Abstract

The effect of plasma treatment on the stabilization of copolymer P(AN-MA) containing 6.1 mol% methyl acrylate (MA) prepared by an electrospinning technique has been investigated at various oxygen contents (10 %, 20 % and 30 %) and different exposure times. The morphology and chemical structural evolution of electrospun and oxidized nanofibers were studied using field–emission scanning electron microscopy (FE-SEM), Fourier transform infrared (FT-IR) spectroscopy and differential scanning calorimetry (DSC). FT-IR analysis indicated that the treated nanofibers were effectively oxidized under different contents of oxygen and prolonged plasma exposure times by increasing the peak intensities of polar groups at 1730 and 3400 cm−1 corresponding to C=O stretching band and OH stretching vibration mode, respectively. Additionally, a reduction in the extent of the cyclization reaction is observed with further increase in exposure times and contents of oxygen, which implies lower conversion of C≡N bands into C=N ones in the copolymer chain. According to the FE-SEM studies, the surfaces of the treated nanofibers were completely etched after 15 min of treatment due to the existence of strong ion bombardment and a reduction in the average fiber diameters was observed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Polyacrylonitrile (PAN) and its copolymers are used as precursors for the production of high strength and modulus carbon fibers. This can make PAN and its copolymers ideal strengthening agents in the production of lightweight composites for automotive applications, aerospace technologies and many other utilities. PAN is considered as the best candidate for the production of high performance carbon fibers comparable to the other applicable precursors including rayon or pitch [1–5].

Developing carbon fiber from PAN-based fiber is generally subjected to three processes; stabilization, carbonization and graphitization [6]. Stabilization is an important step and key to the carbon fiber production compared to other essential stages which can be performed under heat treatment in air or oxygen-containing atmosphere. Cyclization, dehydrogenation and oxidation are three major chemical reactions that occur in the production of carbon fibers. Cyclization can play the key factor in controlling the quality of the produced carbon fiber. Cyclization reaction leads to the development of ladder structures by oligomerization of nitrile (C≡N) groups through a free radical or ionic mechanic pathway [5–10]. The mechanic pathway of cyclization depends on numerous factors including the polymer structure and stabilization environment [10]. The oligomerizations of nitrile groups are affected by different parameters including the method of polymerization, nature of comonomers, additives and preheat treatment [11].

PAN homopolymer demonstrates a sharp exothermic behavior as well as poor properties and processability, making it a non-ideal candidate for the preparation of carbon fibers [7, 10]. As a result, various acidic, neutral or alkaline comonomers are incorporated into PAN polymer chains to relax the exothermic reaction, lower the stabilization temperature and exothermic peak temperature, decrease the peak height as well as improve the stabilization [9, 10]. Acrylate, methacrylate and methylacrylate are among other comonomers that exhibit a diluent effect on the exothermic reactions without inhibiting the reaction during heat treatment of PAN. However, acidic comonomers behave differently and show a marked inhibiting effect on the nitrile oligomerization [9–13].

There are different techniques in the literature for production of PAN-based carbon nanofibers including the traditional vapor growth method or the plasma enhanced chemical vapor deposition method, which is often expensive and complex [2, 14–16]. However, the production of PAN-based carbon nanofiber through a versatile and cost-effective technique well known as the electrospinning process is possible. This process utilizes further thermal reactions including stabilizing, carbonizing and activating electrospun precursors. Electrospinning is a simple and efficient technique for production of nanoscale fibers. It is done by applying an electric field between a droplet of polymer solution or melt held at the end of a capillary and a grounded collector. The nanometer’s diameter dimension allows for a high specific surface area and durable physical properties in the compression process [17–21].

Advanced oxidation and stabilization of the electrospun PAN-based carbon nanofibers can be achieved under heat treatment in the presence of oxygen and a specific temperature zone or under plasma treatment at different exposure times and various contents of oxygen. PAN-based carbon nanofibers have a low cost, good environmental sustainability, high efficiency and low energy consumption. The surface of polymer materials is chemically modified under plasma physical etching or strong ion bombardment with increasing exposure time and oxygen content without affecting its bulk properties [22–27].

