Abstract

Tellurite nonlinear holey fiber is characterized by a high nonlinearity and a broad transparent window. However, these advantages are canceled by its unflattened dispersion in most practical applications. The unflattened dispersion is due to the fact that tellurite holey fiber with complex structure is difficult to fabricate. In this work we develop a dispersion flattened tellurite composite holey fiber (TCHF). The TCHF has only one ring of holes. The holes are formed by two tellurite glasses. The heavy deformation, which probably occurs for tellurite complex microstructured fiber during the fabrication process, is avoided by this simple structure. The fiber is made of two glasses with different refractive-indices, which improves the flexibility in dispersion engineering. By using this structure the dispersion is engineered to be the most flattened for the highly nonlinear soft glass fiber within 1.5–1.6 μm. Owing to the flattened dispersion and high nonlinearity, more than one octave supercontinuum generation is demonstrated by a femtosecond fiber laser.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Silica holey fiber as the nonlinear waveguide has large advantages. By using a small fiber core, the mode field of light can be tightened to be compact. By engineering the holey cladding elaborately, the chromatic dispersion can be tailored to be small and flat to enable an extremely long interaction distance between pump laser and generated frequencies. The interaction distance can be several orders superior to other kinds of waveguide. The main applications of silica highly nonlinear holey fiber (SHNHF) include supercontinuum (SC) generation, ultrashort pulse compression (UPC), four wavelength mixing (FWM), wavelength conversion (WC), Raman and Brillouin fiber laser, slow light technology, etc. [1–5]. Though the prosperity of SHNHF has brought tremendous opportunities for nonlinear optics, it has two limitations: One is that it is opaque in the mid-IR. The other is that its maximal nonlinear coefficient is relatively low. It is only in the magnitude of several tens of W−1 km−1 at 1.55 μm. Tellurite holey fiber can be transparent from visible to 5 μm. Its nonlinearity can be higher than SHNHF by more than one order of magnitude. However, the dispersion of tellurite holey fiber is difficult to tailor because of the difficulties in fabrication. Tellurite glass shows a low viscosity at the fiber drawing temperature. Moreover the viscosity decreases sharply with the increasing temperature. The suitable temperature range for fiber drawing is only about one-tenth of that of silica glass. Tellurite holey fiber with a complex microstructure could be subject to obvious deformation during the fabrication process. For the tellurite highly nonlinear holey fiber the deformation could be very severe, since it is usually characterized by small core, small holes and fragile cobweb [6, 7]. So far most reported tellurite highly nonlinear holey fibers just have a simple air-clad structure. The dispersion is unflattened. As is well known, a flattened dispersion is important for the applications such as FWM, WC, UPC, SCG, etc. For the available tellurite highly nonlinear holey fibers, their unflattened dispersion cancels the advantage of high nonlinearity greatly in practical applications.

In this work we try to develop a dispersion flattened tellurite composite holey fiber (TCHF). The holey structure of the TCHF is composed of only one ring of holes, so the heavy deformation, which probably occurs for tellurite complex microstructured fiber during the fabrication process, can be avoided. Since the holey structure is simple, to improve the flexibility in tailoring dispersion, we use two tellurite glasses which have different refractive-indices to design and fabricate the TCHF. The holes are formed by two tellurite glasses. As shown in the following section, such a holey structure is not difficult to fabricate. By using this composite holey structure we realize a dispersion flattened tellurite highly nonlinear fiber and demonstrate its SC generation.

2 Experiment

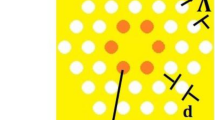

The two tellurite glasses have the components of TeO2–Li2O–WO3–MoO3–Nb2O5 (TLWMN), and TeO2–ZnO–Na2O–La2O3 (TZNL), respectively. At 1.55 μm the refractive-indices are 2.076 for TLWMN, and 1.962 for TZNL. The raw materials in powder were analytic grade. The cane for the fiber drawing was fabricated by the method of rod-in-tube. A TLWMN rod, which had a cross section in the shape of hexagram “✶” was prepared by casting the glass melt in an alloy mold and then annealing it at the glass transition temperature. The TZNL tubes were prepared by the rotational casting method. The TLWMN rod was inserted into a TZNL tube, and then they were elongated into the original cane. The tips of six struts of the rod touched the inside surface of the tube tightly. In this way six holes were formed in the cross section of the original cane. The holes were formed by two different glasses. The original cane was inserted into another TZNL tube and elongated into the final cane. The final cane was inserted into other TZNL jacket tube, and then was fixed at the drawing tower for the fiber drawing. Several hundred meters of fiber was drawn in one time of the fiber drawing.

The fully vectorial finite difference method (FV-FDM) was used to calculate the wavelength dependent propagation constants from which the chromatic dispersion was calculated. The simulation was based on the real fiber structure. To make a comparison, the dispersions of tellurite holey fibers (THFs), which have the same holey structure as TCHF, but are made of one tellurite glass, TLWMN or TZNL, were calculated by FV-FDW. Additionally, the dispersion of TLWMN-TZNL step-index fiber (TSIF) and the dispersion of TLWMN air-clad holey fiber (TAHF) with various core diameters were calculated likewise for discussion.

