Abstract

Numerical simulations show the advantage of using a top-hat intensity profile pumping the amplifier stage in an Ho:LuLiF4 (Ho:LLF) master oscillator power amplifier (MOPA) configuration over a Gaussian pump profile: higher pulse energies could be generated simultaneously with reduced peak fluence in Q-switched operation. In the experimental implementation, the top-hat beam was realized with a coherent beam transformation of the non-absorbed pump beam transmitted by the oscillator to pump the amplifier stage. The Ho:LLF MOPA produced 103.6 mJ at a repetition rate of 100 Hz with a pulse duration of 30 ns at a wavelength of 2053 nm, which corresponds to an optical-to-optical efficiency of 12.9 %. The beam quality was nearly diffraction limited (M 2 = 1.03).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Q-switched solid-state lasers operating in the eye-safe 2 μm wavelength range have applications in a number of areas, including remote sensing, coherent lidar, and medicine, and can be useful for pumping mid-infrared optical parametric oscillator materials. Initial work on 2-μm holmium lasers concentrated on thulium-holmium co-doped operation [1]. More recently, work has concentrated on Ho lasers resonantly pumped by diode-pumped Tm lasers [2, 3]. With the emergence of high-power Tm-doped fiber lasers, efficient and robust Ho:YAG lasers were demonstrated in oscillator [4–6] and MOPA configuration [7]. First work on in-band pumping of Q-switched Ho:YAG lasers by laser diodes at 1.9 μm was published [8]. However, in order to achieve high-energy Q-switched operation, Ho doped fluorides are more attractive laser materials than Ho:YAG as they have much longer upper laser level lifetimes (~14 ms) and higher emission cross sections (1.6 × 10−20 cm2 around 2050 nm vs. 1.2 × 10−20 cm2 at 2090 nm for Ho:YAG) [9, 10]. In addition, the thermal lens is weak and divergent which helps to generate diffraction limited beams even under intense end-pumping. However, Ho:YLF has a somewhat stronger quasi-three-level nature than Ho:YAG [11]. Efficient Q-switched operation of Ho:YLF was demonstrated in oscillator [12, 13] and MOPA configuration [14], as well as single frequency operation from a ring laser cavity [15, 16] and MOPA configuration [17] using mode-matched pumping.

Nowadays, the interest shifts towards investigating other materials in search of potentially more efficient or otherwise beneficial Ho doped laser media. One of these “new” materials is singly doped Ho:LuLiF4 (Ho:LLF). In the Ho:LLF crystal, the smaller host ion size of Lu3+ leads to larger crystal fields and, as a result, larger crystal field splitting of lanthanide ions [18]. A comparative study on thulium-holmium co-doped YLF and LLF laser hosts highlighted the preference of LLF material [19, 20]. Efficient operation in continuous-wave (CW) mode from an in-band pumped singly doped Ho:LLF laser was reported [21].

This paper starts with a numerical simulation of a Ho:LLF amplifier and compares the expected results using a Gaussian and a top-hat beam pump profile. In the following, a Ho:LLF MOPA system is described which was designed to provide damage-free high-pulse energy operation at low repetition rate (100 Hz). We used the approach to pump a relatively short oscillator crystal, which absorbs roughly half the pump power under lasing conditions [22]. The transmitted pump beam with a Gaussian intensity distribution is then converted into a nearly top-hat distribution using a coherent beam transformer for pumping the amplifier stage. These results are compared with those obtained recently from a Ho:LLF MOPA using a Gaussian pump beam profile for the amplifier [23].

