Abstract

The optical parameters of the liquid crystalline materials can be tuned by the dispersion of nanoparticles. Concentration of dopant in the host LC material affects its optical properties significantly, which makes the dispersed system suitable for LC-based devices. In the present investigation, we have studied the effect of different concentrations of nanoparticles on the optical properties of LC, as a guest–host system, where PCNP is guest material and NLC is host material. Porous carbon nanoparticles (PCNPs) were dispersed into the nematic liquid crystal (NLC) in three different concentrations. Optical parameters were measured for pure NLC and NLC-PCNP composites. Photoluminescence (PL) study was performed and it was found that the PL intensity increased for the PCNP dispersed system. High photoluminescence has much importance in the luminescent displays. Full width half maxima (FWHM) were also determined by the Gaussian fitting of PL intensity data. UV absorbance was also measured which gets increased for the PCNP dispersed NLC system when compared to pure NLC. Optical bandgap was found to be reduced after the dispersion of PCNP into NLC. Several other parameters such as absorption coefficient and optical density were also determined. The proposed work may be significant for the liquid crystal displays (LCDs) and other devices which require less bandgap materials. This work may also put some light on the effect of dopants on the LC material in the research based on guest–host system. Increasing the photoluminescence and creating less bandgap materials using carbon nanoparticles is a real challenge, and porous nanoparticles used here overcome this challenge.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The physical characteristics of liquid crystal (LC) materials lie between the liquid and crystal phases. Liquid crystals are competent to illustrate the characteristics of both solids and liquids due to the occurrence of aromatic ring (provides rigidity like solids) and aliphatic tail (provide fluidity like liquids) [1]. LC materials are optically sensitive materials due to photochromic nature and the optical properties of these LC materials can be tuned by changing the temperature, optical field or electric field, which make these materials essentials for optical applications [2]. On the basis of degree of orientational and positional ordering of the molecules, the sub-phases of LCs can be classified. One of the most important phases of LCs is nematic liquid crystal (NLC). Study of different physical properties of NLC such as optical, electro-optical and dielectric properties is nowadays a promising research topic in the field of liquid crystal research. NLCs have several advantages over the other phases of the LCs. There is no positional order in the NLC phase but only the orientational order which makes it useful for display applications [3]. Due the anisotropic structure and birefringent nature, NLCs have different display and non-display applications [4,5,6,7,8]. This produces the reorientation of nematic director when laser light passes through it, since optical torque acting on it because of their anisotropic optical polarizability [9]. Recently, it was reported by Janossy et al. that low concentration of dopant changes the orientational order of the NLC matrix and changes its sign of anisotropy [10].

NLCs have the properties to align in the presence of electric field. An aligned nematic has the properties of uniaxial crystal which is crucial for liquid crystal displays (LCDs). Dispersion of dopants in the NLCs can change the physical properties such as optical, electro-optical and dielectric properties of NLCs. Study of optical properties of NLC is very important due to its scientific applications on LC-based devices. To synthesize a LC for the different properties required for the work is very difficult as well as time consuming. Therefore, if anyhow, we can alter the properties of LCs with dispersion of low concentration of dopants, then it is very important for LC-based devices. Now, the next part is to select the appropriate dopant for this work. Dyes, polymers and carbon nanotubes are being used in the recent past for this purpose [11,12,13] but use of nanoparticles (NPs) are more effective. NPs can play the crucial role for it. Dispersion of small amount of NPs changes the physical properties of NLC matrix [14, 15]. Doping of small concentrations of NPs into LCs is beneficial because high concentrations can cause viscosity problem which will badly affect the response time of the system. Use of small concentrations of ferroelectric NPs [16, 17], semiconducting NPs [18, 19] and metallic NPs [20, 21] in the NLC matrix changes its properties significantly. Carbon dots are also being used nowadays to enhance the device efficiency. Carbon dots are used as supercapacitors which were prepared through thermal synthesis using degassed Cola beverage as a C source [22]. Alas et al. have reported that supercapacitor devices could be made with the help of carbon dots which have the great potential in the development of efficient battery-sized supercapacitor devices [23]. Each NPs have their own effect of alteration of NLC properties depends upon the concentration and size of the NPs. This alteration by the small amount of NPs on the properties of LCs opens the new dimensions in the field of liquid crystal research. Therefore, a much focused investigation on the NLC-NP composite is the need of the hour. Hence, it is necessary and desired to study the effect of NPs on the LCs to get improved optical characteristics of LCs. Optical properties of LCs such as photoluminescence and UV absorbance along with bandgap can be tuned with the help of porous carbon nanoparticles which are crucial for display and non-display devices.