To the best of our knowledge and our literature review, there is no prior focused research aimed at studying the effect of plasma conditions, namely oxygen contents and varying exposure times. This research was conducted to examine these important aspects of the oxidized and stabilized P(AN/MA) electrospun nanofibers. In this work, the electrospun P(AN/MA) nanofibers were oxidized and stabilized at various contents of Ar/O2 mixed gas at different exposure times (5, 10 and 15 min). Plasma oxidation and stabilization of electrospun P(AN/MA) nanofibers took place at room temperature. Using a low-pressure plasma process for producing stabilized nanofiber can assure satisfactory performance of carbon nanofibers. The results of studies of the morphological and structural transformations of the electrospun and stabilized nanofibers during plasma treatment are presented.

2 Experimental

2.1 Materials and solution preparation

A commercial acrylic fiber containing 6.1 % methyl acrylate (MA) and 0.9 % methyl allylsulfonate as comonomers with 300,000–500,000 M w was purchased from Isfahan Polyacryl Inc. (Iran). This material was dissolved in N, N dimethyl formamide (DMF) to yield 15 % solution by weight. The applied polymer contained a small amount of methyl allylsulfonate; the effect of this comonomer was ignored during the whole process. The produced P(AN/MA)/DMF solution was stirred with an electromagnetically driven magnet at room temperature for 6 h in order to obtain a homogeneous solution.

2.2 Electrospinning process

As described above, P(AN/MA) nanofiber with an average fiber diameter of 377 nm was prepared from 15 wt% P(AN/MA)/DMF solution during an electrospinning process. The prepared solution was first placed into a 15 ml plastic syringe equipped with an 18-gauge stainless steel needle. The syringe was fixed on an electric syringe pump (Top5300, Tokyo, Japan) set to maintain a constant feed rate of 0.5 ml/h. A high-voltage power supply (GammaES40P-20 W/DAM) was employed to apply positive charge to the needle tip, and a grounded metal plate covered with an aluminum foil served as the collector. The applied voltage and the distance between the needle tip and the collector were 18 kV and 19 cm, respectively, during the process. The produced P(AN/MA) nanofiber was electrospun for 240 min.

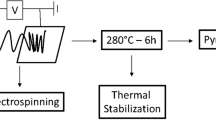

2.3 Atmospheric plasma treatment

The produced electrospun P(AN/MA) nanofibers were stabilized in the presence of various contents of Ar/O2 mixed gas at different plasma exposure times. A schematic of the plasma treatment configuration is shown in Fig. 1; the reactor is a Pyrex cylinder 12 cm long and 16 cm in diameter with two internal Al electrodes separated by a distance of 8 cm. The prepared samples were placed in the middle of the chamber using a glass support. Samples were treated by (Ar/O2) mixed gas in different contents of oxygen (10 %, 20 % and 30 %) and exposed to plasma for three different durations of time (5, 10 and 15 min).

The chamber was evacuated up to 5×10−5 mbar via rotary and turbo pumps prior to the beginning of each experiment. The mixed gas was fed into the chamber via a needle-valve controller at a low pressure. The chamber kept the vacuum at 6×10−2 mbar during the process.

Plasma consists of numerous gas ions which can directly treat the samples located in the chamber. The mixed gas was ionized and converted into the plasma by means of a DC high-voltage power supply.

2.4 Characterization

The diameters and surface morphologies of the electrospun and stabilized P(AN/MA) nanofibers at various contents of Ar/O2 mixed gas and different plasma exposure times were observed using the SU8000 family of ultra-high-resolution field-emission scanning electron microscopy (FE-SEM). The surface chemical functional groups and structural changes in the electrospun and stabilized samples were characterized by Fourier transform infrared (FT-IR) spectroscopy (FTIR-IFSS88 infrared instrument) in the range 4000–500 cm−1. The differential scanning calorimetry (DSC) measurements were carried out to investigate the structural changes occurring during plasma treatment using a 2010 DSCV44E (Universal V3 8 B TA Instruments). The samples were analyzed at 10 °C/min and subjected to heat treatment at a constant temperature, 400 °C, in air atmosphere in a DSC cell.

