Abstract

Self-seeding polyol synthesis method, without additives, was employed for the fabrication of different copper nanostructures. The pertinent parameters including temperature, copper concentration and molar ratio of poly(vinylpyrrolidone) (PVP) to copper were assessed for achieving different size and morphology of copper nanostructures, i.e., nanowire, nanosphere and nanocube. It was found that PVP-to-copper molar ratio has the most significant effect on the geometry of the copper nanostructures.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Copper, the second most consumed non-ferrous metal, is a ductile metal with very high thermal and electrical conductivity. Copper nanostructures are widely employed in nanoelectronics and catalysts [1–3] as well as transparent conductive electrodes [4–7]. Several methods have been introduced for the synthesis/production of nanostructured copper, including chemical/sonochemical techniques [8, 9], metal vapor [10] and microemulsion techniques [11]. It is worthy of note that the chemical reduction techniques such as hydrothermal [12–14] and solvothermal methods [15, 16] are the most widely used ones due to the simplicity, low cost and controllability of copper nanostructure morphologies. In hydrothermal methods, the copper ions are reduced in an aqueous medium via a reducing agent in the presence of a capping agent. The most important difficulty of this process is the use of toxic reducing agents such as hydrazine, sodium borohydride and formaldehyde [4, 6, 12]. However, solvothermal reduction of copper ions in an organic medium, in the presence of a capping agent (such as PVP and EDA), eliminates the use of the above-mentioned toxic reducing agents. When ethylene glycol (an alcohol containing multiple hydroxyl functional groups) is used as the medium, the solvothermal technique is known as the polyol method [15, 17–21]. Ethylene glycol, in polyol synthesis method, serves as both solvent (medium) and reducing agent. Furthermore, using organic medium minimizes the partial oxidation and agglomeration of the final products [22–24].

Regarding the synthesis of copper nanostructures via polyol method, Park et al. [20] successfully controlled the size and the size distribution of copper nanoparticles by adjusting the reducing agent concentration, reaction temperature and precursor injection rate in the polyol synthesis system. They also reported that precursor injection rate is the most influential factor in the system. Moreover, Zhang et al. [25] synthesized ultrafine copper nanoparticles using polyol method. The most distinctive point in their work is the use of NaBH4 as the reducing agent. Besides, Blosi et al. [26] employed the microwave-assisted polyol method for the production and optimization of copper nanoparticles. A literature survey shows that despite the works on the polyol synthesis of copper nanoparticles, there are only very limited studies on the production of other copper nanostructures (nanowire/nanorod and nanocube) via this method. For instance, Wang et al. [27] synthesized copper nanocubes via polyol method with the aid of ascorbic acid as a reducing agent. Additionally, Zhao et al. [15] compared the polyol-synthesized copper nanowires with those from other synthesis methods including vapor infiltration and hydrothermal reduction. They also evaluated the effect of synthesis temperature and PVP concentration on the formation of copper nanowires.

The aim of the present work was to identify the effect of important parameters—i.e., temperature, initial copper concentration and molar ratio of PVP to copper—in a self-seeding polyol synthesis system. The level of each parameter is varied to see whether different copper nanostructures are achievable. The possible outcome of this study has important implications regarding the use of the polyol synthesis method for obtaining different morphologies and sizes.

2 Materials and methods

The ethylene glycol (EG) (C2H6O2, Daejung, 99 %), based solutions of copper nitrate (Cu(NO3)2·3H2O, Merck, 99 %) with concentration of 0.09 M and poly(vinylpyrrolidone) (PVP) (K30, (C6H9NO) n , Daejung, 99.8 %) were prepared. Equal volumes of the solution (6 mL) were injected dropwise at a rate of 30 mL/h into a flask and stirred for 2 h under ambient conditions. Then, the mixture was transferred into a Teflon-lined stainless steel autoclave and heated at 155 °C for 30 h. Ethylene glycol was used as both solvent and reducing agent, while PVP was used as surfactant. Thereafter, the obtained suspension was water-cooled to room temperature. The reddish brown suspensions were diluted with DI water (in a ratio of 1:5) and centrifuged three times at 4500 rpm for 10 min. The final products were dispersed in ethanol before SEM, XRD and UV–visible spectrophotometry examinations. A schematic representation of the experimental procedure is shown in Fig. 1. The effect of temperature, copper concentration and molar ratio of PVP to Cu on the morphology/size of final products were assessed in the range of 145–175 °C, 0.03–0.12 M and 0.5–5, respectively.