2 Amplifier simulation

The simulation has been performed using a two-dimensional rotational symmetric amplifier model [22]. It considers upconversion losses and ground-state depletion, as well as the spatial distribution of the pump and laser beam in radial and axial discretization. Pump and seed laser spot radius (1/e 2) was set to 650 μm and a total pump power of the amplifier of 50 W and a seed laser pulse energy of 37 mJ with a pulse duration of 30 ns at a repetition rate of 100 Hz were assumed, which is close to the values measured in [23]. The other parameter values used in the simulation are listed in Table 1. A single pass of pump and seed laser beam is considered and no thermal effects were taken into account. Figure 1 shows the calculated amplifier energy as a function of amplifier crystal length with Gaussian (sgp = 2) and top-hat (assuming sgp = 10) pump beam profile. The average intensity of the pump beam is ~3.8 kW/cm2 and, therefore, ~5 times the saturation intensity of Ho:LLF at the pump wavelength of 1940 nm (the pump beam is assumed to be unpolarized and an average value for σ- and π-polarization has been taken). This leads to strong bleaching of the amplifier crystal and, therefore, it is evident that the amplifier energy increases with increasing crystal length. Figure 2 shows the radial fluence distribution (integrated intensity of the amplified laser beam over the pulse duration) at the exit face for three different lengths of the amplifier crystal. With the top-hat pump profile, the peak fluence is reduced and more energy is extracted in the wings of the pump beam compared to the Gaussian pump profile. In addition, in case of a top-hat pump profile, the amplified beam radius at the exit face is nearly constant with increasing crystal length. However, in case of a Gaussian pump profile, there is a beam narrowing at the exit face with increasing crystal length of the amplifier. The same holds for the transmitted pump beam: in case of a top-hat profile the transmitted pump beam radius at the exit face is nearly constant, whereas the transmitted pump beam narrows for a Gaussian pump profile. This can be understood by the quasi-three-level nature of Ho:LLF. In order to reach net gain on the laser line in the amplifier, about 25 % of the Ho ions need to be pumped into the upper laser manifold [20]. Hence, with increasing crystal length the gain is more and more restricted to the center of the Gaussian pump profile, where the intensity is high enough to obtain effective inversion. A top-hat pump profile leads to a larger gain region, where the energy can be extracted more efficiently by the seed beam. Therefore, higher pulse energies should be expected using a top-hat pump profile. Since damage thresholds of standard optical coatings on well-polished surfaces are on the order of 20–45 J/cm2 [11] at pulse widths of several tens of ns, a beneficial reduction in peak fluence should be obtained using a top-hat pump profile simultaneously to the increase in efficiency of the amplifier stage.

Results of a simulation of amplifier energy as a function of amplifier crystal length with Gaussian (sgp = 2) and top-hat (sgp = 10) pump beam profile at pump power of 50 W and seed energy of 37 mJ. All other parameters used in the simulation are listed in Table 1

Results of a simulation of fluence at the exit face of the amplifier crystal as a function of radius with Gaussian (sgp = 2) and top-hat (sgp = 10) pump beam profile for different amplifier crystal lengths at pump power of 50 W and seed energy of 37 mJ. All other parameters used in the simulation are listed in Table 1

