Abstract

CdS nanowires (NWs) are obtained by the sulfurization of Cd(OH)2 nanowires at room temperature using H2S. The CdS NWs with diameter of 2–5 nm exhibit high photocatalytic performance due to the ultrafine size. To further improve the performance, Au nanoparticles (NPs) with different sizes, i.e., 5, 20, 40 and 100 nm, that decorated the CdS NWs are synthesized through a simple self-assembly and solid sulfuration process. The synthesized Au NPs–CdS NWs hybrids show higher photocatalytic efficiency than that of pure CdS NWs. Furthermore, 20 nm Au NPs–CdS NWs hybrids with an optimal Au loading of 3.2 wt% exhibit the highest photocatalytic efficiency. Both the enhanced separation of photoinduced hole–electron pairs and the absorption of visible light by incorporating Au NPs significantly improve the photocatalytic performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Photocatalysis as one of the low power consumption technologies has promising perspective in the hydrogen production [1] and environmental protection, such as the oxidization of CO [2, 3] and the degradation of organic pollutant [4, 5]. At present, there are series of problems need to be deeply understood including the mechanism of the photocatalytic reaction [6, 7] and the composition of photocatalyst [8, 9]. The exploration in the mechanism involves the transfer of photoinduced charges [10, 11], the status of the Fermi level of the photocatalyst [12] and the mold of the reaction (oxidation [13] or reduction [14, 15]), providing us new views on photocatalysis and contributing to the deep understanding of photocatalysis. The exploration in the composition and structure of photocatalyst optimizes the parameters resulting in the improvement of the photocatalytic efficiency [16, 17]. Of all the photocatalyst, CdS attracts tremendous attention due to the appropriate band gap (~2.4 eV) which is in accordance well with sunlight spectra [18]. However, the single competent of CdS suffers from low photocatalytic efficiency because of the rapid recombination of photoinduced holes and electrons [19]. Au nanoparticles (NPs) are found to be an effective co-catalyst which can improve the photocatalytic performance of CdS [20].

Indeed, there are many factors affecting the photocatalytic performance of Au–CdS hybrids such as the surface area of the hybrids, the active sites on the surface, the crystallinity of CdS, the interface formed between Au and CdS, the pathway along which photoinduced charges migrate and the intermediate products which are generated during the photocatalytic reaction [21–24], and it is necessary to find the relationship between these factors and photocatalytic activity. So in the past 10 years, various works on Au–CdS hybrids have been carried out [20–25]. For example, Han and co-agents prepared uniform spherical CdS with high crystallinity [8]. They showed that smaller CdS exhibits higher photocatalytic efficiency due to the larger surface area and the shorter route for photogenerated electron to migrate to surface. With 0.5 wt% Au NPs, the rate constant of CdS rose from 0.0710 to 0.1423 min−1 owing to the effective separation of photocatalytic holes and electrons pairs. Liu and coworker synthesized CdS nanowire (NW)–Au nanocrystals (NCs) nanocomposite material [24], which had large surface areas and high carrier mobility. With 1 wt% loading of Au, the sample exhibited the highest photocatalytic performance, while the excess Au led to the descent in the performance because the Au could also be the recombination centers for photoinduced charges. Ma and coworkers synthesized monodispersed Au–CdS core–shell composite with Au core and CdS shell [25]. They demonstrated that Au cores play as the hole receptor, resulting in the improvement of the photocatalytic performance and the stability of photocatalyst. However, there is scanty study on the Au size-dependent photocatalystic activity of Au–CdS composites, compared to other metal–semiconductor hybrids like Au–TiO2 [26, 27].

Herein, Au NPs–CdS NWs (2–5 nm in diameter several micrometers in length) composites were synthesized via a simple self-assembly method by shape reserved converting from Au–NPs–Cd(OH)2 NWs. Compared to the previous reports [24, 28], the prepared Au NPs–CdS NWs hybrids have a shorter electrons migration pathway, due to the ultrathin CdS NWs with diameter of 2–5 nm, while the CdS nanorods were 50 nm in diameter in Liu’s report [24]. So the as-prepared Au NPs–CdS NWs hybrids are expected to have high photocatalytic performance. Furthermore, it is well known that both the loading amount of Au NPs and the size of Au NPs are of great influence on the photocatalytic performance of Au–CdS composites [20–25, 28]. Here, a series of Au NPs–CdS NWs hybrids, with different loading amounts and sizes of Au NPs, i.e., 5, 20, 40 and 100 nm, respectively, were prepared to obtain the best photocatalyst with the optimal loading amount and size of Au NPs. Considering both the size and amount factors of Au NPs are very important to design the optimal Au-decorated CdS composites photocatalyst, especially for ultrathin CdS NWs with diameter of 2-5 nm.

