Abstract

We fabricated and investigated a plasmonic racetrack resonator with a trench structure. Trench channel plasmon polaritons excited by end-fire coupling at a wavelength of 633 nm are observed in the fabricated racetrack resonator. The racetrack resonator also worked as a plasmonic racetrack resonator. The experimental and simulation results of the electric field distributions are in good agreement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In order to increase the integration density of photonic integrated circuits, photonic devices with the order of visible and telecom wavelengths of light are investigated extensively [1, 2]. Many low-loss devices made of dielectric or semiconducting materials have been developed [3, 4]. For instance, a low-loss silicon on insulator (SOI) microring resonator having a radius of 1.5 μm has been fabricated and investigated by Xu et al. [5]. The size of these devices is close to the theoretical size limit of optical devices made of dielectric or semiconducting materials because the size of these devices is smaller than the operational wavelength. Optical devices using surface plasmon polaritons (SPPs) that overcome the diffraction limit of light can be made at the nanoscale. These plasmonic devices significantly increase the density of the photonic integrated circuits. Many plasmonic waveguides have been reported and investigated by several groups [6–14]. Plasmonic resonators are required for building photonic integrated circuits. Recently, plasmonic resonators have been investigated [15–23]. As a result of the insufficient coupling between the waveguide and the resonator, these devices are inadequate for practical applications. Therefore, a resonator with a sufficient coupling efficiency is required for making photonic integrated circuits. A plasmonic racetrack resonator can increase the coupling coefficient between the waveguide and resonator because the racetrack resonator can increase the coupling length. We have reported that the coupling coefficient of the racetrack resonator with a trench structure is up to 3.5 times that of the ring resonator [24]. Wang et al. [25] and Han [26] have investigated plasmonic racetrack resonators in two dimensions. They have reported that a plasmonic racetrack resonator that is several hundreds of nanometers in size can be built and that its coupling coefficient can be greater than that of a plasmonic ring resonator. We have investigated plasmonic racetrack resonators in three dimensions [27]. However, the structure that we investigated requires many fabrication steps. On the other hand, a trench structure [6, 7, 13, 14] can be fabricated in only a few steps. We have investigated and designed a plasmonic racetrack resonator with a trench structure for improving the coupling efficiency [24].

In this paper, we present the fabrication of a plasmonic racetrack resonator with a trench structure and the evaluation of the resonator operating at a wavelength of 633 nm. The best method for evaluating the characteristics of the resonator is to investigate the output dependence for a range of wavelengths. However, we use a single wavelength of 633 nm for operating the resonator. Therefore, to compare the results of two cases, the polarization of the incident light is varied from a transverse magnetic (TM) to a transverse electric (TE) state.

2 Fabrication of a racetrack resonator with a trench structure

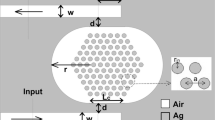

Figure 1 shows (a) the scanning electron microscopy (SEM) images of the fabricated plasmonic racetrack resonator and (b) a magnified view of the coupling region. Various surface roughnesses are observed in the case of a silver surface [shown in Fig. 1(a)]. We have evaluated the surface roughness by using a scanning probe microscope. The heights of the bumps responsible for the surface roughness range from 17 to 30 nm. The structure is fabricated in two steps. First, silver is evaporated onto the substrate. Second, the layer of silver is milled using a focused-ion-beam (FIB) technique. We evaporated a silver film with a thickness of 700 nm on a quartz glass substrate. Then we milled the layer of silver to a depth of 500 nm using the FIB technique. The width, depth, and waveguide-racetrack gaps are 100 nm, 500 nm, and 50 nm, respectively. The length and the radius of the straight and curved portions of the racetrack are 1000 nm and 1500 nm, respectively. The input and output ports are 1000×1000 nm.

SEM images of (a) the plasmonic racetrack resonator and (b) a magnified view of the coupling region. The width and depth of the plasmonic racetrack resonator are 100 nm and 500 nm, respectively. The radius of the curved portions of the plasmonic racetrack resonator is 1500 nm. The length of the straight portion of the racetrack is 1000 nm. The gap between the waveguide and the plasmonic racetrack resonator is 50 nm

3 Simulations

We numerically evaluate the abovementioned structure using a finite-difference time-domain (FDTD) method. The reflective index of the racetrack and the waveguide is set to 1.0 and that of the substrate is set to 1.45, which is close to that of the quartz glass. The permittivity of silver is given by the Drude model according to Eq. (1)

where ϵ ∞ is the relative permittivity at infinite frequency, ω p is the plasma frequency, and γ is the collision frequency; these parameters are set to 6.0, 1.5 × 1016 rad/s, and 7.73 × 1013 rad/s, respectively [28].

