Abstract

Catalytic oxidation reaction monitoring has been performed for the first time with a trace gas carbon dioxide analyser based on a continuous wave (cw), thermoelectrically cooled (TEC), distributed feedback (DFB) quantum cascade laser (QCL) operating at around 2307 cm−1. The reaction kinetics for carbon monoxide oxidation over a platinum catalyst supported on yttria-stabilised zirconia were followed by the QCL CO2 analyser and showed that it is a powerful new tool for measuring low reaction rates associated with low surface area model catalysts operating at atmospheric pressures. A detection limit was determined of 40 ppb (1 standard deviation) for a 0.1 s average and a residual absorption standard deviation of 1.9×10−4.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Trace gas detection is an important requirement in many aspects of experimental scientific research. Recent advances in laser science and engineering have enabled very high sensitivity and specific trace gas detection techniques based on tunable infrared absorption spectroscopy with portable instruments to open up new areas of research and extend others. In the area of heterogeneous catalysis there is an on-going need for developing new catalysts for specific chemical reactions of industrial interest such as in the oil and gas sectors. Understanding the mechanism of catalysis can also lead to new advances being made. In order to gain a better understanding of the mechanism of catalysis at the gas-solid interface, model catalysts (of low surface area and well-defined structure) are required. The challenge lies in the ability to perform kinetic experiments on such model catalysts under real operating conditions (i.e. atmospheric pressure and above) as these systems are normally tested in ultra-high-vacuum (UHV). To achieve this, high-performance gas analysis is required as only traces of the product gases may be present in the outlet stream. The main requirements for following the kinetics of small scale catalytic reactions are: high sensitivity to the analyte, species specificity (no interferences), low volume sampling, time resolution down to sub-second, and finally ease of use. Currently gas chromatography is often used for this type of measurements but it lacks sensitivity and is inconvenient to set-up and calibrate. Alternatively mass spectrometry is used but these instruments are usually expensive and bulky.

Tunable infrared laser absorption spectroscopy provides a promising solution and quantum cascade lasers (QCL) have become the most widely used tunable infrared laser source in recent years. They have been used for the detection of a wide range of trace gases in various areas of scientific research such as atmospheric monitoring, industrial emissions, plasma diagnostics, vehicle exhaust monitoring, isotope ratio analysis and breath analysis [1–8]. This has been primarily due to their room temperature operation in a single device at wavelengths suitable for the detection of fundamental vibrations of many trace gas species of interest. Additionally, they have high output power and improving spectral tunability.

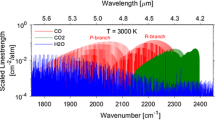

One of the trace gases of interest for catalysis research is carbon dioxide (CO2). For infrared absorption detection of carbon dioxide, the anti-symmetric vibrational band ν 3 centred around 2350 cm−1 (4.25 μm) is usually the most convenient to analyse. However, in this spectral region, it is difficult to manufacture quantum cascade lasers due to lattice matching requirements. Previously cryogenically cooled lead-salt diode lasers have been used to detect CO2 in this vibrational band. Pulsed QCLs and cryogenically cooled continuous wave QCLs have been used in this region for CO2 detection but now continuous wave distributed feedback quantum cascade lasers (cw DFB QCL) operating at or just below room temperature have recently become commercially available. External cavity quantum cascade lasers (ECQCL) [9, 10] are also available in this region but for single species with resolved vibration-rotational spectral structure the narrower tuning range of the DFB lasers is sufficient. Cw DFB QCLs also have the advantage of intrinsic linewidths in the kHz range [11]. Previous work has described the CO2 analyser for 13CO2/12CO2 isotope measurements [12].

This paper describes the first application of a QCL CO2 analyser for studying catalytic oxidation reaction kinetics. The QCL CO2 sensor was tested using CO oxidation over a low surface area Pt catalyst at atmospheric pressure as a probe reaction where the CO2 concentration range was expected to be in the tens to hundreds of ppm. The CO2 analyser and performance are described, followed by a description of the experimental set-up for a catalytic reactor. The measurement results are then described before the discussion and conclusion on the capabilities and potential of QCL analysers for studies of low surface area catalysts under high pressures.

