Abstract

We report one- and two-dimensional arbitrary patterns which are achieved by nanocavity waveguides made of a quasi-metal–dielectric-metal heterostructure with omnidirectional illumination. This proposed heterostructure supports the surface plasmon polaritons whose phase and group velocities have opposite sign for given frequency. Negative refraction and reflection in the waveguide result in imaging nanolithography and the omnidirectional property can be well understood by the dispersive relation of the nanocavity waveguide. Numerical results demonstrate that such an omnidirectional nanolithography scheme is feasible for arbitrary 1D gratings and 2D linearly chirped gratings with TM and circular polarized incidence, respectively, at 365 nm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Photolithography is a powerful microfabrication technique for high-resolution, low-cost and mass fabrication over the past several decades. However, the traditional photolithography is fundamentally limited by the optical diffraction limit. To overcome the resolution barrier, enormous efforts have been devoted to developing subwavelength lithography techniques, such as focused ion-beam lithography [1], electron-beam lithography [2], imprint lithography [3], and so on. Each of them faces its own disadvantages even though these techniques have obtained great success for fabricating nanoscale devices.

Recently, plasmonic lithography [4–15] became available to achieve higher resolution beyond the optical diffraction limit due to the excitation of surface plasmon polaritons (SPPs), whose wavelength is much smaller than that of light in free space at the same frequency. It has been demonstrated that nanoscale gratings can be generated by the surface plasmon interference occurring at the near-field of corrugated metallic film or metallic mask [4, 5]. A metal–dielectric–metal (MDM) structure was introduced to achieve high-density nanoscale photolithography utilizing surface plasmon effects [6–10]. The MDM waveguide structure could be designed to support the first diffraction order [8] or higher diffraction order [9, 10] waves of the mask and make resonant interference lithography. And these all are based on the nonradiative surface plasmon mode existed in the waveguide. Other interference lithography schemes were also mentioned for one- or two-dimensional (1D, 2D) regular nanoscale patterns [11–15]. With the rapid progress in the semiconductor devices, however, various irregular nanoscale structures are becoming imperative. Subwavelength imaging for mask with different slit widths was theoretically investigated by a noncontact scheme with a near-field imaging transfer scheme and the object plane and the imaging plane are both at the same side of the metal layer [16]. To the best of our knowledge, projecting nanoscale patterns with arbitrary figures and varied period based on surface plasmons have still not been reported so far. Furthermore, the patterning nanoscale structures independent of the incident angle of light are highly desirable for practical applications. In this work, we introduce a nanolithography scheme which makes use of the disparate property of nanocavity to achieve 1D and 2D irregular nanoscale patterns at the wavelength of 365 nm with appropriate polarization. Such scheme can achieve nanolithography with omnidirectional illumination, which is feasible for practical applications and with less cost.

2 Nanocavity waveguide structure and its property

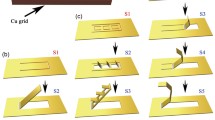

The proposed nanocavity structure consists of a quasi-metal–dielectric–metal waveguide heterostructures (QMDMWHS), as shown in Fig. 1. It is sandwiched by a quartz and wafer substrate and illuminated by a transverse magnetic (TM) light with an incidence angle θ. In the QMDMWHS, a chromium (Cr) mask is a linearly chirped 1D grating, and the mask can be fabricated by electron-beam lithography and lift-off process. The photoresist (PR) layer is sandwiched between the Cr mask and a metal layer.

Generally, a mask can be considered as a film when the slit is narrow enough in contrast to its period. In this work, the proposed QMDMWHS can be approximatively performed as a metal–dielectric–metal (MDM) waveguide structure. The dispersion relation of the MDM waveguide structure can be analyzed through applying Maxwell’s equations to the multilayer system [17].

where the subscripts i = 1, 2, and 3 indicate the photoresist layer, metal slab, and chromium layer, respectively. D is the thickness of the photoresist layer. k 0 is the incident wave vector in free space.