2 Experimental section

2.1 Materials

Cadmium chloride (CdCl2) was purchased from Sigma-Aldrich; aminophenol (NH2CH2CH2OH) (AE) was bought from Acros Chemicals; sodium sulfide (Na2S) was purchased from Aladdin; gold colloids with different sizes, i.e., 5 nm (5 × 1013 units/mL), 20 nm (7 × 1011 units/mL), 40 nm (9 × 1010 units/mL), 100 nm (5.6 × 109 units/mL), were purchased from British Biocell International; polycarbonate (PC) membrane with an average pore size of 200 nm and diameter of 2 cm was purchased from Whatman; quartz plate (2.5 cm × 2.5 cm) was bought from Jinghe Optical Instruments. Ultrapure water (18.2 MΩ) purified from Millipore Direct-Q system was used here.

2.2 Preparation of Au NPs–Cd(OH)2 NWs hybrids

First Cd(OH)2 NWs were synthesized according to a method, developed in Ichinose’s group [29]. Typically, 50 ml CdCl2 (2 mM) aqueous solution was mixed with 50 ml AE (0.8 mM) under stirring at room temperature. After 30 min, Cd(OH)2 NWs aqueous solution was obtained. To obtain Au NPs–Cd(OH)2 NWs hybrids, Au NPs colloid solution with different sizes (5, 20, 40, 100 nm) was dropped into Cd(OH)2 NWs aqueous solution (10 ml) under acutely stirring, respectively. By controlling the volume ratio of the Au NPs colloid solution and Cd(OH)2 NWs solution, the loading amount of Au NPs is easily controlled. For each size Au NPs, three samples with loading amount of Au of 1.6, 3.2 and 6.4 wt% were prepared, respectively. The appearance of purple floccules meant the assembling of negatively charged Au NPs on positively charged Cd(OH)2 NWs by electrostatic attraction. The prepared Au NPs–Cd(OH)2 NWs hybrids were collected by filtering on PC membranes.

2.3 Preparation of Au NPs–CdS NWs hybrids

The prepared Au NPs–Cd(OH)2 NWs hybrids were sulfurized in a glove box by H2S atmosphere, which was generated by adding small amount of HCl into Na2S aqueous solution. The color of the as-prepared samples turned to be more and more yellow. After 2 h, the color did not change further. The Au NPs–CdS NWs hybrids were obtained.

2.4 Characterization

The crystallinity of the samples was characterized by X-ray diffraction (XRD) (PANalytical, Netherlands) instrument with Cu Kα radiation. The structures and morphology of the samples were obtained by SEM (Hitachi S-4800) with X-ray energy-dispersive spectrometer (EDS) and TEM (Philips CM 200). UV–visible absorption spectra of the samples were characterized by Shimadzu UV-3600 spectroscope. The photoluminescence (PL) spectrum of the as-prepared samples was characterized by FLS 92 fluorescence spectrometer. The hybrids were excited by 325-nm light aroused by a laser. The surface areas of the as-prepared samples were measured on an ASIC-2 (Quantachrome Instruments) by multipoint Brunauer–Emmett–Teller (BET) analysis of the nitrogen adsorption isotherms at 77 K.

2.5 Photocatalytic performance

The photocatalytic degradation performance of rhodamine B (RhB) was performed in a special double-deck bottle at constant temperature maintained by circulating water. The xenon lamp (350 W) filtered by a 420-nm filter was used as light source. The concentration of the RhB was 10 µM. In order to obtain the adsorption–desorption equilibrium of RhB, 1.5 mg Au NPs–CdS NWs hybrids and 20 ml RhB (10 µM) were mixed in dark atmosphere for about 1 h. Then the xenon lamp was turned on to start the photocatalytic degradation of RhB. Three milliliters of RhB solution was took out and analyzed by UV-3600 spectroscope for every 30-min intervals. After measurements, the 3 ml solution was returned back to the reaction bottle immediately. All the photocatalysts performance of the synthesized Au NPs–CdS NWs samples was carried out under the same conditions.

