57. and 64.0 %, respectively. To the best of our knowledge, these values are the highest among those reported in diode-pumped Nd:YAG lasers at 1,112 nm. The relative errors for all the calculated efficiencies were approximately ±6 %. In addition, the laser exhibits good short-term stability. The instability of the 1,112 nm laser is less than 1.0 % at the maximum output power of 12.8 W within a given period of 30 min.

Although a slight difference exists in the linewidths of the 808 and 885 nm pump source, that is, 3.0 versus 1.4 nm, respectively, the experimental results clearly indicated a reduction in the pump threshold and remarkable enhancement of the efficiencies after employing Scheme 3. We believe that two factors are mainly responsible for these improved results. One is the composite crystal, which can improve the thermal load uniformity along the crystal length, as compared with a conventional crystal. Considering the undoped pumped cap, the surface contribution to the thermal lens caused by an end bugling is almost eliminated, making the compensation for the thermal lens favorable [25, 26]. The other factor is the direct pumping, which could decrease the heat load caused by the quantum defect between the pump and the laser emission wavelengths, as well as reduce the pump threshold and increase η o-o [16, 17].

Evaluating the contributions of the composite crystal and the 885 nm direct pumping to lowering \( P_{th}^{a} \) is worthwhile. The lasing threshold reduction rates were determined to be ~3 and 32 % for the composite crystal and the 885 nm direct pumping, respectively. Therefore, the 885 nm direct pumping serves a more important role in lowering \( P_{th}^{a} \) for the 1,112 nm laser operation, as compared with the composite crystal, which hardly reduced the threshold power. Similarly, the contribution to enhancing \( \eta_{s}^{a} \) was evaluated. The increasing rates of \( \eta_{s}^{a} \) were determined to be ~25 and 29 % for the composite crystal and the 885 nm direct pumping, respectively. Therefore, the contributions of the composite crystal and the 885 nm direct pumping to the enhancement of \( \eta_{s}^{a} \) were comparable with the 1,112 nm laser operation. However, when \( \eta_{o - o}^{a} \) was considered, the increasing rates were determined to be ~25 and 35 % for the composite crystal and the 885 nm direct pumping, respectively. Thus, the 885 nm direct pumping serves a more important role in enhancing \( \eta_{o - o}^{a} \) for the 1,112 nm laser operation.

The transverse mode of this laser was measured by using an M 2-200 s-FW laser beam analyzer (Ophir–Spiricon Inc.) at the maximum output power of 12.8 W. Figure 7 indicates that the measured beam quality factor at the maximum output power are \( M_{x}^{2} \) = 2.01 in the horizontal axis and \( M_{y}^{2} \) = 2.20 in the vertical axis. The high beam quality was attributed to the combination of the direct pumping with the 885 nm LD and the composite gain medium. The inset depicts the 3D spatial intensity distribution, wherein the symmetrical transverse mode assumes nearly a Gaussian distribution for both directions.

The lasing spectrum of the infrared output was monitored with a fiber spectrometer (NIRQuest, Ocean Optics Co. Ltd.). Figure 8 illustrates the optical spectrum of the 1,112 nm laser at the highest output power. Only one single lasing line is present at 1,112 nm, indicating that both the more efficient transitions of 1,064, 1,318, 1,338, and 946 nm and the 1,116 and 1,123 nm lines with equivalent gains (inset) were suppressed successfully.

5 Conclusion

In conclusion, we have developed an efficient, high-brightness laser at 1,112 nm by combining the direct pumping technique with an 885 nm LD and the composite crystal. A maximum output power of 12.8 W was obtained with \( \eta_{o - o}^{a} \) of ~57.7 %, \( \eta_{s}^{a} \) of ~64.0 %, \( M_{x}^{2} \) of ~2.01, and \( M_{y}^{2} \) of ~2.20. To the best of our knowledge, both these \( \eta_{o - o}^{a} \) and \( \eta_{s}^{a} \) values are the highest among those reported for 1,112 nm Nd:YAG lasers. The experimental results indicate that the contributions of the composite crystal and the 885 nm direct pumping to the enhancement of \( \eta_{s}^{a} \) are comparable with the 1,112 nm laser operation. However, the 885 nm direct pumping serves a more important role in lowering \( P_{th}^{a} \) and enhancing \( \eta_{o - o}^{a} \) for the 1,112 nm laser operation, as compared with the composite crystal. The next step will concentrate on the highly efficient 556 nm lasers with high brightness and high stability through intracavity frequency doubling.

