Abstract

Superhydrophobicity has been a crucial research topic due to its ability to make surfaces stay dry and self-clean. Low-surface-energy organic coatings are widely used to fabricate superhydrophobic surfaces by modifying surface groups and minimizing surface energy. Considering defects would seriously undermine these coatings, which would further lead to hydrophobicity dwindling and lifetime decreasing, researchers have begun to investigate the development of superhydrophobic surfaces without organic coatings. However, it is still controversial whether these superhydrophobic surfaces are really free of organic substances with low surface energy. In this work, O3 bombardment was utilized to construct micro–nanostructures on aluminum foil. The aluminum foil surface turns to superhydrophobic after ozone bombardment with the contact angle (CAs) increasing from 20° to 161°. Results showed the presence of silicon contaminations on alumina surfaces despite the fact that no organic coatings are utilized in the fabrication process. The transition of hydrophilic-to-superhydrophobic was attributed to both surface morphology and silicon contamination from pump oil. Our work reveals that trace organic contamination from pump oil is a key factor that cannot be ignored in scenarios with vacuum pump use, which could provide some favorable evidence to figure out the controversial issue mentioned above.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The fabrication of superhydrophobic surfaces is an essential key to advancing the self-cleaning properties [1, 2], anti-fogging/anti-icing properties [3,4,5,6], and anti-corrosion properties [7,8,9]. Significate progress has been made to fabricate superhydrophobic surfaces in the past few decades [10,11,12,13,14,15,16]. There are a huge amount of ways to fabricate superhydrophobic surfaces; they usually all fall into three categories: (i) construction of hierarchy structures [17,18,19,20], (ii) introduction of low-surface-energy materials, such as fluorochemicals and silicones [21, 22], and (iii) introduction of low-surface-energy materials along with hierarchy structures [23,24,25,26,27,28]. The last approach is vastly employed as the dominant strategy to prepare superhydrophobic surfaces, which is published in the current literature. Kikuchi fabricated alumina nanowires with high roughness through a two-step anodizing process [29]. Followed by chemical modification with fluorinated monolayers, the superhydrophobic material with CAs of 165° was prepared [30,31,32,33,34]. Choi used ultraviolet ozone (UVO) to form nanoscale roughness over the as-formed Al2O3 microstructure; CAs can reach 160° with fluoroalkyl silane modification [23]. While recent reports have shown that the coating lifetime will be significantly shortened by surface defects, such as pinholes [35, 36]. Water blisters initiated at the pinhole defects could attack the coating/substrate interface and result in coating delamination [37]. Scratches in superhydrophobic coatings would lead to intrinsically hydrophobic substrate exposure, leading to wetting and water droplet pinning [38]. Furthermore, it has attached great attention that organic solvents and fluorocarbons typically have great potential damage to the environment. Therefore, there are several works have reported that superhydrophobicity can be realized only by constructing the surface morphology instead of utilizing organic coatings [18,19,20, 39,40,41,42,43,44].

However, some of them are clearly untenable because of the lack of considering organic contaminations. Ta claims superhydrophobic surfaces were fabricated on the surface of copper and/or copper oxides and the change in the wetting property is attributed to the modification of both surface morphology and partial deoxidation of oxides on the surface induced during laser texturing [45]. Boinovich, however, pointed out that organic substances were the crucial reason for superhydrophobicity in the above literature. The rapid deterioration of the sample’s hydrophobicity in contact with methyl alcohol, which is a solvent for many organics, demonstrated the removal of organic molecules from the surface of copper and/or copper oxides and the clear relationship between superhydrophobic and carbon contaminations [46]. Lian holds the view that titanium can achieve the superhydrophilic-to-superhydrophobic wettability transition with the laser process and subsequently low-temperature annealing instead of organic coatings [47]. On the contrary, Gregorčič suggests different views that their annealing happened in a furnace and/or laboratory contaminated by organic compounds, which leads to the transition from hydrophilic to superhydrophobic [48]. Hence, although some results in the literature suggest that hydrophilic-to-hydrophobic transition can be achieved only by constructing the surface morphology [49, 50], the organic contamination is a crucial factor, which cannot be ignored, in the transition from hydrophilic to superhydrophobic [51, 52].

In this work, a one-step O3 bombardment method was proposed to fabricate the micro–nanohierarchy structure. CAs of samples increase dramatically from 19.8° to 161.2° after O3 bombardment. By constructing the micro–nanohierarchy structure, it seems superhydrophobic surfaces are fabricated without utilizing organic coatings. However, further research and analysis have confirmed that silicon contamination indeed exists on the surface of samples. XPS shows the above silicon contamination could be PDMS with the hydrophobic groups of Si–CH3, which is widely utilized to modify surface groups and minimize surface energy. During further annealing treatment, the hydrophobic groups of Si–CH3 decompose and are replaced by hydrophilic groups of Si–OH, therefore, leading to the deterioration of superhydrophobicity. To sum up, the factor of trace organic contamination should be well-considered, while superhydrophobic materials have been fabricated only by constructing surface morphology.