3 Results and discussion

Figure 1a and Fig. S1 show that the Cd(OH)2 NWs are average 1.9 nm in diameter (after subtracting the thickness of Pt layer which was coated for SEM observation) and few micrometers in length [29]. Figure 1b, Fig. S2 and Fig. S3 indicate that the linearly one-dimensional structures are reserved after transferring the Cd(OH)2 NWs to CdS NWs with diameter of 2–5 nm in H2S atmosphere at room temperature. This should be due to the low temperature and very high active ultrafine Cd(OH)2 NWs. Figure 2 shows SEM images of 5 nm Au NPs–Cd(OH)2 NWs, 20 nm Au NPs–Cd(OH)2 NWs, 40 nm Au NPs–Cd(OH)2 NWs and 100 nm Au NPs–Cd(OH)2 NWs with same gold loading amount of 3.2 wt%, respectively. Au NPs–Cd(OH)2 NWs hybrids are formed in few seconds after dropping Au NPs colloid solution into Cd(OH)2 NWs aqueous solution. The positively charged Cd(OH)2 NWs and negatively charged Au NPs were quickly self-assembled together by electrostatic attraction. The Au NPs are well distributed among Cd(OH)2 NWs. Dot-line structures are observed in 5, 20 and 100 nm Au NPs–Cd(OH)2 NWs hybrids, respectively (Fig. 2a, b, d), and 40 nm Au NPs–Cd(OH)2 NWs exhibit a unique starfish-like structure (Fig. 2c). The formation of starfish-like structure has been discussed elsewhere (Fig. S4) [30]. Comparing to 40 nm Au NPs, we assume that both the relative small contact surface area and bigger curvature of 5 nm and 20 nm Au NPs are improper for gathering Cd(OH)2 NWs together to form the arms structures. In case of 100 nm Au NPs, Cd(OH)2 NWs tend to cover their surface rather than blend together due to their large and relative flat surface as shown in Fig. 2d. Figure 3 shows the SEM images of Cd(OH)2 NWs with 1.6, 3.2 and 6.4 wt% loading amount of 20 nm Au NPs (Fig. 3a, c, e) and the corresponding Au NPs–CdS NWs hybrids, (Fig. 3b, d, f). The morphology and structure of Au NPs–CdS NWs are remained as those of Au NPs–Cd(OH)2 NWs after sulfurization. By increasing the loading amount of Au NPs, more and more Au NPs are observed among Cd(OH)2 NWs. The loading amount of Au in the 20 nm 3.2 wt% Au–CdS NWs measured by EDS (Fig. S5) is 3.1 wt% very close to that calculated from the corresponding precursor.

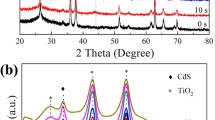

The XRD patterns of 20 nm Au NPs–CdS NWs with different amounts of Au NPs are depicted in Fig. 4d. It shows that the phase of CdS is cubic (JPCDS. 80-0019) with diffraction peaks of (111), (220) and (311). The diffraction peak at 38.2° is the (111) peak of metallic gold (JPCDS.04-0784). This indicates that Au NPs have good crystallization and benefit for the transfer of photogenerated electrons [8]. The samples composed of different amounts of Au NPs have similar XRD patterns. These mean that the phase of CdS is not affected by the size and amount of Au NPs. Figure 4a shows the TEM image of 20 nm Au–CdS. CdS has well-defined linear structure with almost the same diameter as that of Cd(OH)2 NWs. Au NPs are well dispersed among the CdS NWs. Due to the electrostatic attraction and in situ sulfurization at solid state at room temperature, CdS NWs and Au NPs combine each other strongly. Figure 4b, c are the HRTEM of 20 nm Au NPs–CdS NWs, which further demonstrate the compact interface between Au NPs and CdS NWs. The lattice fringes of Au and CdS are clearly observed. The lattice fringes 2.3 Å belong to the (111) plane of metallic gold, and the lattice space 3.3 Å is matched well with the distance of (111) plane of cubic CdS. These results agree well with the XRD patterns.