Recently, carbon-based nanoparticles are very much in use as dopants in the liquid crystalline material. Carbon NPs provide several benefits over other NPs, such as availability of unique carbon nano structures and to use it as guest material into the host material (LC). Investigation of porous functionally graded nanoplates and microplates for different behaviors have been recently reported [24, 25]. Here, nanoplates were made of porous material based on isogeometric approach. Investigation of functionally graded sandwiched nanoplates was also reported by Le et al. which describes that the static bending, free vibration, and buckling responses of sigmoid functionally graded are significantly affected by the material variation [26]. Investigation of effects of material and geometry on stochastic behavior of functionally graded porous microplates was recently reported by Tran et al. [27]. Porous carbon nanoparticles (PCNPs) have several advantages due to their uniform size and shape, low cost and inbuilt porous structure [28,29,30] for the use of dopant for the NLC material. The used PCNPs in the present study have been synthesized from bio-waste Caesalpinia Sappan (CS), mostly available in the region of Peninsular Thailand using catalyst-free approach [31]. The plant Caesalpinia Sappan originated from the Caesalpiniaceae family with ayurvedic name Patangah. It has rich lignocellulosic properties with many therapeutic uses. But so far, no one has tried using PCNPs made from Caesalpinia Sappan for LC display applications. Recently, investigations of electro-optical and optical properties of LC doped with PCNP were reported from different groups [32,33,34], where they showed the effect of PCNPs on liquid crystalline properties. It was shown that birefringence and dielectric anisotropy increased after doping the nanoparticles into pure LC. Increment in the photoluminescence intensity for quantum-doped LC system was also reported [35].

Present reported investigation was based on the effect of porous carbon nanoparticles (PCNPs) on the optical parameters of NLC. Photoluminescence (PL) intensity is measured along with FWHM and quantum yield for pure NLC and all the PCNP composites which are crucial for LC-based devices. In addition to this, UV absorbance measurement was performed for the pure NLC and NLC-PCNP composites. Other parameters such as absorption coefficient and bandgap were also measured.

2 Experimental details

2.1 LC material

LC material used in this reported work is nematic liquid crystal (D30-17). This NLC is commercial and purchased from Grandinchem, China. Phase sequence of this NLC is given as follows:

Here, ‘Cr’ is crystal, ‘N’ is nematic and ‘I’ is isotropic phase. Nematic phase of this LC material varies from − 20 °C to 89 °C and on further heating it goes towards isotropic phase.

2.2 Dopant

The dopant is in the present investigation is porous carbon nanoparticles obtained from Caesalpinia Sappan, named as CS-1000 (it means nanoparticles synthesized at 1000 °C). It has particles’ sizes varying from 25 to 50 nm having spherical shape as evidenced by scanning electron microscope images (Fig. 1a). Spherical porous structure is evidenced by transmission electron microscope images (Fig. 1b). Surface area of the nanoparticles always plays the dominant role in defining the behavior. One can see that said PCNPs exhibit excellent surface area values of ~ 793.89 m2/g (see Fig. 1c). The chemical nature of the PCNPs at their surface is represented by XPS showing prominent peaks corresponding to carbon (C 1 s) at binding energy ∼285 eV and oxygen (O 1 s) at ∼532 eV (Fig. 1d).

2.3 Preparation of NLC-PCNP composites

In the present investigation, PCNPs were dispersed into NLC for the optical study. PCNPs of spherical size were dispersed into the pure NLC with three different weight percentages of PCNPs: 0.1%, 0.25%, 0.5% and we have named these three concentrations as mix 1, mix 2 and mix 3, respectively. PCNPs were first mixed in toluene and then the solution was mixed into the NLC in appropriate volume. Thereafter, the mixture was kept under vacuum for the complete evaporation of the toluene and sample has been left for almost 24 h so the solvent get evaporated by itself.