References

Y.F. Chen, Y.P. Lan, S.W. Tsai, Opt. Commun. 234, 309 (2004)

A. Pietrzak, H. Wenzel, G. Erbert, G. Tränkle, Opt. Lett. 33, 2188 (2008)

S. Uetake, A. Yamaguchi, S. Kato, Y. Takahashi, Appl. Phys. B 92, 33 (2008)

G.M. Hale, M.R. Querry, Appl. Opt. 12, 555 (1973)

A. Roggan, M. Friebel, K. Doerschel, A. Hahn, G.J. Mueller, J. Biomed. Opt. 4, 36 (1999)

I.V. Meglinski, S.J. Matcher, Physiol. Meas. 23, 741–753 (2002)

S. Konno, S. Fujikawa, K. Yasui, Appl. Phys. Lett. 70, 2650 (1997)

R. Zhou, E.B. Li, H.F. Li, P. Wang, J.Q. Yao, Opt. Lett. 31, 1869 (2006)

H.Y. Zhu, G. Zhang, C.H. Huang, Y. Wei, L.X. Huang, J. Chen, W.D. Chen, Z.Q. Chen, Appl. Opt. 46, 384 (2007)

F.Q. Jia, Q. Zheng, Q.H. Xue, Y.K. Bu, Opt. Laser Technol. 38, 569 (2006)

Q. Zheng, Y. Yao, D.P. Qu, K. Zhou, Y. Liu, L. Zhao, J. Opt. Soc. Am. B 26, 1939 (2009)

Z.C. Wang, J.L. Xu, Y. Bo, Q.J. Peng, S.Y. Xie, Y.T. Xu, F. Yang, J.Y. Zhang, D.F. Cui, Z.Y. Xu, Laser Phys. 22, 142 (2012)

J. Marling, IEEE J. Quantum Electron. 14, 56 (1978)

C.Y. Li, Z.C. Wang, Y.T. Xu, F. Yang, B.S. Wang, H.W. Gao, Y. Bo, Q.J. Peng, D.F. Cui, Z.Y. Xu, Laser Phys. 20, 1572 (2010)

S. Singh, R.G. Smith, L.G. Van Uitert, Phys. Rev. B 10, 2566 (1974)

N. Pavel, T. Taira, IEEE J. Sel. Topics Quantum Electron. 11, 631 (2005)

N. Pavel, K. Lünstedt, K. Petermann, G. Huber, Appl. Opt. 46, 8256 (2007)

J. Gao, X.J. Dai, L. Zhang, X.D. Wu, Laser Phys. Lett. 10, 015802 (2013)

T.Y. Fan, IEEE J. Quantum Electron. 29, 1457 (1993)

W. Koechner, Solid-State Laser Engineering (Springer, New York, 2006)

Y. Sato, T. Taira, Opt. Express 14, 10528 (2006)

Y.F. Chen, IEEE J. Quantum Electron. 35, 234 (1999)

Y.F. Chen, T.M. Huang, C.F. Kao, C.L. Wang, S.C. Wang, IEEE J. Quantum Electron. 33, 1424 (1997)

P.A. Belanger, Opt. Lett. 16, 196 (1991)

M. Tsunekane, N. Taguchi, T. Kasamatsu, H. Inaba, IEEE J. Sel. Top. Quantum Electron. 3, 9 (1997)

Y.F. Ma, X. Yu, F.K. Tittel, X.D. Li, Opt. Commun. 285, 1911 (2012)

Acknowledgments

This work was supported by the Knowledge Innovation Program of the Chinese Academy of Sciences (CAS) under contract KGCX2-YW-910, the Natural Science Foundation of Jiangsu Province with grant BK2011330, and a grant from the Youth Innovation Promotion Association, CAS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, J., Dai, X.J., Zhang, L. et al. Highly efficient continuous-wave composite Nd:YAG laser at 1,112 nm under diode pumping directly into the emitting level. Appl. Phys. B 111, 407–413 (2013). https://doi.org/10.1007/s00340-013-5348-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-013-5348-y