Abstract

SnSe with layered structure, as a member of 2D materials and transition metal chalcogenides, is a promising candidate of electrocatalyst for hydrogen evolution. Reduced graphene oxide (RGO) is an excellent substrate of electrocatalyst. In this work, SnSe nanosheets (NSs) had been prepared via liquid exfoliation, and the as-prepared SnSe NSs had been hybridized with RGO by a simple hydrothermal method. The SnSe/RGO hybrid shows superior hydrogen evolution reaction (HER) performance and charge transfer capability than SnSe NSs. In addition, it exhibits a superior HER performance in 1.0 M H2SO4 with overpotential of − 298.79 mV (vs. RHE) at a current density of 10 mA/cm2 and a Tafel slope determined to be only 97.56 mV/dec. Moreover, the SnSe/RGO hybrid as working electrode is provided with excellent durability, which is capable of maintaining working current for 10 h. As demonstrated above, relative high activity and stability and low price make the SnSe/RGO hybrid a promising electrocatalyst.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

2D material with high electrochemical performance and atomic thickness has been widely concerned, since graphene was discovered [1,2,3,4]. 2D materials have unique properties in various fields [5, 6]. The surface atoms are enormously exposed, and the atom utilization rate is greatly improved compared to bulk materials [7]. The larger layer spacing and weaker interlayer coupling are provided with the controllable chemical and physical properties. As a result, the enrichment of reactive sites and the shorter carrier migration distance have become advantages of 2D materials, which also reveals the application in catalytic fields [8,9,10]. As most commercially used catalysts are precious metals, for reducing the cost of electrocatalyst, the discovery of low-cost 2D materials is critical. Recently, metal chalcogenides had received extensive attention for their superior electric conductivity and lower cost than precious metals [11]. Moreover, metal chalcogenides with rich components, controllable active sites and unique electronic structure are potential high efficiency electrocatalysts [12].Metal chalcogenides such as MoS2 [13, 14], WS2 [15, 16] and MoSe2 [17, 18] had been proved to be superb substitutes for noble metal catalyst.

SnSe, as a member of 2D metal chalcogenides, is recognized as a splendid thermoelectric material. Recent research had indicated that SnSe with catalytic activity and lamellar structure can be applied in electrocatalytic hydrogen evolution efficiently. Zhou [8] prepared Sn defective SnSe and explored the Se defects can contribute to the lower Gibbs free energy. Li [19] explored that the SnSe NSs, under ultrasonic vibration shows an excellent H2 production rate determined to be 948.4 µmol h−1 g−1. Feng [20] synthesized 2D SnSe via a simple solution process and explored the oxidation–reduction reaction (ORR) performance of 2D SnSe after annealed at different temperature. However, the SnSe NSs is easy to stack, which hinders the exposure of active sites. The experimental results demonstrate the electrocatalytic performance of SnSe in hydrogen evolution still has great potentials for improvement, such as stacking phenomenon which usually appears in nanosheet or single layer and charge transfer capacity still remains to improve.

Carbon-based materials are widely used in the electrochemical field due to their high conductivity and high specific surface area, such as graphene with unique physical and chemical properties has been considered as ideal supports or hybrids for catalysts [21,22,23,24,25]. Reduced graphene oxide (RGO) with excellent charge transfer capacity and high specific surface area, as a member of graphene materials, has attracted more attentions. Yang [26] prepared AuNPs (nanoparticles)/RGO catalyst with controllable particle size, which have high HER performance and long-term stability. Ye [27] synthesized nanohybrids of hollow CoNiP nanoparticles decorating RGO, applied in electrocatalytic oxygen evolution. Sebastian [28] found that Cu5FeS4/RGO exhibited augmented electrocatalytic ability and demonstrated to be a prospective catalyst. Cai [29] synthesized CoFeP/RGO heterostructure for water splitting, and the RGO can prevent the catalyst from dissolving and agglomerating in the catalytic process and increase the conductivity of the catalyst. Moreover, previous research suggests that the density of states of metal d orbitals may be extended by strong hybridization between metal d orbitals and π-orbital of the RGO [30, 31]. The above report fully confirms that RGO can improve the conductivity, electron transport rate and specific surface area of the hybrid, thus enhancing the electrocatalytic ability.