The SC spectra were measured by using a 1557 nm femtosecond fiber laser. The laser was connected to a single-mode fiber (SMF) by a connector. The beam from the SMF was collimated into parallel by a lens with a numerical aperture (NA) of 0.25. The parallel beam was focused and coupled into the TCHF by a lens with a NA of 0.47. The output end of the TCHF was mechanically spliced with a large-mode-area-fiber by using the butt-joint method. The other end of the large-mode-area-fiber was connected to an optical spectrum analyzer (OSA). The pulse width was 800 fs and the repetition rate was 16.75 MHz. The length of the TCHF was 74 cm. The coupling efficiency, defined as the launched power divided by the power incident on the lens, was about 20%.

The optical loss at 1557 nm for the TCHF was measured by the standard cutback method. After the SC measurement, another CW laser replaced the femtosecond fiber laser at the connector. The loss at 1557 nm is about 5 dB/m. Since the raw materials of the fiber are analytic grade, the losses can be decreased by improving the purity of them.

3 Results and discussions

Figure 1 shows the dispersion of TSIFs with various core diameters. The core and cladding are supposed to be TLWMN and TZNL, respectively. The material dispersion of TLWMN is shown as a reference. With the increasing core diameter, the dispersion curve of fiber gradually approaches the material dispersion. Figure 1 indicates that by using a step-index structure, it is difficult to obtain zero dispersion wavelength (ZDW) shorter than 2 μm. In practical applications it is usually necessary to pump the nonlinear fiber around ZDW. Most commercially available lasers work at wavelengths shorter than 2 μm. Therefore it is difficult for a tellurite fiber in the step-index structure to meet the requirements of most practical applications. Due to the comparatively high refractive-index, the material dispersion of tellurite glass has the ZDW larger than 2 μm. To shift the ZDW to a much shorter wavelength by increasing the waveguide dispersion, a high NA together with a small core is necessary for the fiber structure. For a step-index structure, it is difficult to adjust the compositions of tellurite glasses to obtain a sufficiently large refractive-index difference between core and cladding to meet the requirement of ZDW shift. In this work the refractive-index difference between the two tellurite glasses is already quite high, considering that their physical and chemical properties need to be compatible with each other for the fiber drawing.

Figure 2 shows the dispersion of the TAHFs with various core diameters. For simplicity, the fiber structure is approximately taken as that a circular TLWMN core is surrounded by an air-cladding. The ZDW can be shifted to shorter wavelengths effectively by decreasing the core diameter. However, the slant of the dispersion curve at ZDW is high, and the dispersion reaches a large absolute value given at a wavelength slightly off the ZDW. Such an unflattened dispersion results from the sharp contrast of refractive-indices between core and cladding [8].

Figure 3 shows the fabricated TCHF and its dispersion. Image (a) and (b) in inset (1) were taken by an optical microscope. Image (a) was under reflection mode and (b) was under transmission mode. Since the fiber sample was cut by hand, both ends of it are not strictly parallel and smooth. Image (b) does not show all interfaces of microstructure clearly, but we can still see clear difference between two glasses. Inset (2) shows the calculated dispersion. The ZDW is 1580 nm. A TAHF with the same ZDW is shown for a comparison. The third order dispersions at ZDW are 0.198 ps/(nm2×km) for the TCHF and 1.816 ps/(nm2×km) for the TAHF, respectively. To our knowledge, TCHF has the most flattened dispersion within 1.5–1.6 μm for the highly nonlinear soft glass fibers.

Without holes the TCHF is just step-index. As shown by Fig. 1 there is no ZDW at wavelengths shorter than 2 μm. The function of holes is to realize a large anomalous dispersion to shift the ZDW [9]. Supposed that the holes are extremely large, the structure will just like an air-cladding. As shown by dispersion curves in Figs. 2 and 3, though the ZDW can be shifted effectively, the dispersion is unflattened. Holes with moderate size are necessary to shift the ZDW and ensure a more preferable dispersion simultaneously. As shown in Fig. 3, the dispersions of THFs are much flatter than that of TAHF. However, THFs have only one ring of holes with moderate size, the confinement loss is very high. At ZDW 1580 nm the calculated confinement loss is 76 dB/cm for the THF by TLWMN, and 138 dB/cm for the THF by TZNL. For the wavelengths longer than 1680 nm, no mode can be supported for the THF by TZNL. By using a holey structure with multi-ring holes the confinement loss can be reduced greatly, but it increases the difficulties in fabrication. For our TCHF, the outside segment of the hole-wall is a glass with a lower refractive-index. This glass decreases the confinement loss effectively. At 1580 nm the calculated confinement loss is almost zero. Additionally, by this structure a convex section with maximum located in the wavelength region around the ZDW is formed in the dispersion curve, which results in a flattened dispersion around ZDW.

The TCHF supports multi-modes at 1580 nm. However, since the first higher order mode has a confinement loss about 7 dB/m, an effective single-mode propagation can be obtained by bending the fiber to some extent.