2 Experimental

2.1 Materials

Commercially aluminum anode foils (125 μm, Zhaoqing Huafeng Co. Ltd, Guangdong, China) were used as substrates without further treatment. These aluminum anode foil were fabricated by two procedures: (i) the aluminum etched foil was obtained by electrochemical etching to form tunnel holes, which has inner diameters of 0.5–1.5 μm and depths of about 40 μm, on the surface of the high-purity aluminum foil; (ii) alumina of approximately 725 nm is grown on the surface of the aluminum etched foil by anodization. Deionized water was prepared by the UPD-I-10T water system (18.25 MΩ, Sichuan Youpu Co. Ltd, Chengdu, China).

2.2 Fabrication of the superhydrophobic surface

Pure oxygen (99.99%) was supplied to the ozone generator as the source gas. The ozone generator (CX-MB-II, Shenzhen Yuansu Technology Co. Ltd, China), which is connected to ALD equipment (E200S, Shenzhen Yuansu Technology Co. Ltd, China), was used to transform O2 to O3. The schematic diagram of the device is shown in Fig. S1. The input of O2 flow mass was set as 1000 sccm controlled by the Mass Flow Controller (MFC). The concentrations and output of ozone are 72.57 mg·L−1 and 4.35 g·h−1, respectively.

Samples (4 * 4 cm) were taped to the sample stage with high-temperature resistant tape, evacuating the ALD chamber to 0.005 Torr, and the sample stage was heated to 200 °C. Finally, O3 was continuously introduced into the ALD chamber to bombard samples with 0.5 (S1), 1 (S2), 3 (S3), 5 (S4), 10 (S5), 20 (S6), 30 (S7), and 40 (S8) min. The vacuum pump (TRIVAC C, Leybold Gmbh, Germany) was running throughout the whole process to exclude the deactivated O3 molecules and thus to ensure the reactivity of O3 in the ALD chamber. An untreated sample (S0) was also analyzed for comparison.

2.3 Characterization

The morphology and microstructure of samples with different treatments were observed with the field-emission scanning electron microscope (Gemini SEM 500, ZEISS, German). The crystal structure of alumina was detected by an X’pert Pro X-ray diffractometer (X’pert MRD, PANalytical B.V., Holland). The functional groups on the aluminum foil surface with and without O3 bombardment were characterized by Fourier Transform Infrared Reflection (VERTEX 70, Bruker Optics, Germany). The wetting behavior of samples was measured by Contact Angle Meter (Theta Flex, Biolin Scientific Technology Co. Ltd, Sweden).

3 Results and discussion

3.1 Fabrication of dual-scale structure and superhydrophobic properties

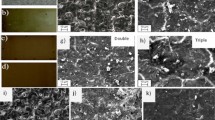

The nanostructure alumina was fabricated on the upper surface and inside the tunnel hole utilizing O3 bombardment. As shown in Fig. 1a, b, there are several holes on the surface of sample S0. In the meantime, the upper surface (Fig. 1c) and the interior (Fig. 1d) of these holes have fluffy Al2O3, which are less number and dense. Figure 1e, f presents these holes becoming gaps with a smaller size and number after 40 min O3 bombardment due to the growth of feather-like Al2O3. The morphology shown in Fig. 1g, h demonstrates that the feather-like Al2O3 grown on the microstructure of sample S8 is much larger and denser than S0. Eventually, nanostructure alumina was fabricated on the surface of microstructure alumina by the O3 bombardment process, forming a dual-scale structure.

According to the metal oxide growth mechanism described by the Wagner theory [53] and Cabrera–Mott theory [54,55,56], the subsequent oxide growth depends on ion diffusion when oxide grown on the metal substrate reaches a certain thickness. It is a widely held view that ion diffusion channels could be defects (such as vacancies and gaps) and grain boundaries. Defects such as oxygen vacancies in alumina can act as diffusion channels for Al3+ with the help of the ultra-high-pressure environment and 200 °C heating, which could be more favorable for the diffusion of ions [57]. In addition, as a highly reactive gas, O3 decomposition occurs readily on the alumina surface [58, 59]. The likely O3 decomposition routes involve the formation of molecular O2 and atomic O species [60, 61]:

Due to its highly reactive nature, atomic O would absorb on the alumina surface and interreact with Al3+ to form alumina. The defects inside and on the surface of alumina film are relatively few and sparsely distributed, so that the Al2O3 formed by O3 bombardment is also sparsely distributed and maintains a feather-like pattern instead of a uniform layer.

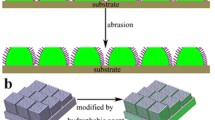

To understand effects of O3 bombardment time on the wettability of samples, different bombarding times, including 0.5, 1, 3, 5, 10, 20, 30, and 40 min, have been investigated. The data in Fig. 2a and Table S1 illustrate that alumina surfaces behave as superhydrophobic with CAs more than 150° after the O3 bombardment. In comparison, sample S0 behaves as hydrophilic with mean CAs of 19.81° (Table S2). As shown in Fig. 2b, the same feather-like Al2O3 in Fig. 1g, h was observed in samples S1, S2, S5, and S6, which may be attributed to the transition from hydrophilicity to superhydrophobicity. Figure 2c displays the design and fabrication schematic for the micro–nanohierarchy structure. The above experiment results show that the alumina surface remains hydrophilic before the O3 bombardment process while suddenly becomes superhydrophobic after the O3 bombardment process.

