Abstract

Laser-induced plasma was produced on preheated (up to 500 °C) aluminum targets in air with a nanosecond-pulsed Nd:YAG laser emitting at 1064 nm. Plasma was generated for laser pulse energies ranging from 60 to 800 mJ and the spatially and time-integrated emission was collected as the sample temperature was increased. Electron temperature was found to be independent of the experimental conditions, while the electron density had a weak dependence on the pulse energy and target temperature. Emission enhancement increased with both varied parameters, although with a tendency to saturation for high-energy and high-temperature regimes. A simple model predicting the ablated volume is discussed in terms of the experimental results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Laser-induced breakdown spectroscopy (LIBS) has been used for the past few decades as an analytical tool to determine the composition of solid, liquid or gaseous samples [1]. This analysis technique has proven to be quite versatile due to the practical null sample preparation and its portability for in situ measurements. However, one of the main limitations is the low sensibility in comparison to other established techniques such as inductively coupled plasma mass spectrometry [1]. Several research groups have investigated methods to increase the plasma emissivity of laser ablation, aiming to an enhancement of the LIBS’ limit of detection; although not all of the proposed techniques are portable. Double-pulse LIBS [2–4], ultra-short pulses laser ablation [5, 6], applying a magnetic field to the plasma [7], ablation in a reduced atmosphere [8, 9], resonance-enhanced LIBS [10], increasing the ablation fluence [11–14] and by heating the target [15, 16], can be considered as alternatives to increase the emission in LIBS experiments. Emission enhancements of up to 100-fold have been reported based on some these techniques.

The last two methods mentioned above are relatively easy to implement when designing a portable LIBS system. Emission enhancements of up to three orders of magnitude have been reported [12] when the laser fluence is raised from 1.5 to 840 J cm−2. Here, the authors concluded that laser ablation goes through four different regimes in accordance to the fluence value and, therefore four different crater shapes are produced. The moderate fluence phase (up to 320 J cm−2) is characterized by a complex shape crater with expulsion of droplets [17] and large amounts of material that do not contribute to the plasma emission. Laser ablation at fluencies higher than 320 J cm−2 shows an increment of the plasma emission mainly due to an increase of the ablated mass. To our knowledge, the plasma emission enhancement when keeping the fluence constant, but increasing the laser pulse energy has not yet been explored.

On the other hand, if a metallic target is heated, its physical properties change; for instance the surface reflectivity reduces [18], and the bond between lattices is weakened. As a result, a laser pulse impinging on a heated target should invest less energy in the ablation process, hence an increase of the ablated mass and the plasma emission enhancement. This approach of having intensified LIBS can be used in industrial environments. So far, laser ablation on heated materials to close-to-melting point have been performed using low laser energy [16, 19] obtaining poor signal-to-noise emission enhancements. Ablation on heated targets has also been studied as a function of the laser energy (up to 30 mJ) [15, 20], but for target temperatures well below the melting point. Implications on the emission enhancement at high laser energies regimes (>100 mJ) combined with sample temperatures close to its melting point are yet to be studied.

The aim of this work is to investigate the effect on the plasma emission when the target is heated. Plasma was produced by varying laser energies, though keeping the fluence rather constant. Line emission intensities were correlated to the crater volume measurements and time-integrated electron temperature and density were obtained.

2 Experimental setup

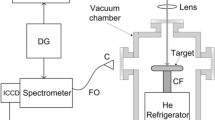

Figure 1 depicts the experimental setup employed to study the optical emission from ablation plasma on a heated target. The target was a commercial Al 6463 alloy constituted by 98 % Al, 0.8 % Mg, 0.5 % Si, 0.2 % Cu and Fe+ traces. The sample was heated to up to 500 °C at the interior of a tube furnace (model 21100, from Barnstead-Thermolyne). Temperature was monitored by a thermocouple attached to the target surface. The ablation was performed by a Nd:YAG laser (Model Surelite III, from Continuum) operated at 1064 nm, delivering 5 ns width pulses at a repetition rate of 2 Hz. The beam was normally concentrated at the target surface by a 15 cm plano-convex lens and the pulse energy was varied from 60 to 800 mJ. The target–lens distance was reduced as the laser energy increased to avoid air breakdown just in front of the target surface. The fluence for each lens position was determined via measuring the beam diameter at the target location. This was performed by displacing a knife edge through the beam and measuring the transmitted energy with a power meter [14].

