Abstract

An azo chromophore molecule 4-[(benzothiazole-2-yl)diazenyl]phenyl-1,3-diamine (BTPD) was prepared with 2-amino benzothiazole and m-phenylenediamine by diazo-coupling reaction. Then, the chromophore molecule BTPD was polymerized with NJ-210 and isophorone diisocyanate (IPDI) to obtain novel azo benzothiazole polymer (BTPU). The structures of BTPD and BTPU were characterized using the Fourier transform infrared, UV–visible spectroscopy, DSC and TGA. The physical properties of the obtained BTPU were investigated. The refractive index (n) of BTPU was demonstrated at different temperature and wavelength (532, 650 and 850 nm) using attenuated total reflection technique. The transmission loss and dispersion characteristic of BTPU film were investigated using the CCD digital imaging devices and Sellmeyer equation. A Y-branch and 2 × 2 Mach–Zehnder interferometer (MZI) polymeric thermo-optic switches based on the thermo-optic effect of prepared BTPU were proposed and the performance of switches was simulated. The results indicated that the power consumption of the Y-branch thermo-optic switch could be only 0.6 mW. The Y-branch and MZI switching rising and falling times obtained were 8.0 and 1.8 ms.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, azo polymers have received much attention owing to their potential application in nonlinear optical (NLO) materials, optical data storage, optical information transmission, sensors and actuators, holographic data recording systems, optical switching and processing [1–5]. In past decades, azo polymers with different polymeric structures have been synthesized, such as side-chain polymers, main-chain polymers, dendritic polymers, crosslinked network, and block copolymers [6–10].

When compared with silica-based materials, polymer materials have attracted considerable attentions in applications of optical waveguide and optical interconnection because of their easy processability, relatively low cost good compatibility with semiconductor materials, good thermal stability, precisely adjustable refractive index, chemical and environmental resistance, strong interfacial adhesion on substrates as well as facile controllability of optical properties [11–13]. Optical switches and related arrays play an important role in optical communication networks. With the development of communication system, the optical switch which with low crosstalk, low loss, low power consumption as well as wavelength and polarization insensitivity is preferable in optical networks [14]. A multitude of switches, such as the switches based on micro-optoelectronic mechanical systems (MOEMS), those based on the liquid crystal, etc., can be candidates for all-optical networks. However, as compared to the above switches, the waveguide switches show wide potential application for their high reliability because no moving part is contained in such switches. Among various optical waveguide switches, the thermo-optic (TO) waveguide switch is one of the fundamental device structures that are essential for achieving reconfigurable functionality through their optical switching function. Conventional thermo-optic waveguide switches are usually based on the Y-branch structure or the Mach–Zehnder interferometer (MZI) structure. The former is usually made of the polymer materials and has the advantages of medium device size, smaller crass-talks, and larger operation bandwidth, but it also has the disadvantages of larger power consumption. The latter is usually made of the silica materials and has the advantages of low power consumption and 2 × 2 operation. However, it also has the disadvantages of larger device size, narrower operation bandwidth, and larger cross-talks. One can see that the advantages and disadvantages of these two conventional approaches are somehow complementary.

Noh et al. [15] reported a thermo-optic 2 × 2 switch based on ultraviolet curable fluorinated polymer. The cross talks of initial bar and cross states, the power consumption and switching time are more than 40 dB, 350 mW and <7 ms, respectively. Han et al. [16] presented a polymer 1 × 2 thermo-optic total-internal-reflection digital optical switch (TIR-DOS). The structure of TIR-DOS was created by adding a reflection port to that of a conventional multimode filtering variable optical attenuator. The electrical power consumption of fabricated 1 × 2 TIR-DOS is 18 mW. Wang et al. [17] reported a thermo-optic 2 × 2 switch based on the fluorinated polymer. The fabricated device has a power consumption of 66 mW in the bar state. Yeo and Shin [18] reported a polymer-silica hybrid 1 × 2 Y-branch thermo-optic switch. The top cladding and the core layers are composed of polymer, while the bottom cladding layer is made of silica. The switching power of the proposed device is about 70 mW. In this work, a novel azo benzothiazole polymer (BTPU) has been successfully prepared. The chemical structure and thermo-optic property of BTPU were well characterized and demonstrated. A Y-branch thermo-optic switch and a waveguide-integrated 2 × 2 Mach–Zehnder interferometer (MZI) switch operating at the infrared communication wavelength of 1,550 nm were proposed and theoretically discussed. To the best of our knowledge, this is the first time that the prepared azo benzothiazole polymer (BTPU) is reported.