3 Results and discussion

3.1 Effect of plasma treatment on the stabilization of electrospun nanofiber

Stabilization is the integral part and can be regarded as the key step of the carbon fiber production amongst the other essential stages. High-performance carbon nanofiber can be obtained from PAN precursor oxidized in an oxygen-containing atmosphere during the stabilization process. In fact, PAN precursor acquires stability by an oxidative cross-linking reaction of adjoining molecules in the stabilization along with a cyclization reaction of nitrile groups under an oxidizing atmosphere with plasma [5, 28]. Oxygen is considered to affect stabilization of polymers based on PAN precursor. Oxygen can act as a dehydrogenation agent in the conversion of C–C to C=C bands which combines it with the cyclization reaction resulting in the formation of a conjugated naphthyridine ring structure. It can also generate oxygen groups in the polymer backbone including –OH and C=O etc. These groups promote intermolecular cross linking of the polymer chains and provide greater stability to sustain high-temperature carbonization treatment [12]. The types of applied gas as well as its oxygen content, exposure times and the stabilization temperatures were observed to increase the rate at which the stabilization reactions take place [28].

The chemical reactions taking place in PAN fibers or nanofibers due to any modification techniques were most commonly characterized by FT-IR measurement [3, 5, 7, 8, 10, 11, 13, 29]. So, the chemical reactions forming in the oxidized samples at different exposure times (5, 10 and 15 min) and in the various oxygen contents (10 %, 20 % and 30 %) were investigated via FT-IR measurements as shown in Fig. 4.

It is generally accepted that the chemical functional species in P(AN/MA) nanofibers include [3, 13] carbon chains, the nitrile group (C≡N), methylene groups (CH– and CH2–) and oxygen-containing groups such as –C–OCH3 and C=O due to the existence of MA comonomer in the structure as shown in Fig. 2.

Chemical structure of P(AN/MA) copolymer [13]

The linear structure was chemically transformed into a planar structure by ring formation and aromatization through a free-radical mechanism during the stabilization process under plasma oxygen flow (Fig. 3). The proposed structures are based on earlier published work [30]. The possibility of some intermolecular cross-linking structure increases during cyclization reactions due to the existence of oxygen and free radicals leading to the formation of undissolvable structures. One possibility of formation of free radicals is from the intermediate acrylamide, a mechanism proposed by Grassie and McGuchan [9].

The proposed structure of oxygen-stabilized P(AN/MA) copolymer in the plasma process [30]

The cyclization reaction can be initiated at many more sites by the activated pair of unshared electrons in the presence of O2 nucleophile and thus cause the structure to reach the stabilized state much faster. Generally, a gradual decrease in the strong nitrile and the formation of the imine bands in the cyclic structure reveal the extent of cyclization [13].

The FT-IR spectrum of electrospun P(AN/MA) nanofiber before any treatment process is shown in Fig. 4. A characteristic band at 1730 cm−1 appears due to the ester group of C=O stretching in the comonomer MA units. Of particular interest is the band at 2242 cm−1, which is assigned to the C≡N stretching of the acrylonitrile unit in the polymer chain. Other absorption bands correspond to 2930 cm−1 (ν C–H in CH2), 1448 cm−1 (δ C–H in CH2), 1358 cm−1 (δ C–H in CH), 3400 cm−1 (OH and COOH), 1730 cm−1 (C=O) and 1070 cm−1 (C–C) in the FT-IR spectra [7, 31]. Moreover, with an increase in exposure times and oxygen flows, a new band at 1655 cm−1 appears with a gradual increase in the cyclic structure. This is due to the combination of vibrations of C=C and C=N stretching and NH in-plane bending of the ladder-frame structure of the stabilized one related to –C=C–C=N and –C=N–C=N– chemical structures illustrated in Fig. 3. This new band confirms the cyclization reaction through nitrile groups. The formation of the –NH band is mainly due to hydrogen atoms in broken triple bands [7, 11].

