Abstract

The determination to develop high-speed, efficient and versatile micro/nano photonic systems has inspired vast studies on photonic circuits. We demonstrate here a near-ultraviolet (NUV) monolithic multicomponent integrated circuit on Si substrate, including two non-suspended multiple quantum wells diodes (MQW-diodes) and an arc-shape waveguide. The two MQW-diodes which are fabricated by the same process can function as emitter and detector, respectively, and their roles can be switched with each other, because the InGaN/GaN multiple quantum wells, which are employed in the emitter to produce near-ultraviolet light, are also utilized by the detector for photodetection. The arc-shape waveguide which serves as a communication channel between the emitter and the detector can change the light propagation direction by 90°. Due to light confinement structure of the wafer, silicon removal and back GaN etching is avoided, which makes the devices more robust, as well as simplifying the processing flow. Two MQW-diodes can communicate with each other at 100 Mbps via the arc-shape waveguide, and the light signals of 200 Mbps from the emitter can also be detected by a commercial photodiode module via free space, which forms a three-dimensional NUV light communication system. This work paves the way toward comprehensive photonic integration for wide variety of potential applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past few decades, silicon photonics, which features low-loss, high refractive-index contrast and complementary metal oxide semiconductor (CMOS) compatibility, has injected revolutionary vitality into the field of integrated optics [1,2,3]. InP-based monolithic integration has also made great technological progress [4,5,6]. However, the potential of photonic integration in the short wavelength region has not been fully explored. Thanks to the outstanding contributions of Isamu Akasaki, Hiroshi Amano and Shuji Nakamura, the high quality gallium nitride (GaN) crystal was grown and p-type doping of GaN with Mg was discovered [7,8,9,10]. The ability to inject holes from the p-type GaN layer into multiple quantum wells (MQWs) layer leads to the invention of blue light emitting diodes (LEDs), which promotes the development of photonic integrated circuits (PICs) at visible wavelength. Given that a promising integration platform can provide compactness, functionality, power and cost effectiveness advantages, GaN-based PICs which have a wide range of emerging applications, including optical interconnects, light communication, biochemical sensing, bio-imaging, and quantum computing, are currently attracting significant research interests [11,12,13,14,15].

Various GaN-based active and passive components, such as metal–oxide–semiconductor field effect transistors (MOSFETs) [16, 17], high-electron-mobility transistor (HEMTs) [18, 19], complementary metal oxide semiconductors (CMOSs) [20], light emitters [21], photodetectors [22, 23], photonic crystals [24] and waveguides [25] can be integrated into a single chip. With the increasing integration and complexity of the PICs, the planar guidance of light energy, especially the large angle transmission, has become a new challenge.

Moreover, there are no simple known ways to p-type dope high Al-content AlGaN and difficult to extract very short wavelength light trapped inside the semiconductor material [26]. So, developing photonic light emitters at ever shorter wavelengths, from the blue (∼450 nm) and visible to near-ultraviolet (NUV) and deep-ultraviolet (DUV) which powered by AlN of bandgap ∼6.2 eV (∼200 nm), is another challenge [27]. Extending the wavelength range into the near-ultraviolet and deep-ultraviolet not only expands the bandwidth of light communication links but also paves the way for their integration into lots of applications exploiting NUV and DUV radiation, including physiotherapeutics, hothouse agrotechnics, resin curing, identification and so on[28, 29].

