Abstract

We report Tunable Diode Laser Spectroscopy measurements of propane using a recently developed 3.37 μm GaInAsSb/AlGaInAsSb DFB laser. We have demonstrated that Wavelength Modulation Spectroscopy can be utilized to enhance a sharp feature in the broader propane spectrum around 3370.4 nm. A minimum detectable concentration of 30 ppb×m was obtained at a response time of 0.5 s. This corresponded to a minimum detectable absorption of 8 × 10−5 which is why an improvement of the sensitivity by an order of magnitude is possible using this laser and a more optimized optical setup.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Propylene is a key petrochemical building block which is used to produce primarily polypropylene and a number of common chemicals like isopropyl alcohol and acetone [1]. Most propylene is produced as a by-product of ethylene production in steam cracking plants. Propane dehydrogenation is also common when low cost propane is available as feedstock. Typical propylene purity ranges between 99. 5% and 99.8 % in weight. When propylene is produced in the presence of hydrogen it is often accompanied by the formation of other lighter hydrocarbons. Typical product specification of allowed impurities is ≤0.5 % ethane + propane, ≤100 ppm ethylene and ≤25 ppm acetylene. There are also limits on the levels of H2S, CO, CO2, O2 and humidity [1]. Today the analysis and quality control of propylene concentrates is determined using gas chromatographs (GC) [2]. Separation of the compounds typically encountered in a propylene stream is sometimes difficult and the response time for measuring propane in propylene using a GC is on the order of 5–10 minutes. The real-time capability offered by Tunable Diode Laser Spectroscopy (TDLS) has the potential to improve the control of the manufacturing process leading to savings in cost and improvement in product quality. The lack of suitable room-temperature single-mode diode laser sources emitting in the wavelength range of the main hydro carbon absorption bands, i.e. in the 3 to 3.5 μm range has limited the application of TDLS instrumentation in the hydrocarbon processing industry. During the last few years there has been a rapid progress in GaSb based quantum well laser fabrication. Room-temperature monomode DFB lasers with an emission wavelength at around 3.06 μm have been demonstrated [3]. These lasers have successfully been utilized for high sensitivity detection of acetylene [4]. Further improvement of the laser structure has recently extended the operation of continuous wave type-I quantum well GaSb based DFB laser emission into the 3.4 μm wavelength range [5, 6]. This has made it possible to cover a large part of the main hydrocarbon absorption bands. In this paper we present tunable diode laser spectroscopy of propane around 3.37 μm. We have demonstrated the use of Wavelength Modulation Spectroscopy (WMS) to enhance the sharp absorption feature in the otherwise relatively broad propane spectrum around 3.37 μm.

Figure 1 shows an FTIR absorption spectrum with 0.125 cm−1 resolution of 1 ppm×m propane in the wavelength range 3200 nm to 3600 nm from the PNNL spectroscopic database [7]. The data show a narrow feature with a half width around 2.3 nm (60.7 GHz) at 3370.4 nm (2697 cm−1) on a broader absorption feature with a half width around 55 nm (1452 GHz). The peak absorbance is close to 3 × 10−3 for a gas concentration of 1 ppm × meter, which makes this feature suitable for high sensitivity detection of propane.

From this FTIR spectrum we can already conclude that, in order to cover the narrow feature, 60 GHz of dynamic current tuning range are necessary. This is feasible for a DFB laser, whereas the broader feature would require the use of a laser in an external cavity configuration or a widely tunable laser operating in the 3.3–3.4 μm wavelength range [6]. That is, the spectral features of propane are so broad that it is not possible to scan the entire feature using a DFB laser. TDLS has historically mostly been applied to isolated spectral features with well known lineshapes. In this situation the laser intensity in direct absorption (DAS) or WMS is easily determined using a part of the spectra outside the absorption line. However, in the case with the propane feature the usual advantage using DAS is lost since we cannot scan the entire absorption feature. Wavelength Modulation Spectroscopy with 2f detection on the other hand is a derivative method and is more sensitive to the curvature of the line-shape than to the absolute magnitude of the absorption [8].