Optical characteristic is important for the metal–semiconductor hybrids [31]. To investigate the properties of Au NPs–CdS NWs hybrids, UV–visible spectra of Cd(OH)2 NWs, CdS NWs and Au NPs–CdS NWs hybrids were recorded and are shown in Fig. 5a. A typical absorption curve of 20 nm Au NPs is shown in the inset of Fig. 5a. Gold nanoparticles have strong absorption peak among 510–600 nm (determined by the size, shape of Au NPs) due to surface plasmon resonance (SPR) [12, 32, 33]. The Au NPs–CdS NWs hybrids exhibit a broadened and redshift absorption peak comparing to Au NPs. The change is a sign that Au–CdS have formed well in metal–semiconductor heterostructure, because high dielectric coefficient and exciton–plasmon coupling of CdS can change the SPR peak of Au NPs [33, 34]. For 20 nm Au NPs–CdS NWs hybrids with different amounts of Au NPs, the absorption of light (400–700 nm) is enhanced with the increase in the amount of Au NPs. CdS has a band gap of 2.42 eV; as a result, the enhanced absorption from 400 to 512 nm can immediately increase the photogenerated electrons of CdS [25]. These results show that Au NPs can effectively increase the visible light absorption of CdS, which would result in better photocatalytic performance. The UV–visible spectra of 5 and 40 nm Au NPs–CdS NWs hybrids perform similar optical properties with that of 20 nm Au NPs–CdS NWs, as shown in Fig S6, Fig. S7 and the pervious report [30]. As depicted in Fig S4, the SPR peak of 100 nm Au is 600 nm. It reveals that 100 nm Au NPs–CdS NWs hybrids tend to absorb the light over 512 nm. As a result, 100 nm Au NPs–CdS NWs hybrids have fewer photogenerated charges than other size Au NPs–CdS NWs hybrids with smaller Au NPs.

a UV–visible absorption spectra of Cd(OH)2, CdS and 20 nm CdS loading with different amounts of Au NPs: 1.6, 3.2 and 6.4 wt%, respectively. The inset is the absorption spectra of 20 nm Au NPs in aqueous solution. b PL spectra of CdS NWs and CdS loading with 1.6, 3.2 and 6.4 wt% of 20 nm Au NPs, respectively

To get more information about Au NPs–CdS NWs hybrids, PL spectra of the prepared Au NPs–CdS NWs were carried out by a laser with exciting light of 325 nm. As shown in Fig. 5b, the pure CdS NWs have a strong and broad emission peak around 530 nm. However, the PL spectra of the Au NPs–CdS NWs show great quenching. With 1.6 wt% 20 nm Au NPs, about 68.8 % PL is quenched. And 89.6 % is quenched when the content of Au NPs is 6.4 wt%. The remarkable quenching of PL spectra shows that Au NPs play an important role in the photogenerated charges transfer process [35, 36]. Similar quenching of PL spectra has been observed in previous reports such as Au–ZnS [37] and Au–CdS [8, 36], due to the efficient separation of photoinduced electrons and holes. In the transfer process, Au NPs act as electron acceptors. The photogenerated electrons on CdS conduction band can easily migrate to Au NPs, since the Fermi energy level of Au NPs is lower than the conduction band of CdS [8, 24]. Moreover, since the absorption peak of Au NPs is close to the emission peak of CdS, the quenching of PL spectra may be attributed to the absorption of Au NPs. We also perform the PL spectra of Au NPs-decorated CdS NWs with different Au NPs sizes. The changes of PL intensity for other size Au NPs of Au NPs–CdS NWs are similar to that of 20 nm Au NPs–CdS NWs, as shown in Fig. S8.

With the enhanced absorption of visible light and the separation of photogenerated hole–electron pairs, Au NPs–CdS NWs hybrids are assumed to have highly efficient photocatalytical performance. So we further explored the photocatalytic activity of Au NPs–CdS NWs hybrids by the photodegradation of RhB under visible light. The results are shown in Fig. 6. There are 28.5 and 7 % of RhB decomposed in 2 h for the pure CdS NWs and Au NPs, respectively. It is deserved to be noted that the photocatalytic efficiency of the CdS NWs is higher than the CdS microspheres [38] and amine-functioned CdS quantum dots [39]. Comparing with CdS microspheres, the size of CdS NWs is much smaller; therefore, the migratory route for photoinduced charges is shorter. The photogenerated carriers easily transfer to the CdS surface and result in higher photocatalytic activity, since the CdS quantum dots were modified by amine, which may reduce the active sites on the surface. But in our case, the smaller CdS NWs were converted directly from positive-charged Cd(OH)2 NWs without any functional ligands. Most of their surfaces are active. Therefore, the CdS NWs reported here demonstrate higher photocatalytical activity than CdS microspheres [38] and ligands functional CdS quantum dots [39].