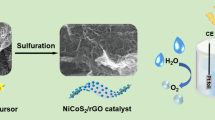

In this work, SnSe NSs were obtained via liquid-phase exfoliation. Graphene oxide (GO) was prepared by an improved Hummers’ method. The as-prepared nanosheets were hybridized with RGO through a simple hydrothermal method. Scanning electron microscopy (SEM) was measured to observe the micromorphology of SnSe NSs and SnSe/RGO. The electrochemical test results demonstrate remarkable electrocatalyst hydrogen evolution performance and excellent stability of SnSe/RGO hybrid. It exhibits smaller overpotential, lower Tafel slope and higher charge transfer capacity. The results of experiments have proved that SnSe/RGO hybrid is a promising and durable catalyst.

2 Experimental section

2.1 Preparation of SnSe nanosheets

The SnSe NS were obtained using a simple liquid exfoliation process, as shown in Fig. 1. In detail, 0.22 g of bulk SnSe powder was grinded for 30 min, and then dispersed in 80 ml NMP solution. The above solution was subject to ultrasonic treatment for 7.5 h in cell pulverizer for 7.5 h. The obtained suspension was suction-filtered after being washed with acetone and ethanol to get the SnSe NS powder.

2.2 Synthesis of SnSe/RGO hybrid

The SnSe/RGO hybrid was synthesized via a typical hydrothermal method, as illustrated in Fig. 1. At length, GO was obtained via an improved Hummers’ method. The GO and SnSe NSs were added to ethylene glycol in a mass ratio of 1:4, stirred to obtain a uniformly dispersed suspension. Then, the mixed suspension was put into Teflon-lined autoclave, spending 12 h at 150 ℃. After cooling down to room temperature, the RGO water suspension was collected via the same suction filtration process. The last, it was dried in a freeze dryer for 12 h and samples were obtained.

2.3 Characterization and electrochemical test

Scanning electron microscopy (SEM, Tescan Vega 3 SBH) was used to characterize micromorphology of each sample. All the Raman spectra in this paper were tested via Renishaw InVia Raman microscope at room temperature, using 532-nm excitation laser.

The electrochemical test was carried out through a typical three electrode system and the electrochemical workstation (CHI660E, CH Instruments, Inc., Shanghai) in H2SO4 electrolyte. The three electrodes are working electrode (glass carbon electrode with contact area of 0.07 cm2), reference electrode (carbon rod) and counter electrode (Hg/HgO electrode) respectively. The linear sweep voltammogram (LSV) curves were tested at a scan rate of 10 mV/s. The Electrochemical Impedance Spectroscopy (EIS) test was accomplished at overpotential, with the frequency of 100 kHz–1 Hz.

3 Results and discussion

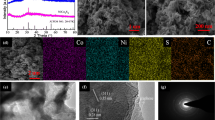

The micromorphology and microstructure of bulk SnSe and as-prepared SnSe NSs were characterized via SEM. Figure 2a and b demonstrates the obvious layered structure of the bulk SnSe from its section. After half an hour of grinding and being sonicated for 7.5 h, the bulk SnSe has been successfully exfoliated to nanosheets, which can be confirmed from Fig. 2c. But, the stacking of prepared nanosheets is an obstacle to electrocatalytic reactions. Figure 2d shows the structure of SnSe/RGO hybrid, in which the large-scaled SnSe NSs were dispersed on the RGO, separately. It is worth to notice that the stacking of SnSe NSs was obviously decreased after hybridizing with RGO. The Raman spectrum is illustrated in Fig. 3, peaks at 69.2 cm−1, 150.6 cm−1 and 127.1 cm−1 are consistent with the Raman Spectra of SnSe in previous researches [32], which correspond to the A1g, A2g and A3g mode of SnSe. Furthermore, the peak at 104 cm−1 is the main peak of SnSe NSs, belonging to the B3g mode of SnSe NSs. Meantime, the peaks at 1334.4 cm−1 and 1600.1 cm−1 can be assigned to the D and G peaks of RGO, respectively. The intensity of D peak is higher than the G peak, which reveals that the graphene oxide is successfully reduced to RGO [33, 34]. Therefore, the SnSe/hybrid is successfully obtained. Moreover, the nitrogen adsorption/desorption isotherms of SnSe/RGO are shown in Fig. 4d, which shows a H3 hysteresis loops. The BET area of the SnSe/RGO hybrid is determined to be 7.8286 m2/g.