In this work, we used a GaN-on-Silicon wafer which incorporates GaN waveguide layers and AlGaN cladding layers. A NUV monolithic multicomponent chip, including two non-suspended multiple quantum wells diodes (MQW-diodes) and a arc-shape waveguide, was designed and fabricated. Due to the inherent characteristics of InGaN MQWs, the MQW-diodes can be responsible for light emission and photodetection, which enables them to act as emitter or photodetector. And because of the omnidirectional nature of the MQW-diode emission, a well-designed high confinement waveguide is beneficial for efficient routing of light signals between the emitter and photodetector. In our previous study, the PICs based on suspended structure for in-plane data transmission have been demonstrated [30, 31]. Silicon substrate is unfavorable for light transmission owing to its strong light absorption properties. So selective-area silicon removal and back GaN etching has to been performed to achieve suspended device structure, which leads to the fragility of the devices and more complex process flow to a certain extent. Here, silicon removal and back GaN etching is avoided benefitting from light confinement structure of the wafer. The non-suspended MQW-diodes can communicate with each other at 100 Mbps via an arc-shape waveguide changing the light propagation direction by 90°, and the light signals of 200 Mbps from the emitter can also be detected by a commercial photodiode module via free space, which demonstrates a three-dimensional NUV light communication for potential applications.

2 Experimental results and discussion

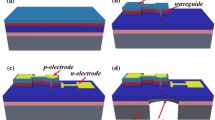

The monolithic multicomponent chip is fabricated using a GaN-on-Silicon wafer whose layer structure details can be found in reference [32]. The detailed fabrication process flow of the proposed monolithic multicomponent chip is schematically illustrated in Fig. 1. First, the p-mesas for two MQW-diodes were defined by photolithography, and the unmasked regions were dry-etched down to the AlGaN cladding layer using inductively coupled plasma reactive ion etching (ICP-RIE) with Cl2 and BCl3 hybrid gases. Second, the device was defined using another photolithography step and the Si-doped n-type GaN surface was exposed with an etching depth of 3 μm by ICP-RIE. Third, a 150-nm-thick SiO2 layer was deposited on the device regions for electrical isolation using a combination of plasma-enhanced chemical vapor deposition (PECVD), photolithography and wet-etching with HF/NH4F mixture. Finally, p-type and n-type electrode regions were defined by a photolithography step and the metal electrodes with 20/30/50 nm Pd/Pt/Au metallization stacks were formed using a combination of electron beam evaporation and lift-off process, followed by rapid thermal annealing to form ohmic contacts. An important point to emphasize at this stage is that all these process steps are entirely conventional and are therefore allowed immediate implementation on a standard light emitting diode (LED) fabrication line. In our previous research, the silicon substrate underneath the device region was usually completely removed to avoid the absorption of downward-emitting light by the silicon substrate [30, 31]. Due to the thick waveguide layers and thick cladding layers, which are located on both sides of the InGaN MQWs layer, most emission photons from the MQWs active region are confined to transverse transmission inside the device that is beneficial for the application of an on-chip light communication via waveguides. As a result, the fabrication process is simplified and the substrate remains intact, which is conducive to large-scale mass production of the devices in the future.

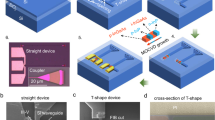

Figure 2a shows a top view scanning electron microscope (SEM) image of the fabricated monolithic multicomponent chip. The p-electrode measuring 20 μm in diameter is connected with a 50 μm-diameter bonding pad. The distance between the n-electrode and the edge of the mesa is 5 μm. To decrease the physical dimension of the MQW-diode and reduce the junction capacitance, a SiO2 isolation layer is introduced between the p-electrode and the p-type GaN layer, which can lead to the reduction of RC (resistive–capacitive) time constant and the higher modulation rate [33]. Figure 2b demonstrates a high-magnification SEM image of the arc-shape waveguide. Both ends of the arc-shape waveguide are respectively connected to an MQW-diode acting as a transceiver. The arc-shape waveguide consists two 40 μm-long and 8 μm-wide straight waveguide and a quarter arc waveguide with a 70 μm-radius, which serves as a communication channel and plays an important role for the light coupling of two MQW-diodes.