3 Experimental setup

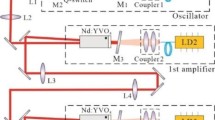

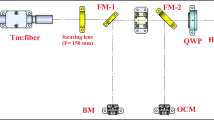

The layout of the MOPA laser system is shown in Fig. 3. A single 80 W Tm-fiber laser (Model TLR-80-1940, from IPG Photonics) was used as pump source. The folded resonator was ~715 mm long with a convex high-reflector (HR2) with a radius of curvature of 200 mm, a concave high-reflector (HR1) with a radius of curvature of 500 mm, which was tilted by approximately 9° to the optical axis and a flat output coupler (OC). The distance between both high reflectors (HR1 and HR2) was approximately 150 mm. A Brewster-cut acousto optic modulator (AOM) was used for Q-switch operation. The folded-cavity holmium oscillator is described in detail in [20, 24]. However, the 30 mm long, 0.5 at.% doped a-cut Ho:LLF rod of the oscillator therein was replaced by a 60 mm long, 0.25 at.% a-cut Ho:LLF rod. Neglecting thermal lensing, the calculated TEM00 beam radius in the crystal was 690 μm, which was assumed to increase at higher pump power due to the effect of the negative thermal lensing in Ho:LLF. The non-absorbed pump beam from the oscillator crystal (1.14 mm in 1/e 2 diameter at full pump power) is expanded with two lenses (f = −50 mm and f = 150 mm) to a beam with a diameter of 4 mm and enters the coherent beam transformer consisting of two aspheric lenses AS1 and AS2 described in detail in [25]. The distance between both lenses AS1 and AS2 was chosen to be ~150 mm. The aspheric surfaces have been optimized for transforming a 5 mm diameter Gaussian input beam into a 5 mm diameter flat-top beam with plane output wave front. Due to a slight mismatch between the input beam diameter and the design specifications of the beam transformer, the top-hat output beam shows an annular modulation in its flat intensity profile which can be seen in the inset in Fig. 3. The output beam (4.12 mm in diameter (1/e 2) at full pump power) is reduced with two additional lenses (f = 250 mm and f = 100 mm) to form a top-hat like pump spot at the position of the amplifier with a measured diameter of ~1.35 mm. The fact that the top-hat beam can be easily transformed by an additional telescope while maintaining a good collimation follows from the good wavefront flatness obtained by coherent beam transformation. Due to imperfect AR coatings of the coherent beam transformer and the lenses, 8 % of the pump light was lost between the dichroic pump exit mirror DM from the oscillator to the entrance face of the amplifier. Two 0.5 at.% a-cut Ho:LLF rods with length of 30 and 40 mm and diameter of 6 mm were used to form the amplifier stage. The end faces were antireflection coated for the 1900–2100 nm wavelength range. The crystals were mounted in water-cooled copper mounts maintained at a temperature of 17 °C and positioned between two flat dichroic mirrors (DM) with high reflectivity (R > 99.8 %) in the 2050–2100 nm wavelength range and high transmission (T > 99.5 %) at the pump wavelength. Both mirrors (DM) were tilted by approximately 10° to the optical axis. The transmitted pump light was measured behind the last mirror DM during laser operation providing the calculation of laser performance as a function of the absorbed pump power, too. Since the absorption in Ho:LLF is strongly polarization dependent, the transmitted pump light from the oscillator crystal is partially polarized. Therefore, both amplifier crystals were orientated with its c axis rotated by 90° (perpendicular to the projection plane in Fig. 3) with respect to the c axis of the oscillator crystal to achieve maximum absorption in the amplifier crystals. A lens with a focal length of f = 1000 mm lens was used to form a waist of the oscillator beam at the position of the amplifier crystals with a diameter of ~1.3 mm. A half-wave plate was used to rotate the polarization of the oscillator beam by 90° for amplification on π-polarization with respect to the amplifier crystal axis.

4 Experimental results

4.1 Oscillator

Q-switch performance of the oscillator is shown in Fig. 4 as a function of (a) pump power and (b) absorbed pump power. At a repetition rate of 100 Hz, a maximum pulse energy of 46 mJ with 30 ns pulse width was obtained from the oscillator at maximum pump power of 84.5 W corresponding to an optical-to-optical efficiency of 5.4 %. The transmitted pump power was 55.5 W. With respect to the absorbed 29 W of pump power, the optical-to-optical efficiency was 15.9 %. The oscillator operated on π-polarization at a wavelength of 2053 nm and the beam was diffraction limited. The emission spectrum of the Ho:LLF laser depicted in Fig. 5 shows a clear operation on several spectral lines. The equally spaced lines (0.244 nm) are due to an Etalon effect of the used plan parallel Infrasil output coupler with a thickness of 6 mm, coated with R = 50 % on one side and AR on the other side for the 2050 nm wavelength range. The laser oscillator, therefore, has to be considered to operate on a very large number of longitudinal modes. The beating of these modes can be clearly seen on the temporal pulse shape taken by a fast detector and also shown in Fig. 5.