Composites: Mix 1 → Pure NLC + 0.1% PCNP

Mix 2 → Pure NLC + 0.25% PCNP

Mix 3 → Pure NLC + 0.5% PCNP

2.4 Instruments used

Photoluminescence (PL) measurement for pure NLC and all composites was performed by Spectrophotometer (Agilent technologies) at room temperature. 305 nm excitation wavelength was taken for this measurement. UV–visible absorption study was carried out by UV–visible Spectrophotometer (ELICO, SL 210). The surface elemental distribution of the sample was identified by energy-dispersive X-ray spectroscopy (EDS; X Max 80, Oxford Instrument, UK). The morphology and particle size were determined using field emission scanning electron spectroscopy (from Thermo Fisher Scientific Model Apreo 2S), whereas morphology of the samples was performed from Transmission Electron Microscope (Titan-Themis 300 kV from FEI, Thermo). X-ray photoelectron spectroscopy (XPS) was used to understand the surface chemistry of the CSPCNs (Thermo/ESCALAB 250XI, USA). The static volumetric N2 gas adsorption–desorption isotherms were deciphered to obtain SSA using Brunauer–Emmett–Teller (BET) method.

3 Results and discussion

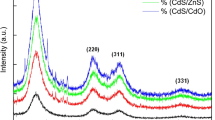

Photoluminescence (PL) property was measured for pure NLC and PCNP composites to study the effect of porous carbon nanoparticles on the optical behavior of liquid crystal. It was measured at room temperature with 305 nm excitation wavelength. Figure 2 depicts the change in the PL intensity (arbitrary unit) as a function of wavelength (nanometer) for pure NLC and three NLC-PCNP mixtures. Increased PL intensity is observed for the PCNP composites when compared to pure NLC and this increment follows the concentrations of PCNP. As the concentration of PCNP increases into the NLC, PL intensity gets increases. Dispersion of PCNPs into pure NLC increases the scattering area, and incident photons gets elastically scattered to excite more NLC molecules. Constructive combination emissions from nematic and PCNP molecules may also be the reason for the increased PL intensity [36]. In this study, the PL emission peak for pure NLC is observed at 523 nm, whereas for PCNP composites, these peaks are observed at 524 nm, 524 nm and 525 nm, respectively. This shows that slight shift in the PL intensity peak in wavelength scale is observed for the dispersed system. The transition between highest occupied molecular orbital (HOMO) to lowest unoccupied molecular orbital (LUMO) is taking place by excitation of light when NLC molecules excited by the dispersion of PCNPs. This phenomenon supports the enhancement of photoluminescence intensity for the PCNP dispersed system. Enhanced photoluminescence observed in this work may be very useful in the luminescent display because display devices require high luminescence. To support the increased PL intensity result, we have done the Gaussian fitting of the PL data.

The enhancement in the photoluminescence intensity for the PCNP dispersed system can also be confirmed from the Gaussian fit of photoluminescence spectra for pure NLC and all three mixtures of PCNPs, shown in Fig. 3. The PL intensity was fitted with Gaussian equation for pure NLC and NLC-PCNP system and it is found that this plot is in consistent with the experimental plot for PL intensity, discussed earlier. Full width half maxima (FWHM) parameter was measured using this fitted data.

Figure 4A depicts the full width half maxima (FWHM) obtained from Gaussian fit with respect to concentration of dopant. It is observed that the FWHM has been increased for the PCNP dispersed system when compared to pure NLC. The increment in the FWHM for PCNP dispersed system ensures that composites system have high PL increment due to suppression of surface state emission [37]. It is reported by Bae et al. that FWHP < 25 nm is mainly due to the direct transitions of electrons between the conduction band and valence band tails [38]. The change in the FWHM parameter for the dopant dispersed LC system was reported by the Vimal et al. [39]. The increment in the FWHM for NLC-PCNP composites indicates that PCNPs are supporting radiative emissions from bands rather than defects levels of NLC material. Figure 4 (B) shows the change in PL intensity peak as function of dopant concentration which increases for the NLC-PCNP mixtures. PL intensity peak for pure NLC is found at 473.67, whereas for mix 1, mix 2 and mix 3, the intensity of peaks are obtained at 616.98, 757.33 and 765.31, respectively.

Figure 5 shows the variation of quantum yield with change in concentration of dopant. It is clearly observed that the quantum yield is increased for the dispersed system and this increment follows the concentrations of PCNP.