A probe station connected with an Agilent B1500A semiconductor device analyzer was used to check that the proposed device is behaving as a diode. A typical LED current–voltage characteristics of the left MQW-diode is observed with the expected forward-bias conditions, as shown in Fig. 3(a). The turn-on voltage is approximately 2.9 V which is comparatively low and the current density is only 2.04 × 10–6 A mm−2 under the reverse bias voltage of −4.0 V. As soon as the applied forward bias voltage exceeded the turn-on voltage, the current density surged quickly. At 4.0 V and 5.0 V forward bias voltage, respectively, the current density of 4.91 A mm−2 and 18.54 A mm−2 were recorded. And with the 6.0 V applied voltage, the current density rose to 46.41 A mm−2, indicating good electrical qualities and high-quality manufacturing. The electrical-to-optical (E/O) conversion characteristics of the fabricated devices was also investigated. An excellent E/O conversion efficiency is indicated by the left MQW-light diode's output intensity increasing roughly linearly with injection current density. Similar electrical and E/O conversion performance is shown by the right MQW-diode in Fig. 3b. The two insets in Fig. 3 are the light-emission images of two devices under injection current of 5.0 mA.

The optical characteristics of the MQW-diodes, as a function of injection current, was analyzed by electroluminescence (EL) measurements taken at room temperature. Figure 4a illustrates the EL spectra of the MQW-diodes on the left under injection current levels of 1.0 mA–13.0 mA. The intensity of the emissions rose monotonically when the current injection was increased. Two distinct peaks at 381 and 383 nm are seen in the EL spectra, which are attributed to the excitation of the MQWs active layers. With the variation of injection current, the dominant and secondary EL peaks remain stable, which indicates low current-crowding and self-heating effects [34]. By rapidly and directly changing the intensity of transmitted light, light communication may be accomplished. The prospective application of the light communication emitter is made possible by the approximately 8.6 ratio of the dominant EL peak intensity between 13.0 mA and 1.0 mA. The inclusion of waveguide and cladding layer structure prevents the silicon substrate from absorbing downward light, which is conducive to the lateral transmission of on-chip light signals. The optical properties of the MQW-diode on the right are comparable to those of the MQW-diode on the left, as demonstrated in Fig. 4b.

FullWave simulations were performed by RSoft photonics suite in order to look into how light propagates through the arc-shaped waveguide. The launch field is a 383 nm Gaussian beam, whose wavelength is in accordance with the dominant EL peak. The dimension of the arc-shape waveguide is set according to the actual size of the device. Figure 5a demonstrates the plan-view simulation of the field distribution along the arc-shape waveguide without gaps. The light energy is effectively confined in the waveguide due to the significant refractive index difference between the GaN waveguide and air. The guided light energy moves ahead along the arc-shape waveguide, a minor portion of the guided light energy deviates during propagation, while the majority of the light energy diffracts into the open space at the end facet. The gaps in the waveguide will result in large light energy loss, as demonstrated in Fig. 5b–c, demonstrating the critical function that the GaN waveguide plays in on-chip light coupling and light transmission.

The inherent properties of the InGaN/GaN MQW active layer provide the MQW-diodes the ability to emit light, guide light, and detect light, which allows the homogeneous integration of the on-chip emitter, waveguide and detector. To further investigate the photoelectric response performance of the monolithic multicomponent chip, the induced photocurrent measurement was conducted. A portion of the light energy is coupled into the arc-shape waveguide when the MQW-diode on the left is used as a light signal emitter and is confined to traveling forward along it. The light energy coming from the arc-shape waveguide can be sensed by the MQW-diode on the right which is operated as a light signal detector. The photogenerated carriers are created following the absorption of these incoming photons. And light-power dependent photocurrent is produced in the light signal detector as a result of the electrons and holes flowing to the n-electrode and p-electrode, respectively. Figure 6a illustrates the induced photocurrent of the detector (the MQW-diode on the left), with the emitter (the MQW-diode on the right) running under various injection current levels of 0 mA to 5.0 mA. The driving current in the detector can be disregarded when the applied voltage is lower than the turn-on voltage, particularly when it is lower than 1.5 V. The photocurrent of the detector improves when the injection current of the emitter rises because more photons can be detected by the detector. The induced photocurrent measured at -4.0 V increases from 55.6 nA to 336.4 nA when the emitter's injection current is increased from 1.0 mA to 5.0 mA, a 6.05-fold increase. Figure 6b and c show the induced photocurrent via the waveguide with gaps. The generated photocurrent can still be detected when the emitter and detector are coupled through the waveguide with gaps, but the photocurrent strength is noticeably reduced. The more gaps, the greater the decrease of the measured photocurrent, as demonstrated in Fig. 6d. The experimental results here are consistent with the simulation results. In addition, removing the MQWs layer from the arc-shape waveguide may be beneficial for reducing the transmission loss of the light energy, because the MQWs layer has a high absorption coefficient when unpumped.