For a rough surface, there exist two different wetting regimes: homogeneous and heterogeneous ones. Both regimes correspond to the minimum Gibbs free energy of the three-phase system containing a wetted substrate, wetting liquid, and surrounding phase (other liquid or vapor) [51, 62]. In the heterogeneous wetting regime, the contact angle can be explained with the Cassie–Baxter model:

where θCB refers to the apparent contact angle; θ corresponds to Young’s angle; rsl is the roughness of wetted areas; f1 refers to the fractional contacts of substrate surface wetted by liquid [63].

According to the Cassie–Baxter equation, θCB can be manipulated by varying the surface morphology and topography, while such superhydrophobic states are only the realization of metastability. Besides, organic contamination should not be neglected when superhydrophobicity is achieved by simply varying the surface morphology and topography. Therefore, it is important to realize whether organic contaminations exist or not.

3.2 Effects and origins of organic contamination

To investigate whether organic contamination exists or not, a series of tests and analyses have proceeded. As displayed in Fig. 3a, no carbon peaks were founded in the X-ray diffraction results. There are five same characteristic peaks in the samples without (S0) and with (S8) O3 bombardment, which are indexed as Al2O3 (202), Al2O3 (214), Al2O3 (131), Al (111), and Al (200), respectively. The intensity of these diffraction peaks shows no differences as well. Characteristic peaks of Al (111) and Al (200) can be attributed to Al substrates. Besides, due to low surface energy, organic solvent and fluorocarbon coatings are widely used to modify surfaces and obtain superhydrophobicity. Surface functional groups of these modified coatings significantly contribute to their low surface energy. Therefore, it is vital to investigate the discrepancy of functional groups on alumina surfaces without (S0) and with (S8) O3 bombardment. There are two varieties displayed in Fig. 3b. The absorption peak at 3408 cm−1, identified as the O–H stretching mode in water, has a distinct reduction after bombardment. It indicates that H2O molecules, which absorb on alumina surfaces and remain in the micro–nanostructure gaps, are mainly decreased due to the superhydrophobicity. Correspondingly, the Al–O stretching vibration in Al2O3, located in 1073 cm−1, becomes stronger after bombardment due to the generation of feather-like Al2O3. It is worth noting that no other new absorption peaks appear after the O3 bombardment.

However, XRD and FTIR were not sensitive enough to detect organic contamination in very small amounts. More detailed analyses of surface chemistry need to be provided to establish whether organic contamination is contributing to achieving superhydrophobicity instead of hydrophilicity. Therefore, XPS was carried out to detect organic contamination. As shown in Fig. 3c, the high resolution Al 2p core level spectrum locates at Eb = 74.7 eV, suggesting that the Al is entirely in the trivalent state [64, 65]. The O 1s components of S0 display two main spectral features located at Eb = 531.08 and 532.55 eV (Fig. 3d), which correspond to the O–Al and O–H bonds, respectively [66]. However, the corresponding intensity of O–H bonds of S8 has a relative drop. In the meantime, there is a new peak located at Eb = 531.80 eV appears, suggesting the O–Si bonds were introduced to the surface of aluminum foil [66]. Figure 3e illustrates the intensity of C 1s spectrum decreased and two peaks located at Eb = 284.3 eV (C–Si) and Eb = 285.0 eV (C–H) emerge after the O3 bombardment, though its intensity was not very strong [67]. More importantly, we observed a peak at Eb = 101.9 eV in the Si 2p spectrum of S8 (Fig. 3f) [68]. The appearance of the Si 2p peak illustrates that samples have been contaminated during the O3 bombardment process. It is worth noting that PDMS has highly similar XPS characteristics to the silicon contamination in our work [69, 70]. Taken together, these results suggest that this silicon contamination could be polydimethylsiloxane (PDMS).

PDMS is one of the most widely used silicone-based polymers in microfluidics. There are different methods have been developed to transform the hydrophobic PDMS surface into a hydrophilic surface, such as plasma oxidation, thermal aging, and chemical coating [71]. Especially, the hydrophobicity of PDMS will turn to hydrophilic after a proper annealing process due to the hydrophobic groups of Si–CH3 being replaced by hydrophilic groups of Si–OH [72, 73]. Therefore, to verify whether silicon contamination (PDMS) is contributing to the realization of superhydrophobicity, high-temperature annealing treatment in the air has proceeded to sample S8. As displayed in Fig. 2a and Table 1, CAs decrease dramatically from 161.15° to 64.00° after S8 was annealed in the air atmosphere for 2 min at 500 °C, which could be contributed to the removal of hydrophobic groups of Si–CH3. When the above sample was re-bombarded for 40 min, the superhydrophobic was restored with CAs of 154.93°, indicating that contamination occurred again during the O3 bombardment process.