2 Experimental

2.1 Materials

Polyether polyol (NJ-210, Mn = 1,120 g/mol) was produced by Ningwu Chemical CO., Ltd. in Jurong, Jiangsu, China. Isophorone diisocyanate (IPDI) was supplied by Rongrong Chemical Co., Ltd. in Shanghai, China. m-phenylenediamine was provided by Shanghai Aladdin reagent Co., Ltd, Shanghai, China. 2-amino benzothiazole, N, N-Dimethylformamide (DMF) and Dibutylbis (lauroyloxy) tin (T-12) were obtained from Sinopharm Chemical Reagent Co. Ltd., Shanghai, China. The other reagents and solvents were obtained commercially and were used as received.

2.2 Characterization

FT-IR spectra of samples were obtained between 4,000 and 400 cm−1 with an FTIR spectrometer (AVATAR 360, Madison, Nicolet). A minimum of 32 scans was signal-averaged with a resolution of 2 cm−1 in the 4,000–500 cm−1 ranges. Ultraviolet–visible (UV–vis) spectra of samples were recorded with a Shimadzu (Japan) UV-2450 spectrometer at 25 °C. Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) were performed on a Netzsch (Germany) STA 449C instrument. The programmed heating range was from room temperature to 1,000 °C at a heating rate of 10 °C/min under a nitrogen atmosphere. The measurement was taken with 6–10 mg samples. The tensile strength and elongation at break testing for polymer film were carried out on a tensile tester (KY-8000A, Jiangdu Kaiyuan Test Machine, Jiangdu, China) at room temperature at a speed of 50 mm/min. All measurements had an average of three runs. The dumbbell-type specimen was 30 mm length at two ends, 0.2 mm thick and 4 mm wide at the neck. The hardness was measured with a sclerometer (KYLX-A, Jiangdu Kaiyuan Test Machine) (Jiangdu, China); measurements were done three times for the polymer sample, and the average value was calculated. The thermal conductivity, thermal diffusion coefficient, and specific heat capacity of polymer film were obtained from a thermal conductivity detector (TC3010, Xi’an Xiaxi Electronic Technology Co., Ltd, Xi’an, China) at room temperature.

2.3 Preparation of azo benzothiazole polymer (BTPU)

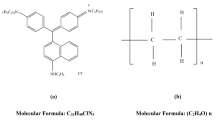

m-phenylenediamine (1.08 g) was added 10 mL DMF to make its solution. 2-Amino benzothiazole (1.50 g), 10 mL H2O, and NaNO2 (0.84 g), were mixed to form a paste, which was poured into a mixture of crushed ice and 5.0 mL concentrated sulfuric acid (H2SO4). The reaction was carried out for 2.0 h in an ice bath. After neutralizing with sodium hydroxide (NaOH) dissolved in H2O for 0.5 h, the solution was washed with water until 5–7. The diazonium salt solution was added slowly into the solution of m-phenylenediamine during stirring and the mixture reacted for 2 h. The solution was placed for overnight. The next day, the product was filtered, washed with water to neutral and dried. A chromophore molecule 4-[(benzothiazole-2-yl) diazenyl]phenyl-1,3-diamine (BTPD) was prepared.