2 Quantum cascade laser CO2 analyser

Parts of the laser spectrometer have been previously described and further details relevant to the application are given here [13]. The P(46) vibration-rotational line of the ν 3 anti-symmetric vibrational stretch at 2306.926 cm−1 was used for all measurements. This had a linestrength at room temperature (296 K) of S=2.637×10−19 cm molecule−1 [14]. As can be seen from the simulated spectrum in Fig. 1, this is one of the weaker lines of the ν 3 band. The laser was originally designed for wider applications such as the simultaneous detection of 13CO2 and 12CO2. The quantum cascade laser (Hamamatsu) operated in continuous wave and in a single longitudinal laser mode due to its distributed feedback structure. The spectral range from 2305 to 2313 cm−1 could be accessed by reducing the laser temperature from 25 ∘C down to 5 ∘C. This was achieved by mounting the laser onto an air-cooled thermoelectric cooling element (TEC). The laser operating temperature was stabilised by a temperature controller. In order to minimise power consumption it was decided to operate around 25 ∘C with the compromise of a weaker CO2 absorption line. A current controller was used to drive the stabilised QCL current up to the manufacturer’s recommended maximum of 1 A with a lasing threshold of 0.9 A. The divergent laser beam was collimated to around 3 mm diameter using an anti-reflection coated aspheric lens of focal length about 4 mm with an output power of the laser of around 2–3 mW. A wedged calcium fluoride beam splitter was used to divide the laser output so that a reference signal could be obtained before the beam passed through the gas cell. Both beams were focussed by off-axis parabolic (OAP) mirrors onto 1 mm2 (HgCdZn)Te photodetectors. These were cooled by two-stage thermoelectric coolers and both detector outputs were fed to 1 MHz bandwidth preamplifiers. The laser signal on the detectors had to be attenuated by the use of insulating tape so that the power was reduced to below 10 μW. The signals from the detector/preamplifiers were fed to a 16-bit data acquisition card (DACQ) at a sampling rate of 200 kHz. A schematic of the QCL spectrometer is shown in Fig. 2.

The intrinsic linewidth of the laser has been estimated to be less than 36 kHz at a laser power of around 25 mW [11]. This was determined from the minimum of the two-sample variance of the laser frequency difference between two adjacent measurement points on the side of an absorption lineshape. Additional noise contributions to the linewidth are made by the laser current controller.

The gas sampling cell was constructed out of aluminium and had an absorption pathlength of 54.2 cm and an internal diameter of 2.2 cm giving an overall cell volume of around 206 cm3. Wedged CaF2 optical windows were mounted at both ends of the cell to minimise étalon effects. A mass flow controller provided a 10 sccm gas flow into the cell (increased to 70 sccm for the catalyst experiments) and a pressure controller connected to a diaphragm vacuum pump controlled the gas pressure in the cell. The gas temperature was monitored on the surface of the cell outlet and the readings fed to the data acquisition card. A particulate filter was also installed into the inlet gas line to remove any particles arising from the catalytic reactor.

In order to remove laser intensity variations and the effects of absorption by atmospheric carbon dioxide, the ratio of the two detector signals was taken. The optical pathlength of the main beam outside the gas sampling cell was set within a few mm to be the same as the pathlength of the reference beam in order to cancel absorption due to atmospheric carbon dioxide. Also the light intensities at each detector were adjusted to be approximately equal.

A LabView program was written to control the laser operation by means of a voltage waveform of 200 points in a 1 ms time interval. The voltage was ramped to provide a current ramp through the laser giving a spectral sweep of around 0.14 cm−1 for a 10 mA current ramp. The first 10 points of the each scan were always set below laser threshold in order to provide a reference point for detector offsets and drifts. Scans were averaged and displayed within LabView. The reference signal was normalised to the main signal at points 49–51 and then a ratio of the two signals was taken to provide the transmission spectrum. Wavelength calibration was achieved by inserting a solid germanium étalon into the reference beam in order to convert from a points scale to a wavenumber scale. The transmission spectrum was fitted to a Lorentzian lineshape together with a second-order polynomial function for the variation in background light intensity. The mole fraction (or volume mixing ratio) x in ppm of CO2 was determined from the absorption peak area A (cm−1), the pathlength L (cm), the linestrength at temperature T (K) and the gas pressure p (Torr):

The final term converts from pressure units of Torr to Pa. k is Boltzmann’s constant. An example of an absorption line with a Lorentzian lineshape fit is given in Fig. 3 showing 12.75 ppm of CO2 in He. The spectrum is for the average of 100 scans over a period of 0.1 s at a gas cell pressure of 100 Torr and a gas flow rate of 10 sccm. The absorption residual standard deviation was 3.3×10−4 at 10 Hz data rate. The limiting noise was due to optical fringes produced by the windows of the gas cell. Derived gas mole fractions were saved every 0.437 seconds (averaging time of 0.1 s plus 0.337 s line fitting). For a CO2 mole fraction of 12.75 ppm in helium the measurement precision was estimated to be around 40 ppb derived from the square root of the two-sample variance.