For comparison, the photocatalytic performance of Au–CdS hybrids was explored. 20 nm Au NPs–CdS NWs with 3.2 wt% Au exhibits the high photocatalytic activity, and 72.0 % RhB is degraded in 2 h. When loading Au of 1.6 and 6.4 wt%, 46 and 50 % RhB are decomposed, respectively. The result demonstrates that the heterostructures formed between CdS and Au play an important role in the photocatalytic reaction. When the loading amount of 20 nm Au is 3.2 wt%, the Au NPs–CdS NWs perform the highest photocatalytic activity, and more Au NPs or less Au NPs will result in the descent of the activity. As is well known that Au NPs can enhance the absorption of light and the separation of photoinduced hole and electron pairs, which can significantly improve the photocatalytic performance [40, 41].

However, excess Au NPs will lead to the decline of photocatalytic activity, because excess Au NPs covering the active sites of CdS will decrease the absorption of light and the amount of photogenerated hole–electron pairs, and overfull Au NPs can also be the recombination centers of photoinduced charges rather than the electron acceptors [8, 24]. 5 and 100 nm Au NPs–CdS NWs hybrids perform highest activity at the loading amount of 6.4 and 3.2 wt%, respectively. 40 nm Au NPs–CdS NWs hybrids, which have been discussed elsewhere [30], perform highest activity with loading amount of 16 wt% Au NPs. In the previous reports [42], it has been noted that smaller Au NPs are more active. However, this is not the case in our case, since 5 nm Au NPs–CdS NWs show lower performance than that of 20 nm Au

NPs–CdS NWs. These might be due to the reduction in active sites on CdS NWs, which are occupied by small Au NPs. For 100 nm Au NPs–CdS NWs, it shows the lowest photocatalytic efficiency, which is due to the less active Au NPs and the smaller interface between CdS and Au. In the case of 40 nm Au NPs–CdS NWs, a unique structure is obtained, which is reported elsewhere [30]. The structure is formed by several tens of nanostrands blending together. As a result, the surface areas of the Au–CdS turn to be less, leading to a lower reaction rate. Moreover, the less activity of 40 nm Au NPs also accounts for the lower efficiency. To have a further comparison of these samples, first-order kinetic model is used to measure the reaction rates of the samples. The formula ln (C 0/C) = kt, in which C 0 is the start concentration of RhB, and C is instantaneous concentration of RhB at time t. The reaction rates of the samples are calculated and given in Table 1. It exhibits the highest photocatalytic efficiency of 20 nm Au NPs–CdS NWs among all the samples. And the reaction rate of 20 nm Au NPs–CdS NWs hybrid is higher than that of Xing and Liu’ work [38, 39]. We ascribe the higher rate constant to the short electrons migration pathway, due to the ultrathin structure and non-ligand function of CdS NWs.

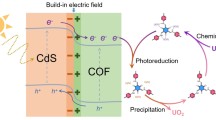

To see the nature migration of photoinduced hole and electron pairs in photocatalytic, the photodegradation mechanism of Au NPs–CdS NWs hybrids is proposed in Scheme 1. For large size of Au NPs, such as 20 nm, the photogenerated holes exist in the valence band of CdS and photogenerated electrons exist in the conduct band of CdS under the visible light. Then the photogenerated electrons tend to migrate to the surface of Au NPs, due to the lower Fermi level of Au. Then the photoinduced electrons on the surface Au NPs can combine with oxygen to form superoxide anion radicals (O2−), and the photoinduced holes in the valence band of CdS can react with OH– to produce \(\cdot {\text{OH}}\) [8]. Both O2− and \(\cdot {\text{OH}}\) have strong oxidizing property, resulting in the decomposition of RhB. For small size of Au NPs, such as 5 nm, the process of photodegradation seems to be different. The Fermi level of small Au NPs is easier to have a negative shift than large Au NPs, because of the electron accumulation on the surface of Au NPs. And the negative shift of the Fermi level contributes to the enhanced photocatalytic efficiency, due to the shorter pathway of the electron migration [12]. Thus, in previous report, the smaller sizes of Au NPs tend to be more active [12, 42]. The corresponding BET surface area of Au–CdS NWs is given in table S1. Based on the above results, it is clear that active sites on the Au NPs and CdS NWs, the absorption of visible light and the surface area of Au–CdS are contributed to the photocatalytic performance. In our case, 20 nm 3.2 wt% Au–CdS NWs with optimal size and loading amount show the best performance.