The emission from the ablation plasma was collected by a quartz optical fiber bundle coupled to a 50 cm focal length spectrometer (SpectraPro 2500, from Acton Research) equipped with a 1800 grooves mm−1 diffraction grating. The instrumental broadening of this system is about 0.3 Å. Spectra were captured via an intensified charge-coupled device (ICCD) camera (PiMAX 1,024 × 1,024, from Princeton Instruments) synchronized with the ablation laser trigger by means of a pulse/delay generator (model 575-8C, from Berkeley Nucleonics). The optical fiber end pointing to the plasma was orientated at about 20° with respect to the laser beam direction (see Fig. 1) 10 cm away from the furnace entrance. The emission enhancement was evaluated by means of temporally and spatially integrated spectra; as a result, the ICCD exposure time was set to 30 μs in all experiments and the camera was triggered 0.5 μs after the plasma onset to minimize the initial continuum emission. To improve the signal-to-noise ratio, 20 consecutive pulses were accumulated and previous to each acquisition the target was cleaned with 15 laser shots.

The volume of the produced crater was determined by assuming an ellipsoidal shape. Crater depth and ellipse’s axes were measured by a confocal microscope (model FV1000, from Olympus) with a scale factor of 1.657 μm/pixel and 4 μm/slice parallel and perpendicular to the target surface, respectively.

3 Results and discussion

The lens’ focal point was set behind the target surface from 0.5 to 11 mm, depending on the laser energy. As the laser energy is increased, beam self-focusing can occur, resulting in air breakdown just in front of the target surface. This was verified by the appearance of nitrogen emission lines. Then, when the laser energy was increased, the lens–target distance was reduced via a micrometric translation stage to maximize the Al and to minimize the N transitions intensities. The average working fluence was (400 ± 75) J cm−2.

3.1 Spectroscopy

Emission lines enhancement was studied in the UV region as a function of the laser energy and the target temperature. The studied transitions were fitted with Lorentzian functions and the intensity here reported corresponds to the area under the peak.

Different minority species were monitored including magnesium (277.98 and 285.21 nm from Mg I; 279.08 and 280.27 nm from Mg II), silicon (288.16 nm from Si I), chromium (283.53 nm from Cr II) and iron (302.05 nm from Fe I). Also the following non-resonant and high upper level energy aluminum lines were studied: 305.01, 305.47, 305.71, 306.43 and 306.61 nm from Al I; and 281.61 nm from Al II. Aluminum transitions above were chosen to minimize the effect of self-absorption that might occur within the plasma plume.

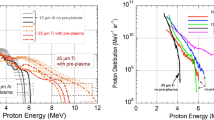

Figure 2 shows the emission line intensity as a function of the target temperature (T S) for different transitions and laser energy of 120 mJ. The reported values have been normalized with respect to the corresponding ones obtained at room temperature (23 °C). The maximum sample temperature studied in this work was 500 °C because the target becomes significantly softer at higher values and the shot-to-shot signal variation drastically increases. In this figure an increment of the intensity is observed when the target temperature was raised for both, ionic and neutral species. Weak transitions at room temperature such as Si I (288.16 nm) and Mg I (277.98 nm) achieved one of the highest enhancements (up to 19-fold); besides Cr and Fe lines, that were not observed at room temperature, appeared at high target temperatures (>300 °C), even for the lowest reported laser pulse energy. It should be noticed that for the Al-alloy employed as target, the chromium concentration is below 0.05 %. These results clearly remark the fact that having a hot target is a good approach to improve LIBS sensitivity.