Figure 4 shows the spectra for Al 2p, O 1s, C 1s, and Si 2p for totals and the fit of sample S8 after 500 °C anneal, which can distinctly prove the transition of surface functional groups from Si–CH3 to Si–OH. The peak of Al 2p still locates at Eb = 74.7 eV (Fig. 4a). Compare to sample S8, peaks for O1s O–Al (531.08 eV), O1s O–Si (531.80 eV), and O1s O–H (532.55 eV) increase due to the oxidization during annealing (Fig. 4b). As displayed in Fig. 4c, the characteristic peak of the binding energy at 285.0 eV corresponds to C–H disappears, indicating the removal of hydrophobic groups of Si–CH3. What is more, it is found that the position of the Si 2p characteristic peak is shifted to higher binding energy before and after annealing (Fig. 4d), indicating that part of the atom bonding to Si was transformed from C atoms to O atoms. Si 2p peak was fitted with two distinctive subpeaks for Si–O2 at 101.9 eV and Si–O3 at 102.9 eV [74]. The appearance of the peak of Si–O3 also shows PDMS was been oxidized during annealing.

Table 2 shows the elemental surface composition of S0, S8, and annealed S8 determined by XPS. As we can see, no detectable signals for Si atoms were found in sample S0. However, there exist the Si element of 6.71% in sample S8, which indicates the presence of silicon contamination. The Al and O compositions of S8 are lower than S0, because Al2O3 was buried inside the PDMS and the hydrophobic groups were at the outermost surface. After 500 °C anneal, the O compositions increase, whereas the C composition decreases, which also demonstrates the oxidization of Si–CH3 during the annealing proceed.

By the above analysis, we may draw a conclusion that silicon contamination indeed exists, although no organic solvents were used in the preparation of our samples. Besides, silicon contamination has a great contribution to the realization of superhydrophobicity. However, superhydrophobicity was not founded (Fig. S1) when aluminum foils with plat surface were treated with the same treatment as S8, which illustrates that the surface morphology is indispensable to the realization of superhydrophobicity as well. Based on the above analysis, we may confirm that the considerable discrepancy in wettability between samples without and with O3 bombardment is due to both the construction of micro–nanohierarchy surface morphology and the presence of PDMS contaminations on the surface of Al2O3.

Although residual precursors could be present in the piping of ALD equipment, the temperature of the sample stage is set to 200 °C, which is consistent with the deposition temperature of oxide films (TiO2, Al2O3, and SnO2) deposited in our laboratory. Therefore, these organics would be reacted by the highly reactive O3 molecules and cannot be adsorbed on the surface of samples. However, pump oil contains a variety of organic substances, which makes pump oil a possible source of silicon contamination. The LVO100 Leybold pump oil used in our laboratory is a lubricant prepared by chemical synthesis into a higher molecular compound and then further processed. This kind of pump oil contains PDMS in its composition.

Normally, people believe that pump oil will not be inverted suctioned into the ALD chamber, but in fact, the improper use of the vacuum pump does make the inverted suction happens. As shown in Fig. S2, there is a valve between the vacuum pump and the ALD chamber. The correct operation order for evacuating the ALD chamber is to open the vacuum pump first and then open the valve. However, when the valve is opened first and the pressure inside the ALD chamber is less than atmospheric pressure, the pump oil will be suctioned into the ALD chamber and contaminate samples due to the pump chamber being at atmospheric pressure. The lower pressure inside the ALD chamber, the higher the pressure difference between the ALD chamber and the pump chamber, and the greater possibility of pump oil inverted suction into the ALD chamber and contaminating samples. Thus, silicon contamination was introduced to the surface of samples during the O3 bombardment and, therefore, attributed to the realization of superhydrophobicity with the construct of micro–nanohierarchy structures.

4 Conclusions

The alumina surfaces with micro–nanohierarchy structures were manufactured by the O3 bombardment method. The formation process of feather-like Al2O3 and the mechanism of superhydrophobicity were analyzed. There are two main factors for the hydrophilic-to-superhydrophobic transition: the construction of the micro-nanostructure and the trace silicon contaminations on the surface of Al2O3. Trace silicon contaminations are derived from pump oil, which contained PDMS in its composition. We believe that this research is helpful in paying attention to pump oil contamination in scenarios with vacuum pump use.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

C. Neinhuis, W. Barthlott, Characterization and distribution of water-repellent, self-cleaning plant surfaces. Ann. Bot. 79(6), 667–677 (1997)

I.P. Parkin, R.G. Palgrave, Self-cleaning coatings. J. Mater. Chem. 15(17), 1689–1695 (2005)

S. Farhadi, M. Farzaneh, S.A. Kulinich, Anti-icing performance of superhydrophobic surfaces. Appl. Surf. Sci. 257(14), 6264–6269 (2011)