The nonlinear coefficient (γ) was calculated in the same way as that in reference [10]. γ at 1557 nm is 679 km−1 W−1. The measured pulse-energy-dependent SC spectra were shown in Fig. 4. For the pulse with the maximal energy the peak power is 1851 W. The nonlinear length is 7.96×10−4 m. The dispersion length is 2.31 m. The effective fiber length is 0.49 m.

Since the pump wavelength locates at the normal dispersion region, self-phase modulation (SPM) must play an important role in the mechanisms of SC generation [11]. Owing to the flattened dispersion of TCHF, the dispersion length is much longer than the nonlinear length and effective fiber length. The SC broadening benefits from the long dispersion length, since the temporal broadening of pulse is mitigated. In this case the spectrum broadening can be evaluated approximately by δf=(n 2 PL eff)/(A eff λτ) [12, 13], where n 2 is the nonlinear refractive-index of the glass, P is the peak power of the launched pump pulse, L eff is the effective fiber length, A eff is the effective mode area, λ is the wavelength of the pump laser, and τ is the pump pulse width. In our case n 2=5.9×10−19 m2/W, and A eff=3.49×10−12 m2. With the highest pulse energy the δf=1.25×1014 Hz. Therefore the calculated shortest wavelength of SC is 0.94 μm. It is close to the measured one. The longest wavelength is 4.4 μm, which is beyond the scope of OSA (Yokogawa AQ6375, Japan). Since we cannot eliminate hydroxides during the fabrication process due to the limitation of experimental conditions, and the raw materials of TCHF are not of high purity, the fiber loss probably is quite high at some wavelength regions of mid-IR, where the loss is much more sensitive to impurities than in near-IR. The longest wavelength of real SC spectrum must be shorter than 4.4 μm.

4 Conclusions

We have developed a dispersion flattened tellurite highly nonlinear holey fiber. The fiber has only one ring of holes. The holes are formed by two tellurite glasses. The fiber was fabricated by a simple rod-in-tube method. In this scheme, on the one hand the dispersion is engineered to be the most flattened for the high nonlinear soft glass fibers within 1.5–1.6 μm, and on the other hand the difficulties in the fabrication of dispersion flattened soft glass holey fiber with complex microstructure are avoided. Owing to the flattened dispersion and high nonlinearity, more than one octave SC generation was demonstrated by using the fiber under the pump of a 1557 nm femtosecond fiber laser. The work paves the way for the various potential applications of highly nonlinear soft glass holey fiber.

References

Y.P. Yatsenko, A.F. Kosolapov, A.E. Levchenko, S.L. Semjonov, E.M. Dianov, Opt. Lett. 34, 2581 (2009)

G. Chang, T.B. Norris, H.G. Winful, Opt. Lett. 28, 546 (2003)

J.W. Nicholson, A.D. Yablon, M.F. Yan, P. Wisk, R. Bise, D.J. Trevor, J. Alonzo, T. Stockert, J. Fleming, E. Monberg, F. Dimarcello, J. Fini, Opt. Lett. 33, 2038 (2008)

B.A. Cumberland, J.C. Travers, S.V. Popov, J.R. Taylor, Opt. Lett. 33, 2122 (2008)

S. Yang, H. Chen, C. Qiu, M. Chen, M.H. Chen, S. Xie, J. Li, W. Chen, Opt. Lett. 33, 95 (2008)

M. Liao, X. Yan, Z. Duan, T. Suzuki, Y. Ohishi, J. Lightwave Technol. 29, 1018 (2011)

X. Feng, A.K. Mairaj, D.W. Hewak, T.M. Monro, J. Lightwave Technol. 23, 2046 (2005)

C.M.B. Cordeiro, W.J. Wadsworth, T.A. Birks, P.J. St. Russell, Opt. Lett. 30, 1980 (2005)

T. Hasegawa, E. Sasaoka, M. Onishi, M. Nishimura, Y. Tsuji, M. Koshiba, Opt. Express 9, 681 (2001)

M. Liao, C. Chaudhari, G. Qin, X. Yan, T. Suzuki, Y. Ohishi, Opt. Express 17, 12174 (2009)

J.M. Dudley, G. Genty, S. Coen Mod, Phys. Rev. 78, 1135 (2006)

G. Qin, X. Yan, C. Kito, M. Liao, C. Chaudhari, T. Suzuki, Y. Ohishi, Opt. Lett. 34, 2015 (2009)

C. Xia, M. Kumar, O.P. Kulkarni, M.N. Islam, F.L. Terry, Jr., M.J. Freeman, M. Poulain, G. Mazé, Opt. Lett. 31, 2553 (2006)

Acknowledgements

Meisong Liao acknowledges the support of the JSPS Postdoctoral Fellowship. The authors acknowledge the support of MEXT, the Support Program for Forming Strategic Research Infrastructure (2011–2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liao, M., Duan, Z., Gao, W. et al. Dispersion engineering of tellurite holey fiber with holes formed by two glasses for highly nonlinear applications. Appl. Phys. B 105, 681–684 (2011). https://doi.org/10.1007/s00340-011-4821-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-011-4821-8