To simultaneously investigate the effect of the laser energy and the target temperature, typical line intensity behavior for neutral and ionic transitions is shown in Fig. 3. Here, at a given TS, the emissivity improves with the energy to up to two orders of magnitude. This effect is more prominent at low temperatures. At a fixed laser energy, the intensity grows with the temperature, especially at the low-energy regime; while, at high laser energies such an enhancement is not observed. Furthermore, the emission line intensity saturates for energies higher than 500 mJ. As a consequence, under our experimental conditions, it is not worthwhile heating the target above 300 °C for experiments performed at moderate energies (>200 mJ) and it is not necessary at all to heat the target for energies above 400 mJ. The effect of increasing the sample temperature on the spectra at fixed laser energy is just on the emission lines intensity; neither the background root-mean-square (RMS) nor the position of the peaks significantly changed. As a result, the signal-to-noise ratio is effectively raised by a maximum of about one order of magnitude, depending on the studied transition and the laser energy. Considering now a fixed sample temperature, the background RMS grows with the laser energy to up to one order of magnitude; then, although the line intensity is up to 100-fold more intense, the effective signal-to-noise ratio only improves to up to one order of magnitude.

The observed saturation at high-energy regimes can be explained as follows: the leading part of the laser pulse is responsible for the plasma generation, while the rest interacts with the plume. Thus, ablation at high laser energy regimes produces high-density plasmas, which might increase the plasma shielding and laser radiation scattering. As a result, a reduced part of the laser pulse is effectively employed for exciting the species within the plume and the emission intensity does not improve. On the other hand, high target temperatures show that saturation begins to appear for slightly lower energies, since the ablation process has now been facilitated. This will be further discussed in Sect. 3.3.

3.2 Plasma characterization

Electron temperature and electron density were determined to assess global changes within the plasma plume for different experimental conditions. Electron temperature was determined via the Saha–Boltzmann method assuming that the plasma is in local thermal equilibrium [21]. The Saha equation relates the densities of consecutive ionization degrees for a temperature T. Disregarding higher ionic species (above z = 2), the Saha–Boltzmann plot can be written in a similar way as the standard Boltzmann expression:

where I z j and E z j correspond to the line emission intensity (area under the curve) and the upper energy level j for an ionization degree z respectively; z = 0 corresponds to neutral atoms, while z = 1 to the single ionized species. λ is the transition wavelength, A is the transition probability, g is the degeneracy of the level, k the Boltzmann constant, T the electron temperature, h the Plank constant, c the speed of light and N the total number density in the plasma.

The superscript * terms of Eq. (1) are defined as:

and

where m is the electron mass, n e the electron density, Q 0(T) is the partition function of the neutral atoms, E 0∞ is the ionization energy of the neutral atom and S 10 is the ratio of the ions to neutrals number densities which is obtained from the Saha equation as:

where Q z(T) is the partition function for the ionic state z and ΔE 0∞ is a correction to the ionization energy E 0∞ due to interactions within the plasma.

The electron density is obtained from the Stark broadening of the emission lines which also depends on the temperature T [22]; since the electron density slowly varies with the temperature, it can be approximated as:

where Δλ is the full-width at half-maximum (FWHM) of the emission line and W is the Stark broadening parameter. Once the electron density has been determined, the electron temperature is calculated by using Eq. (1) in an iterative process that rapidly converges, assuming typical guess values of 8,000 K.

Transitions employed to determine the electron temperature were the minority Mg lines, so the self-absorption can safely be neglected and the plasma can be considered as optically thin. The relevant spectroscopic parameters were obtained from the NIST atomic spectra database [23]. The electron density was determined with the Al II (281.61 nm) transition obtaining its Stark parameter from [24].

Electron density as a function of the laser energy for different sample temperatures is shown in Fig. 4a. The main source of uncertainty in the density calculation comes from the determination of W, which is within 40 % for this emission line [24]. The contribution to the uncertainty due to the line width measurement was less than 5 %. Regardless the systematic error of the W parameter, the electron density at room temperature increases a factor of two with the laser energy. This could be due to an increase of the ablated mass (see Sect. 3.3). Nevertheless, this growth rate declined as the sample temperature was increased. For a fixed energy, the electron density decreases with temperature, as a result of a faster plasma expansion. Since the target is inside the furnace, not only it gets hotter but also the air surrounding it. The plume expansion speed is proportional to the square root of the air temperature [25]; therefore, assuming an ideal gas behavior, the speed of the plasma’s shock wave front increases to up to a factor of about 1.6 at 500 °C.