The maximum pulse energy of 46 mJ (30 ns) obtained with the 60 mm long, 0.25 at.% (crystal 1) doped crystal is considerable higher than the 37 mJ (38 ns) obtained with a 30 mm long, 0.5 at.% (crystal 2) doped crystal [20, 23] under identical pump and resonator conditions. The laser threshold power with crystal 1 is 29.1 W and only little lower than the laser threshold power of 29.7 W measured with crystal 2. The slopes with respect to absorbed pump power of 30.3 and 30.4 % are nearly identical for both crystals. Measuring the transmission of pump light through the crystals without lasing at low pump power gave values of small signal transmission of 26.3 and 29.1 % with crystals 1 and 2, respectively. This indicates that the absorption coefficient length product α·L of both crystals is different. Indeed, crystal 1 absorbed 29 W and crystal 2 absorbed 26.1 W at full pump power in Q-switched operation at 100 Hz resulting in higher gain and, therefore, higher pulse energy and shorter pulse duration.

4.2 Amplifier

Q-switch performance of Ho:LLF MOPA is shown in Fig. 6 as a function of (a) pump power and (b) absorbed pump power. At a repetition rate of 100 Hz, a maximum pulse energy of 103.6 mJ with 30 ns pulse width was obtained from the MOPA. At full pump power (84.5 W), 51 W of pump light was incident on the amplifier and a gain of 2.25 was obtained at maximum seed energy of 46 mJ corresponding to an optical-to-optical efficiency of 12.9 % of the MOPA system. Both amplifier crystals absorbed 68 % (34.7 W) of the transmitted pump light, which left 20 % (16 W) of the total usable pump light (80 W) unused. With a linear fit of the data shown in Fig. 6a, a slope efficiency of the amplified beam versus total fiber laser pump power of 22.7 % was obtained. With respect to the total absorbed power (29 + 34.7 W), the slope efficiency was 34.4 % and the overall efficiency was 16.2 %. The efficiency with respect to incident pump power could be further increased by reflecting the 16 W transmitted pump light back into the amplifier. This was not attempted as it was unclear at the time what the fiber laser’s tolerance to back reflection was.

The amplifier small signal gain was measured at maximum pump power (51 W incident on the amplifier). The oscillator seed energy was attenuated by introducing a half-wave plate together with two thin-film polarizers behind the mode matching f = 1000 mm lens. Figure 7 shows the measured amplifier small signal energy and gain. Some numerical simulations have been carried out and are shown in Fig. 8. A list of parameter values used is shown in Table 1. The value of the stimulated emission cross-section has been taken from literature [21] and the pump absorption cross-section has been set to reflect the measured small signal absorption of the pump light (taken into account that the pump light is partially polarized and the absorption coefficient of Ho:LLF depends strongly on the polarization state of the pump light). The radii of pump and seed beam have been measured with a Pyrocam III camera (Ophir Optronics Ltd.). A Super-Gaussian pump parameter of 10 was assumed. Taken into account the literature value of 14.8 ms for the upper level lifetime, the simulation overestimates the amplifier performance: 119 mJ should be extracted at a seed energy of 45 mJ corresponding to a gain of 2.64. However, the small signal gain of ~8 is close to the measured value (red curve in Fig. 7). Reducing the upper level lifetime to 11 ms or introducing, a small value of 0.8 × 10−18 cm3/s for the total upconversion (UC) constant in the simulations decreases the maximum pulse energy to 102 mJ and the small signal gain to a value of 6. However, the measured small signal gain value in the range of 6–8 implies that the amplifier is operated nearly in saturation at full available seed energy.

Simulated amplifier small signal output energy and gain at maximum pump power assuming different values of the upper level lifetime and total UC loss constant [22]

At this point, the experimental results obtained with the top-hat pumped Ho:LLF amplifier can be compared with the work previously published using a Gaussian pump profile [23]. Here, a pulse energy of 82 mJ was obtained from the amplifier at a seed energy of 45 mJ at a total pump power of 55.5 W incident on the amplifier crystals. A pump spot diameter of 1.4 mm and a seed spot diameter of 1.6 mm were measured in this experiment. The optical-to-optical efficiency of 9.9 % was lower than the results presented in this work.