S.A. Kulinich, S. Farhadi, K. Nose, X.W. Du, Superhydrophobic surfaces: are they really ice-repellent? Langmuir 27(1), 25–29 (2011)

O. Parent, A. Ilinca, Anti-icing and de-icing techniques for wind turbines: critical review. Cold Reg. Sci. Technol. 65(1), 88–96 (2011)

Q.L. Zhang, M. He, J. Chen, J.J. Wang, Y.L. Song, L. Jiang, Anti-icing surfaces based on enhanced self-propelled jumping of condensed water microdroplets. Chem. Commun. 49(40), 4516–4518 (2013)

S.L. Zheng, C. Li, Q.T. Fu, W. Hu, T.F. Xiang, Q. Wang, M.P. Du, X.C. Liu, Z. Chen, Development of stable superhydrophobic coatings on aluminum surface for corrosion-resistant, self-cleaning, and anti-icing applications. Mater. Des. 93, 261–270 (2016)

E. Vazirinasab, R. Jafari, G. Momen, Application of superhydrophobic coatings as a corrosion barrier: a review. Surf. Coat. Technol. 341, 40–56 (2018)

F.Z. Zhang, L.L. Zhao, H.Y. Chen, S.L. Xu, D.G. Evans, X. Duan, Corrosion resistance of superhydrophobic layered double hydroxide films on aluminum. Angew. Chem. Int. Ed. Engl. 47(13), 2466–2469 (2008)

G.Y. Wang, Y.Z. Shen, J. Tao, X.Y. Luo, L.Q. Zhang, Y.P. Xia, Fabrication of a superhydrophobic surface with a hierarchical nanoflake–micropit structure and its anti-icing properties. RSC Adv. 7(16), 9981–9988 (2017)

R.Y. Sun, J. Zhao, Z. Li, N. Qin, J.L. Mo, Y.J. Pan, D.B. Luo, Robust superhydrophobic aluminum alloy surfaces with anti-icing ability, thermostability, and mechanical durability. Prog. Org. Coat. 147, 105745 (2020)

C.H. Xue, S.T. Jia, J. Zhang, J.Z. Ma, Large-area fabrication of superhydrophobic surfaces for practical applications: an overview. Sci. Technol. Adv. Mater. 11(3), 033002 (2010)

E.K. Sam, D.K. Sam, X.M. Lv, B.T. Liu, X.X. Xiao, S.H. Gong, W.T. Yu, J. Chen, J. Liu, Recent development in the fabrication of self-healing superhydrophobic surfaces. Chem. Eng. J. 373, 531–546 (2019)

N.F. Himma, N. Prasetya, S. Anisah, I.G. Wenten, Superhydrophobic membrane: progress in preparation and its separation properties. Rev. Chem. Eng. 35(2), 211–238 (2019)

Y.X. Bai, H.P. Zhang, Y.Y. Shao, H. Zhang, J. Zhu, Recent progresses of superhydrophobic coatings in different application fields: an overview. Coatings 11(2), 116–146 (2021)

S.W. Lv, X.M. Zhang, X.D. Yang, X.L. Liu, Z.J. Yang, Y. Zhai, Fabrication of superhydrophobic surface with corrosion resistance via cyclic chemical etching process on aluminum substrate. Mater. Res. Express 9(2), 026520 (2022)

Q. Yin, Q. Guo, Z.L. Wang, Y.Q. Chen, H.G. Duan, P. Cheng, 3D-printed bioinspired Cassie-Baxter wettability for controllable microdroplet manipulation. ACS Appl. Mater. Interfaces 13(1), 1979–1987 (2021)

L. Savio, K.B. Bhavitha, G. Bracco, G. Luciano, D. Cavallo, G. Paolini, S. Passaglia, G. Carraro, L. Vattuone, R. Masini, M. Smerieri, Correlating hydrophobicity to surface chemistry of microstructured aluminium surfaces. Appl. Surf. Sci. 542, 148574 (2021)

H.Y. Tao, X.W. Song, Z.Q. Hao, J.Q. Lin, One-step formation of multifunctional nano- and microscale structures on metal surface by femtosecond laser. Chin. Opt. Lett. 13(6), 061402–061405 (2015)

M.J. Eskandari, A. Shafyei, F. Karimzadeh, Investigation of wetting properties of gold nanolayer coated aluminum surfaces textured with continuous-wave fiber laser ablation. Thin Solid Films 711, 138278 (2020)

X.L. Wang, H.Y. Hu, Q. Ye, T.T. Gao, F. Zhou, Q.J. Xue, Superamphiphobic coatings with coralline-like structure enabled by one-step spray of polyurethane/carbon nanotube composites. J. Mater. Chem. 22(19), 9624–9631 (2012)

A. Hooda, M.S. Goyat, J.K. Pandey, A. Kumar, R. Gupta, A review on fundamentals, constraints and fabrication techniques of superhydrophobic coatings. Prog. Org. Coat. 142, 105557 (2020)