On the other hand, the electron temperature remains constant with the laser energy and the sample temperature (see Fig. 4b) within the experimental error, which was about 10 %. The reported electron temperature did not increase with the laser energy at constant sample temperature, although a rising on the electron density (see Fig. 4a) was observed. The increment of the ablated mass leads to an enhancement of the electron density, while the mean ionization degree of the plasma remains constant. As the sample temperature is raised, an increment of the electron temperature would be expected because it would be easier to ionize the species; i.e. laser energy is not employed to boost the sample temperature to the melting point, and now this energy would be available to increase the ionization degree of the plasma. However, since spectra were spatially integrated, and the plasma within a hotter environment expands faster, any plasma temperature variation might be compensated when averaging the hotter core to the cooler and larger plasma border [25].

3.3 Crater analysis

Crater volume for all experimental conditions was obtained by assuming an ellipsoidal shape down from the sample surface. Reported volumes correspond to craters made with 200 laser shots. Figure 5 shows the crater volume as function of the laser energy for four sample temperatures. Larger uncertainties shown at high energies are due to the difficulty to determine the crater border. In all traces the volume increases with the laser pulse energy; further, the growing rate is amplified as the target gets hotter. Regardless of the sample temperature, the volume tends to saturation for high energies (>600 mJ), being the same behavior as that observed with the line intensity (see Fig. 3). Although the fluence was kept approximately constant, the increment of the pulse energy leads to an increase of the ablated mass because a larger target area was irradiated. This increment contributes to the emission lines’ intensity enhancement as shown in Fig. 3. The saturation of the crater volume at high energies might be due to the plasma opacity to the laser radiation.

For fixed laser energies, the volume monotonously grows with the target temperature, this growth being steeper at high laser energies. However, the ~20-fold increase of the ablated volume at high energies does not corresponded with an increase of the emission lines intensity (see Fig. 3). At high temperatures, the sample is sufficiently softened that large amounts of material are deposited around the ablated crater (see below). The mass removed in this way may not contribute to the plasma emission for such high energies as a result of the plasma opacity; then laser photons are unable to excite the species via inverse Bremsstrahlung or any other process. Unfortunately, it is not possible to quantitatively determine the ablated mass since the material condensed in the crater rim may not have the same density as the target bulk [8, 26].

The crater volume as a function of the temperature and laser energy can be modeled by applying Beer’s law to the penetration of the laser radiation into the target [15, 27, 28]. In this model it is assumed that the penetration depth, z, of the laser radiation determines the ablation depth, if the radiation energy at z is above certain threshold energy, E th, i.e.

where E(r,0) is the laser energy at the target surface (z = 0), r is the spot’s radial coordinate, and δ is the penetration depth of the laser radiation into the material bulk. The latter is defined at half of the material’s skin depth, Δ,

where ω, S, μ are the radiation frequency, material’s electrical conductivity and permeability, respectively.

The spatial distribution of the laser energy at the target surface follows a Gaussian function:

where E 0 is the peak energy at the surface and 3σ = R S , is the spot radius.

As the target temperature is increased, its reflectivity, R(T), is reduced [18] and E(r,0) must be modified as follows:

Substituting Eq. (9) into Eq. (6), the ablation depth can be determined:

The threshold fluence for ablation of aluminum has been reported by several authors from 1.01 J cm−2 [14] to 1.5 J cm−2 [12]. The transition from normal vaporization to phase explosion was obtained at fluencies higher than 5.2 J cm−2 [29]. Threshold laser energies then vary from 500 μJ to 1.5 mJ, according to the focus conditions. The ablated volume, V, is calculated as

The model outlined above determines the ablated volume as a function of the laser energy and the target temperature. It assumes that if the laser radiation penetrates the bulk material at energies higher than certain threshold, all material on top of that will be ablated.