3 Results and discussion

3.1 Copper nanowires

In order to monitor the products of polyol process, conducted at 155 °C with MR of 1 and copper concentration of 0.09 M, SEM imaging was carried out at different time intervals in an overall time of 30 h (Fig. 2). As it can be seen in Fig. 2a, at the initial times of the process, copper nanoparticles are formed. By increasing the reaction time to 14 h (Fig. 2b), some short nanorods appear and after 18 h, the length of nanorods increases (Fig. 2c). However, Cu nanowires are observed after 24 h (Fig. 2d) with diameter and length of 80–100 nm and 2–5 μm, respectively. After 30 h, the length of nanowires reaches 10–15 µm without any significant change in the diameter. Hereafter, some short, thick rods are observed (42 h) which can be very likely attributed to the expansion of nanoparticles at the expense of the nanowires’ re-dissolution. The obtained results indicate that the adequate time for achieving the nanowires with a relatively high length is around 30 h.

The crystallographic structure of the initial seeds in the nucleation process plays an important role in nanowire formation. It has been reported [5, 19, 28] that multiple-twined decahedrons serve as the seeds for nanowires, while spherical seeds would result in nanoparticles. These decahedrons have high energy in the binding of different (111) facets and can serve as the main host for the precipitation of Cu reduced atoms. Moreover, PVP has been known to have strong binding with (100) facets of decahedrons. Thus, for minimizing the energy and due to the stronger interaction of PVP with (100), compared to that of (111) facets, reduced copper atoms are preferentially absorbed on (100) facets resulting in the growth along the \( \left\langle {100} \right\rangle \) direction. In the following step, copper nanorods are grown through the well-known Ostwald ripening mechanisms in the presence of PVP chains and finally, copper nanowires are grown at the expense of short nanorods and nanowires. It should be pointed out that PVP continuingly acts as a capping agent for preferential growth along the \( \left\langle {100} \right\rangle \) direction. After that, PVP enables the two ends of the nanorods to grow and form nanowires while tightly passivating the side surfaces of (110) [29].

In order to evaluate the probability of the presence of copper nanowires under different conditions, the concentration of copper, molar ratio of PVP to copper and temperature are varied in a range around the one resulted in the production of nanowires, i.e., 0.09 M Cu(NO3)2 with MR = 1 at 155 °C.

3.2 Effect of copper concentration

Figure 3 shows SEM images of the copper nanostructures at copper concentrations of 0.03, 0.06, 0.09 and 0.12 M (MR = 1, temperature = 155 °C and the synthesis time = 30 h). At the lowest level of copper concentration (0.03 M), microparticles are produced (Fig. 3a). Under these conditions, it seems that after a slight nucleation of copper atoms, the metal concentration drops below the nucleation concentration. However, the copper concentration is still high enough for the growth of particles without any specific geometry. By an increase in copper concentration to 0.06 M, as can be seen in Fig. 3b, a mixture of microparticles and nanoparticles are formed. In this case, more seeds are available and consequently, smaller anisotropic particles are formed. The higher anisotropy is observed when the copper concentration increases to 0.09 M (Fig. 3c). Close observation of Fig. 3c reveals that the favorable concentration of copper for attaining copper nanowires is 0.09 M; at this concentration, highly crystalline and anisotropic structures of copper nanowires are achieved. However, further increase in the copper concentration to 0.12 M leads to the formation of Cu nanoparticles, as shown in the Fig. 3d.