It is thought that the hydrophilic functional groups containing the OH group at the surface could be induced by plasma modification, especially by O2 and N2 plasma treatments [24, 32, 33]. As shown in Fig. 4, a sharp increase in peak intensities at 1730 cm−1 (C=O stretching band) due to the oxidation process in the plasma treatment and a gradual increase in peak intensities at 3400 cm−1 (OH stretching vibration mode) and 1655 cm−1 (C=C, C=N and –NH mixed) can be seen with an increase in exposure time at different oxygen flows. This implies the effective conversion of C–C into C=C bands as well as producing more oxygen groups including –OH and C=O under plasma oxidative environment. Furthermore, an increase of –CH groups in the formation of the C–CH=C structure at 1448 cm−1 [7, 31] attributed to δ C–H in CH2 can be observed after the treatment at prolonged exposure times and greater oxygen flows. This is mainly due to the extent of dehydrogenation in conversion of C–C to C=C in combination with cyclization resulting in the formation of a conjugated naphthyridine ring structure, whereas a peak at 1358 cm−1 (δ C–H in CH) is nearly constant even at prolonged exposure times (see Fig. 4).

A gradual decrease in the formation of the C=N bands at 2358 cm−1 is observed at prolonged exposure times and higher oxygen contents, which implies the lower extent of cyclization. The extent of oxidation is more dominant than the extent of cyclization reaction with increase in exposure time and oxygen flow under plasma oxidative environment.

The highest oligomerizations of nitrile groups in the cyclic structures of P(AN/MA) nanofibers are observed when they were treated under 10 %, 20 % and 30 % of oxygen flow after 5, 10 and 15 min of plasma exposure times, respectively (see Fig. 4). This implies the highest conversion of C≡N into C=N bands under the mentioned conditions.

Although the oxidation rate reaches its maximum extent under 30 % oxygen flow and prolonged exposure times as shown by a sharp increase in peak intensities at 1730 cm−1 (C=O) and 1655 cm−1 (C=C, C=N and –NH mixed), it does not seem to be considered as an optimum condition. This is due to higher tendency in the surface of the treated samples to be etched or even decomposed at severe conditions (Fig. 4c). At severe plasma conditions; the occurrence of the etching effect is highly probable due to the increase in the amount of strong ion bombardment throughout the process.

Since both the cyclization rate in the conversion of C≡N bands into C=N ones and the oxidation reaction pertaining to C=O bands are high in the P(AN/MA) nanofibers treated at 20 % of oxygen and 10 min of exposure, it is considered to be an optimum stabilization condition for production of high-performance carbon nanofiber under further processing based on FT-IR results (Fig. 4b).

3.2 Effect of plasma treatment on the average fiber diameters and the morphology of P(AN/MA) nanofiber

Plasma interacts in numerous ways with a polymer surface. In severe conditions, the polymer surface is subject to etching effects, whereby the polymer is continuously degraded. In fact, physical etching occurs under strong ion bombardment. When plasma gas was irradiated on the surface of polymers, C–H and OH bands are broken down and consequently free radicals are produced which then interact with the ambient oxygen. In this way, oxygen-containing groups (carbonyl, carboxyl etc.) are created, which increases the polymer surface polarity. Therefore, plasma can change surface properties using etching and chemical methods [24, 34].

According to the FE-SEM images of Fig. 5, the treated nanofibers have been rougher under plasma physical etching or strong ion bombardment with increasing exposure time and oxygen content. Oxygen plasma shows a greater etching effect on P(AN/MA) surfaces at prolonged exposure time and higher oxygen containing mixed gas. The etching effect is more severe on the surface than in the bulk of the plasma-treated nanofiber after prolonged exposures, as shown in the FE-SEM images of Figs. 5d, 5g and 5j.