Figure 6A depicts the change in the UV–visible absorbance in arbitrary unit as a function of wavelength for pure NLC and PCNP composites. The absorption peak in the UV region is primarily due to the π–π excitation of the π-electron system of the composite. It is observed that the UV absorbance is increased after the dispersion of PCNP into the pure NLC. As the concentration of PCNP increases in the NLC matrix, the UV absorbance increases with it. This increment is possibly due to the coupling between the radiation field i.e., electromagnetic waves of light source and phonons associated with the PCNPs. The UV absorbance peak of pure NLC is found to be near 305 nm. Slight shift of absorbance value in the wavelength scale is also observed here. Figure 6B depicts the optical bandgap which was calculated using Tauc plot method [40, 41]. Optical bandgap is the photon energy axis intercepts of the plot of hν versus (αhν)2. It is observed that bandgap is reduced for NLC-PCNP composites when compared to pure NLC. Bandgap for pure NLC, mix 1, mix 2 and mix 3 are found to be 3.0 eV, 2.9 eV, 2.7 eV and 2.5 eV, respectively. The number of electron–hole pairs participating in the oxidation or reduction reaction is very less in this case because when PCNPs are dispersed into pure NLC then interaction of PCNPs with NLC molecules confines the spectrum of photons which are responsible for creating those electron–hole pair; so bandgap reduces for the NLC-PCNP composites [42, 43]. The outcome of the present investigation might be significant for the devices requiring less bandgap materials. To satisfy this behavior of reduced bandgap, we have also determined the absorption coefficient parameter.

There are many parameters on which the optical properties of the materials depends such as: preparation technique, surface morphology and their doping. The study of the spectral behavior of the absorption coefficient provides information about the electronic states of the optical absorption spectrum in the high energy part, whereas the other lower energy part of the spectrum corresponds to the atomic vibrations [44, 45]. Optical absorption coefficient (a) has several applications in optoelectronics, photovoltaic and display devices. Therefore, it is important to study the optical absorption coefficient here.

Mathematically, absorption coefficient (α) can be given as [46]

where ‘A’ is the absorption of dielectric materials with respect to wavelength region and ‘t’ is the thickness. The variation of absorption coefficient with respect to change in wavelength is shown in Fig. 7A. It is observed that the absorption coefficient is increased after the dispersion of nanoparticles when compared to pure NLC. Moreover, up to a certain wavelength, the absorption coefficient decreases with increased wavelength for all the composites and after that, it becomes almost invariant. The absorption edge was calculated for pure NLC and each mixture by extrapolating the steep portion of the absorption coefficient curve to intercept the wavelength axis. The effect of the NLC-PCNP composites on the onset of the absorption edge is shown in Fig. 7B. It is seen that all the intersection points are located in the visible region for pure NLC and PCNP dispersed system. In addition, the absorption edge is shifted towards longer wavelengths as we increase the concentration of PCNPs into pure NLC. This shift supports the behavior of reduced optical bandgap of NLC with increased concentration of PCNPs. These achieved results are in good agreement with other earlier works [41, 47]. Hassanien et al. have reported in these works that the absorption edge is shifted towards the higher wavelength and absorption coefficient varies for CdSSe composite system up to a certain wavelength and after that wavelength it almost becomes invariant.

The optical density (Dopt) of the dielectric medium is directly proportional to both the thickness of film samples and the absorption coefficient. Dopt can be calculated by the formula given in Eq. 2 [47, 48]:

where ‘α’ is the absorption coefficient and ‘t’ is the thickness. The variation of optical density (Dopt) with change in photon energy (hν) in electron volt is shown in Fig. 8. It is observed that the optical density increases for the PCNP dispersed system. Optical density behavior with the energy of the incident photon is similar to the behavior of the absorption coefficient.

Increased photoluminescence and decreased bandgap along with absorption coefficient results found in this investigation are very prominent for the composite study of liquid crystalline materials dispersed with nanoparticles. These outcomes have many applications in display and non-display devices.