3.3 Effect of PVP-to-Cu molar ratio

Figure 4 shows the SEM images of the copper nanostructures synthesized using different molar ratios of PVP to Cu (0.5, 1, 1.5, 3 and 5). At the lowest molar ratio (0.5), clusters of nanoparticles are observed (Fig. 4a), which is due to inadequate level of PVP for preventing colloid sintering of formed copper nanoparticles. In fact a critical level of PVP is essential for covering the particles and inhibiting the metal–metal bond formation [30]. In molar ratio of 1, high-aspect-ratio nanowires are obtained as shown in Fig. 4b. Since multiple-twinned decahedrons have the highest energy in their boundaries, copper atoms would preferentially crystallize on these sites. Furthermore, in the metals with FCC structure, (110) facets are the least stable planes which provide the opportunity for the higher growth rate in the absence of PVP [15]. The necessity for energy minimization and faster growth, together with the stronger surface interaction of PVP with (100) planes, results in the reaction of PVP chains only with (100) faces of multiple-twinned particles, i.e., longitudinal growth in the \( \left\langle {100} \right\rangle \) direction occurs and five-twinned nanowires are formed. By increasing the molar ratio to 1.5, thicker nanowires together with higher number of microparticles are produced as can be observed in Fig. 4c.

When molar ratio increases to 3, a new morphology of nanocubes appears (Fig. 4d). Under these conditions, single-twinned seeds serve as the favorable seeds to grow on both {111} and {100} faces and cubic nanoparticles are formed. At the molar ratio of 3, the high coverage of PVP over all the surfaces of initial seeds results in the isotropic growth. It is clearly observed that the surfaces of nanocubes are smooth with edge lengths of 100–200 nm. As shown in Fig. 4e, at the molar ratio of 5, the PVP molecules completely cover the entire surfaces including the twin boundaries of initial copper seeds of MTPs; this complete coverage prevents the interaction between PVP and various crystallographic planes and hinders the anisotropic growth. As a result, Cu nanoparticles are formed.

3.4 Effect of temperature

The SEM images corresponding to Cu nanostructures obtained at 145, 155, 165 and 175 °C are shown in Fig. 5. As a matter of knowledge, the reduction of metal ions via ethylene glycol proceeds as [15]:

At the first step, EG converts to acetaldehyde (CH3CHO) and then CH3CHO acts as the reducing agent.

The pivotal point in the reduction capability of EG, i.e., EG conversion to acetaldehyde, is temperature which must be higher than 145 °C [12, 31]. As it can be observed in Fig. 5a, copper microparticles are produced at 145 °C, indicating that the specific faces are not formed at this temperature. On the other hand, it is very likely that required energy for the diffusion of PVP molecules on the surface of copper seeds for anisotropic growth [15] is not acquired at 145 °C. However, by increasing the temperature to 155 °C, multiple-twined particles can be formed, resulting in the appearance of Cu nanowires (Fig. 5b). Increasing the temperature to higher than 155 °C leads to the formation of copper nanoparticle clusters (Fig. 5c, d). Moreover, high temperatures may lead to hyperactive behavior of PVP, which results in covering the whole surface of initial seeds by PVP. To sum up, the suitable temperature for the production of copper nanowires is proposed as 155 °C.

3.5 X-ray diffraction and UV–visible spectrophotometry

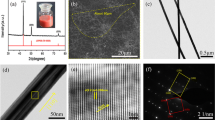

The XRD patterns of Cu nanostructures are presented in Fig. 6. Regarding the detection limit of XRD analysis which is ~5 %, there are no peaks corresponding to the CuO and Cu2O impurities. Furthermore, the peaks appear at 43°, 50° and 74°, which are assigned to (111), (200) and (220) planes of Cu, confirming the presence of pure copper [12].

Another important point is the stability of the obtained nanostructures. The XRD patterns of Cu nanowires which were kept in ethanol for 2 months together with the pattern corresponding to Cu nanowires which were kept in air (no protection) are also shown in Fig. 6d, e, respectively. A minor peak ascribed to (111) crystal plane of Cu2O is found at 36.5° for the latter (Fig. 6e), which indicates the oxidation of copper nanowires in air.

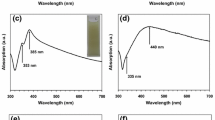

The UV–visible spectra of copper nanocube, nanowire and nanoparticle are presented in Fig. 7. The appearance of surface plasmon resonance (SPR) at 610, 700 and 720 nm confirms the presence of nanocubes in the final products. Moreover, the peaks at 600 and 570 nm corroborate the existence of nanowires and nanoparticles, respectively.

