Abstract

Herein, we report the large-scale synthesis and compare the effect of transition metal oxide (Co3O4/Fe3O4) nanoparticles assistance on electrochemical energy storage performance of zinc oxide (ZnO)-graphene oxide (GO)-polyaniline (PANI) nanocomposites. The resultant quaternary nanoarchitectonics composites of Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2) exhibit layered fibrous structure on the surface, where these fibers form a porous and mesh-like network. The systematic electrochemical analyses reveal that S1 has better electrochemical performance as compared to S2. Specifically, S1 has a higher specific capacitance (246.33 F/g) relative to S2 (110.17 F/g) at a current density of 1 A/g due to higher reduction potential of Co (+ 1.81 V) than that of Fe (0.77 V). This higher potential causes Co to be more reactive in the redox transitions than Fe. Moreover, the enhanced ionic intercalation and improved electrical conductivity associated with their specific morphology plays a role to enhance the energy storage performances. Therefore, Co3O4–ZnO–GO–PANI nanoarchitectonics composite can be used as a promising electrode material for high-performance energy storage device fabrication.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The past few decades have seen a great deal of innovation in the fabrication of different nanocomposites along with nanoarchitectonics structure and making use of their unique physicochemical properties for wide-ranging applications in various fields such as medicine, energy, biology, sensing [1,2,3,4,5]. With the present energy crisis and the ever-increasing energy consumption, it has now become essential to focus on the research and development of a steady supply of clean energy. The urgency is compounded by the limited and polluting nature of conventional energy sources like fossil fuels [6, 7]. The effective, efficient, low cost and environmentally friendly energy storage systems are therefore required to overcome the energy deficiency for profound benefit of the society [8]. In this context, researchers have devoted a lot of effort to fabricate innovative materials for energy storage devices, including supercapacitors, batteries, and fuel cells [9]. Electrochemical supercapacitors have now become suitable candidates for next generation energy storage devices to store a large amount of charge and deliver them at high power ratings [10]. It has many advantages such as long service life, being environmentally friendly, large power density, fast charge–discharge as well as excellent stability when compared with electrolytic capacitor and conventional batteries [11, 12]. Supercapacitors have already been used in extensive applications such as instant switches, backup power supply, portable electronics, energy management, etc. [13, 14].

The continued research and development in the fabrication of innovative materials towards better energy storage systems play a key role for making progress in energy storage by supercapacitors. Based on this, we have fabricated Co3O4–ZnO–GO–PANI and Fe3O4–ZnO–GO–PANI based quaternary nanoarchitectonics systems. In these systems, graphene oxide (GO) contains abundant oxygenated functional groups, thus its derivatives are considered as potential materials for the immobilization and growth of nanoparticles [15]. The oxygenated functional groups in GO also play an important role to serve as nucleation sites to design GO-and reduced graphene oxide (RGO)-based nanocomposite systems [16]. Moreover, GO is a lucrative material due to having a unique two-dimensional planar structure with high surface area as well as full surface accessibility and edge reactivity [17]. On the other hand, transition metal oxides (TMO) have also been explored as potential electrode materials in supercapacitors. Their capacitive properties are attributed to their multiple oxidation states, which lead to a pseudo capacitance charge storage mechanism [18]. Zinc oxide (ZnO) is one such TMO which has already found applications in various fields such as photocatalysis, medicine, cosmetics, energy storage etc. [19,20,21,22]. Its nanostructures possess many desirable properties such as high surface area, high electrical conductivity, environmental compatibility and good electrochemical activity with modifying electronic structure and shape [23]. The integration of ZnO with carbon materials such as graphene and carbon nanotubes to create hybrid electrodes with superior capacitive performance have been reported [24, 25]. Our effort is to combine transition metal oxide in quaternary nanoarchitectonics composite to explore its synergistic effect to increase the electrode conductivity along with its electrochemical performance [26,27,28]. In addition to this, various conducting polymers like polyaniline (PANI) and polypyrrole (PPy) are known to show pseudo-capacitive properties via redox reactions which are useful for supercapacitor applications [29, 30]. PANI especially, is easy to synthesis, has low production cost, high thermal and environmental stability and high-range electrical conductivity [31]. In this regard, quaternary nanoarchitectonics composite (composed of four components: transition metal oxide Co3O4/Fe3O4, a carbon-based material like GO, another transition metal oxide like ZnO and a conducting polymer like PANI) are very effective for further improving the stability and energy storage capacity of supercapacitors performance [32].