S.J. Choi, K.Y. Suh, H.H. Lee, A geometry controllable approach for the fabrication of biomimetic hierarchical structure and its superhydrophobicity with near-zero sliding angle. Nanotechnology 19(27), 275305 (2008)

S.Y. Li, X.G. Xiang, B.H. Ma, X.D. Meng, Facile preparation of diverse alumina surface structures by anodization and superhydrophobic surfaces with tunable water droplet adhesion. J. Alloys Compd. 779, 219–228 (2019)

S. Peng, D. Tian, X.J. Yang, W.L. Deng, Highly efficient and large-scale fabrication of superhydrophobic alumina surface with strong stability based on self-congregated alumina nanowires. ACS Appl. Mater. Interfaces 6(7), 4831–4841 (2014)

T. Fujii, Y. Aoki, H. Habazaki, Fabrication of super-oil-repellent dual pillar surfaces with optimized pillar intervals. Langmuir 27(19), 11752–11756 (2011)

X.T. Zhu, Z.Z. Zhang, X.H. Xu, X.H. Men, J. Yang, X.Y. Zhou, Q.J. Xue, Facile fabrication of a superamphiphobic surface on the copper substrate. J. Colloid Interface Sci. 367(1), 443–449 (2012)

X. Deng, L. Mammen, H.J. Butt, D. Vollmer, Candle soot as a template for a transparent robust superamphiphobic coating. Science 335(6064), 67–70 (2012)

D. Nakajima, T. Kikuchi, S. Natsui, R.O. Suzuki, Highly ordered anodic alumina nanofibers fabricated via two distinct anodizing processes. ECS Electrochem. Lett. 4(5), H14–H17 (2015)

T. Kikuchi, F. Onoda, M. Iwai, R.O. Suzuki, Influence of sub-10 nm anodic alumina nanowire morphology formed by two-step anodizing aluminum on water wettability and slipping behavior. Appl. Surf. Sci. 546, 149090 (2021)

D. Nakajima, T. Kikuchi, S. Natsui, R.O. Suzuki, Mirror-finished superhydrophobic aluminum surfaces modified by anodic alumina nanofibers and self-assembled monolayers. Appl. Surf. Sci. 440, 506–513 (2018)

D. Nakajima, T. Kikuchi, T. Yoshioka, H. Matsushima, M. Ueda, R.O. Suzuki, S. Natsui, A superhydrophilic aluminum surface with fast water evaporation based on anodic alumina bundle structures via anodizing in pyrophosphoric acid. Materials (Basel) 12(21), 3497–3509 (2019)

R. Kondo, D. Nakajima, T. Kikuchi, S. Natsui, R.O. Suzuki, Superhydrophilic and superhydrophobic aluminum alloys fabricated via pyrophosphoric acid anodizing and fluorinated SAM modification. J. Alloys Compd. 725, 379–387 (2017)

D. Nakajima, T. Kikuchi, S. Natsui, R.O. Suzuki, Advancing and receding contact angle investigations for highly sticky and slippery aluminum surfaces fabricated from nanostructured anodic oxide. RSC Adv. 8(65), 37315–37323 (2018)

P. Hale, S. Turgeon, P. Horny, F. Lewis, N. Brack, G.V. Riessen, P. Pigram, D. Mantovani, X-ray photoelectron emission microscopy and time-of-flight secondary ion mass spectrometry analysis of ultrathin fluoropolymer coatings for stent applications. Langmuir 24(15), 7897–7905 (2008)

H.C. Hu, Y. Li, N. Zhang, Y.S. Ding, Synthesis and characterization of a poly(o-anisidine)–SiC composite and its application for corrosion protection of steel. RSC Adv. 7(19), 11732–11742 (2017)

J.C. Ma, H. Cha, M.K. Kim, D.G. Cahill, N. Miljkovic, Condensation induced delamination of nanoscale hydrophobic films. Adv. Funct. Mater. 29(43), 4516–4518 (2019)

D.H. Wang, Q.Q. Sun, M.J. Hokkanen, C.L. Zhang, F.Y. Lin, Q. Liu, S.P. Zhu, T.F. Zhou, Q. Chang, B. He, Q. Zhou, L.Q. Chen, Z.K. Wang, R. Ras, X. Deng, Design of robust superhydrophobic surfaces. Nature 582(7810), 55–59 (2020)

Z.J. Chen, Y.B. Guo, S.M. Fang, A facial approach to fabricate superhydrophobic aluminum surface. Surf. Interface Anal. 42(1), 1–6 (2009)

B. Yan, J. Tao, C. Pang, Z. Zheng, Z. Shen, C.H. Huan, T. Yu, Reversible UV-light-induced ultrahydrophobic-to-ultrahydrophilic transition in an alpha-Fe2O3 nanoflakes film. Langmuir 24(19), 10569–10571 (2008)

C. Yang, S.H. Cui, Y.C. Weng, Z.C. Wu, L.L. Liu, Z.Y. Ma, X.B. Tian, R.K.Y. Fu, P.K. Chu, Z.Z. Wu, Scalable superhydrophobic T-shape micro/nano structured inorganic alumina coatings. Chem. Eng. J. 409, 128142 (2021)