Photocurrent plots of the MQW-diode on the right measured under illumination by the MQW-diode on the left at various injection currents: a via waveguide without gaps; b via waveguide with a gap; c via waveguide with 2 gaps; d induced photocurrent of the MQW-diodes act as receiver via different waveguides

Both on-chip and free-space light communication experiments were carried out to assess the data transmission capability of the fabricated monolithic multicomponent chip. Figure 7a depicts the schematic of the experimental setup. The left MQW-diode was directly driven as a emitter by a combination of an Agilent arbitrary waveform generator and a DC power source. The pseudo-random binary sequence (PRBS) electrical signals, which are amplified and dc-biased with a bias-tee circuit to generate a voltage swing from 0 to 6 V, are applied to the emitter to output modulated light pulses in the way of on–off keying modulation. Part of the light pulses transmit down the GaN arc-shape waveguide for absorption by the detector at the other end. The detector is zerobiased. After E/O conversion, the generated electrical signals are analyzed by an Agilent digital storage oscilloscope (DSO) and an open eye diagram at 100 Mbps is observed in Fig. 7b, illustrating the potential for high-speed NUV light communication applications. It is worth noting that, from the perspective of simplifying the fabrication process, the n-GaN layer located below the arc-shape waveguide has been retained. However, despite the presence of the waveguide layers and cladding layers, a small portion of light energy still propagates through the n-GaN layer and reaches the detector, which can cause crosstalk issues to some extent. And this problem can be solved through silicon substrate selective removal and back n-GaN layer etching.

In addition to the light pulses coupled in the waveguide, some light pulses are transmitted via free space, and can be detected by a Hamamatsu C12702-11 photodiode module, which makes it possible for three-dimensional light communication. The Hamamatsu photodiode module integrates a temperature-compensation bias circuit, a current-to-voltage converter and an avalanche photodiode (APD). The temperature-compensation bias circuit can maintain a nearly constant APD gain when the ambient temperature changes and the current-to-voltage converter optimizes signal readout from the APD by low-noise bipolar transistors and operational amplifiers. So in comparison with the MQW-diode as photodetector, the Hamamatsu photodiode module can detect light with higher sensitivity. Figure 7c shows the eye diagram which measured at the data transmission rates of 200 Mbps. Free-space light communication has a communication rate that is much greater than on-chip light communication, which also offers guidance for further optimizing on-chip light communication. Utilizing modulation techniques such as orthogonal frequency division multiplexing (OFDM) and orthogonal frequency division multiple access (OFDMA) can significantly increase the communication rate [35, 36].

3 Conclusions

In summary, a monolithic multicomponent chip, incorporating two non-suspended MQW-diodes and a arc-shape waveguide on the GaN-on-silicon platform, has been demonstrated. Due to light confinement structure of the wafer, silicon removal and back GaN etching is avoided, which makes the devices more robust, as well as simplifying the processing flow. The MQW-diodes can be operated as light emitter and photodetector owing to the inherent properties of InGaN MQWs, respectively, while the arc-shape waveguide is constructed as a light channel for signal transmission between two MQW-diodes. Two non-suspended MQW-diodes can communicate with each other at 100 Mbps via the arc-shape waveguide changing the light propagation direction by 90°, and the light signals of 200 Mbps from the emitter can also be detected by the Hamamatsu photodiode module via free space, which forms a three-dimensional NUV light communication system. This work paves the way toward comprehensive photonic integration for wide variety of potential applications, such as on-chip NUV light communication, internet-of-things (IoT) and biosensing.