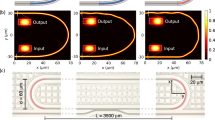

Figure 2(a) shows the output, which is normalized by the maximum value of the output intensity at the output port as a function of the wavelength. A 4.8-fs broadband Gaussian pulse with a center wavelength of 633 nm is used for evaluating the racetrack. The resonance wavelength is 638 nm, and its the normalized output is 0.90. The Q factor is 62 at a wavelength of 638 nm. We intended to use a He–Ne laser as an excitation source for the experimentation. Therefore, the incident light of the simulation is a 633 nm continuous wave. The coupling coefficient between the waveguide and the racetrack is 0.15 at a wavelength of 633 nm. Figures 2(b) and (c) show the electric field profiles (|E|) for the 633 nm wavelength with the polarization of incident light of (b) TM and (c) TE. Trench channel plasmon polaritons (CPPs) excited by the 633 nm wavelength light do not show the greatest output in Fig. 2(a). However, a part of the trench CPPs is stored in the resonator and output to the output port.

4 Results and discussion

Figure 3 presents a schematic representation of the experimental setup for evaluating the function of the fabricated resonator. We used a wavelength of 633 nm and a He–Ne laser as the excitation source. Light is transmitted through the polarizer and propagated along the polarization-maintaining fibre. Then the light maintaining the polarization irradiates the input port. Trench CPPs are excited by end-fire coupling. The fibre is rotated to vary the polarization of the incident light.

Figures 4(a), (b), and (c) show optical images of (a) the racetrack resonator and the polarization of the incident light of (b) TM and (c) TE, respectively. Incident light with a wavelength of 633 nm is irradiated at the input port. Figure 4(b) shows an image of the light that is decoupled from the trench CPPs and the shape of the racetrack. The trench CPPs are excited and stored in the racetrack resonator (Fig. 4(b)). In Fig. 4(c), the trench CPPs are not excited and no racetrack shape is shown. The optical images in Figs. 4(b) and (c) are similar to the simulation results shown in Figs. 2(b) and (c). These results show that the fabricated plasmonic racetrack resonator works as a plasmonic resonator when the polarization of the incident light is TM. However, the optical images result from the radiation loss of the racetrack resonator structure. The radiation loss is large because of the low confinement of the trench CPPs. The values of the propagation loss and the total insertion loss for the racetrack resonator with a trench structure are 0.08 dB/μm and −15 dB, respectively [24]. The factors that increase the losses in practical devices can be described as follows: The racetrack structure increases the coupling loss because the coupling length of the racetrack structure is increased [25]. The roughnesses of the metal surface are seen in the structure [shown in Fig. 1(a)]. In the case of the fabrication of the trench structure on such a rough surface, the roughnesses cause the difference in the trench depth. The roughnesses of the trench walls and the difference in the trench depth increase the radiation loss [29]. Therefore, we need to fabricate a structure with an appropriate coupling length, smooth trench wall, and steady trench depth. The trench CPPs are coupled to conventional SPPs and the edge and coupled wedge SPP modes if the trench CPP mode that propagates in the trench structure approaches the cut-off condition [30]. The coupling from the trench CPPs to other SPPs increases losses [31].

The Q factor of the wavelength characteristics [shown in Fig. 2(a)] is 62, as stated in Sect. 3. To the best of our knowledge, the highest Q factor attained by a plasmonic resonator is 1376 ± 65, as reported by Min et al. [16]. For the reasons mentioned above, the Q factor of the racetrack resonator with a trench structure is low. The intrinsic metal loss as well as the coupling loss and radiation loss decrease the Q factor [16]. Therefore, we need to consider new structures such as a combination of several resonators as well as fabricate a smooth trench wall for increasing the Q factor.

5 Conclusions

We have fabricated a plasmonic racetrack resonator and evaluated it at a wavelength of 633 nm. Further, we observed the operation of the racetrack resonator at the same wavelength. However, the losses of the racetrack resonator structure were large because of the low confinement of the trench CPPs. Therefore, we need to improve the structure and minimize the loss without decreasing the coupling coefficient and the Q factor.

The plasmonic racetrack resonator with a trench structure can be fabricated in several steps; it is compact, and the increase in the coupling coefficient has potential applications in the photonic integrated circuits.