NJ-210 (10 g) and IPDI (5.6 g) dissolved in DMF (15 mL) were added into a 250 mL four-necked flask equipped with a mechanical stirrer, thermometer and reflux condenser. Dibutylbis(lauroyloxy)tin (T-12, 1.0 mL) as a catalyst was added and the mixture was stirred at 80 °C for 3 h to prepare the –NCO prepolymer. Then, the BTPD (2.65 g) dissolved in 12 mL DMF was added into the mixture and further stirred for 3 h at 65 °C. The red product was dried at 60 °C under vacuum for 24 h. The synthetic route of azo benzothiazole polymer (BTPU) was shown in Scheme 1.

3 Results and discussion

3.1 Structure characterization

The UV–Vis absorption spectra of the BTPD and BTPU are shown in Fig. 1. From Fig. 1, two absorption peaks of the BTPD and BTPU are observed at 343 and 480 nm, 343 and 480 nm, respectively, corresponding to the π–π* and n–π* transitions of the absorption peak (–N=N– groups).

FT-IR spectra of BTPD and BTPU are shown in Fig. 2. From the FT-IR spectrum of BTPD, it shows that the band at 3,543 cm−1 is corresponded to the stretching vibration of free and hydrogen-bonded NH groups. The absorption peak at 2,930 cm−1 is attributed to the stretch vibration of Ar–H bond. The symmetrical vibration of –N = N– group was observed at 1,505 cm−1, indicating that the –N=N– group existed. According to the FT-IR spectra of BTPU, the characteristic absorption peak corresponded to the stretching vibration of free and hydrogen-bonded NH groups is observed at 3,480–3,550 cm−1. The bond at 1,256 cm−1 is attributed to the stretching vibration of C–N. In addition, the absorption band at 1,672 cm−1 is corresponded to the stretch vibration of ester group bond, showing that the BTPU contain the –OCONH– and –NHCONH-groups. The disappearance of the peak at 2,273 cm−1, which corresponded to the -NCO group, indicated that the -NCO had reacted with -NH2 completely.

3.2 The physical property of BTPU

Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) were performed and the curves were shown in Fig. 3. From Fig. 3, the glass transition temperature (Tg) and the decomposition temperature (Td) at 5 % mass loss of BTPU were 135 and 262 °C, respectively. The results indicate that the BTPU has excellent thermal stability. The thermal conductivity, thermal diffusion coefficient, and specific heat capacity of BTPU film were obtained from a thermal conductivity detector (TC3010, Xi’an Xiaxi Electronic Technology Co., Ltd, Xi’an, China) at room temperature and were shown in Table 1. The tensile strength, elongation at break and hardness of BTPU film were measured and also listed in Table 1.

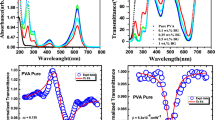

3.3 Thermo-optic property of BTPU

Thermo-optic coefficient (dn/dT) is the variation of refractive index depended on the temperature and is the main factors to affect the driver power and response speed of the optical switch. Measurement of refractive indices was performed using attenuated total reflection (ATR) technique [5, 6]. In the experiment, the prepared BTPU solution, which was filtered through a syringe with a 0.45-μm Teflon filter before it was applied, was spin-coated onto the hypotenuse face of a prism and dried in vacuum overnight at room temperature to evaporate traces of the solvents. The typical thickness of the fabricated films is between 0.2 and 15 μm. Then, a laser beam (λ = 532, 650 or 850 nm) passed through a polarizer, then reached the interface between the prism and the gold film with an appropriate angle. The reflected light was detected by a photodiode and averaged to reduce the noise. The prism–waveguide coupling system and detector were mounted on a high precision θ/2θ computer-controlled goniometer and a series of dips in reflectivity due to resonant transfer of energy into guide modes were generated on a computer screen and saved in a data file. The setup accuracy and distinguishability of the apparatus are ±0.001 and ±0.0005, respectively. The scanned ATR spectra of BTPU polymer were shown in Fig. 4. The various synchronization angles of the ATR spectra at different temperature were measured. The refractive index of the BTPU film at different temperature and at different laser wavelength was shown in Fig. 5. The dn/dT of BTPU were −4.320 × 10−4 °C−1 (532 nm), −5.566 × 10−4 °C−1 (650 nm) and −6.211 × 10−4 °C−1 (850 nm), respectively. The dn/dT of BTPU was bigger than those of inorganic materials such as zinc silicate glass (5.5 × 10−6 °C−1), silica glass (10.8 × 10−6 °C−1), borosilicate glass (4.1 × 10−6 °C−1) and organic materials such as poly(methyl methacrylate) (−1.20 × 10−4 °C−1), polystyrene (−1.23 × 10−4 °C−1) and azo PUI (−4.0296 × 10−4 °C−1)[19].