The electrocatalytic activity of as-prepared SnSe NSs and SnSe/RGO have been evaluated using H2SO4 as electrolyte. Before the test, each working electrode with sample was first subjected to 20 cyclic voltammetry (C-V) cycles to activate its electrochemical performance. An important index to measure HER performance of catalyzer is overpotential at 10 mA/cm2. Figure 4a shows the LSV curves of SnSe NSs, RGO and SnSe/RGO hybrid at scanning rate of 10 mV/s in 1.0 M H2SO4 electrolyte. The SnSe/RGO hybrid has a small overpotential of − 0.29879 V (vs. RHE) at 10 mA/cm2, which is obviously smaller compared to SnSe NSs and RGO. It means that the HER process at a low potential can still be carried out by SnSe/RGO hybrid. Otherwise, the value of Tafel slope is also a significant index to measure the HER performance. The corresponding Tafel slopes can be calculated from the fitted polarization curves by the equation η = a + b log |J| (where η is the value of overpotential, J is the value of current density). The lower Tafel slopes correspond to the superior HER performance. As illustrated in Fig. 4b, the Tafel slope of SnSe/RGO hybrid is 97.56 mV/dec while SnSe NSs exhibits Tafel slope of 149.38 mV/dec in 1.0 M H2SO4.The SnSe/RGO hybrid has lower Tafel slope, which indicates that the SnSe/RGO hybrid possesses enhanced HER performance. The enhanced electrocatalytic performance for HER is probably attributed to the electronic coupling strong chemical between the RGO and SnSe [35]. As is known to all, conductivity is a critical factor affecting the electrocatalytic hydrogen evolution process. The increase in HER activity is probably due to the improvement on conductivity, more exposure of active sites and the increasing specific surface area, as results of the hybridization with RGO [30]. Figure 4c illustrates EIS curves of the SnSe/RGO hybrid, SnSe NSs and RGO. The SnSe/RGO hybrid evidently has smaller semicircular curves, which demonstrates that the electron transport ability of SnSe NSs is enhanced by hybridizing with RGO.

To further explore the electrocatalytic performance and investigate the mechanism of electrocatalyst hydrogen generation of SnSe/RGO hybrid. The LSV curves of SnSe/RGO hybrid in different concentration of H2SO4 electrolyte (0.1 M, 0.2 M, 0.5 M, 1.0 M) are shown in Fig. 5a. The curves of SnSe/RGO hybrid in 1.0 M H2SO4 exhibit an evidently lower onset potential than others. The calculated Tafel slopes at different concentration are illustrated in Fig. 5b, the calculated Tafel slopes of SnSe/RGO hybrid in 0.1 M, 0.2 M, 0.5 M and 1.0 M H2SO4 electrolyte are determined to be 149.71, 142.08, 103.82 and 97.56 mV/dec, respectively. It is noteworthy that the Tafel slope at 1.0 M H2SO4 is the lowest compared to other curves, determined to be 97.56 mV/dec. Moreover, Fig. 5c summarizes the Tafel slopes and overpotential at 10 mA/cm2 in different H+ concentrations (C[H+]). It is obvious that the corresponding overpotential at 10 mA/cm2 of SnSe/RGO hybrid in 0.1 M, 0.2 M, 0.5 M and 1.0 M H2SO4 electrolyte is identified to be − 332.69 mV, − 327.48 mV, − 300 mV, − 298.79 mV, respectively. With the rise of hydrogen ion concentration, the onset voltage of SnSe/RGO hybrid for HER decreases. Hence, with the increasing H2SO4 concentration the value of Tafel slopes and the overpotential get lower, which indicates that the HER performance becomes superior. The HER process under acidic condition includes three main steps, according to previous studies, known as Volmer, Heyrovsky and Tafel reaction [36, 37].