FE-SEM images of the electrospun and stabilized nanofibers under different contents of Ar/O2 mixed gases and various exposure times: (a) electrospun nanofiber, (b, c, d) stabilized nanofiber at 90/10 (Ar/O2), (e, f, g) stabilized nanofiber at 80/20 (Ar/O2) and (h, i, j) stabilized nanofiber at 70/30 (Ar/O2) and exposure times of 5, 10 and 15 min, respectively

Additionally, the average fiber diameters of the electrospun and stabilized P(AN/MA) nanofibers under different contents of Ar/O2 mixed gases and various exposure times have been determined from the FE-SEM images. According to Fig. 6, the average fiber diameters were reduced from 377 nm in the electrospun P(AN/MA) nanofiber to 180, 150 and 130 nm in the stabilized ones under 10 %, 20 % and 30 % of oxygen for 15 min of plasma exposure, respectively.

The reduction in the average fiber diameters of the modified P(AN/MA) nanofibers may be due to the oxidation of P(AN/MA) precursor and the escape of oxygen in the form of CO and CO2 gases in the samples subjected to a larger amount of O2 and higher exposure times during the plasma treatments as well as the transformation of the P(AN/MA) linear chain into the ladder form [34]. In fact, with increasing treatment times and oxygen exposure, more oxygen-bearing groups including –OH and C=O etc. are created in the polymer backbone. This can promote intermolecular cross linking of the polymer chains and formation of hydrogen bonding and cause a decrease of the average fiber diameter.

3.3 DSC measurements

The qualitative and quantitative kinetics of stabilization can be investigated either through the isothermal curve versus time or from a non-isothermal curve versus temperature [35]. In this research, differential scanning calorimetry (DSC) was used to study the reaction time, reaction heat (ΔH) and reaction peak temperature (T p) of the electrospun and modified P(AN/MA) nanofibers under plasma exposure. The various parameters obtained from these exotherms—namely, initial induction time (t i), complete reaction time (t f), reaction time (Δt=t f−t i), peak temperature (T p), reaction heat (ΔH) and the heat liberated per unit time (ΔH/Δt)—are listed in Table 1. The initial induction time shows the time needed for the reaction to start under the isotherm conditions and can be found from the starting point of the exothermic curve. The reaction time is shown by the time taken from the start until the end of the curve. The reaction time depends on the isothermal treatment time and oxygen content as shown in Table 1. The initial induction time does not vary much even at prolonged exposure times and higher oxygen contents for any of the oxidized specimens. This indicates that the initiation of the exothermic reaction is not much affected by an increase in the oxygen contents or exposure times (Table 1). However, the reaction times in the electrospun specimen decrease from 14.4 min to lower times in the oxidized ones.

The heat released by the reaction (ΔH) is directly proportional to the amount of nitriles oligomerized, which can be calculated from peak areas (see Table 1). With an increase in exposure times under 10 % and 30 % of oxygen content, the heat released by the reaction is decreased, which results in fewer nitriles being oligomerized. However, in the case of 20 % O2 flow, the heat liberation is first increased from 1868 J g−1 for 20 % PA5 to 2020 J g−1 for 20 % PA10 and then decreased with further exposures. The lowest ΔH values among the treated copolymers under different contents of oxygen belong to 10 % PA15, 20 % PA15 and 30 % PA15 (1850, 1573 and 1479 J g−1, respectively).

From the data, it can be concluded that the rate of cyclization reactions will retard with further increase in exposure times and oxygen contents that results in reducing the amount of nitriles being oligomerized. The reduction in the amount of heat liberation implies that the oxidative reaction tends to be more dominant in the case of highly concentrated produced oxygen-containing groups including –OH and C=O, etching the conversion of C≡N bands into C=N ones in the copolymer chain.

As shown in Table 1, the heat liberated per unit time for P(AN/MA) copolymers treated under 20 % oxygen flow for different exposure times and in the case of 30 % PA10 and 30 % PA15 are much lower than the others. This makes them the best candidates for producing high-performance carbon fibers (20 % PA5; 205.2, 20 % PA10; 226.9, 20 % PA15; 201.6, 30 % PA10; 212.6 and 30 % PA15; 202.6 J g−1 min−1). The higher rate of heat evolution during thermo-oxidative stabilization would lead to burning out of the core, resulting into a poor quality of the carbon fibers [11].