3.4 Transmission loss and dispersion characteristic property of BTPU

Transmission loss of optical waveguide in thin film is an important parameter which evaluates the dielectric slab waveguide. Transmission loss of optical waveguide devices is produced mainly by the following factors: waveguide material loss caused by scattering and absorption; substrate surface finish by polishing process constraints, irregular interface leading coupling loss between guided mode and radiation mode; curved waveguide surface, causing the loss caused by energy radiation. The digital imaging device Charge Coupled Device (CCD) was used to record the scattered light intensity of points on the transmission line, and transfer into an internal light intensity.

After spatial average filter, a transmission attenuation curve can be obtained. The attenuation loss of the guided mode power with propagation distance can be expressed:

where P 0 is initial incident light intensity of Z = 0, P Z is transmission light intensity of Z = z, the attenuation coefficient is defined as:

L is the transmission loss of optical waveguide.

In optical communication systems, light is used to transport information between different users. The scattered relative light intensity distribution of optical waveguide BTPU along the propagation path was measured by CCD device and the results were shown in Fig. 6. The transmission loss was obtained and the value was 0.244 dB/cm. It was clearly seen that the optical transmission loss of BTPU thin film waveguide was comparatively smaller than some materials such as tin oxide (3 ± 0.5 dB/cm) [20], polymer PMMA (0.94 dB/cm) [21], poled polyimide (1.01 dB/cm) [22] and azobenzene polyurethane (0.565 dB/cm) [23]. Digital optical switch (DOS) has become, since its invention, a very attractive component for space switching in multi-wavelength optical communication system applications. Therefore, the conclusion of the experiment has a little significance to develop new DOS.

The dispersion relation between refractive index and wavelength can be expressed by Sellmeyer dispersion equation:

where, λ is the incident laser wavelength (vacuum), A, B and C are the coefficients of Sellmeyer dispersion equation. The coefficients A, B and C of BTPU at different temperature were shown in Table 2. The dispersion curves of BTPU at different temperatures were shown in Fig. 7. The results showed BTPU had a normal dispersion characteristic.

3.5 Design and simulation of 1 × 2 Y-branch thermo-optic switch

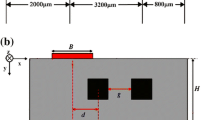

In this work, a 1 × 2 Y-branch polymeric thermo-optic switch based on thermo-optic effect of prepared BTPU was designed and shown in Fig. 8. The BTPU thin film waveguide was determined to be buried square waveguide (BSC) with a 3 × 3 μm2 cross section. The BSC waveguides have the advantage of good fiber-to-waveguide coupling and little polarization dependency compared with the rectangular waveguide. When the heater is turned on, the refractive index under the heater is decreased due to the thermo-optic characteristics of the polymer material.

The upper cladding thickness was determined to be 5 μm to avoid mode attenuation to the heater. The heater was a heating electrode. When an electric current passed through the electrode, the electric resistance of electrode generated heat. The refractive indices of core and cladding are 1.4976 and 1.4879 (1,550 nm), respectively. The parameters for the polymer are as follows: (1) thermo-optic coefficient = −6.51 × 10−4 °C−1 (1.55 μm); (2) specific heat capacity = 3.22 kJ/(kg K); (3) density = 1,080 kg/m3; (4) thermal conductivity coefficient = 0.09188 W/(m K). With these parameters and the branching angle of 0.143°, the thermo-optic switch was analyzed using finite difference beam propagation method (FD-BPM) by introducing constant refractive index difference (△n) between branches along propagation distance which leaded to the difference in effective refractive index (△N eff).