There are very few reports are available on such kind of ternary/quaternary composites as electrode materials for electrochemical capacitors. The demonstration of the solid-state binder-free device is rare which significantly restricts their practical applications in supercapacitors. Chee et al. have synthesized PPy/GO/ZnO-nanocomposite and obtained specific capacitance of 94.6 F/g at 1 A/g current density [33]. Lim et al., reported a ternary polypyrrole/graphene/nano manganese oxide composite with a specific capacitance of 320.6 F/g at scan rate of 1 mVs−1 [34]. Ishaq et al. synthesized rGO/Me-Fe2O3/Ppy (Me=Mn, Ni) ternary composite and obtained a specific capacitance of 232 F/g at scan rate of 5 mVs−1 [32]. Under these circumstances, the present study is focused on the fabrication of a low cost, environmentally friendly energy storage system using a quaternary nanoarchitectonics composite system as supercapacitor and here we study a comparison between the electrochemical behavior resulting from the addition of two different metal-based oxide. We have synthesized well crystalline quaternary nanoarchitectonics of Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2) on a large scale for high performance supercapacitors applications. The composites were characterized by X-Ray diffraction (XRD), The X-ray photoelectron spectroscopy (XPS), Field Emission Scanning Electron Microscopy (FESEM), Brunauer–Emmett–Teller (BET) surface area analysis techniques. Furthermore, we have studied the energy storage performances of S1 and S2 by cyclic voltammogram (CV), galvanostatic charge–discharge (GCD) and electrochemical impedance spectroscopy (EIS) analysis. From the electrochemical analysis, it has been observed that (S1) composite shows better performance than S2 as an electrode for fabrication of high-performance energy storage device. This is due to the higher reduction potential of Co than that of Fe. The enhanced ionic intercalation and improved electrical conductivity associated with their specific structures and morphology also plays the important role to enhance the electrochemical performances. There are a few reports on transition metal, carbon and polymer-based combined composites and we compared our result with that previously published report, illustrated in Table 1 later [33, 35,36,37,38,39,40,41,42,43,44,45,46,47,48,49]. Moreover, to the best of our knowledge, probably the electrochemical storage performance of this particular combination of Co3O4–ZnO–GO–PANI and Fe3O4–ZnO–GO–PANI quaternary nanoarchitectonics is explored for the first time here, whereas the previous reported composites are ternary or bimetallic oxides of these materials.

2 Experimental section

2.1 Materials and methods

2.1.1 Materials

Graphite powder, sulfuric acid (98 wt.%), hydrogen peroxide (30%), sodium nitrate (NaNO3), potassium permanganate (KMnO4), zinc nitrate hexahydrate (Zn (NO3)2.6H2O), sodium hydroxide (NaOH), Co(II)nitrate hexahydrate (Co(NO3)2.6H2O), Fe(III) nitrate nonahydrate (Fe(NO3)3.9H2O), APS (Ammonium Persulphate (NH4)2S2O8), hydrochloric acid (HCl), aniline (C6H5NH2), absolute ethanol (C2H6O) were purchased from Merck India and used without further purification for synthesis purpose. Doubly distilled water (18 MΩ) was used as a solvent for all the experiments.

2.1.2 Experimental methods

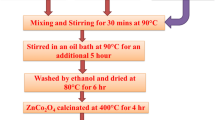

We have synthesized both Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2) composites via a three-step processes. In the first step, we prepared GO flakes, and in the second step, we prepared Co3O4–ZnO–GO and Fe3O4–ZnO–GO by taking the previously prepared GO solution. In the final step, we added PANI to prepare Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2) composites, which we have described below in details.

2.1.3 Synthesis of GO flakes

GO solution was synthesized by using standard Hummer’s method following the systematic process described in our previous reports [50].

2.1.4 Synthesis of Co3O4–ZnO–GO and Fe3O4–ZnO–GO–PANI composites

In both cases, firstly 100 mg of GO flakes were dispersed in 50 ml of distilled water by sonication. Then, 70 ml of 0.1 M zinc nitrate hexahydrate solution was added to it and 20 ml of distilled water was also added and kept for stirring in an ice-bath for 30 min. Afterwards 75 ml of 2 M sodium hydroxide was added dropwise to the solution under continuous stirring. A precipitate has been observed and it was kept stirring for another 30 min. Then the solution was heated at 80 °C in a water bath. Subsequently, 50 ml of 0.02 M of Co (II) nitrate hexahydrate/Fe (III) nitrate nonahydrate was added drop wise under with vigorous stirring. Then, the mixed solution was kept another 6 h with constant stirring at temperature 80 °C. The obtained precipitate was washed three times by centrifugation using distilled water and ethanol and dried in a vacuum oven at 60 °C for 4 h to get Co3O4–ZnO–GO and Fe3O4–ZnO–GO composites powders.