Brightness determination was done by inspection of the Ho:LLF laser beam with a Pyrocam III camera using the test method for laser beam parameters: beam widths, divergence angle, and beam propagation factor M 2 (EN ISO 11146). Figure 9 shows the evolution of the focused Ho:LLF laser beam at pulse energy of 98 mJ after it has been passed through a positive 700 mm focal length lens which was positioned approximately 1090 mm from the amplifier crystal. The insets show the intensity distribution of the beam at relative positions of 0, 1000 and 1500 mm, and fits to a Gaussian intensity distribution gave correlation values of 0.93, 0.97, and 0.80, respectively. The beam diameters were computed with 90/10 knife edge method and multiplier value of 1.561 [27]. The beam quality factors M 2 were determined by fitting the standard Gaussian beam propagation expression to the measured data. This results in M 2 x = 1.03 and M 2 y = 1.03, where x denotes the direction parallel to the c axis of the amplifier crystals. The beam is slightly astigmatic which is possibly a result of the different thermal conductivities along the a and c axis of Ho:LLF (5 vs. 6.3 W/m/K for a and c axis, respectively [28]). Due to the lower thermal conductivity along the a axis, the negative thermal lens is little higher leading to higher divergence of the laser beam in y direction. A back calculation of the measured Gaussian beam through the 700 mm focal length lens towards the amplifier results in a beam diameter of 1.35 mm at the position of the amplifier crystals which agrees well with the measured diameter of the seed beam of 1.3 mm. The peak fluence on the exit face of the amplifier is calculated to 15.5 J/cm2, well below the damage threshold of the AR coating of ~36 J/cm2 which has been calculated from a damage appeared in an early experiment.

5 Conclusion

Using a two-dimensional rotational symmetric amplifier model, it has been shown that with a top-hat pump profile in a Ho:LLF amplifier the peak fluence could be reduced and more energy could be extracted in the wings of the pump beam compared to a Gaussian pump profile. A Ho:LLF MOPA system was developed and successfully demonstrated to provide damage-free operation at low repetition rate exceeding the 100 mJ range. The transmitted pump beam from the oscillator with a Gaussian intensity distribution was converted into a nearly top-hat distribution using a coherent beam transformer for pumping the amplifier stage. The system produced pulse energy of 103.6 mJ at a repetition rate of 100 Hz with a pulse duration of 30 ns at a wavelength of 2053 nm, which corresponds to an optical-to-optical efficiency of 12.9 %. The beam quality was nearly diffraction limited (M 2 = 1.03). The peak fluence on the exit face of the amplifier is calculated to 15.5 J/cm2, well below the damage threshold of the AR coating. The efficiency of the system could be further increased by reflecting the 16 W transmitted pump light back into the amplifier or using a longer amplifier crystal.

References

T.Y. Fan, G. Huber, R.L. Byer, P. Mitzscherlich, IEEE J. Quant. Electron. 24, 924 (1988)

P.A. Budni, L.A. Pomeranz, M.L. Lemons, C.A. Miller, J.R. Mosto, E.P. Chicklis, J. Opt. Soc. Am. B 17, 723 (2000)

P.A. Budni, C.R. Ibach, S.D. Setzler, E.J. Gustafson, R.T. Castro, E.P. Chicklis, Opt. Lett. 28, 1016 (2003)

E. Lippert, G. Arisholm, G. Rustad, K. Stenersen, in Advanced Solid-State Photonics, ed. by J.J. Zayhowski. OSA Trends in Optics and Photonics Series, vol 83 (Optical Society of America, Washington, DC, 2003), p. 292

D.Y. Shen, A. Abdolvand, L.J. Cooper, W.A. Clarkson, Appl. Phys. B 79, 559 (2004)