4 Conclusions

The proposed work is about the effect of PCNPs on the optical parameters of NLC in different concentrations. Concentrations of PCNPs significantly affect the properties of pure NLC which is very useful for the research work regarding guest–host system. PL intensity was enhanced after the dispersion of PCNPs into the pure NLC. This enhanced PL intensity is very helpful for the luminescent displays because it requires high photoluminescent materials. It is very difficult to synthesized highly luminescent material, so dispersion of PCNPs technique reported here might open an easy and applicable way to get high PL and use it for display devices. FWHM and quantum yield were also determined and both found to be increased for the PCNP composites when compared to pure NLC material. UV absorbance measured in this reported work is found to be increased for PCNP dispersed NLC system as compares to pure NLC. Bandgap is very important parameter for any materials, so optical bandgap was also calculated and found to be reduced for NLC-PCNP composites. Absorption coefficient and optical density parameters are also determined to explain the optical behavior of PCNPs into the NLC material. It is found that the both absorption coefficient and optical density are found to be increased for composite system than that of pure NLC. The increased PL and reduced bandgap along with other outcomes of this work such as UV absorbance and quantum yield are significant for the display and non-display devices. Therefore, it can be said that the present proposed work about the tuning of optical parameters of NLC-PCNP composite may be helpful in the fabrication of efficient liquid crystal displays and optoelectronic devices which requires less bandgap materials. Dispersion of PCNP in different concentrations enhances the optical properties of NLC material which makes this composite mixture study very useful for LC-based devices.

Data availability

Data available upon request.

References

D. Andrienko, Introduction to Liquid Crystals. International Max Planck Research School, Bad Marienberg (2006).

H. Coles, S. Morris, Nat. Photon. 4, 676 (2010)

S.P. Yadav, K.K. Pandey, A.K. Misra, R. Manohar, Acta Phys. Pol. A 199, 824 (2011)

P.G. de Gennes, J. Prost, The Physics of Liquid Crystals (Oxford University Press, Oxford, 1993)

M. Pande, P.K. Tripathi, A.K. Misra, S. Manohar, R. Manohar, S. Singh, Appl. Phys. A. 122, 217 (2016)

I.C. Khoo, Liquid Crystals: Physical Properties and Nonlinear Optical Phenomena (Wiley, New York, 1995)

P. Klysubun, Nonlinear optical studies of dye-doped nematic liquid crystals. Ph.D. Dissertation, Virginia Polytechnic Institute and State University, Virginia (2002)

S. Yilmaz, A. Bozkurt, Mater. Chem. Phys. 107, 410 (2008)

L. Marrucci, Y.R. Shen, The Optics of Thermotropic Liquid Crystals, ed. by R. Sambles, S. Elston (Taylor and Francis, London, 1997)

I. Janossy, L. Csillag, A.D. Lloyd, Phys. Rev. A 44, 8410 (1991)

S.P. Yadav, M. Pande, R. Manohar, S. Singh, Liq. Cryst. 40, 1503 (2013)

S.E. Hicks, S.P. Hurley, Y.C. Yang, D.K. Yang, Soft Matter 9, 3834 (2013)

B.R. Jian, C.Y. Tang, W. Lee, Carbon 49, 910 (2011)

W.K. Nayek, S. Ghos, S. Karan, T.P. Majumder, S.K. Roy, Appl. Phys. Lett. 93, 112905–112911 (2008)

W.K. Lee, S.J. Hwang, M.J. Cho, H.G. Park, J.W. Han, S. Song, J.H. Jang, D.S. Seo, Nanoscale 5, 193 (2013)

Y. Reznikov, O. Buchnev, O. Tereshchenko, V. Reshetnyak, A. Glushchenko, J. West, Appl. Phys. Lett. 82, 1917 (2003)

F. Li, O. Buchnev, C.I. Cheon, A. Glushchenko, V. Reshetnyak, Y. Reznikov, T. Sluckin, J.L. West, Phys. Rev. Lett. 97, 147801 (2006)

W.T. Chen, P.S. Chen, C.Y. Chao, J. Appl. Phys. 48, 015006 (2009)

T. Zhang, C. Zhong, J. Xu, J. Appl. Phys. 48, 055002 (2009)

Y. Shiraishi, N. Toshima, K. Maeda, H. Yoshikawa, J. Xu, S. Kobayashi, Appl. Phys. Lett. 81, 2845 (2002)

S. Kobayashi, T. Miyama, N. Nishida, Y. Sakai, H. Shiraki, Y. Shiraishi, N. Toshima, J. Disp. Technol. 2, 121 (2006)

R. Genc, M.O. Alas, E. Harputlu, S. Repp, N. Kremer, M. Castellano, S.G. Colak, K. Ocakoglu, E. Erdem, Sci. Rep. 7(1), 11222 (2017)