2.1.5 Synthesis of Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2) quaternary nanoarchitectonics composites

125 mg of the Co3O4–ZnO–GO or Fe3O4–ZnO–GO composites powder was added to 40 ml distilled water and sonicated for 1 h to obtain a homogenous dispersion. Then, 2.05 g of APS was dissolved in 30 ml of distilled water and stored in the refrigerator at 4 °C. 1.5 ml of aniline and 4 ml of HCl were added with 10 ml of distilled water and stirred in an ice bath for another 1 h. This mixture was added drop wise to the Co3O4–ZnO–GO or Fe3O4–ZnO–GO dispersions and sonicated for 1 h, so that the aniline was dispersed on the surface of the composites. After this, 13 ml APS solution was added drop wise under stirring in an ice bath until a slight dark green color has been observed around the black dispersion. Then, the solution was stirred for another 1 h. The precipitates were then washed three times with distilled water and ethanol by centrifuging at 10,000 rpm for five minutes. Finally, the specimen was dried at 60 °C for 6 h in vacuum to get the resultant Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2) composites samples.

Note that the individual components of the final composite (ZnO, Co3O4–ZnO, Fe3O4–ZnO, GO and PANI) were also synthesized separately to study their electrochemical properties.

2.2 Characterization techniques

The room temperature powder X-ray diffraction (XRD) patterns of the sample was recorded by using Bruker D8 Advanced Diffractometer (voltage: 40 kV with monochromatic Cu Kα radiation (λ = 0.15418 nm) with a step size of 0.5° over the range of 2θ = 10°–80°. The field emission scanning electron microscope (FESEM) was used for morphological analysis by FEI INSPECT F50 instrument with sputtered Au coating. The operating voltage was 10 kV and the magnification range were 10,000–20,000×. The presence of constituent elements in the samples was probed using an Energy dispersive X-ray spectroscopy (EDS) system attached to the FESEM equipment. Quantum 2000 X-ray photoelectron spectrometer (Physical Electronics, Minnesota, US), equipped with an Al Kα monochromatic source (1448.6 eV), a hemispherical capacitor electron analyser, and a 16-channel plate detector were utilized for XPS. Mechanically pressed powder sample has been taken on indium foil and all spectra were collected in fixed analyzer transmission mode at an emission angle of 45° with X-ray spot size of 150 µm and a pressure of less than 4 × 10–7 Pa. The nitrogen adsorption–desorption Brunauer–Emmett–Teller (BET) isotherm of both samples S1 and S2 were measured by a Quantachrome NovaWin2 Instrument. The degassing temperature was 70 °C for 6 h under vacuum and flowing nitrogen gas was applied.

2.3 Fabrication of working electrodes and electrochemical experiments

Electrochemical performance of all samples was evaluated by using a CHI 660C (CH Instruments, USA) electrochemical workstation. A platinum wire was used as the counter electrode and a saturated Calomel Electrode (SCE) was used as the reference electrode. A thin film of the synthesized material was prepared by drop casting method on Indium Tin Oxide (ITO) (1 cm × 1 cm) electrode. This was used as working electrode. All the electrodes were held in place by steel clips. 1 M aqueous solution of sodium sulphate (Na2SO4) was used as the electrolyte solution. The weight of the ITO coated glass before and after drop casting the sample was measured to get the effective weight of the supercapacitor material used in the study. The ITO glass pieces were cleaned by sonication in acetone and ethanol. In all cases, the slurry used for drop-casting on the ITO surface was prepared by taking 70 wt.% of the active material, 20 wt.% of carbon black (grade N330) and 10 wt.% of Nafion. 1 mg of active material was taken for all studies. These were dispersed in NMP (N-methyl pyrrolidone) solvent by sonication before drop-casting using a micropipette.

The values of specific capacitance (Csp), energy density (E) and power density (P) of the sample from GCD plot, were calculated by using the following Eq. (1) [51]

Where I is the discharge current (A), Δt is the discharge time (s), m is the mass of the active material (g) and ΔV is the potential window (V).

3 Results and discussion

Figure 1 depicts the scheme of the formation process of both synthesized materials Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2). The detailed process has already been described in the experimental section.