References

R. Scarmozzino, A. Gopinath, R. Pregla, S. Helfert, IEEE J. Sel. Top. Quantum Electron. 6, 150 (2000)

G.C. Valey, Opt. Express 15, 1955 (2007)

Y. Akahane, T. Asano, B.-S. Song, S. Noda, Nature (London) 425, 944 (2003)

B.G. Lee, A. Biberman, P. Dong, M. Lipson, K. Bergman, IEEE Photonics Technol. Lett. 20, 767 (2008)

Q. Xu, D. Fattal, R.G. Beausoleil, Opt. Express 16, 4309 (2008)

S.I. Bozhevolnyi, V.S. Volkov, E. Devaux, T.W. Ebbesen, Phys. Rev. Lett. 95, 046802 (2005)

K. Tanaka, M. Tanaka, Appl. Phys. Lett. 82, 1158 (2003)

J.A. Dionne, L.A. Sweatlock, H.A. Atwater, Phys. Rev. B, Condens. Matter Mater. Phys. 72, 075405 (2005)

D.F.P. Pile, T. Ogawa, D.K. Gramotnev, Y. Matsuzaki, K.C. Vernon, K. Yamaguchi, T. Okamoto, M. Haraguchi, M. Fukui, Appl. Phys. Lett. 87, 261114 (2005)

D. Dai, S. He, Opt. Express 17, 16646 (2009)

G.C. des Francs, J. Grandidier, S. Massenot, A. Bouhelier, J.-C. Weeber, A. Dereux, Phys. Rev. B, Condens. Matter Mater. Phys. 80, 115419 (2009)

R.B. Nielsen, I.F. Cuesta, A. Boltasseva, V.S. Volkov, S.I. Bozhevolnyi, A. Klukowska, A. Kristensen, Opt. Lett. 33, 2800 (2008)

I.-M. Lee, J. Jung, J. Park, H. Kim, B. Lee, Opt. Express 15, 16596 (2007)

T. Srivastave, A. Kumar, J. Appl. Phys. 106, 043104 (2009)

S. Xiao, L. Liu, M. Qiu, Opt. Express 14, 2932 (2006)

B. Min, E. Ostby, V. Sorger, E.U. Avila, L. Yang, X. Zhang, K. Vahala, Nature (London) 457, 455 (2009)

Q. Zhang, X.-G. Huang, X.-S. Lin, J. Tao, X.-P. Jin, Opt. Express 17, 7549 (2009)

B. Wang, G.P. Wang, Appl. Phys. Lett. 89, 133106 (2006)

T.-B. Wang, X.-W. Wen, C.-P. Yin, H.-Z. Wang, Opt. Express 17, 24096 (2009)

S. Randhawa, A.V. Krasavin, T. Holmgaard, J. Renger, S.I. Bozhevolnyi, A.V. Zayats, R. Quidant, Appl. Phys. Lett. 98, 161102 (2011)

V.S. Volkov, S.I. Bozhevolnyi, E. Devaux, J.-Y. Laluet, T.W. Ebbesen, Nano Lett. 7, 880 (2007)

S.I. Bozhevolnyi, V.S. Volkov, E. Devaux, J.-Y. Laluet, T.W. Ebbesen, Nature (London) 440, 508 (2006)

T. Holmgaard, Z. Chen, S.I. Bozhevolnyi, L. Markey, A. Dereux, Opt. Express 17, 2968 (2009)

H. Okamoto, K. Yamaguchi, M. Haraguchi, T. Okamoto, C. Sun, Jpn. J. Appl. Phys. 50, 092201 (2011)

X. Wang, P. Wang, C. Chen, J. Chen, Y. Lu, H. Ming, Q. Zhan, J. Appl. Phys. 107, 124517 (2010)

Z. Han, Photonics Nanostruct. Fundam. Appl. 8, 172 (2010)

H. Okamoto, K. Yamaguchi, M. Haraguchi, T. Okamoto, J. Nonlinear Opt. Phys. Mater. 19, 583 (2010)

Z. Liu, S. Durant, H. Lee, Y. Xiong, Y. Pikus, C. Sun, X. Zhang, Opt. Lett. 32, 629 (2007)

T. Nikolajsen, K. Leosson, I. Salakhutdinov, S.I. Bozhevolnyi, Appl. Phys. Lett. 82, 668 (2003)

S.I. Bozhevolnyi, Opt. Express 14, 9467 (2006)

A. Hosseini, Y. Massoud, Appl. Phys. Lett. 90, 181102 (2007)

Acknowledgements

The authors are grateful to S. Itami, S. Onishi, Y. Oshima, and M. Kataoka of the Anan National College of Technology for their support. This work was supported by a Grant-in-Aid for Scientific Research (C) (22510131) from the Japan Society for the Promotion of Science, the Telecommunications Advancement Foundation, a Cooperative Education/Research Project between the Toyohashi University of Technology and the National College of Technology as well as between the Nagaoka University of Technology and the National College of Technology, and Mitutoyo Association for Science and Technology. This work was carried out using equipment that was provided by the Cybermedia Center of Osaka University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okamoto, H., Yamaguchi, K., Haraguchi, M. et al. Experimental demonstration of plasmonic racetrack resonators with a trench structure. Appl. Phys. B 108, 149–152 (2012). https://doi.org/10.1007/s00340-012-5081-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5081-y