S. Parvate, P. Dixit, S. Chattopadhyay, Superhydrophobic surfaces: insights from theory and experiment. J. Phys. Chem. B 124(8), 1323–1360 (2020)

A. Chaudhary, H.C. Barshilia, Nanometric multiscale rough CuO/Cu(OH)2 superhydrophobic surfaces prepared by a facile one-step solution-immersion process: transition to superhydrophilicity with oxygen plasma treatment. J. Phys. Chem. C 115(37), 18213–18220 (2011)

K.S. Liu, M.Y. Cao, A. Fujishima, L. Jiang, Bio-inspired titanium dioxide materials with special wettability and their applications. Chem. Rev. 114(19), 10044–10094 (2014)

D.V. Ta, A. Dunn, T.J. Wasley, R.W. Kay, J. Stringer, P.J. Smith, C. Connaughton, J.D. Shephard, Nanosecond laser textured superhydrophobic metallic surfaces and their chemical sensing applications. Appl. Surf. Sci. 357, 248–254 (2015)

L.B. Boinovich, A.M. Emelyanenko, K.A. Emelyanenko, A.G. Domantovsky, A.A. Shiryaev, Comment on “Nanosecond laser textured superhydrophobic metallic surfaces and their chemical sensing applications” by Duong V. Ta, Andrew Dunn, Thomas J. Wasley, Robert W. Kay, Jonathan Stringer, Patrick J. Smith, Colm Connaughton, Jonathan D. Shephard (Appl. Surf. Sci. 357 (2015) 248–254). Appl. Surf. Sci. 379, 111–113 (2016)

Z.X. Lian, J.K. Xu, Z.J. Yu, P. Yu, W.F. Ren, Z.B. Wang, H.D. Yu, Bioinspired reversible switch between underwater superoleophobicity/superaerophobicity and oleophilicity/aerophilicity and improved antireflective property on the nanosecond laser-ablated superhydrophobic titanium surfaces. ACS Appl. Mater. Interfaces 12(5), 6573–6580 (2020)

P. Gregorčič, Comment on “Bioinspired reversible switch between underwater superoleophobicity/superaerophobicity and oleophilicity/aerophilicity and improved antireflective property on the nanosecond laser-ablated superhydrophobic titanium surfaces.” ACS Appl. Mater. Interfaces 13(2), 2117–2127 (2021)

T.L. Liu, C.J. Kim, Repellent surfaces. Turning a surface superrepellent even to completely wetting liquids. Science 346(6213), 1096–1100 (2014)

Q.S. Zheng, Y. Yu, Z.H. Zhao, Effects of hydraulic pressure on the stability and transition of wetting modes of superhydrophobic surfaces. Langmuir 21(26), 12207–12212 (2005)

L.B. Boinovich, A.M. Emelyanenko, A.S. Pashinin, C.H. Lee, J. Drelich, Y.K. Yap, Origins of thermodynamically stable superhydrophobicity of boron nitride nanotubes coatings. Langmuir 28(2), 1206–1216 (2012)

V.S. Yalishev, M. Iqbal, V.V. Kim, S.A. Khan, R.A. Ganeev, A.S. Alnaser, Reversible wettability transition of laser-textured metals after vacuum storing and low-temperature annealing. Appl. Phys. A 127(5), 393 (2021)

J.M. Bailey, I.M. Ritchie, Metal oxidation: an electrochemical perspective. Oxid. Met. 30(5–6), 405–418 (1988)

C. Ocal, S. Ferrer, N. García, Diffusion of metallic atoms through thin oxides in metallic substrates. Surf. Sci. 162(1–3), 558–562 (1985)

M.C. Muñoz, J.L. Sacedón, Electron stimulated oxidation of silicon surfaces. J. Chem. Phys. 74(8), 4693–4700 (1981)

L.P. Ramírez, F. Bournel, J.J. Gallet, L. Dudy, F. Rochet, Testing the Cabrera-Mott oxidation model for aluminum under realistic conditions with near-ambient pressure photoemission. J. Phys. Chem. C 126(5), 2517–2530 (2022)

Z.Q. Yang, L.L. He, J. Chen, H.T. Cong, H.Q. Ye, Microstructure and thermal stability of an ultrafine Al/Al2O3 composite. J. Mater. Res. 18(2), 272–278 (2011)

S. Fukuzaki, H. Urano, T. Yamaguchi, Effect of modification of alumina surfaces by ozone on adsorption behavior of bovine serum albumin at alumina-water interfaces. J. Ferment. Bioeng. 84(5), 407–413 (1997)

F. Qi, Z.L. Chen, B.B. Xu, J.M. Shen, J. Ma, C. Joll, A. Heitz, Influence of surface texture and acid–base properties on ozone decomposition catalyzed by aluminum (hydroxyl) oxides. Appl. Catal. B 84(3–4), 684–690 (2008)