To get the structural and compositional information, we have carried out powder XRD measurements at room temperature. Figure 2 shows the XRD pattern of Co3O4–ZnO–GO–PANI (S1), Co3O4–ZnO and Co3O4 materials along with Fe3O4–ZnO–GO–PANI (S2), Fe3O4–ZnO and Fe3O4. The XRD pattern of Co3O4–ZnO–GO–PANI illustrates diffraction peaks corresponding to (111), (220), (311), (222), (400), (511) and (440) planes of Co3O4 (JCPDS No: 42–1467) [52], and (100), (001), (101), (102), (110), (103), (200), (112), (201) and (202) planes of ZnO (JCPDS No: 36–2451) and those miller indices are consistent with the reported paper of ZnO nanorod [53]. In addition, (011), (020) and (220) planes of PANI (JCPDS No: 72–0634) [54] and (001) plane of GO [55] are also present in the sample S1. Similarly, the diffraction peaks corresponding to ZnO, PANI and GO are also present in S2. Besides that, the diffraction pattern of S2 illustrate peaks corresponding to (220), (311), (400), (422), (511), (440) planes (JCDS No: 65–3107) of Fe3O4 which are consistent with the reported paper [56]. The XRD of bare PANI and GO have also been studied in the supporting information, shown in Figure S1. The XRD diffraction pattern exhibits peaks corresponding to (011), (020), (200), (121), (022) (JCPDS No: 72–0634) planes of PANI [54] and (001) peak related to the evidence of GO [55]. The calculated average crystalline size (using Scherrer formula) of Co3O4 and Fe3O4 are 65 nm and 53 nm, respectively.

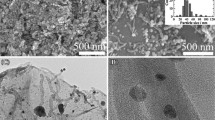

The FESEM images of GO, PANI, Co3O4–ZnO, Fe3O4–ZnO, Co3O4–ZnO–GO, Fe3O4–ZnO–GO, Co3O4–ZnO–GO–PANI (S1) and Fe3O4–ZnO–GO–PANI (S2) have been shown in Fig. 3. The FESEM image of GO shows sheets-based flower like morphology, whereas PANI shows layers of fibrous structure. These fibers form a porous, mesh-like network. Both resultant composite samples are covered with PANI. We have observed three kinds of morphologies: some nanorods (ZnO) of size ~ 600 nm and spherical nanoparticles of Co3O4 (average size ~ 80 nm) in S1 and Fe3O4 (average size ~ 60 nm) based in S2 along flat sheet. Both samples (S1 and S2) have porous structure which will be beneficial for electrochemical energy storage performances. To get the elemental information, we have studied EDS, which is illustrated in Figure S2.

To accesses the chemical composition and oxidation states of the constituent elements in composites S1 and S2, X-ray photoelectron spectroscopy (XPS) analysis was performed. Figure 4a–d depicts the high resolution XPS spectrum Co3O4–ZnO–GO–PANI (S1) of corresponding to Co 2p, C1s, O1s and N1s. Similarly Fig. 4e–h depicts the high resolution XPS spectrum of Fe3O4–ZnO–GO–PANI (S2) corresponding to Fe 2p, C1s, O1s and N1s. The XPS spectrum of S1 possesses spectrums of Co 2p, C 1s, O 1s and N 1s. The Co 2p spectrum of S1 shows two major peaks at 785 eV (Co 2p3/2) and 801.69 eV (Co 2p1/2) and shake up satellite at 790. 39 eV and 807.02 eV. The Co 2p1/2 peak could be divided into Co2+ and Co3+ peaks centered at 807.26 eV and 801.69 eV. Similarly, the Co 2p3/2 could be deconvoluted to Co2+ and Co3+ peaks at 786.46 eV and 784.57 eV and this confirms the existence of Co3O4 [57]. The XPS spectrum of Fe3O4–ZnO–GO–PANI (S2) consist of Fe2p, C 1 s, O 1 s and N1s spectrums. In S2, Fe 2p XPS spectrum shows two peaks at BE 710.21 eV and 724.55 eV and those are assigned to Fe 2p3/2 and Fe 2p1/2 of Fe3O4 [50]. The small satellite peaks at 718.1 eV is due to Fe3+. The Fe 2p3/2 peak at ∼ 710.21 were deconvoluted into two peaks of to Fe2+ (709.95 eV) and Fe3+(711.70 eV), whereas Fe 2p1/2 peak at ∼ 724.55 deconvoluted into two peaks of to Fe2+ (7723.58 eV) and Fe3+(725.52 eV). These characteristics confirms the existence of Fe3O4 [50]. Besides that, both samples have Zn 2p spectrum (Fig S3) and it contains of two peaks at BE 1043.1 eV and 1025.3 eV which are assigned to the Zn 2p1/2 and Zn 2p3/2 peaks of ZnO in the composites [58]. In addition, both samples also contain peaks of C 1s and O 1s where C1s XPS spectrum shows three components, and these are attributed to the presence of C–C/C=C (284.18 eV), –C–N/C=N (285.68 eV), C=O (287.63 eV), and O=C–OH (289.12 eV) and it confirms the presence of GO in both samples. The O1s spectrum deconvoluted with the peaks of metal-O/ C=O (530.49 eV), metal-O–CH (531.97 eV), H–O–H (533.44 eV) and it confirms metal–oxygen-carbon bonding in the resultant composite [16, 50]. The N 1 s spectrum in both samples have three peaks with =N-metal, –NH, and –N+ at 398.61 eV, 400.74 eV, and 402.2 eV respectively [59]. This characteristics peaks indicates the formation of PANI in S1 and S2. Therefore, the XPS analysis confirms the presence of Co3O4, ZnO, GO, PANI in S1 and Fe3O4, ZnO, GO and PANI in S2. In addition, XPS analysis also depicts the formation of metal (Co/Zn/Fe)–O–C–N bonding in the corresponding composite.