The field distribution at the output waveguides with heating of BTPU was shown in Fig. 9. From Fig. 9, the results indicated that the thermo-optic effect could influence the optical field. The optical power of the output terminal was calculated when two branches had different refractive indexes. The output power dependence on △n was shown in Fig. 10. From Fig. 10, the thermo-optic switches all were turned off when the △n was 5.5 × 10−4.

The distribution of optical field at △n = 5.5 × 10−4, distribution of temperature at Z = 4,000 μm and isotherm of temperature field were shown in Figs. 11, 12 and 13, respectively. According to the thermo-optic coefficient, when the heat rates of the heating electrodes was 7.5 × 104 W/m2, the temperature difference of the sandwich layer of BTPU in the two branches was 0.69 °C. The power consumption of thermo-optic switch could be only 0.6 mW. The simulated switching behaviors in time (under the electrode heating) had also been performed and were shown in Fig. 14. It can be seen that the stable temperature was 274.65 K and a 8.0 ms switching time can be achieved with the present design. This is a significant improvement in reducing the power consumption when compared with those of the normal Y-branch polymer thermo-optic switch.

3.6 Design and simulation of 2 × 2 Mach–Zehnder interferometer (MZI) thermo-optic switch

2 × 2 Mach–Zehnder interferometer (MZI) thermo-optic switch with two rib waveguides, dual driving electrodes and two critical 3 dB couplers based on the thermo-optic effect of prepared BTPU was designed and shown in Fig. 15. The length of power divider, interference arm and arc were 430 μm, 5,000 and 2,000 μm, respectively. The total length is 14,860 μm. The distance of the input port is 20 μm (centre distance). The distance of the narrowest point is 4 μm. The other parameters are the same as above.

The optical power of the output terminal was calculated when two arms had different refractive indexes. The output power dependence on △n was shown in Fig. 16. From Fig. 16, the thermo-optic switches all were turned off when the △n was 2.2 × 10−4.

The distribution of optical field of BTPU when the switch was turned on or off and distribution of temperature field of steady-state were shown in Figs. 17 and 18 respectively. According to the thermo-optic coefficient, when the heat rates of the heating electrodes was 8.0 × 104 W/m2, the temperature difference of the sandwich layer of BTPU in the two branches were 0.348 °C. The response rising and falling time of the switches (under the electrode heating) had also been performed and were shown in Fig. 19. From Fig. 19, the rising (t rise) and falling (t fall) time of BTPU were about 1.8 ms.

4 Conclusion

A novel azo benzothiazole polymer (BTPU) was successfully prepared. The refractive index (n) of BTPU was determined at different temperature and wavelength (532, 650 and 850 nm) by attenuated total reflection (ATR) technique. The thermo-optic coefficient of BTPU film was −4.320 × 10−4 °C−1 (532 nm), −5.566 × 10−4 °C−1 (650 nm) and −6.211 × 10−4 °C−1 (850 nm), respectively. Using the CCD digital imaging devices, transmission loss of BTPU was measured and the value was 0.244 dB/cm. A Y-branch thermo-optic switch and a waveguide-integrated 2 × 2 Mach–Zehnder interferometer (MZI) switch operating at the infrared communication wavelength of 1,550 nm were proposed and theoretically discussed. The results showed that the power consumption of the designed Y-branch thermo-optic switch could be only 0.6 mW, and the response time was about 8.0 ms. Moreover, the response time of the MZI switch was about 1.8 ms. These obtained results have significance in developing thermo-optic switch or other related field.