3 Experimental catalyst measurement

The QCL CO2 analyser was tested using CO oxidation over a low surface area Pt catalyst supported on yttria-stabilised-zirconia (YSZ) at atmospheric pressures as a probe reaction. The catalytic reactor was fabricated from a closed-at-one-end quartz tube and the supported Pt catalyst was placed at the bottom of the reactor. The reactor volume was approximately 40 cm3. The outlet flow of the reactor was split, with approximately 70 ml (STP) min−1 fed to the QCL CO2 analyser; the remaining outlet flow was vented. The total flow rate could vary depending on the experimental conditions. The gas lines used were 1/8″ PFA tubing. Swagelok fittings were used throughout the testing rig and the catalytic reactor. A schematic of the testing rig is shown in Fig. 4.

The catalyst was prepared by sputtering of a dense Pt film on a single crystal YSZ (111) support. The geometric projected surface area of the Pt film was approximately 37 mm2. Atomic force microscopy (AFM) and scanning electron microscopy (SEM) analysis of a fresh Pt film showed very small surface roughness and no porosity. It is therefore expected that the actual Pt surface area is similar to the geometric projected surface. This was used for the calculation of the area-specific reaction rates.

CO oxidation experiments were conducted at 340 ∘C (temperature of the reactor) at a flow rate of 150 ml (STP) min−1, this corresponds to a total molar flow rate of approximately 0.1 mmol s−1. The reactants, provided by BOC were 5 % CO/He and 20 % O2/He. Pure He (N5 grade) was also used as the balance gas in all reaction mixtures. The kinetics of CO oxidation were studied as a function of the oxygen and carbon monoxide mole fractions (x O2 and x CO, respectively). These mole fractions were determined at the inlet of the reactor by gas chromatography (Varian CP3800). For the reaction kinetics with respect to oxygen, the CO mole fraction was kept constant at approximately 0.5 % (5000 ppm) while the oxygen mole fraction varied between 0.3–6 % (3000–60000 ppm). For the reaction kinetics with respect to CO, the oxygen mole fraction was kept constant at approximately 0.7 % (7000 ppm) and the CO mole fraction varied between 0.2–3 % (2000–70000 ppm). The area-specific reaction rates were calculated based on the outlet mole fraction of CO2(x CO2-OUT) measured by the QCL analyser and are given in mmol s−1 m−2. The reactor was operated under differential conversion (below 1 %, determined from the CO2 outlet mole fraction) so that the inlet and outlet mole fractions of both CO and O2 can be considered to be equal. The CO2 mole fraction at the outlet stream varied between 30–900 ppm for the experiments presented here.

4 Results and discussion

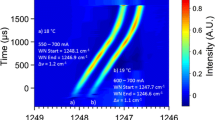

Figure 5 shows the outlet mole fraction of CO2, in ppm, (as obtained from the QCL CO2 analyser) as a function of time under different reaction mixtures (Fig. 5a x CO≈5000 ppm and x O2≈30000 ppm and Fig. 5b x CO≈5000 ppm and x O2≈7000 ppm) at 340 ∘C. In addition Fig. 5c shows the response from the QCL CO2 analyser using a calibration gas with a CO2 mole fraction of 100 ppm as a control measurement (no reactants were present during this measurement). As can be seen in this figure, oscillations of a frequency of approximately 0.02 Hz were observed in the CO2 mole fraction for the oxygen-rich reaction mixture. These oscillations are often encountered in CO oxidation and are due to the periodic formation and dissociation of Pt oxides [15]. Over time the oscillations stopped and the CO2 mole fraction settled to a lower value (of approximately 450 ppm) for these conditions. No oscillations were observed for the oxygen-lean reaction mixture (Fig. 5b) or the calibration gas (Fig. 5c). Some fluctuation in the CO2 mole fraction was observed in both of these cases but this fluctuation did not appear to follow any pattern, in contrast to the very regular oscillations shown in Fig. 5a. Furthermore, no oscillations were observed when a gas mixture containing approximately 540 ppm CO2 (balance He) was fed directly to the QCL CO2 analyser (by-passing the reactor) at room temperature or when it was fed through the reactor at 340 ∘C (with no reactive gases). These results suggest that the observed oscillations were in fact of catalytic nature (possibly due to the higher oxygen mole fraction used in the case shown in Fig. 5a) and not an artefact of the analysis method.