4 Conclusion

The polyol method was successfully applied for the synthesis of different copper nanostructures by adjusting the process parameters including temperature, copper concentration, molar ratio of PVP to Cu and reaction time. Based on the obtained results, the favorable conditions for the synthesis of Cu nanowires with the length and diameter ranges of 10–15 µm and 80–100 nm were copper concentration of 0.09 M, PVP-to-Cu molar ratio of 1, temperature of 155 °C and time of 30 h. Moreover, copper nanocubes were obtained under same conditions except for the PVP-to-copper molar ratio which should be set at 3.

References

K.J. Ziegler, R.C. Doty, K.P. Johnston, B.A. Korgel, Synthesis of organic monolayer-stabilized copper nanocrystals in supercritical water. J. Am. Chem. Soc. 123(32), 7797–7803 (2001)

C.F. Monson, A.T. Woolley, DNA-templated construction of copper nanowires. Nano Lett. 3(3), 359–363 (2003)

Y. Feng, X. Zheng, Plasma-enhanced catalytic CuO nanowires for CO oxidation. Nano Lett. 10(11), 4762–4766 (2010)

A.R. Rathmell, S.M. Bergin, Y.L. Hua, Z.Y. Li, B.J. Wiley, The growth mechanism of copper nanowires and their properties in flexible, transparent conducting films. Adv. Mater. 22(32), 3558–3563 (2010)

M. Mohl, P. Pusztai, A. Kukovecz, Z. Konya, J. Kukkola, K. Kordas, R. Vajtai, P.M. Ajayan, Low-temperature large-scale synthesis and electrical testing of ultralong copper nanowires. Langmuir 26(21), 16496–16502 (2010)

A. Rathmell, B. Wiley, The synthesis and coating of long, thin copper nanowires to make flexible, transparent conducting films on plastic substrates. Adv. Mater. 23(41), 4798–4803 (2011)

H. Guo, L. Na, Y. Chen, Zh Wang, Q. Xie, T. Zheng, N. Gao, Sh Li, J. Kang, D. Cai, D.L. Peng, Copper nanowires as fully transparent conductive electrodes. Sci. Rep. 3, 2323 (2013)

H.H. Huang, F.Q. Yan, Y.M. Kek, C.H. Chew, G.Q. Xu, W. Ji, P.S. Oh, S.H. Tang, Synthesis, characterization, and nonlinear optical properties of copper nanoparticles. Langmuir 13(2), 172–175 (1997)

R.V. Kumar, Y. Mastai, Y. Diamant, A. Gedanken, Sonochemical synthesis of amorphous Cu and nanocrystalline Cu2O embedded in a polyaniline matrix. J. Mater. Chem. 11(4), 1209–1213 (2001)

G. Vitulli, M. Bermini, S. Bertozzi, E. Pitzalis, P. Salvadori, S. Coluccia, G. Martra, Nanoscale copper particles derived from solvated Cu atoms in the activation of molecular oxygen. Chem. Mater. 14(3), 1183–1186 (2002)

C.L. Kitchens, C.B. Roberts, Copper nanoparticle synthesis in compressed liquid and supercritical fluid reverse micelle systems. Ind. Eng. Chem. Res. 43(19), 6070–6081 (2004)

Y. Chang, M.L. Lye, H.C. Zeng, Large-scale synthesis of high-quality ultralong copper nanowires. Langmuir 21(9), 3746–3748 (2005)

Y.Q. Liu, M. Zhang, F.X. Wang, G.B. Pan, Facile microwave-assisted synthesis of uniform single-crystal copper nanowires with excellent electrical conductivity. RSC Adv. 2, 11235–11237 (2012)

S. Xu, X. Sun, H. Ye, T. You, X. Song, S. Sun, Selective synthesis of copper nanoplates and nanowires via a surfactant-assisted hydrothermal process. Mater. Chem. Phys. 120(1), 1–5 (2010)