The nitrogen adsorption–desorption Brunauer–Emmett–Teller (BET) isotherm measurements of both samples were performed at 77 K. The BET isotherm curve (Fig. 5) of both samples S1 and S2 show type III isotherm with hysteresis loop indicating mesoporous characteristics of the samples. The calculated BET surface area are 142.32 m2/g and 120.54 m2/g for S1 and S2 samples, respectively. The results implies that S1 composite possesses more surface area than S2, which will be advantageous for electrochemical energy storage performance.

Figure 6a–b shows the scan rate dependent CV plots for both samples S1 and S2. It has been observed that the current density increases with the increase of scan rate, which reveals a surface confined process [60]. Fig. 6c shows the CV plots of the composite sample S1 with all of its individuals’ components whereas Fig. 6d shows CV plots of the composite sample S2 with all its individuals’ components. By comparing all CV plots, it has been observed that the area under the curve of Co3O4–ZnO–GO–PANI (S1) is far better compared to their individual counterparts. This is due to the synergistic effects of all the components, and it results in much higher capacitance in the final composite. The same tendency has also been observed in S2 sample. In both cases, the resultant sample shows better performance than their individual counterparts due to synergistic effects. Moreover, it has also been observed that the shape of the CV graph of the final composite is very slanted unlike the square graphs in EDLC due to the presence of pseudo capacitive elements.

Figure 7 shows galvanometric charge–discharge (GCD) plots of S1 and S2 along with the other component materials-based electrodes at current density 1 A/g. We have calculated the specific capacitances values by using the Eq. 1. The calculated specific capacitance value of S1 (246.33 F/g) is higher than that of S2 (110.17 F/g) at a current density of 1 A/g. Moreover, the specific capacitance value of the resultant final composites is greater than their individual components. We have also plotted GCD plots of S1 and S2 at different current densities, depicted in Figure S4 in supplementary information. Figure S4(a) shows charge–discharge plots of S1 at current densities 0.5, 0.7, 1, 2, 3 A/g. It has been observed that the charging and discharging time increases as the current densities decreases. The calculated specific capacitance values of S1 material-based electrode are 350 F/g, 246 F/g, 115 F/g, and 48 F/g at current density 0.5 A/g, 1 A/g, 2 A/g, and 3 A/g, respectively. The vertical drop in potential at the beginning of discharge cycle is called the IR drop and is related to the resistance of the sample where the IR drop is higher due to higher resistance. Figure S4(b) shows charge–discharge plots S2 at different current densities (0.5, 0.7, 1, 2, 3 A/g). It has been observed that the charging and discharging time increases as the current densities decreases. Here the calculated specific capacitance values of S2 material-based electrode are 238 F/g, 110 F/g, 50 F/g, and 24 F/g at current density 0.5 A/g, 1 A/g, 2 A/g, and 3 A/g, respectively.

By comparing the CV plot (Fig. 8a) and GCD plot (Fig. 8b) of both samples S1 and S2, we observed that S1 has better capacitance performance than S2. So, the incorporation of Co3O4 with ZnO–GO–PANI in S1 shows better performance comparted to the incorporation of Fe3O4 in S2.