K. Thomas, P.E. Hoggan, L. Mariey, J. Lamotte, J.C. Lavalley, Experimental and theoretical study of ozone adsorption on alumina. Catal. Lett. 46(1/2), 77–82 (1997)

I. Popova, V. Zhukov, J.T. Yates, Comparative study of Al(111) oxidation with O3 and O2. Surf. Sci. 518(1–2), 39–48 (2002)

A. Marmur, Wetting on hydrophobic rough surfaces: to be heterogeneous or not to be? Langmuir 19(20), 8343–8348 (2003)

J.W. Drelich, L. Boinovich, E. Chibowski, C.D. Volpe, L. Hołysz, A. Marmur, S. Siboni, Contact angles: history of over 200 years of open questions. Surf. Innov. 8(1–2), 3–27 (2020)

L.D. Lai, J.F. Yan, J. Li, B. Lai, Co/Al2O3-EPM as peroxymonosulfate activator for sulfamethoxazole removal: performance, biotoxicity, degradation pathways and mechanism. Chem. Eng. J. 343, 676–688 (2018)

P. Marcus, C. Hinnen, I. Olefjord, Determination of attenuation lengths of photoelectrons in aluminium and aluminium oxide by angle-dependent X-ray photoelectron spectroscopy. Surf. Interface Anal. 20(11), 923–929 (1993)

Y. Ai, N. Yin, Y.Q. Ouyang, Y.X. Xu, P.F. Yang, Waste non-burn-free brick derived sulfhydryl functioned magnetic zeolites and their efficient removal of uranium (VI) ions. Appl. Surf. Sci. 571, 151241 (2022)

M.B. Kant, S.D. Shinde, D. Bodas, K.R. Patil, V.G. Sathe, K.P. Adhi, S.W. Gosavi, Surface studies on benzophenone doped PDMS microstructures fabricated using KrF excimer laser direct write lithography. Appl. Surf. Sci. 314, 292–300 (2014)

I. Milošev, Ž Jovanović, J.B. Bajat, R. Jančić-Heinemann, V.B. Mišković-Stanković, Surface analysis and electrochemical behavior of aluminum pretreated by vinyltriethoxysilane films in mild NaCl solution. J. Electrochem. Soc. 159(7), C303–C311 (2012)

T.P. Galhenage, D.C. Webster, A.M.S. Moreira, R.J. Burgett, S.J. Stafslien, L. Vanderwal, J.A. Finlay, S.C. Franco, A.S. Clare, Poly(ethylene) glycol-modified, amphiphilic, siloxane–polyurethane coatings and their performance as fouling-release surfaces. J. Coat. Technol. Res. 14(2), 307–322 (2016)

S. Aerts, A. Vanhulsel, A. Buekenhoudt, H. Weyten, S. Kuypers, H. Chen, M. Bryjak, L.E.M. Gevers, I.F.J. Vankelecom, P.A. Jacobs, Plasma-treated PDMS-membranes in solvent resistant nanofiltration: characterization and study of transport mechanism. J. Membr. Sci. 275(1–2), 212–219 (2006)

S.H. Tan, N.T. Nguyen, Y.C. Chua, T.G. Kang, Oxygen plasma treatment for reducing hydrophobicity of a sealed polydimethylsiloxane microchannel. Biomicrofluidics 4(3), 32204 (2010)

A. Öztürk, A.B. Yurtcan, Effect of calcination temperature on hydrophobicity of microporous layers prepared with two different molecular weights of PDMS polymer on PEM fuel cell performance with low Pt loading. Int. J. Hydrogen Energy 42(9), 6250–6261 (2017)

K.Q. Li, X.R. Zeng, H.Q. Li, X.J. Lai, H. Xie, Effects of calcination temperature on the microstructure and wetting behavior of superhydrophobic polydimethylsiloxane/silica coating. Colloids Surf. A 445, 111–118 (2014)

Y.G. Kim, N. Lim, J. Kim, C. Kim, J. Lee, K.H. Kwon, Study on the surface energy characteristics of polydimethylsiloxane (PDMS) films modified by C4F8/O2/Ar plasma treatment. Appl. Surf. Sci. 477, 198–203 (2019)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Granted no. 51777152), the Natural Science Foundation of Shaanxi Province (Granted no. 2021JZ-01), and the Postdoctoral Science Foundation of China (Granted no. 2020M683465). The authors thank Mr. Ren at the Instrument Analysis Center of Xi’an Jiaotong University for his assistance with SEM measurement. The authors thank Ms. Liang of Xi’an Jiaotong University for her assistance with the mechanism study.

Author information

Authors and Affiliations

Contributions

Conceptualization, ZL, XD, LX; methodology, ZL, ZL; investigation, ZL, ZZ; writing—original draft, ZL; writing—review and editing, ZL, XD, LX; funding acquisition, XD, ZL. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Liang, Z., Du, X. et al. Effects of trace organic contamination on micro–nanostructure-induced superhydrophobic properties. Appl. Phys. A 129, 432 (2023). https://doi.org/10.1007/s00339-023-06712-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06712-z