M.Ö. Alaş, A. Güngör, R. Genç, E. Erdem, Nanoscale 11(27), 12804 (2019)

P.P. Van, C.H. Thai, H.N. Xuan, M.A. Wahab, Eur. J. Mech. A. Solids 78, 103851 (2019)

C.L. Thanh, T.N. Nguyen, T.H. Vu, S. Khatir, M.A. Wahab, Eng. Comput. 38, 449 (2022)

T.C. Le, K.D. Nguyen, M.H. Le, T.S. To, P.P. Vu, M.A. Wahab, Phys. B 631, 413726 (2022)

V.T. Tran, T.K. Nguyen, H.N. Xuan, M.A. Wahab, Thin-Walled Struct. Part B 182, 110267 (2023)

G. Zhang, Thesis, Stressed Liquid Crystals: Properties and Applications (Kent State University, Ohio, 2007), p.88

S.T. Wu, U. Efron, L.D. Hess, Appl Opt. 23(21), 3911 (1984)

S. Doke, K. Sonawane, V.R. Reddy, P. Ganguly, S. Mahamuni, Liq Cryst. 45(10), 1518 (2018)

V.S. Bhat, T.J. Jayeoye, T. Rujiralai, U. Sirimahachai, K.F. Chong, G. Hegde, Nano Select 1(2), 226–243 (2020)

A. Kumar, G. Hegde, S. Manaf, Z. Ngaini, K.V. Sharma, Chem. Commun. 50, 12702 (2014)

A. Rastogi, G. Hegde, T. Manohar, R. Manohar, Liq. Cryst. 48(6), 812 (2021)

G. Pathak, G. Hegde, S.S. Punjalkatte, T. Rujiralai, G. Hegde, V. Prasad, Liquid Crystals, 1–12 (2021).

G. Pathak, G. Hegde, V. Prasad, Liq. Cryst. 48(4), 579 (2021)

G. Pathak, S. Pandey, R. Katiyar, A. Srivastava, R. Dabrowski, K. Garbat, R. Manohar, J. Lumin. 192, 33 (2017)

D.P. Singh, S.K. Gupta, A. Srivastava, R. Manohar, J. Lumin. 139, 60 (2013)

W.K. Bae, M.K. Nam, K. Char, S.H. Lee, Chem. Mater. 20, 5307 (2008)

T. Vimal, D.P. Singh, K. Agrahari, A. Srivastava, R. Manohar, Phot. Let. Pol. 8(1), 23–25 (2016)

J. Tauc, Mater. Res. Bull. 3, 37 (1968)

A.S. Hassanien, A.A. Ak, Superlattices Microstruct. 89, 153 (2016)

R. Asahi, T. Morikawa, T. Ohwaki, K. Aoki, Y. Taga, Science 293, 269 (2001)

W. Choi, A. Termin, M.R. Hoffmann, J. Phys. Chem. 98, 13669 (1994)

F. Urbach, Phys. Rev. 92, 1324 (1953)

M. El-Hagary, M.E. Ismail, E.R. Shaaban, A. El-Taher, Rad. Phys. Chem. 81, 1572 (2012)

K. Rakesh, S.R. Sonker, S.R. Sabhajeet, B.C. Yadav, J Mater Sci: Mater Electron. 27, 11726 (2016)

A.S. Hassanien, A.A. Akl, J. Alloys Compd. 648, 280 (2015)

B. Van Zeghbroeck, Principles of Electronic Devices: Principle of Semiconductor Devices, 1997.

Acknowledgements

The author Govind Pathak is thankful to CSIR, New Delhi, India (File No. 09/0107(12335)/2021-EMR-I) for financial assistance in the form of Research Associate fellowship. Rajiv Manohar is also thankful to the DST, India for the project and financial help. The authors are also thankful to APJ Abdul Kalam Centre for Innovation for the experimental facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest between the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pathak, G., Rujiralai, T., Hegde, G. et al. Influence of composite mixtures between nematic liquid crystal and porous carbon nanoparticles towards photoluminescence and UV absorbance. Appl. Phys. A 129, 261 (2023). https://doi.org/10.1007/s00339-023-06550-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06550-z