Figure 6 shows the theoretical and experimental results of the crater volume as a function of the sample temperature for three representative laser energies. The model only considers the crater volume produced by the removed material that has been vaporized by the incoming laser radiation. This model agrees with the experimental results at ambient temperature and successfully predicts the volume enlargement with the laser energy. As the energy was increased, so was the irradiated area, this parameter being more important for the volume calculation than the penetration depth. On the other hand, the target reflectivity at high temperatures is reduced to about 25 % with respect to that at ambient temperatures. Then, the model foresees an increment of about a factor of 2 of the ablated volume at ambient temperature failing to predict the order of magnitude enhancement observed in the experimental results. The discrepancy between the model and the experiment is enlarged as the target is heated closer to its melting point. The plume expansion during the ablation process creates a high pressure region just above the target surface due to the laser energy absorbed by the plasma [30]. As a result a shock wave is launched not only against the ambient gas, but also towards the target surface. This compression wave may promote a transverse movement of melted material [31, 32], increasing the crater volume. If the laser impinges an already heated target, this mechanism of melt expulsion might be more evident. Therefore, craters produced on targets at temperatures higher than the ambient temperature are much bigger than those predicted by a model that only handles the vaporized material by the laser photons. In fact, large amount of condensed material around the crater rim became apparent for the naked eye at high sample temperatures, which could be due to that melt displacement discussed above. Although the volume fraction produced by melt displacement is not considered by the model exposed here, material removed in this way might also contribute to the evaporated material; therefore, it may have the potential to become excited and to contribute to the plasma emission as shown in Fig. 3. This could specially be true for low laser energies, where the plume opacity to the laser radiation might not be as high as that at high laser energies.

Measured crater volume and theoretical ablated volume, as obtained from Eq. (11), as a function of the sample temperature and some representative laser energies. For a given laser energy, theoretical graphs are depicted as: solid line (120 mJ), dashed line (400 mJ) and dashed-dotted line (600 mJ)

4 Conclusions

In this work LIBS emission enhancement is reported as the sample temperature and the laser energy are increased. It was found a signal-to-noise ratio enhancement of up to one order of magnitude by increasing the sample temperature. A similar improvement was obtained when increasing the laser energy only. However, it is not meaningful to increase the sample temperature for 500 mJ pulses and above due to the opacity of the plume to the laser radiation. As a result, the LIBS’ limit of detection can be enlarged by an inexpensive method since only moderate temperatures and laser energies are necessary.

A model for the ablated volume based on the Beer’s absorption law considering the temperature dependence of the target reflectivity was implemented and compared to the experimental results. It successfully reproduces the ablated volume at room ambient conditions, although it fails to reproduce the measured crater volumes at higher temperatures. Melt displacement by the plasma’s shockwave could be attributable to this discrepancy. However, in all cases, the emission enhancement can be mainly assigned to an increment of the ablated mass.

References

E. Tognoni, V. Palleschi, M. Corsi, G. Cristoforetti, N. Omenetto, I. Gornushkin, B. W. Smith, J. D. Winefordner, Laser-induced breakdown spectroscopy (LIBS), Fundamentals and applications, ed. A. Miziolek, V. Palleschi, I. Schechter (Cambridge University Press, Cambridge, 2006)

V.I. Babushok, F.C. DeLucia, J.L. Gottfried, C.A. Munson, A.W. Miziolek, Spectrochim. Acta B 61, 999 (2006)

J. Scaffidi, S.M. Angel, D.A. Cremers, Anal. Chem. 78, 24 (2006)

J. Scaffidi, J. Pender, W. Pearman, S.R. Goode, B.W. Colston Jr, J.C. Carter, S.M. Angel, Appl. Opt. 42, 6099 (2003)

B. Le Drogoff, J. Margot, M. Chaker, M. Sabsabi, O. Barthelemy, T.W. Johnston, S. Laville, F. Vidal, Y. von Kaenel, Spectrochim. Acta B 56, 987 (2001)

E.L. Gurevich, R. Hergenroder, Appl. Spectrosc. 61, 233A (2007)