4 Conclusions

In summary, we prepared a series of Au NPs–CdS NWs hybrids via a simple self-assembly and solid sulfurization process. The structures of Au NPs–CdS NWs hybrids highly rely on the surface area, size and the surface charge of Au NPs, where the 40 nm Au NPs can form Au NPs–CdS NWs SFs and other sizes of Au NPs can form Au NPs–CdS NWs. As-synthesized CdS NWs perform better photocatalytic activity than those of the previously reported bigger CdS nanostructures, due to the shorter migratory route for photoinduced charges. CdS NWs show better performance when Au NPs are loaded due to the enhanced separation of photoinduced holes and electrons. Moreover, the photocatalytic performance of Au NPs–CdS NWs hybrids is different when the different amounts and different sizes of Au NPs are loaded on the CdS NWs. The CdS NWs loading with 3.2 wt% 20 nm Au NPs exhibits the highest photocatalystic efficiency, which indicates the optimal collocation of Au NPs–CdS NWs.

References

X.A. Wang, K. Maeda, A. Thomas, K. Takanabe, G. Xin, J. Carlsson, K. Domen, M. Antonietti, Nat. Mater. 9, 76 (2009)

S. Roy, M.S. Hegde, N. Ravishankar, G. Madras, J. Phys. Chem. C 111, 8153 (2007)

M.S. Chen, D.W. Goodman, Chem. Soc. Rev. 37, 1860 (2008)

L.W. Zhang, H.B. Fu, Y.F. Zhu, Adv. Funct. Mater. 18, 2180 (2008)

H. Zhang, X.J. Lv, Y.M. Li, Y. Wang, J.H. Li, ACS Nano 4, 380 (2010)

V. Schwartz, D.R. Mullins, W.F. Yan, B. Chen, S. Dai, S.H. Overbury, J. Phys. Chem. B 108, 15782 (2004)

M.J. Batista, A. Kubacka, M.F. Garcia, ACS Catal. 4, 4277 (2014)

S.C. Han, L.F. Hu, N. Gao, A.A. Ghamdi, X.S. Fang, Adv. Funct. Mater. 24, 3725 (2014)

X.B. Chen, S.H. Shen, L.J. Guo, S.S. Mao, Chem. Rev. 110, 6503 (2010)

A.T. Yeh, C.V. Shank, J.K. McCusker, Science 289, 935 (2000)

H.W. Tseng, M.B. Wilker, N.H. Damrauer, G. Dukovic, J. Am. Chem. Soc. 135, 3383 (2013)

V. Subramanian, E.E. Wolf, P.V. Kamat, J. Am. Chem. Soc. 126, 4943 (2004)

X.J. Lang, H.W. Ji, C.C. Chen, W.H. Ma, J.C. Zhao, Angew. Chem. Int. Ed. 50, 3934 (2011)

Y.T. Liang, B.J. Vijayan, K.A. Gray, M.C. Hersam, Nano Lett. 11, 2865 (2011)

Y.C. Zhang, J. Li, M. Zhang, D.D. Dionysiou, Environ. Sci. Technol. 45, 9324 (2011)

G. Manna, R. Bose, N. Pradhan, Angew. Chem. Int. Ed. 53, 1 (2014)

N. Zhang, S.Q. Liu, X.Z. Fu, Y.J. Xu, J. Phys. Chem. C 115, 9136 (2011)

X. Zong, G.P. Wu, H.J. Yan, G.J. Ma, J.Y. Shi, F.Y. Wen, L. Wang, C. Li, J. Phys. Chem. C 114, 1963 (2010)

P. Gao, J.C. Liu, S.S. Lee, T. Zhang, D.D. Sun, J. Mater. Chem. 22, 2292 (2012)

Z.B. Yu, Y.P. Xie, G. Liu, G.Q. Lu, X.L. Ma, H.M. Cheng, J. Mater. Chem. A 1, 2773 (2013)