Zh Yuxin, Y. Zhang, Y. Li, Z. Yan, Soft synthesis of single-crystal copper nanowires of various scales. New J. Chem. 36, 130–138 (2012)

Y. Zhao, Y. Zhang, Y. Li, Zh He, Z. Yan, Rapid and large-scale synthesis of Cu nanowires via a continuous flow solvothermal process and its application in dye-sensitized solar cells (DSSCs). RSC Advances 2(11), 1544–11551 (2012)

F. Fievet, J.P. Lagier, B. Beaudoin, M. Filgarz, B. Blin, Homogeneous and heterogeneous nucleations in the polyol process for the preparation of micron and submicron size metal particles. Solid State Ionics 32(33), 198–205 (1989)

Y. Sun, Y. Xia, Large-scale synthesis of uniform silver nanowires through a soft, self-seeding, polyol process. Adv. Mater. 14(11), 833–837 (2002)

B. Wiley, Y. Sun, B. Mayers, Y. Xia, Shape-controlled synthesis of metal nanostructures: the case of silver. Chem. Eur. J. 11(2), 454–463 (2005)

B.K. Park, S. Jeong, D. Kim, J. Moon, S. Lim, J.S. Kim, Synthesis and size control of monodisperse copper nanoparticles by polyol method. J. Colloid. Interf. Sci. 311(2), 417–424 (2007)

W.J. Zhang, P. Chen, Q.S. Gao, Y.H. Zhang, Y. Tang, High-concentration preparation of silver nanowires: restraining in situ nitric acidic etching by steel-assisted polyol method. Chem. Mater. 20(5), 1699–1704 (2008)

P.Y. Silvert, K. Tekaia-Elhissen, Synthesis of monodisperse submicronic gold particles by the polyol process. Solid State Ionics 82(1–2), 53–60 (1995)

J. Xiong, Y.W.Q. Xue, X. Wu, Synthesis of highly stable dispersions of nanosized copper particles using l-ascorbic acid. Green Chem. 13(4), 900–904 (2011)

Q.L. Zhang, Z.M. Yang, B.J. Ding, X.Z. Lan, Y.J. Guo, Preparation of copper nanoparticles by chemical reduction method using potassium borohydride. Trans. Nanferrous Met. Soc. China 20, 240–244 (2010)

H.X. Zhang, U. Siegert, R. Liu, W.B. Cai, Facile fabrication of ultrafine copper nanoparticles in organic solvent. Nanoscale Res. Lett. 4(7), 705–708 (2009)

M. Blosi, S. Albonetti, M. Dondi, C. Maretelli, G. Baldi, Microwave-assisted polyol synthesis of Cu nanoparticles. J. Nanopart. Res. 13(1), 127–138 (2011)

Y. Wang, P. Chen, M. Liu, Synthesis of well-defined copper nanocubes by a one-pot solution process. Nanotechnology 17(24), 6000–6006 (2006)

S. Chang, K. Chen, Q. Hua, Y. Ma, W. Huang, Evidence for the growth mechanisms of silver nanocubes and nanowires. J. Phys. Chem. C 115(16), 7979–7986 (2011)

Y.G. Sun, B. Mayers, T. Herricks, Y.N. Xia, Polyol synthesis of uniform silver nanowires: a plausible growth mechanism and the supporting evidence. Nano Lett. 3(7), 955–960 (2003)

L. Samiee, M. Dehghani Mobarake, R. Karami, M. Ayazi, Developing of ethylene glycol as a new reducing agent for preparation of Pd-Ag/PSS composite membrane for hydrogen separation. J. Petrol Sci. Technol. 2(2), 25–32 (2012)

C.C. Luo, Y.H. Zhang, X.W. Zeng, Y.W. Zeng, Y.G. Wang, The role of poly(ethylene glycol) in the formation of silver nanoparticles. J. Colloid. Interf. Sci. 288(2), 444–448 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseini, M., Fatmehsari, D.H. & Marashi, S.P.H. Synthesis of different copper nanostructures by the use of polyol technique. Appl. Phys. A 120, 1579–1586 (2015). https://doi.org/10.1007/s00339-015-9358-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9358-y