V.N. Rai, J.P. Singh, F.Y. Yueh, R.L. Cook, Laser Part. Beams 21, 65 (2003)

G. Cristoforetti, Spectrochim. Acta B 64, 26 (2009)

L. Peter, R. Noll, Appl. Phys. B 86, 159 (2007)

C. Goueguel, S. Laville, F. Vidal, M. Sabsabi, M. Chaker, J. Anal. At. Spectrom. 25, 635 (2010)

L.M. Cabalín, D. Romero, J.M. Baena, J.J. Laserna, Fresenius J. Anal. Chem. 365, 404 (1999)

G. Cristoforetti, S. Legnaioli, V. Palleschi, E. Tognoni, P.A. Benedetti, J. Anal. At. Spectrom. 23, 1518 (2008)

S. Amoruso, A. Amodeo, V. Berardi, R. Bruzzese, N. Spinelli, R. Velotta, Appl. Surf. Sci. 96–98, 175 (1996)

L.M. Cabalín, J.J. Laserna, Spectrochim. Acta B 53, 723 (1998)

S.H. Tavassoli, A. Gragossian, Opt. Laser Technol. 41, 481 (2009)

S. Palanco, L.M. Cabalín, D. Romero, J.J. Laserna, J. Anal. At. Spectrom. 14, 1883 (1999)

J.H. Yoo, S.H. Jeong, R. Greif, R.E. Russo, J. Appl. Phys. 88, 1638 (2000)

K. Ujihara, J. Appl. Phys. 43, 2376 (1971)

C. Lopez-Moreno, K. Amponsah-Manager, B.W. Smith, I.B. Gornushkin, N. Omenetto, S. Palanco, J.J. Laserna, J.D. Winefordner, J. Anal. At. Spectrom. 20, 552 (2005)

S.H. Tavassoli, M. Khalaji, J. Appl. Phys. 103, 083118 (2008)

J.A. Aguilera, C. Aragon, Spectrochim. Acta B 59, 1861 (2004)

H.R. Griem, Principles of plasma spectroscopy (Cambridge University Press, Cambridge, 1997)

Y. Ralchenko, A.E. Kramida, J. Reader, NA Team, (National Institute of Standards and Technology, Gaithersburg, MD., 2010)

N. Konjevic, A. Lesage, J. Phys. Chem. Ref. Data 31, 819 (2002)

A. De Giacomo, M. Dell’Aglio, D. Bruno, R. Gaudiuso, O. De Pascale, Spectrochim. Acta B 63, 805 (2008)

P.A. Benedetti, G. Cristoforetti, S. Legnaioli, V. Palleschi, L. Pardini, A. Salvetti, E. Tognoni, Spectrochim. Acta B 60, 1392 (2005)

S.R. Franklin, R.K. Thareja, Appl. Surf. Sci. 222, 293 (2004)

B.J. Garrison, Y.G. Yingling, M.I. Zeifman, Chem. Rev. 103, 321 (2003)

C. Porneala, D.A. Willis, Appl. Phys. Lett. 89, 211121 (2006)

J.R. Ho, C.P. Grigoropoulos, J.A.C. Humphrey, J. Appl. Phys. 79, 7205 (1995)

H.C. Liu, X.L. Mao, J.H. Yoo, R.E. Russo, Spectrochim. Acta B 54, 1607 (1999)

G.K.L. Ng, P.L. Crouse, L. Li, Int. J. Heat Mass Tran. 49, 1358 (2006)

Acknowledgments

This work was supported by the National Autonomous University of Mexico (DGAPA-UNAM: IN101212) and the National Council of Science and Technology of Mexico (CONACyT 102364-F). R Sanginés acknowledges the DGAPA- UNAM Postdoctoral fellowship. The authors acknowledge K. Jiménez-Durán who performed the microscopy measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sanginés, R., Sobral, H. & Alvarez-Zauco, E. Emission enhancement in laser-produced plasmas on preheated targets. Appl. Phys. B 108, 867–873 (2012). https://doi.org/10.1007/s00340-012-5130-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5130-6