Data availability

The data are available from the corresponding author on reasonable request.

References

D. Thomson, A. Zilkie, J.E. Bowers, T. Komljenovic, G.T. Reed, L. Vivien, D.M. Morini, E. Cassan, L. Virot, J.M. Fédéli, J. Opt. 18, 073003 (2016)

R. Soref, IEEE, J. Sel. Top. Quantum Electron. 12, 1678–1687 (2006)

J. Leuthold, C. Koos, W. Freude, Nat. Photonics 4, 535–544 (2010)

M. Smit, K. Williams, D.T.J. Van, APL Photonics 4, 050901 (2019)

K.A. Williams, E.A.J.M. Bente, D. Heiss, Y. Jiao, K. Ławniczuk, X.J.M. Leijtens, J.J.G.M. van der Tol, M.K. Smit, Photonics Res. 3, B60–B68 (2015)

Z. Yan, Y. Han, L.Y. Lin, Y. Xue, C. Ma, W.K. Ng, K.S. Wong, K.M. Lau, Light: Sci. Appl. 10, 1–10 (2021)

H. Amano, N. Sawaki, I. Akasaki, Y. Toyoda, Appl. Phys. Lett. 48, 353–355 (1986)

I. Akasaki, H. Amano, MRS Online Proc. Libr. (OPL) 242 (1992)

S. Nakamura, T.M.T. Mukai, M.S.M. Senoh, Jpn. J. Appl. Phys. 30, L1998 (1991)

S. Nakamura, T.M.T. Mukai, M.S.M. Senoh, Jpn. J. Appl. Phys. 31, 2883 (1992)

M.D. Brubaker, P.T. Blanchard, J.B. Schlager, A.W. Sanders, A. Roshko, S.M. Duff, J.M. Gray, V.M. Bright, N.A. Sanford, K.A. Bertness, Nano Lett. 13, 374–377 (2013)

J.F.C. Carreira, E. Xie, R. Bian, C. Chen, J.J.D. McKendry, B. Guilhabert, H. Haas, E. Gu, M.D. Dawson, Opt. Express 27, A1517–A1528 (2019)

O. Weidemann, P.K. Kandaswamy, E. Monroy, G. Jegert, M. Stutzmann, M. Eickhoff, Appl. Phys. Lett. 94, 113108 (2009)

S.T. Jagsch, N.V. Triviño, F. Lohof, G. Callsen, S. Kalinowski, I.M. Rousseau, R. Barzel, J.F. Carlin, F. Jahnke, R. Butté, C. Gies, A. Hoffmann, N. Grandjean, S. Reitzenstein, Nat. Commun. 9, 1–7 (2018)

W. Cai, J.L. Yuan, S.Y. Ni, Z. Shi, W.D. Zhou, Y.H. Liu, Y.J. Wang, H. Amano, Appl. Phys. Express 12, 032004 (2019)

R.A. Khadar, C. Liu, R. Soleimanzadeh, E. Matioli, IEEE Electron Device Lett. 40, 443–446 (2019)

R. Tanaka, S. Takashima, K. Ueno, H. Matsuyama, M. Edo, Jpn. J. Appl. Phys. 59, SGGD02 (2020)

R.Z. Zhang, J.P. Kozak, M. Xiao, J.C. Liu, Y.H. Zhang, T. Power, Electr. 35, 13409–13419 (2020)

L. Arivazhagan, D. Nirmal, D. Godfrey, J. Ajayan, P. Prajoon, A. S. Augustine Fletcher, A. A. A. Jone, J. S. R. Kumar, AEU-Int. J. Electron. C. 108, 189–194 (2019)

R.M. Chu, Y. Cao, M. Chen, R. Li, D. Zehnder, IEEE Electron Device Lett. 37, 269–271 (2016)

H.S. Wasisto, J.D. Prades, J. Gülink, A. Waag, Appl. Phys. Rev. 6, 041315 (2019)