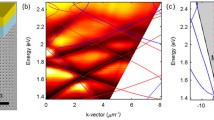

Figure 2 shows the dispersive curve of a Cr–PR–Ag waveguide with 60 nm PR thickness (Fig. 2, inset) with a TM polarization light. The Drude model, \( \varepsilon \left( \omega \right) = \varepsilon_{\infty} - \omega_{p}^{2} [\omega (\omega + iV_{c} )]^{ - 1} \), is used to describe the permittivity of both the Cr and Ag, where the parameters, \( \varepsilon_{\infty } = 3.2, \) \( \omega_{p} = 2.2 \times 10^{16} {\kern 1pt} {\kern 1pt} {\text{rad}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\text{s}}^{ - 1} \) and \( V_{c} = 3.8 \times 10^{15} {\kern 1pt} {\kern 1pt} {\text{rad}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\text{s}}^{ - 1} \) for Cr and \( \varepsilon_{\infty } = 6.0, \) \( \omega_{p} = 1.5 \times 10^{16} {\kern 1pt} {\kern 1pt} {\text{rad}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\text{s}}^{ - 1} \) and \( V_{c} = 7.73 \times 10^{13} {\kern 1pt} {\kern 1pt} {\text{rad}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\text{s}}^{ - 1} \) for silver. The refractive index of the negative photoresist in this work is 1.7. Below the band marked by the box in Fig. 2 is the nonradiative surface plasmon. Due to their bound nature, the SPPs excitations need special phase-matching techniques such as grating or prism coupling. The works in [8–10] are all utilizing this surface plasmon mode to achieve resonant interference lithography. Above the box is the radiative surface plasmon. Some interesting phenomena can be seen from the dispersion band marked by the box, which is the motive of this work. Firstly, it can be seen that the SPP group and phase velocities in the box have opposite signs. That means the effective plasmonic mode index in the photoresist core is negative, which will lead to negative refractive in the waveguide [18, 19]. We show an intuitionistic sketch map of the Fourier information of a slit propagating in the waveguide in Fig. 3. The diffraction order waves from the slit will propagation and arise negative refraction at the mask/photoresist interface. The reflected waves (dashed line) will interact with forward waves from the slit and result in the information of the slit concentrated in the photoresist and the adjacent slit will affect weakly with each other. Higher diffraction orders, of course, will be considered as the same way as the first two orders waves presented in Fig. 3 while with weak intensity. Secondly, such a flat dispersion band marked by the box indicates that the SPP group and phase velocities have opposite signs for all incidence angles at the working wavelength range concerned, which makes the practical application convenient. The perforated mask, used as one layer of the nanocavity, will be reproduced in the PR layer independent of the incidence angle. Only its intensity reduces along with the increasing of the incident angle as less light will transmit through the slit at higher incident angles.

To understand the scheme better, we demonstrate the direction of electrical and magnetic in the waveguide, by finite element method (FEM) for the proposed structure in Fig. 4a, b, respectively. Clearly, the electrical and magnetic fields are moving in phase in the photoresist layer while the magnetic field is out of phase on both sides of the middle plane in the photoresist layer. The electromagnetic wave reflected from the PR/metal interfaces interferes with the incoming wave from the slits. This helps in preventing the interaction of adjacent electric field from neighboring apertures and thus high-density patterning becomes feasible [6].