References

F.X. Qiu, Z.L. Da, D.Y. Yang, G.R. Cao, P.P. Li, Dyes Pigments 77, 564 (2008)

L. Angiolini, T. Benelli, L. Giorgini, F. Mauriello, E. Salatelli, Sensor. Actuat. B 126, 56 (2007)

X. Ke, X. Yan, N. Srisanit, M. Wang, J. Yang, X. Huang, S. Zhong, Opt. Commun. 217, 69 (2003)

E. Heydari, E. Mohajerani, A. Shams, Opt. Commun. 284, 1208–1212 (2011)

J.H. Liu, F.X. Qiu, G.R. Cao, Y.J. Guan, Q. Shen, D.Y. Yang, Q. Guo, J. Polym. Sci. B 49, 939 (2011)

F.X. Qiu, Z.J. Cao, G.R. Cao, Y.J. Guan, Q. Shen, Q. Wang, D.Y. Yang, Mater. Chem. Phys. 135, 518 (2012)

D.M. Junge, D.V. McGrath, J. Am. Chem. Soc. 121, 4912 (1999)

Y. Tian, K. Watanabe, X. Kong, J. Abe, T. Iyoda, Macromolecules 35, 3739 (2002)

F.X. Qiu, C.H. Ge, X.X. Gu, D.Y. Yang, Int. J. Polym. Anal. Charact. 16, 36 (2011)

R.H. Lambeth, J.S. Moore, Macromolecules 40, 1838 (2007)

H. Yu, L.H. Wang, Z.G. Wang, X.Y. Han, M.S. Zhao, Polymer 51, 14 (2010)

J.W. Kang, J.P. Kim, W.Y. Lee, J.S. Kim, J.S. Lee, J.J. Kim, J. Lightwave Technol. 19, 872 (2001)

S.H. Baek, J.W. Kang, X.D. Li, M.H. Lee, J.J. Kim, Opt. Lett. 29, 301 (2004)

I. Yulianti, A.S.M. Supa’at, S.M. Idrus, A.M. Al-Hetar, Opt. Laser Technol. 42, 180 (2010)

Y.O. Noh, J.M. Kim, M.S. Yang, H.J. Choi, H.J. Lee, Y.H. Won, S.G. Han, IEEE Photonic. Technol. Lett. 16, 446 (2004)

Y.T. Han, J.U. Shin, S.H. Park, S.P. Han, Y. Baek, C.H. Lee, Y.O. Noh, H.H. Park, ETRI J. 33, 275 (2011)

X. Wang, B. Howley, M.Y. Chen, R. Chen, IEEE Photonic. Technol. Lett. 18, 16 (2006)

D.M. Yeo, S.Y. Shin, Opt. Commun. 267, 388 (2006)

F.X. Qiu, D.Y. Yang, G.R. Cao, R.X. Zhang, P.P. Li, Sens. Actuat. B 135, 499 (2009)

R.B. Patil, R.K. Puri, V. Puri, Appl. Surf. Sci. 255, 4272 (2009)

S.J. Park, K.S. Cho, C.G. Choi, Colloid Interf. Sci. 258, 425 (2003)

W. Shi, C.S. Fang, Y. Sui, J. Yin, Opt. Commun. 183, 304 (2000)

J.H. Liu, F.X. Qiu, G.R. Cao, Q. Shen, Z.J. Cao, D.Y. Yang, J. Appl. Polym. Sci. 121, 2572 (2011)

Acknowledgments

This project was supported by the Agricultural Independent Innovation of Jiangsu Province (CX(11)2032), China Postdoctoral Science Foundation (2011M500865), Jiangsu Key Laboratory for Chemistry of Low-Dimensional Material (JSKC12105) and the Innovation Program for Graduate Education of Jiangsu Province (CXZZ12_0696).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Z., Qiu, F., Wang, Q. et al. Preparation, thermo-optic property and simulation of optical switch based on azo benzothiazole polymer. Appl. Phys. B 111, 93–102 (2013). https://doi.org/10.1007/s00340-012-5311-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5311-3