A.E. Saunders, I. Popov, U. Banin, J. Phys. Chem. B 110, 25421 (2006)

W.T. Chen, T.T. Yang, Y.J. Hsu, Chem. Mater. 20, 7204 (2008)

P.V. Kamat, B. Shanghavi, J. Phys. Chem. B 101, 7675 (1997)

S.Q. Liu, Y.J. Xu, Nanoscale 5, 9330 (2013)

X. Ma, K. Zhao, H.J. Tang, Y. Chen, C.G. Lu, W. Liu, Y. Gao, H.J. Zhao, Z.Y. Tang, Small 10, 4664 (2014)

M. Murdoch, G.I.N. Waterhouse, M.A. Nadeem, J.B. Metson, M.A. Keane, R.F. Howe, J. Llorca, H. Idriss, Nat. Chem. 3, 489 (2011)

C. Yogi, K. Kojima, T. Hashishin, N. Wada, Y. Inada, E.D. Gaspera, M. Bersani, A. Martucci, L.J. Liu, T.K. Sham, J. Phys. Chem. C 115, 6554 (2011)

N.Z. Bao, L.M. Shen, T. Takata, D.L. Lu, K. Domen, Chem. Lett. 35, 318 (2006)

I. Ichinose, K. Kurashima, T. Kunitake, J. Am. Chem. Soc. 126, 7162 (2004)

X.Y. Wang, Y.L. Ying, J.H. Lei, P. Hu, X.S. Peng, RSC. Adv. 4, 42441 (2014)

E. Shaviv, O. Schbert, M.A. Santos, G. Goldoni, R.D. Felice, F. Vallee, N.D. Fatti, U. Banin, C. Sonnichsen, ACS Nano 5, 4712 (2011)

R.A. Reynolds, C.A. Mirkin, R.L. Letsinger, J. Am. Chem. Soc. 122, 3795 (2000)

G. Manna, R. Bose, N. Pradhan, Angew. Chem. Int. Ed. 53, 1 (2014)

D. Mongin, E. Shaviv, P. Maioli, A. Crut, U. Banin, N.D. Fatti, F. Vallee, ACS Nano 6, 7034 (2012)

E. Khon, A. Mereshchenko, A.N. Tarnovsky, K. Acharya, A. Klinkova, N.N. Hewa-Kasakarage, I. Nemitz, M. Zamkov, Nano Lett. 11, 1792 (2011)

K.F. Wu, W.E. Rodriguez-Cordoba, Y. Yang, T.Q. Lian, Nano Lett. 13, 5255 (2013)

J.Y. Zhang, Y.H. Wang, J. Zhang, Z. Lin, F. Huang, J.G. Yu, A.C.S. Appl, Mater. Interfaces 5, 1031 (2013)

Y. Liu, Y.X. Yu, W.D. Zhang, J. Alloy. Compd. 569, 102 (2013)

X.L. Xing, R.J. Liu, X.L. Yu, G.J. Zhang, H.B. Gao, J.N. Yao, B.Z. Ren, Z.X. Jiang, H. Zhao, J. Mater. Chem. A 1, 1488 (2013)

T.T. Yang, W.T. Chen, Y.J. Hsu, K.H. Wei, T.Y. Lin, T.W. Lin, J. Phys. Chem. C 114, 11414 (2010)

M. Lin, X.F. Yu, S. Liang, X.N. Peng, Z.J. Yang, Y.L. Wang, Q.Q. Wang, Adv. Funct. Mater. 21, 1788 (2011)

A. Stephen, K. Hashmi, G.J. Hutchings, Angew. Chem. Int. Ed. 45, 7896 (2006)

Acknowledgments

This work was supported by Natural Science Foundation for Outstanding Young Scientist of Zhejiang Province, China (LR14E020001), the National Basic Research Program of China 973 Program (2015CB655302) and the National Natural Science Foundations of China (NSFC 21271154).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, X., Ying, Y., Hu, P. et al. Au nanoparticle-decorated ultrathin CdS nanowires for high-efficiency photodegradation of organic dyes. Appl. Phys. A 120, 1291–1297 (2015). https://doi.org/10.1007/s00339-015-9382-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9382-y