E. Lippert, S. Nicolas, G. Arisholm, K. Stenersen, G. Rustad, Appl. Opt. 45, 3839 (2006)

K. Schmidt, C. Reiter, H. Voss, F. Massmann, M. Ostermeyer, Conference on Lasers and Electro-Optics Europe and 12th European Quantum Electronics Conference, CLEO EUROPE/EQEC 2011, art. no. 5942460

S. Lamrini, P. Koopmann, M. Schäfer, K. Scholle, P. Fuhrberg, Opt. Lett. 37, 515 (2012)

A.A. Kaminskii, Laser Crystals (Springer, Berlin, 1981)

B.M. Walsh, N.P. Barnes, B. Di Bartolo, J. Appl. Phys. 83, 2772 (1998)

M. Eichhorn, Appl. Phys. B 93, 269 (2008)

A. Dergachev, P.F. Moulton, in Advanced Solid-State Photonics, ed. by J.J. Zayhowski. OSA Trends in Optics and Photonics Series, vol 83 (Optical Society of America, Washington, DC, 2003), p. 137

Y. Bai, J. Yu, M. Petros, P.J. Petzar, B.C. Trieu, H.R. Lee, U. Singh: Conference on Lasers and Electro-Optics/Quantum Electronics and Laser Science Conference and Photonic Applications Systems Technologies, OSA Technical Digest Series (CD) (Optical Society of America, 2007), paper CTuN5

A. Dergachev, D. Armstrong, A. Smith, T. Drake, M. Dubois, Opt. Express 15, 14404 (2007)

Y. Bai, J. Yu, P. Petzar, M. Petros, S. Chen, B. Trieu, H. Lee, U. Singh: Conference on Lasers and Electro-Optics/International Quantum Electronics Conference, OSA Technical Digest (CD) (Optical Society of America, 2009), paper CWH5

L.R. Botha, C. Bollig, M.J.D. Esser, R.N. Campbell, C. Jacobs, D.R. Preussler, Opt. Express 17, 20615 (2009)

H.J. Strauss, W. Koen, C. Bollig, M.J.D. Esser, C. Jacobs, O.J.P. Collett, D.R. Preussler, Opt. Express 19, 13974 (2011)

B.M. Walsh, G.W. Grew, N.P. Barnes, J. Phys. Condens. Matter 17, 7643 (2005)

B. Walsh, N.P. Barnes, J. Yu, M. Petros, in Advanced Solid-State Lasers, ed. by M. Fermann, L. Marshall. Trends in Optics and Photonics Series, vol 68 (Optical Society of America, 2002), paper TuB8

M. Schellhorn, Appl. Phys. B 103, 777 (2011)

J.W. Kim, J.I. Mackenzie, D. Parisi, S. Veronesi, M. Tonelli, W.A. Clarkson, Opt. Lett. 35, 420 (2010)

W. Koen, C. Bollig, H. Strauss, M. Schellhorn, C. Jacobs, M.J.D. Esser, Appl. Phys. B 99, 101 (2010)

M. Schellhorn, Lasers, Sources, and Related Photonic Devices Technical Digest, Advanced Solid-State Photonics (ASSP) (Optical Society of America, Washington, DC, 2012), paper AW4A.04

M. Schellhorn, Opt. Lett. 35, 2609 (2010)

M. Eichhorn, G. Stöppler, M. Schellhorn, K.T. Zawilski, P.G. Schunemann, Appl. Phys. B 108, 109 (2012)

B.M. Walsh, N.P. Barnes, M. Petros, J. Yu, U.N. Singh, J. Appl. Phys. 95, 3255 (2004)

A.E. Siegman, M.W. Sasnett, J.F. Johnston Jr, IEEE J. Quant. Electron. 27, 1098 (1991)

R.L. Aggarwal, D.J. Ripin, J.R. Ochoa, T.Y. Fan, J. Appl. Phys. 98, 103514 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schellhorn, M., Eichhorn, M. High-energy Ho:LLF MOPA laser system using a top-hat pump profile for the amplifier stage. Appl. Phys. B 109, 351–357 (2012). https://doi.org/10.1007/s00340-012-5155-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5155-x