Mole fraction of CO2 in the outlet stream as a function of time during CO oxidation of a Pt catalyst film at 340 ∘C using a flow rate of 150 ml (STP) min−1 at different reactant compositions. (a) CO mole fraction of 5000 ppm and O2 mole fraction of 30000 ppm, (b) CO mole fraction of 5000 ppm and O2 mole fraction of 7000 ppm, (c) a calibration gas with a CO2 mole fraction of 100 ppm (±5 ppm) was used here as a control measurement (no reactants were present)

Figure 6 shows the steady state reaction kinetics for CO oxidation as a function of (a) the oxygen mole fraction and (b) the CO mole fraction. These measurements were taken after cessation of the oscillations. The reaction rates are given in mmol s−1 m−2. As can be seen in Fig. 6 the reaction follows first order kinetics in O2 and negative order kinetics in CO for the entire range of oxygen and carbon monoxide mole fractions used in this work. This behaviour of CO oxidation is well documented and is indicative of competitive adsorption of CO and O2 on the catalyst active sites. It has been found that in general for O2 mole fractions between 0.5–5 % the reaction follows first order kinetics with respect to oxygen while it follows negative order kinetics with respect to CO for carbon monoxide mole fractions in the range of 1–5 % [16]. The results presented here are in reasonable agreement with these findings. Moreover, the reaction rates measured in this study (i.e. 0.1–3 mmol s−1 m−2) are of the same order of magnitude as similar studies on a low surface area Pt catalyst performed under UHV conditions (where the reactants were introduced in the UHV chamber with the appropriate high vacuum leak valves) [17].

The detection limit for CO2 attained in these experiments was around 36 ppb obtained for 0.1 s averaging (detection bandwidth and pathlength normalised sensitivity of 6.15 ppb m Hz−1/2) and for a CO2 mole fraction of 2.5 ppm in helium. An Allan variance analysis was carried out on the concentration stabilised data sets and it showed that the minimum occurred for a single measurement. Improvements can be made by faster data processing which would allow more spectra to be averaged in the same time period. The measurement precision obtained in this work with the quantum cascade laser analyser is an improvement on that of 50 ppb in a 40 s integration obtained from a cryogenically cooled lead-salt diode laser spectrometer at 2291.6 cm−1 with a 5 m absorption pathlength and balanced InSb liquid nitrogen cooled detectors (1581 ppb m Hz−1/2) [18]. It is also comparable with a precision of 50–100 ppb (in 1 s) obtained by similar system based upon a pulsed QCL at around 2310 cm−1 and two 7 m multi-pass cells (350–700 ppb m Hz−1/2) [3].

Further improvements to the analyser can be made such as reducing the cell volume from around 200 cm3 down to less than 10 cm3. When this is combined with reduced sample pressures the sample volume can be reduced to below 1 cm3. The sensitivity can be increased by using longer optical absorption pathlengths. Cavity-ring-down or cavity-enhanced absorption spectroscopy are also possibilities to increase the absorption pathlength and thus the sensitivity. There have been several examples recently of these techniques being applied in the mid-IR range with cw QCLs [19]. Alternatively a multi-pass astigmatic Herriott cell has been used to obtain pathlengths of 75 m or more for CO2 detection [20] but at the expense of larger cell volumes. Moving to a stronger vibration-rotation line of CO2 such as the R(16) at 2361.466 cm−1 (S=3.524×10−18 cm molecule−1) [14] would give over a ten times improvement in sensitivity.

The analyser is also capable of measuring 13CO2/12CO2 ratios [12] and will enable more detailed mechanistic studies of the catalyst activity to be studied. More interesting isotopic studies for work using membrane catalytic systems would be to measure the oxygen isotopes e.g. C17O16O.

5 Conclusions

A trace gas analyser for carbon dioxide detection based on continuous wave quantum cascade lasers has been developed and tested on a catalytic oxidation reaction system. The results presented here show that the QCL CO2 analyser is a very powerful tool for measuring the low reaction rates associated with low surface area model catalysts under real operating conditions (i.e. atmospheric pressures). Indeed the analyser can clearly follow the oscillations in the rate of CO2 production due to the formation and dissociation of Pt oxides. Even though the CO2 concentrations studied here are in the ppm range the high sensitivity will enable the analyser to be used for the study of micro- and nano-patterned catalyst materials where much smaller catalyst areas and flows could be used requiring lower sample volumes and improved sensitivity. Improvements in the analyser will be based on reducing the cell volume for the study of smaller sample sizes and using cavity ring-down or cavity-enhanced absorption spectroscopy.