a LSV curves of SnSe/RGO hybrid in 0.1 M, 0.2 M, 0.5 M and 1.0 M H2SO4; b Tafel plot of SnSe/RGO hybrid in 0.1 M, 0.2 M, 0.5 M and 1.0 M H2SO4; c The Tafel slope and overpotential at 10 mA/cm2 as a function of the concentration of H+ (C[H+]); d EIS plot of SnSe/RGO hybrid in 0.1 M, 0.2 M, 0.5 M and 1.0 M H2SO4

With the increasing C[H+], the H+ adsorption process occurred at the surface of SnSe/RGO hybrid is promoted. For further exploration of HER performance at different concentrations, the EIS test was also conducted. As shown in Fig. 5d, it is noticed that the SnSe/RGO hybrid in 1.0 M H2SO4 exhibits a semicircle with smaller diameter at the high-frequency area of the EIS spectrum, which means it possesses higher electrochemical activity and higher charge transfer capability. Besides, the difference in the starting point of the EIS curve at the high-frequency region is caused by the different internal resistances of solutions with different concentrations of electrolytes. Moreover, as illustrated in Table 1, SnSe/RGO exhibits a lower Tafel slope and overpotential at 10 mV compared to other materials and precious metals, and the simple synthesis process and low price also make it a potential electrocatalyst.

Besides the Tafel slope and overpotential, the durability is also a significant factor to evaluate electrocatalysts. As illustrated in Fig. 6a, the long-time stability test of SnSe/RGO hybrid is carried out in 1.0 M H2SO4. The working electrode remained at the overvoltage at the current density reaches 10 mA/cm2 for 4000 s, and the current almost did not drop. The fluctuation can be attributed to the adsorption and detachment of hydrogen bubbles from the electrode surface. Figure 6b exhibits the LSV curve after 1000 C-V cycles, which shows no evident variation than the curve before 1000 cycles. It suggests that the SnSe/RGO hybrid possesses is a potentially stable electrocatalyst for HER with excellent stability.

4 Conclusion

In this work, SnSe NSs had been obtained via liquid exfoliation. Through a simple hydrothermal method, it was hybridized with RGO and the SnSe/RGO hybrid was successfully prepared. The electrocatalytic performance of the as-prepared hybrid for HER was tested and evaluated. The SnSe/RGO hybrid shows a superior HER performance, which is owning to the increasing specific surface area and charge transfer capability that is probably caused by the electronic coupling between the RGO and SnSe. Moreover, owning to the large specific surface area of RGO, the SnSe NSs scattered on it and rarely stacked. The measurement of hydrogen production capacity at different concentrations of H2SO4 electrolyte reveals that the high C[H+] could promote the electro catalytic hydrogen evolution process. Meantime, the stability test in 1.0 M H2SO4 for 10 h demonstrates that SnSe/RGO hybrid is a durable electrocatalyst, which can maintain 10 mA/cm2 for a long time without evident fluctuation. The SnSe/RGO hybrid is proved to be a potential and durable electrocatalyst. The hybridization with RGO is a significant solution to improve the charge transfer capability and HER performance of the electrocatalyst.

Data availability statement

All relevant data supporting the discoveries of this study are contained in this article or its supplementary information files.