The specific capacitance of the Co3O4–ZnO–GO–PANI quaternary nanoarchitectonics (S1) is compared with previously reported transition metal–carbon-polymer combined composites-based electrode and the results are shown in Table 1 [33, 35,36,37,38,39,40,41,42,43,44,45,46,47,48,49]. From Table 1, it is evident that the proposed electrode has better electrochemical energy storage performance than the other related reported electrode performance. We have also carried out the electrochemical impedance spectroscopy (EIS) of both S1 and S2 samples, shown in Fig. 8c. The Nyquist plot consists of two parts. The first semicircle is in the high-frequency region is associated with redox charge transfer. The second part reveals the electron transfer at the electrode/electrolyte interface. By comparing the EIS plot, we have observed that the diameter of the semicircle of S1 have less value than the diameter of semicircle of S2 implies better conductivity in S1 relative to S2. Figure 8d displays the comparative specific capacitances (Csp) vs current density plot of both samples. So, the higher specific capacitance value in S1 relative to S2 can infer that Co3O4 incorporation with GO–ZnO–PANI composite shows better energy storage performance than that of Fe3O4 incorporated GO–ZnO–PANI composites. This could be due to the higher reduction potential of Co3+(aq) + e- → Co2+(aq) (+ 1.81 V) than that of Fe3+(aq) + e- → Fe2+(aq) (0.77 V). Moreover, the pseudocapacitance behavior arises due to the transitions in different redox states. This higher reduction potential of Co acts to be more reactive in the redox transitions than Fe, which results in S1 is more capacitive than S2. In addition, during the preparation of the samples, Co2+ salt (Cobalt (II) nitrate) and Fe3+ salt (Iron (III) nitrate) were taken. Co2+ having a 3d7 configuration is less stable than Co3+ having a 3d6 configuration. On the other hand, Fe3+ ion having 3d5 configuration (half-filled) is more stable than Fe2+ having 3d6 configuration. Co2+ is easily oxidized to Co3+ and Fe3+ is not readily reduced to Fe2+. This could be the reason behind the enhancement of energy storage performance of Co3O4-ZnO-GO-PANI (S1) compared to Fe3O4–ZnO–GO–PANI (S2).

4 Conclusion

The well crystalline quaternary nanoarchitectonics of Co3O4–ZnO–GO–PANI (S1) and Fe3O4-ZnO–GO–PANI (S2) were synthesized on a large scale through a chemical process. The synthesis of the composites has been carried out systematically and characterized by XRD, FESEM, EDS, XPS and BET analysis. The XRD and XPS studies confirm the formation of Co3O4, ZnO, GO, PANI and Fe3O4, ZnO, GO, PANI components in S1 and S2 quaternary nanoarchitectonics, respectively. The FESEM analysis shows both composites exhibit layered fibrous structure on the surface, where these fibers form a porous and mesh-like network. The spherical Co3O4 (size ~ 80 nm) and Fe3O4 (size ~ 60 nm) along with nanorod shaped ZnO (size ~ 600 nm) have also been observed in the composite. Type- III BET isotherm revels mesoporous structure in both samples, whereas the calculated BET surface area are 142.32 m2/g and 120.54 m2/g for S1 and S2, respectively. This implies S1 composite possesses more surface area than S2. The mesoporous and fibrous structure are beneficial for good electrochemical storage performance. The electrochemical analysis (CV, GCD and EIS) illustrates that both S1 and S2 based electrodes show better electrochemical storage performance than the individual counterparts due to synergistic effects. Besides that, the sample S1 exhibits higher specific capacitance (246.33 F/g) than that of S2 (110.17 F/g) at a current density of 1 A/g. This is due to higher reduction potential of Co (+ 1.81 V) than that of Fe (0.77 V) and this higher potential causes Co to be more reactive in the redox transitions than Fe. Co2+ is easily oxidized to Co3+ (S1), whereas Fe3+ is not readily reduced to Fe2+ (S2). Moreover, the enhanced ionic intercalation and improved electrical conductivity associated with their specific porous fibrous structures plays a role to enhance the energy storage performances. This concept behind the addition of Co based transition metal oxides can be useful to enhance electrochemical storage. So, we can use our Co3O4–ZnO–GO–PANI composite as a promising material for electrode fabrication for high-performance energy storage devices.

Data availability

The authors confirms that the data supporting the findings of this study are available within this published article (and its supplementary information files).