References

G. Duxbury, N. Langford, M.T. McCulloch, S. Wright, Chem. Soc. Rev. 34, 921 (2005)

A. Kosterev, G. Wysocki, Y. Bakhirkin, S. So, R. Lewicki, M. Fraser, F. Tittel, R.F. Curl, Appl. Phys. B, Lasers Opt. 90, 165 (2008)

J.B. McManus, J.H. Shorter, D.D. Nelson, M.S. Zahniser, D.E. Glenn, R.M. McGovern, Appl. Phys. B, Lasers Opt. 92, 387 (2008)

V. Zeninari, B. Parvitte, L. Joly, T. Le Barbu, N. Amarouche, G. Durry, Appl. Phys. B, Lasers Opt. 85, 265 (2006)

T.H. Risby, F.K. Tittel, Opt. Eng. 49, 111123 (2010)

V.L. Kasyutich, R.J. Holdsworth, P.A. Martin, J. Phys. Conf. Ser. 157, 012006 (2009)

J.B. McManus, D.D. Nelson, M.S. Zahniser, Isot. Environ. Health Stud. 46, 49 (2010)

G. Hancock, G. Ritchie, J.-P. van Helden, R. Walker, D. Weidmann, Opt. Eng. 49, 111121 (2010)

G.N. Rao, A. Karpf, Appl. Opt. 50, A100 (2011)

V.L. Kasyutich, R.K. Raja Ibrahim, P.A. Martin, Infrared Phys. Technol. 53, 381 (2010)

V.L. Kasyutich, P.A. Martin, Opt. Commun. 284, 5723 (2011)

V.L. Kasyutich, P.A. Martin, Infrared Phys. Technol. 55, 60 (2012)

V.L. Kasyutich, P.A. Martin, Sens. Actuators B, Chem. 157, 635 (2011)

L.S. Rothman, I.E. Gordon, A. Barbe, D.C. Benner, P.F. Bernath, M. Birk, V. Boudon, L.R. Brown, A. Campargue, J.P. Champion, K. Chance, L.H. Coudert, V. Dana, V.M. Devi, S. Fally, J.M. Flaud, R.R. Gamache, A. Goldman, D. Jacquemart, I. Kleiner, N. Lacome, W.J. Lafferty, J.Y. Mandin, S.T. Massie, S.N. Mikhailenko, C.E. Miller, N. Moazzen-Ahmadi, O.V. Naumenko, A.V. Nikitin, J. Orphal, V.I. Perevalov, A. Perrin, A. Predoi-Cross, C.P. Rinsland, M. Rotger, M. Šimečková, M.A.H. Smith, K. Sung, S.A. Tashkun, J. Tennyson, R.A. Toth, A.C. Vandaele, J. Vander Auwera, J. Quant. Spectrosc. Radiat. Transf. 110, 533 (2009)

M. Tsampas, F. Sapountzi, C. Vayenas, Catal. Today 146, 351 (2009)

A. Wootsch, C. Descorme, S. Rousselet, D. Duprez, C. Templier, Appl. Surf. Sci. 253, 1310 (2006)

C. Xia, C. Falgairette, Y. Li, G. Foti, C. Comninellis, W. Harbich, Appl. Catal. B, Environ. (2012). doi:10.1016/j.apcatb.2011.11.044

V.L. Kasyutich, A. McMahon, T. Barnhart, P.A. Martin, Appl. Phys. B, Lasers Opt. 93, 701 (2008)

S. Welzel, G. Lombardi, P.B. Davies, R. Engeln, D.C. Schram, J. Ropcke, J. Appl. Phys. 104, 093115 (2008)

J.B. McManus, M.S. Zahniser, D.D. Nelson Jr., J.H. Shorter, S. Herndon, E. Wood, R. Wehr, Opt. Eng. 49, 111124 (2010). doi:10.1117/1.3498782

Acknowledgements

This work was funded by the Engineering and Physical Sciences Research Council (EPSRC) project EP/G022933/1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kasyutich, V.L., Poulidi, D., Jalil, M. et al. Application of a cw quantum cascade laser CO2 analyser to catalytic oxidation reaction monitoring. Appl. Phys. B 110, 263–269 (2013). https://doi.org/10.1007/s00340-012-5154-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5154-y