References

W. Zhang, K. Zhou, Ultrathin two-dimensional nanostructured materials for highly efficient water oxidation. Small 13, 1700806 (2017)

H. Liu, W. Lei, Z. Tong, X. Li, Z. Wu, Q. Jia, S. Zhang, H. Zhang, Defect engineering of 2D materials for electrochemical energy storage. Adv. Mater. Interfaces 7, 2000494 (2020)

L.S.L. Huijuan, F. Qingliang, Research and application progress of electrochemical sensors based on two-dimensional layered semiconductor materials. Mater. Rep. 36, 20080298–20080210 (2022)

H. Qiao, Z. Huang, X. Ren, S. Liu, Y. Zhang, X. Qi, H. Zhang, Self-powered photodetectors based on 2D materials. Adv. Opt. Mater. 8, 1900765 (2020)

C. Huo, Z. Yan, X. Song, H. Zeng, 2D materials via liquid exfoliation: a review on fabrication and applications. Sci. Bull. 60, 1994–2008 (2015)

H. Qiao, H. Liu, Z. Huang, R. Hu, Q. Ma, J. Zhong, X. Qi, Tunable electronic and optical properties of 2D monoelemental materials beyond graphene for promising applications. Energy Environ. Mater. 4, 522–543 (2021)

G.F.Y. Chen, T. Xiaolong, Y.I. Honghong, M. Leilei, Y. Qingjun, Z. Shunzheng, Review on the synthesis techniques of two-dimensional materials and their application in the field of catalysis. Mater. Rep. 34, 13005–13016 (2020)

Q. Zhou, M. Wang, Y. Li, Y. Liu, Y. Chen, Q. Wu, S. Wang, Fabrication of highly textured 2D SnSe layers with tunable electronic properties for hydrogen evolution. Molecules 26, 3319 (2021)

H. Qiao, H. Liu, Z. Huang, Q. Ma, S. Luo, J. Li, Y. Liu, J. Zhong, X. Qi, Black phosphorus nanosheets modified with au nanoparticles as high conductivity and high activity electrocatalyst for oxygen evolution reaction. Adv. Energy Mater. 10, 2002424 (2020)

H. Qiao, Z. Li, F. Liu, Q. Ma, X. Ren, Z. Huang, H. Liu, J. Deng, Y. Zhang, Y. Liu, X. Qi, H. Zhang, Au Nanoparticle modification induces charge-transfer channels to enhance the electrocatalytic hydrogen evolution reaction of InSe nanosheets. ACS Appl. Mater. Interfaces 14, 2908–2917 (2022)

J. Zhao, J. Wang, Z. Chen, J. Ju, X. Han, Y. Deng, Metal chalcogenides: an emerging material for electrocatalysis. APL Mater. 9, 050902 (2021)

J. Yin, J. Jin, H. Lin, Z. Yin, J. Li, M. Lu, L. Guo, P. Xi, Y. Tang, C.-H. Yan, Optimized metal chalcogenides for boosting water splitting. Adv. Sci. 7, 1903070 (2020)

S.A. Shah, X. Shen, M. Xie, G. Zhu, Z. Ji, H. Zhou, K. Xu, X. Yue, A. Yuan, J. Zhu, Y. Chen, Nickel@nitrogen-doped carbon@MoS2 nanosheets: an efficient electrocatalyst for hydrogen evolution reaction. Small 15, e1804545 (2019)

Q. Yang, Y. He, Y. Fan, F. Li, X. Chen, Exfoliation of the defect-rich MoS2 nanosheets to obtain nanodots modified MoS2 thin nanosheets for electrocatalytic hydrogen evolution. J. Mater. Sci. 28, 7413–7418 (2017)

Z. Wu, B. Fang, A. Bonakdarpour, A. Sun, D.P. Wilkinson, D. Wang, WS2 nanosheets as a highly efficient electrocatalyst for hydrogen evolution reaction. Appl. Catal. B 125, 59–66 (2012)

L. Cheng, W. Huang, Q. Gong, C. Liu, Z. Liu, Y. Li, H. Dai, Ultrathin WS2 Nanoflakes as a High-Performance Electrocatalyst for the Hydrogen Evolution Reaction. Angew. Chem. Int. Ed. 53, 7860–7863 (2014)

D. Damien, A. Anil, D. Chatterjee, M.M. Shaijumon, Direct deposition of MoSe2 nanocrystals onto conducting substrates: towards ultra-efficient electrocatalysts for hydrogen evolution. J. Mater. Chem. A 5, 13364–13372 (2017)