3 Numerical results and discussion

3.1 One-dimensional case

We first consider patterning a 1D linearly chirped nanoscale grating with the proposed scheme at a working wavelength of 365 nm (i-line) with TM polarization and normal incidence. Figure 5a shows the total electric field intensity distribution of the proposed configuration calculated by FEM. The Cr mask is perforated with linearly increased period (increased by 20 nm step) and the period started from 140 nm, as shown in Fig. 1. Note that with no matter how wide of the slit, it will be principle imaged in the photoresist layer with this proposed scheme, and the more width of the slit the more effect of concentration will be demonstrated. However, considering the fabrication technique and applications nowadays, we investigate the case of the slits with its width 40 nm. The thickness of the slit is 40 nm. The thickness of photoresist and Ag film are 60 and 30 nm, respectively. The zero value along the vertical axis corresponds to the mask/photoresist interface. The boundary conditions in x and z directions are both perfect matched layer (PML). The permittivity of the silver is \( \varepsilon_{\text{Ag}} = - 2.4347 + 0.1263i \) at 365 nm from Drude model. Clearly the linearly chirped nanoscale 1D gratings were well reproduced in the photoresist without the influence from the adjacent slits. In order to confirm this effect, we did the same simulation for the control configuration where the silver film and the substrate were replaced by a PR with the same thickness (see Fig. 5b). It is shown that the electric field in the photoresist was redistributed. Furthermore, from Fig. 2 the flat disperse band indicates that the slits will be reproduced with omnidirectional illumination. We simulated the configuration as Fig. 5a with the incidence angles θ = 0°, 20°, 40°, 60°, and 80°, respectively, and images of the slits with high quality were also obtained for all these cases (not shown here). Figure 5c illustrates the electric field intensity in the PR at z = 30 nm for these incidence angles with TM polarization of 365 nm incidence. The electric field intensity decreased with the incidence angle increasing, while the intensity contrast of these patterns is more than 0.81, which well satisfies the minimum contrast required for common negative photoresist [20].

a The electric field intensity distribution in the proposed configurations for the TM-polarized incidence of 365 nm. The thickness of the Cr mask and the slit width are all 40 nm. The period of the mask starts from 140 nm and linearly increased with a step of 20 nm. The thickness of the PR and silver is 60 nm and 30 nm, respectively. b The electric field intensity distribution for the same configuration except that the silver layer and the wafer substrate were replaced by a PR with the same thickness. c The electric field intensity in the PR in the plane of z = 30 nm for different incidence angles for the configuration (a). d The electric field intensity in the PR in the plane of z = 30 nm for different incidence angles for arbitrary gratings. The case of θ = 80° has had its intensity increased two fold compared to the case of other incidence angles. (The grating’s dimensions are in text)

We then demonstrate patterning arbitrary 1D structure by this proposed method. The mask is a perforated grating with arbitrary period and slit width. The slits width are 40, 20, 30, 10, 10, 30, 20, 40, 40, 40, 40, 40, 40, and 40 nm, respectively, and the Cr width between the slits are 100, 100, 100, 100, 100, 100, 100, 120, 100, 70, 120, 105, and 190 nm, respectively. The thickness of mask, photoresist, and silver film are the same with the above 1D chirped grating. The total electric field intensity distribution of the proposed configuration was calculated by finite-difference time-domain method at 365 nm with TM polarization. Figure 5d illustrates the electric field intensity in the PR at z = 30 nm at the incidence angles of θ = 0°, 20°, 40°, 60°, and 80°, respectively. This arbitrary 1D structure was again reproduced in the photoresist. For the two narrower slits (i.e., 10 and 20 nm width), it is easy to understand its lower intensity due to its lower transmission from the mask. Thus, it is feasible to resolve two slits with 10 nm width and center-to-center 110 nm by this proposed scheme.

3.2 Two-dimensional case

The proposed method can also be easily extended to 2D patterns generation with circular polarization illumination. We still use the above MDM structure while the mask is a 2D pattern linearly chirped both in x and y directions, as shown in Fig. 6a, b for x–y plane and x–z plane, respectively. The thickness of the Cr mask is 40 nm, and the width of the slits is 60 nm. The period of the mask is originated from 160 nm and increased with a 20 nm step, both in x and y directions. The slits of the mask were also filled with the photoresist. The thickness of the photoresist layer is 60 nm. The total electric field intensity distribution of the 2D imaging patterns in the PR layer was analyzed at different incidence angles θ = 0°, 20°, and 40°, respectively, with circular polarization light at 365 nm. Well-defined 2D patterns were reproduced in the photoresist layer by the proposed scheme (not shown here). As an example, we here demonstrate the total electric field intensity distribution in the plane of z = 35 nm at normal incidence, shown in Fig. 6c. The intensity contrast is more than 0.24, which satisfies the minimum required for the common negative photoresist [20].