D.Y. Guo, Y.L. Su, H.Z. Shi, P.G. Li, N. Zhao, J.H. Ye, S.L. Wang, A.P. Liu, Z.W. Chen, C.R. Li, W.H. Tang, ACS Nano 12, 12827–12835 (2018)

A. Dubey, R. Mishra, Y.H. Hsieh, C.W. Cheng, B.H. Wu, L.J. Chen, S.J. Gwo, T.J. Yen, Adv. Sci. 7, 2002274 (2020)

Y.S. Choi, K. Hennessy, R. Sharma, E. Haberer, Y. Gao, S.P. DenBaars, S. Nakamura, E.L. Hu, Appl. Phys. Lett. 87, 243101 (2005)

G. Muziol, H. Turski, M. Siekacz, S. Grzanka, P. Perlin, C. Skierbiszewski, Appl. Phys. Express 9, 092103 (2016)

M. Kneissl, J. Rass, III-Nitride ultraviolet emitters (Springer, Berlin, 2016), pp.4–9

D. Jena, R. Page, J. Casamento, P. Dang, J. Singhal, Z. X. Zhang, J. Wright, G. Khalsa, Y. J. Cho, H. G. Xing, Jpn. J. Appl. Phys. 58, SC0801 (2019)

Y.A. Goldberg, Semicond. Sci. Technol. 14, R41 (1999)

Y. Peng, R. L. Liang, Y. Mou, J. N. Dai, M. X. Chen, X. B. Luo, J. Electron. Packaging. 141, (2019)

W. Cai, Y.C. Yang, X.M. Gao, J.L. Yuan, W. Yuan, H.B. Zhu, Y.J. Wang, Opt. Express 24, 6004–6010 (2016)

J.L. Yuan, W. Cai, X.M. Gao, G.X. Zhu, D. Bai, H.B. Zhu, Y.J. Wang, Appl. Phys. Express 9, 032202 (2016)

M.X. Feng, Z.C. Li, J. Wang, R. Zhou, Q. Sun, X.J. Sun, D.B. Li, H.W. Gao, Y. Zhou, S.M. Zhang, D.Y. Li, L.Q. Zhang, J.P. Liu, H.B. Wang, M. Ikeda, X.H. Zheng, H. Yang, ACS Photonics 5, 699–704 (2018)

F.H. Zhang, Z. Shi, X.M. Gao, C. Qin, S. Zhang, Y. Jiang, F. Wu, Y.J. Wang, Opt. Lett. 43, 1874–1877 (2018)

J.B. Yan, J.L. Yuan, Y. Jiang, H.B. Zhu, H.W. Choi, Y.J. Wang, Appl. Phys. Express 15, 032003 (2022)

S.M. Islim, R.X. Ferreira, X.Y. He, E.Y. Xie, S. Videv, S. Viola, S. Watson, N. Bamiedakis, R.V. Penty, I.H. White, A.E. Kelly, E. Gu, H. Haas, M.D. Dawson, Photonics Res. 5, A35–A43 (2017)

Z.X. Wei, L. Zhang, L. Wang, C.J. Chen, Z.M. Wang, K.C. Chen, M.C. Wu, Y.H. Dong, L. Wang, Y. Luo, H.Y. Fu, Opt. Express 28, 18332–18342 (2020)

Acknowledgements

This research was funded by China Postdoctoral Science Foundation [Grant Number 2020M681683]; and Innovation Research Foundation of NJIT [Grant Number ZKJ202004].

Author information

Authors and Affiliations

Contributions

Wei Cai conceived of the study and designed the study. Eryuan Guo and Yukuan Dai collected the data. Wei Cai and Liangbao Jiao analyzed the data and were involved in writing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cai, W., Jiao, L., Guo, E. et al. Monolithic multicomponent integrated circuit with an arc-shape waveguide on Si substrate. Appl. Phys. A 129, 378 (2023). https://doi.org/10.1007/s00339-023-06665-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06665-3