H. Shi, H. Zhang, M. Li, Y. Wang, D. Wang, Nanoflower-like 1T/2H mixed-phase MoSe2 as an efficient electrocatalyst for hydrogen evolution. J. Alloy. Compd. 878, 160381 (2021)

S. Li, Z. Zhao, J. Li, H. Liu, M. Liu, Y. Zhang, L. Su, A.I. Pérez-Jiménez, Y. Guo, F. Yang, Y. Liu, J. Zhao, J. Zhang, L.-D. Zhao, Y. Lin, Mechanically induced highly efficient hydrogen evolution from water over piezoelectric SnSe nanosheets. Small 18, 2202507 (2022)

Z. Feng, C.D. Jadhav, G.P. Patil, Y. Wang, C. Zhang, V.S. Baviskar, Z. Jia, R. Minnes, Solution processed 2D SnSe nanosheets catalysts: temperature dependent oxygen reduction reaction performance in alkaline media. J. Electroanal. Chem. 916, 116381 (2022)

W.-H. Hu, X. Shang, G.-Q. Han, B. Dong, Y.-R. Liu, X. Li, Y.-M. Chai, Y.-Q. Liu, C.-G. Liu, MoSx supported graphene oxides with different degree of oxidation as efficient electrocatalysts for hydrogen evolution. Carbon 100, 236–242 (2016)

K. Wang, S. Wang, K.S. Hui, H. Gao, D.A. Dinh, C. Yuan, C. Zha, Z. Shao, Z. Tang, K.N. Hui, Synergistically boosting the elementary reactions over multiheterogeneous ordered macroporous Mo2C/NC-Ru for highly efficient alkaline hydrogen evolution, carbon. Energy 4, 856–866 (2022)

K. Wang, S. Wang, K.S. Hui, J. Li, C. Zha, D.A. Dinh, Z. Shao, B. Yan, Z. Tang, K.N. Hui, Dense platinum/nickel oxide heterointerfaces with abundant oxygen vacancies enable ampere-level current density ultrastable hydrogen evolution in alkaline. Adv. Funct. Mater. 33, 2211273 (2023)

R. Hou, S. Zhang, Y. Zhang, N. Li, S. Wang, B. Ding, G. Shao, P. Zhang, A “three-region” configuration for enhanced electrochemical kinetics and high-areal capacity lithium-sulfur batteries. Adv. Funct. Mater. 32, 2200302 (2022)

Y. Zhang, Z. Wu, S. Wang, N. Li, S.R.P. Silva, G. Shao, P. Zhang, Complex permittivity-dependent plasma confinement-assisted growth of asymmetric vertical graphene nanofiber membrane for high-performance Li-S full cells. InfoMat 4, e12294 (2022)

L. Luo, C. Liu, Z. Li, L. Zhang, W. Xie, T. Zhang, Z. Chen, Anchoring ultrafine molybdenum phosphide on hierarchical three-dimensional CNTs/rGO framework as efficient electrocatalysts for hydrogen evolution. J. Mater. Sci. 33, 3175–3185 (2022)

L. Ye, Z. Wen, Reduced graphene oxide supporting hollow bimetallic phosphide nanoparticle hybrids for electrocatalytic oxygen evolution. Electrochem. Commun. 83, 85–89 (2017)

A. Sebastian, V. Deepthi, I. Sheebha, B. Vidhya, V. Maheskumar, A. Sakunthala, A comparative study on the electrocatalytic and photocatalytic activity of reduced graphene oxide (rGO) and doped rGO based Cu5FeS4 composite. Int. J. Hydrog. Energy 47, 27541–27554 (2022)

X. Cai, Q. Song, D. Jiao, H. Yu, X. Tan, R. Wang, S. Luo, Bifunctional electrocatalysts of CoFeP/rGO heterostructure for water splitting. Int. J. Hydrog. Energy 47, 39499–39508 (2022)

D. Mukherjee, P.M. Austeria, S. Sampath, Two-dimensional, few-layer phosphochalcogenide, FePS3: a new catalyst for electrochemical hydrogen evolution over wide pH range. ACS Energy Lett. 1, 367–372 (2016)