The broad propane absorption feature will contribute to the absolute absorption magnitude and will scale the measured spectrum signal due to its influence on the received optical intensity, much in the same way as the attenuation from optical elements and scattering objects in the measurement path. The WMS line, however, will always be centered around the zero baseline for all concentrations in contrast to the DAS line. Using Beer–Lambert law the received optical intensity for a wavelength region at the peak of the broad feature (the plateau excluding the sharp peak) can be written

where I 0 is the transmitted laser intensity, T 0 is the transmission determined by optical losses and other broadband attenuation in the measurement path. We have defined a concentration dependent transmission T α to take care of the attenuation by the broad feature. The intensity of the light at the sharp peak in the spectrum is therefore

The WMS signal can now be written [9]

where β is a constant comprising all gain settings in the system, χ 1, χ 2 and χ 3 is the first, second and third Fourier component of a modulated absorption line giving the characteristic line shape of the WMS signal. κ 1 ν a is the linear intensity modulation amplitude and ϕ 1 is the phase between intensity and wavelength modulation. We observe that the transmission T 0 T α has to be continuously measured in every sweep, in order to correctly normalize the spectra.

2 Measurements

In order to reach the required wavelength we utilized a monomode, room-temperature continuous-wave operating GaInAsSb/AlGaInAsSb DFB laser recently developed in the European SensHy project [10]. A plot of the injection current versus output power with the emission spectrum inset is shown in Fig. 2.

I−P curve and emission spectrum of the 3370 nm GaInAsSb/AlGaInAsSb DFB laser [5]

The threshold current at a chip temperature of 10 °C was 90 mA. The laser has monomode emission at 3370.4 nm with an optical power close to 1 mW at an injection current of 125 mA. The side mode suppression was better than 30 dB.

Figure 3 shows the measurement setup. The diverging beam from the laser was collimated by an F/0.53 off-axis parabolic mirror with a focal length of 20.3 mm. The laser beam was passed through a 15 cm gas absorption cell with wedged CaF2 windows. Using an identical off-axis parabolic mirror, the laser radiation was focused on an InAs/InAsSbP detector (Roithner PD36-05-TEC). The laser injection and Peltier currents were supplied by a combined laser and thermo-electrical cooler (TEC) driver (ILX LDC-3724). A suitable center frequency of the laser was chosen by adjusting the temperature of the TEC. The wavelength tuning was realized via modulation of the injection current. To perform Wavelength Modulation Spectroscopy (WMS) a waveform generator supplied a scan of 23 Hz and a 6 kHz sinusoidal modulation to the laser. The scan waveform consisted of two parts: a flat region for measurement of the transmission T 0 T α outside the sharp propane absorption profile and a scan for sweeping the frequency across the sharp feature. The pre-amplified detector signal was filtered, digitized, demodulated (at 2f frequency) and finally normalized in the signal processing electronics.

The data were acquired using the Siemens data acquisition software LDScom. The calibrated gas mixtures were made with a HovagaGas gas mixer (IAS GmbH).

The laser was characterized by exchanging the absorption cell for a 2.54 cm (1″) germanium etalon with a free spectral range of 1.43 GHz. The measured wavelength tuning characteristics of the 3370 nm laser is shown in Fig. 4. The laser current was varied between 130 mA and 225 mA, while the WMS signal from the etalon was recorded. The measured detuning response is shown in Fig. 4a. The corresponding FM-index of the laser, obtained by a fit to the etalon trace, is illustrated in Fig. 4b. It was found that the maximum tuning range of this laser was 60 GHz. The current tuning (FM-index) for the 23 Hz sweep rate varied from 0.56 GHz/mA in the beginning of the sweep to 0.64 GHz/mA at the end of the sweep. The smooth tuning rate is clearly shown by the etalon trace in Fig. 4c.

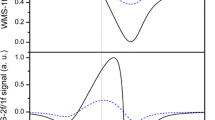

The resulting WMS signal from a set of calibrated gas mixtures of propane diluted with dry nitrogen to a total gas pressure of 1005 mbar is shown in Fig. 5. The wavelength axis has been linearized and calibrated using the etalon. From these spectra we calculated that the sharp feature has a line width around 30 GHz full width-half maximum. It is clear that the tuning capability of the delivered laser makes it possible to perform high quality WMS on this absorption feature even including some baseline.

A test of the performance of the propane measurement was made by investigating the linearity of the measurement for propane concentrations up to 500 ppm. The measurements were made in an absorption cell with a length of 15 cm. The system was span calibrated by flushing calibration gas containing 50 ppm of propane in nitrogen buffer. In Fig. 6 the measured vs. actual concentration for propane concentrations up to 500 ppm is plotted. For propane concentrations above 30 ppm × m (200 ppm) we find that the linear approximation for Beer–Lamberts law is no longer valid. That is, the error in the approximation grows with increasing concentration. We have

The blue curve shows the measurement result obtained from the curve fit to the WMS signal normalized with the actual transmission in each sweep. This algorithm assumes that the linearization in Beer–Lamberts law can be made. The red curve shows the measurement values corrected by numerically calculating the exact value using the exponential. The result shows that excellent propane sensing performance over a wide range of concentrations can be obtained using the modified algorithm. The correction can also be implemented by a calibration curve that is applied at the output of the measurement instrument.