References

C. Sanchez, B. Julian, P. Belleville, M. Popall, J. Mater. Chem. 15, 3559 (2005)

K. Ariga, Nanoscale Horiz. 6, 364 (2021)

K. Ariga, R. Fakhrullin, Bull. Chem. Soc. Jpn. 95, 774 (2022)

M. Peng, L. Wang, L. Li, Z. Peng, X. Tang, T. Hu, K. Yuan, Y. Chen, eScience 1, 83 (2021)

X. Feng, X. Shi, J. Ning, D. Wang, J. Zhang, Y. Hao, Z.S. Wu, eScience 1, 124 (2021)

F. Perera, Int. J. Environ. Res. Public Health 15, 16 (2018)

F. Perera, N. Engl. J. Med. 386, 2303 (2022)

P. Lu, D. Xue, H. Yang, Y. Liu, Int J Smart Nano Mater. 4, 2 (2013)

V.K. Thakur, Nanomaterials 10, 1817 (2020)

B.K. Kim, S. Sy, A. Yu, J. Zhang, Handb. Clean Energy Syst. 1, 25 (2015)

A. Gonzalez, E. Goikolea, J.A. Barrena, R. Mysyk, Renew. Sust. Energ. Rev. 58, 1189 (2016)

J. Li, C. Zhao, Y. Yang, C. Li, T. Hollenkamp, N. Burke, Z.Y. Hu, G.V. Tendeloo, W. Chen, J. Alloys Compd. 810, 151841 (2019)

F. Chen, P. Wan, H. Xu, X. Sun, A.C.S. Appl, Mater. Interfaces. 9, 17865 (2017)

S. Palchoudhury, K. Ramasamy, R.K. Gupta, A. Gupta, Front. Mater. 5, 83 (2019)

S.K. Krishnan, E. Singh, P. Singh, M. Meyyappan, H.S. Nalwa, RSC Adv. 9, 8778 (2019)

S. Majumder, B. Satpati, S. Kumar, S. Banerjee, ACS Appl. Nano Mater. 1, 3945 (2018)

N.A. Zubir, C. Yacou, J. Motuzas, X. Zhang, J.C.D. Costa, Sci. Rep. 4, 4594 (2014)

V. Sharma, I. Singh, A. Chandra, Sci. Rep. 8, 1307 (2018)

S. Ghosh, B. Sanjeev, M. Gupta, A.B.V.K. Kumar, Ceram. Int. 45, 1314 (2019)

C. Pushpalatha, J. Suresh, V.S. Gayathri, S.V. Sowmya, D. Augustine, A. Alamoudi, B. Zidane, N. Albar, S. Patil, Front. Bioeng. Biotechnol. 10, 917990 (2022)

P.J. Lu, S.C. Huang, Y.P. Chen, L.C. Chiueh, D.Y.C. Shih, J. Food Drug. Anal. 23, 587 (2015)

M. Yadav, N. Singh, A. Kumar, J. Mater. Sci. Mater. Electron. 29, 6853 (2018)

M. Saranya, R. Ramachandran, F. Wang, J Sci.-Adv. Mater. Dev. 1, 454 (2016)

R. Ranjithkumar, S.E. Arasi, S. Sudhahar, N. Nallamuthu, P. Devendran, P. Lakshmanan, M.K. Kumar, Phys. B: Condens. Matter. 568, 51 (2019)

Y. Haldorai, W. Voit, J. Shim, Electrochim. Acta. 120, 65 (2014)

C. An, Y. Zhang, H. Guo, Y. Wang, Nanoscale Adv. 1, 4644 (2019)

Q. Gao, J. Wanga, B. Ke, J. Wang, Y. Li, Ceram. Int. 44, 18770 (2018)

C.K. Brozek, D. Zhou, H. Liu, X. Li, K.R. Kittilstved, D.R. Gamelin, ACS Nano Lett. 18, 3297 (2018)

G.A. Snook, P. Kao, A.S. Best, J. Power Sources 196, 1 (2011)

Q. Feng, A.L. Zhong, J.Y. Pei, Y. Zhao, D.L. Zhang, D.F. Liu, Y.X. Zhang, Z.M. Dang, Chem. Rev. 122, 3820 (2022)

H. Wang, J. Lin, Z.X. Shen, J. Sci.-Adv. Mater. Dev. 1, 225 (2016)

S. Ishaq, M. Moussa, F. Kanwal, M. Eshan, M. Saleem, T.N. Van, D. Losic, Sci. Rep. 9, 5974 (2019)

W.K. Chee, H.N. Lim, I. Harrison, K.F. Chong, Z. Zainal, C.H. Ng, N.M. Huang, Electrochim. Acta. 157, 88 (2015)

Y.S. Lim, Y.P. Tan, H.N. Lim, N.M. Huang, W.T. Tan, M.A. Yarmo, C.Y. Yin, Ceram. Int. 40, 3855 (2014)