C. Gong, G. Lee, B. Shan, E.M. Vogel, R.M. Wallace, K. Cho, First-principles study of metal–graphene interfaces. J. Appl. Phys. 108, 123711 (2010)

H. Qiao, Z. Huang, X. Ren, H. Yao, S. Luo, P. Tang, X. Qi, J. Zhong, Photoresponse improvement in liquid-exfoliated SnSe nanosheets by reduced graphene oxide hybridization. J. Mater. Sci. 53, 4371–4377 (2017)

K.N. Kudin, B. Ozbas, H.C. Schniepp, R.K. Prud’homme, I.A. Aksay, R. Car, Raman spectra of graphite oxide and functionalized graphene sheets. Nano Lett. 8, 36–41 (2008)

S. Stankovich, D.A. Dikin, R.D. Piner, K.A. Kohlhaas, A. Kleinhammes, Y. Jia, Y. Wu, S.T. Nguyen, R.S. Ruoff, Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45, 1558–1565 (2007)

Y. Li, H. Wang, L. Xie, Y. Liang, G. Hong, H. Dai, MoS2 nanoparticles grown on graphene: an advanced catalyst for the hydrogen evolution reaction. J. Am. Chem. Soc. 133, 7296–7299 (2011)

A. Lasia, Mechanism and kinetics of the hydrogen evolution reaction. Int. J. Hydrog. Energy 44, 19484–19518 (2019)

C.-Z. Yuan, K.S. Hui, H. Yin, S. Zhu, J. Zhang, X.-L. Wu, X. Hong, W. Zhou, X. Fan, F. Bin, F. Chen, K.N. Hui, Regulating intrinsic electronic structures of transition-metal-based catalysts and the potential applications for electrocatalytic water splitting. ACS Mater. Lett. 3, 752–780 (2021)

W. Shen, L. Ge, Y. Sun, F. Liao, L. Xu, Q. Dang, Z. Kang, M. Shao, Rhodium nanoparticles/F-doped graphene composites as multifunctional electrocatalyst superior to Pt/C for hydrogen evolution and formic acid oxidation reaction. ACS Appl. Mater. Interfaces 10, 33153–33161 (2018)

D. Han, N. Gao, J. Ge, C. Liu, W. Xing, Activating MoS2 via electronic structure modulation and phase engineering for hydrogen evolution reaction. Catal. Commun. 164, 1046 (2022)

X. Zhang, H. Fei, Z. Wu, D. Wang, A facile preparation of WS2 nanosheets as a highly effective HER catalyst. Tungsten 1, 101–109 (2019)

N. Sen, A. Das, S. Maity, S. Ghosh, M. Samanta, K.K. Chattopadhyay, Tailoring the Sb2Se3/rGO heterointerfaces for modulation of electrocatalytic hydrogen evolution performances in acidic media. ACS Appl. Energy Mater. 6, 58–67 (2022)

Acknowledgements

This work was supported by the Grants from Provincial Natural Science Foundation of Hunan (No. 2022JJ30553, 2021JJ40524), Scientific Research Fund of Hunan Provincial Education Department (Nos. 21A0080, 19C1746), Suzhou key industrial technology innovation project (SYG201921), Hunan Key Laboratory of Two-Dimensional Materials (No. 2018TP1010), and Program of Changjiang Scholars and Innovative Research Team in University (IRT-17R91).

Author information

Authors and Affiliations

Contributions

All authors have contributed to this study. CL contributed to original draft writing, material preparation and electrochemical test. HQ contributed to investigation and writing editing. YL contributed to formal analysis and methodology. ZH contributed to writing—review and administration, SL contributed to characterization test. ZW contributed to investigation. XQ contributed to investigation and writing editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors indicate that there is no conflict of interest in all aspects of this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Qiao, H., Liu, Y. et al. SnSe nanosheet hybridized with reduced graphene oxide for enhanced hydrogen revolution reaction. Appl. Phys. A 129, 426 (2023). https://doi.org/10.1007/s00339-023-06690-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06690-2