In order to demonstrate the stability and the response time of the propane measurement we performed propane measurements using a 15 cm flow cell. Each data point in Fig. 7 was obtained by a curve fit to the propane line in real time at 23 Hz scan rate. A trial function stored in a 256 point long look-up table was fitted to the recorded signal (also stored in a 256 long buffer) using a least-squares method. The trial function was recorded during calibration process by flushing calibration gas containing 50 ppm of propane in nitrogen buffer and stored in a look-up table. Free parameters of the fit where the buffer position, amplitude as well as a linear background. This method is applicable at stable pressure and temperature conditions and where no foreign gas broadening occurs. Otherwise the fitting procedure should be performed by fitting an analytical formula (see Eq. (3)) instead of a recorded trial function. The propane gas flow was mixed with dry nitrogen down to a concentration of 5 ppm. The gas flow to the cell was then rapidly switched between the diluted propane and dry nitrogen. In Fig. 7 we clearly see the rapid response and the low noise level. The noise level is calculated by the standard deviation of the concentration values produced in real time by the curve fit. The minimum detectable concentration is estimated to 30 ppb × m at a response time of 0.5 s using the two-sigma value of the noise. This corresponds to an absorbance of 8 × 10−5, which is why there is a potential for improvement of the sensitivity by one order of magnitude using a more refined optical setup.

We observe that the system is very stable within the time frame of this measurement (150 s).

3 Conclusions

We have, to our knowledge, for the first time demonstrated detection of propane utilizing Wavelength Modulation Spectroscopy on an absorption feature at 3.37 μm. A monomode, room-temperature continuous-wave operating GaInAsSb/AlGaInAsSb DFB laser recently developed in the European SensHy project was utilized. The tuning capability of this laser makes it possible to perform high quality WMS on this sharp absorption feature, even including some baseline. We obtained a minimum detectable concentration of 30 ppb × m at a response time of 0.5 s. The performance achieved shows that the technique has the sensitivity and the short response time necessary to improve the control of the hydrocarbon manufacturing process used in propylene manufacturing. This new application of TDLS can lead to savings in cost and improvement in product quality.

References

R.A. Meyers, Handbook of Petrochemicals Production Processes (McGraw-Hill, New York, 2005) (ISBN-0-07-141042-2)

A.W. Drews, in Manual on Hydrocarbon Analysis, 6th revised edn. American Society for Testing & Materials (1998). ISBN-13:978-0803120808

S. Belahsene, L. Naehle, M. Fischer, J. Koeth, G. Boisser, P. Grech, G. Narcy, A. Vicet, Y. Rouillard, IEEE Photonics Technol. Lett. 22, 1084 (2010)

P. Kluczynski, S. Lundqvist, S. Belahsene, Y. Rouillard, Opt. Lett. 34, 3767 (2009)

L. Naehle, S. Belahsene, M. v. Edlinger, M. Fischer, G. Boissier, P. Grech, G. Narcy, A. Vicet, Y. Rouillard, J. Koeth, L. Worschech, Electron. Lett. 47, 46 (2010)

L. Naehle, C. Zimmermann, S. Belahsene, M. Fischer, G. Boissier, P. Grech, G. Narcy, S. Lundqvist, Y. Rouillard, J. Koeth, M. Kamp, L. Worschech, Electron. Lett. 47, 1 (2011)

S.W. Sharpe, T.J. Johnson, R.L. Sams, P.M. Chu, G.C. Rhoderick, P.A. Johnson, Appl. Spectrosc. 58, 1452 (2004)

J.T.C. Liu, J.B. Jeffries, R.K. Hanson, Appl. Opt. 43, 6500 (2004)

P. Kluczynski, O. Axner, Appl. Opt. 38, 5803 (1999)

SensHy, Photonic sensing of hydrocarbons based on innovative mid infrared lasers. www.senshy.eu

Acknowledgement

This work has been funded by the European Commission in the frame of the FP7 project SensHy (grant No. 223998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kluczynski, P., Lundqvist, S., Belahsene, S. et al. Detection of propane using tunable diode laser spectroscopy at 3.37 μm. Appl. Phys. B 108, 183–188 (2012). https://doi.org/10.1007/s00340-012-5054-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5054-1