K. Qu, Y. Bai, M. Deng, J. Electrochem. Soc. 168, 120542 (2021)

M. Handayani, Y. Mulyaningsih, M.A. Anggoro, A. Abbas, I. Setiawan, F. Triawan, N. Darsono, Y.N. Thaha, I. Kartika, G.K. Sunnardianto, I. Anshori, G. Lisak, Mater. Lett. 314, 131846 (2022)

S. Palsaniya, H.B. Nemade, A.K. Dasmahapatra, J. Phys. Chem. Solids 154, 110081 (2021)

X. Li, C. Zhang, S. Xin, Z. Yang, Y. Lid, D. Zhang, P. Yao, ACS Appl. Mater. Interfaces 8, 21373 (2016)

W.K. Chee, H.N. Lim, N.M. Huang, Int. J. Energy Res. 39, 111 (2015)

K. Lee, C.W. Park, S.J. Lee, J.D. Kim, J. Alloys Compd. 739, 522 (2018)

J. Kalaiarasi, C. Pragathiswaran, P. Subramani, J. Mol. Struct. 1242, 130704 (2021)

A. Moyseowicz, A. Sliwak, E. Miniach, G. Gryglewicz, Compos. B. Eng 109, 23 (2017)

Y. Guo, B. Chang, T. Wen, C. Zhao, H. Yin, Y. Zhou, Y. Wang, B. Yang, S. Zhang, RSC Adv. 6, 19394 (2016)

C.R. Mariappan, V. Gajraj, S. Gade, A. Kumar, S. Dsoke, S. Indris, H. Ehrenberg, G. VijayaPrakash, R. Jose, J. Electroanal. Chem. 845, 72 (2019)

Y.J. Peng, T.-H. Wu, C.-T. Hsu, S.-M. Li, M.-G. Chen, C.-C. Hu, J. Power Sources 272, 970 (2014)

R. Tummala, R.K. Guduru, P.S. Mohanty, J. Power Sources 209, 44 (2012)

Q. Guan, J. Cheng, B. Wang, W. Ni, G. Gu, X. Li, L. Huang, G. Yang, F. Nie, ACS Appl. Mater. Interfaces 6, 7626 (2014)

Q. Wang, L. Jiao, H. Du, Y. Wang, H. Yuan, J. Power Sources. 245, 110 (2014)

D. Su, L. Zhang, Z. Tang, T. Yu, H. Liu, J. Zhang, Y. Liu, A. Yuan, Q. Kong, Nanosci. Nanotechnol. 18, 7 (2018)

S. Majumder, M. Sardar, B. Satpati, S. Kumar, S. Banerjee, J. Phys. Chem. C. 122, 21356 (2018)

S. Majumder, S. Banerjee, Microsc. Microanal. 25, 1394 (2019)

J. Sun, H. Wang, Y. Li, M. Zhao, J. Porous Mater. 28, 889 (2021)

V.P. Dinesh, P. Biji, A. Ashok, S.K. Dhara, M. Kamruddin, A.K. Tyagib, B. Raj, RSC Adv. 4, 58930 (2014)

S. Yang, S. Zhu, R. Hong, Coating 10, 1215 (2020)

F.T. Johra, J.W. Lee, W.G. Jung, J. Ind. Eng. Chem. 20, 2883 (2014)

K. He, F.-X. Ma, Xu. Cheng-Yan, J. Cumings, J. Appl. Phys. 113, 17B528 (2013)

L. Zhang, H. Li, B. Yang, Y. Zhou, Z. Zhang, Y. Wang, J. Solid State Electrochem. 23, 3287 (2019)

Y.C. Liang, C.C. Wang, RSC Adv. 8, 5063 (2018)

N. Maity, A. Mandal, A.K. Nandi, J. Mater. Chem. C 5, 12121 (2017)

G. Strack, S. Babanova, K. Farrington, H.R. Huckarift, P. Atanassov, G.R. Johnson, J. Electrochem. Soc. 160, G3178 (2013)

Acknowledgements

One of the authors (S.M.) gratefully acknowledges Swiss Govt Excellence Scholarship ((ESKAS Nr. 2021.0203) for providing Postdoctoral research fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghosh, S., Majumder, S. & Banerjee, S. Transition metal oxide assisted quaternary nanoarchitectonics based composite towards enhanced electrochemical energy storage performance. Appl. Phys. A 129, 384 (2023). https://doi.org/10.1007/s00339-023-06661-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06661-7