The cross-section of a x–y plane, b x–z plane of the proposed configuration of the two-dimensional linearly chirped nanoscale patterns. The thickness of the Cr mask is 40 nm, and the slit width is 60 nm. The period of the mask originated from 160 nm and increased with a step of 20 nm, both in x and y directions. c The total electric field intensity distribution in the PR plane at z = 35 nm for normal incidence with circular polarized illumination at 365 nm

4 Conclusion

In conclusion, we proposed a nanolithography scheme for patterning arbitrary 1D and 2D nanoscale structures independent of incidence angle for a given working wavelength. The nanolithography scheme can resolve the object with a width of 10 nm and center-to-center distance 110 nm with 365 nm light. With appropriate mask and instruments, we believe that our proposed imaging lithography technique will extend to resolve the object with width and center-to-center distance both in the tens of nanometer. The patterns developed in the photoresist layer can be transferred to the wafer substrate by two steps of ion-beam etching and reactive ion etching processes. This scheme provides a method to pattern arbitrary nanoscale structures independent of the incident angle for practical applications and should be interesting to fabrication of plasmonic devices and relative structures.

References

J. Melngailis, A.A. Mondelli, I.L. Berry, R. Mohondro, J. Vac. Sci. Technol., B 16, 927 (1998)

C. Vieu, F. Carcenac, A. Pepin, Y. Chen, M. Mejias, A. Lebib, L. Manin Ferlazzo, L. Couraud, H. Launois, Appl. Surf. Sci. 164, 111 (2000)

S.Y. Chou, P.R. Krauss, P.J. Renstrom, Science 272, 85 (1996)

X. Luo, T. Ishihara, Appl. Phys. Lett. 84, 4780 (2004)

W. Srituravanich, N. Fang, C. Sun, Q. Luo, X. Zhang, Nano Lett. 4, 1085 (2004)

D.B. Shao, S.C. Chen, Opt. Express 13, 6964 (2005)

M.D. Arnold, R.J. Blaikie, Opt. Express 15, 11542 (2007)

X. Yang, L. Fang, B. Zeng, C. Wang, Q. Feng, X. Luo, J. Opt. 12, 045001 (2010)

W. Ge, C. Wang, Y. Xue, B. Cao, B, Zhang, K. Xu, Opt. Express 19, 6714 (2011)

X. Yang, W. Li, D.H. Zhang, Appl. Phys. A 107, 123 (2012)

X. Jiao, P. Wang, D. Zhang, L. Tang, J. Xie, H. Ming, Opt. Express 14, 4850 (2006)

L.L. Doskolovich, E.A. Kadomina, I.I. Kadomin, J. Opt. A: Pure Appl. Opt. 9, 854 (2007)

T. Xu, L. Fang, J. Ma, B. Zeng, Y. Liu, J. Cui, C. Wang, Q. Feng, X. Luo, Appl. Phys. B 97, 175 (2009)

V.M. Murukeshan, K.V. Sreekanth, Opt. Lett. 34, 845 (2009)

X. Yang, B. Zeng, C. Wang, X. Luo, Opt. Express 17, 21560 (2009)

V. Intaraprasonk, Z. Yu, S. Fan, J. Opt. Soc. Am. B 28, 1335 (2011)

A. Mainer, Plasmonics: Fundamentals and Applications (Berlin, Springer, chapter 2, pp 30, 2007)

I.I. Smolyaninov, Y.-J. Hung, C.C. Davis, Science 315, 1699 (2007)

J. Lezec Henri, A. Dionne Jennifer, A. Atwater Harry, Science 316, 430 (2007)

M. J. Madou, Fundamentals of Microfabrication (CRC Press, Boca Raton, FL, 2002)

Acknowledgments

This work is supported by A*Star (092154009), National Research Foundation (NRF-G-CPR 2007-01), Singapore. X.F. Yang acknowledges support from the National Natural Science Foundation of China (Grant No. 11104063) and Doctor Funding Project of Henan Polytechnic University (Grant No. B2011-082).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, X., Zhang, D.H., Xu, Z. et al. Designing arbitrary nanoscale patterns by a nanocavity waveguide with omnidirectional illumination. Appl. Phys. B 109, 215–219 (2012). https://doi.org/10.1007/s00340-012-5197-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5197-0