DSC exotherms of P(AN/MA) with heat rate of 10 °C/min are attributable to the variety of reactions occurring under different oxygen-containing gases and various exposure times, as shown in Fig. 7. Broadly, these reactions may be mainly classified as oxidative reactions and cyclization reactions. Oxidative reactions involve a group of reactions (i.e. dehydrogenation and other elimination reactions) that cause the conversion of C–C to C=C structures and generate oxygen-containing groups such as –OH and C=O etc. Cyclization reactions lead to the development of ladder structures by oligomerization of nitrile (C≡N) groups [12]. The combination of chemical reactions taking place during stabilization and their relative importance remain unclear. Depending on the composition of the polymer, the stabilization environment and the temperature profile, different reactions take place, making it difficult to determine the exact reaction paths and the final chemical structures. This case is further complicated because of possible additional reaction mechanisms with different amounts of oxygen and exposure times in the oxidative environment.

The DSC exotherm in the case of PA0 has the appearance of doublets with superposition of two peaks initiated at about 227 and 281 °C (22.7 and 28.1 min) and centered at 231 and 305 °C respectively (Figs. 7a and 7c). However, this doublet characteristic is diminished in the case of the modified P(AN/MA) copolymers at higher oxygen contents and prolonged exposure times. The modified P(AN/MA) nanofibers at different exposure times under 20 % of oxygen content exhibit only one exothermic peak initiated at about 277, 280 and 283 °C (27.7, 28.0 and 28.3 min) and centered at 316, 324 and 323 °C, respectively (Fig. 7b). However, the exothermic peaks in the modified specimen under 30 % of oxygen content were initiated at about 290, 283 and 290 °C (29, 28.3 and 29 min) and centered at 322, 320 and 317 °C, respectively (Fig. 7c).

Theoretically, the appearance of two separated peaks in copolymers implies the occurrence of two distinct reactions under two different pathways [10]. Therefore, the doublet reaction occurring in the electrospun P(AN/MA) nanofiber may be attributed to the PAN and MA as a comonomer that initiates the reactions at a lower temperature (227 °C). Even though MA is considered to be a poor initiator compared to the acidic comonomers, it can still initiate the reaction at lower temperatures, accelerate the cyclization reactions and enhance the stabilization. In the case of fibers containing MA, a nucleophilic attack can also occur at the comonomer sites, generating new functionalities leading to enhanced cyclization and other reactions through a free-radical mechanism that reduces the initial induction time [9–13].

It seems to be logical to make an assumption that the appearance of only one distinct exothermic peak found in the oxidized P(AN-MA) copolymer under different oxygen-containing gases and exposures is probably due to the overlapping of the free-radical cyclization reactions and other exothermic reactions including oxidation and cyclization processes. The oxidative reaction is more dominant than cyclization reactions in the oxygen environment causing the formation of only one distinct exothermic peak under different oxygen contents and exposure times, which is in a complete accordance with the obtained FT-IR results.

According to all the DSC exotherms examined, a peak forms at the initial stage of the reaction and then the curve falls until the reaction ceases. However, the slope depends on the exposure time and oxygen content in the plasma treatment. At prolonged exposure times, the exothermic peaks nearly shift to a lower heat flow, as shown in Fig. 7. The broadening of the exothermic peak can be probably contributed to the oxidation process and the contribution of comonomer MA, which initiates cyclization at a lower temperature through a free-radical mechanism. The broader exotherms (higher reaction times) are observed in the modified specimens in the case of 10 % PA5, 20 % PA5 and 30 % PA10. Additionally, the exothermic peaks for 10 % PA5, 20 % PA5 and 30 % PA10 shift to lower initial temperatures (274, 277 and 283 °C, respectively) that cause the exothermic reaction to become relaxed (Table 1). The broad exotherms and lower t i values in P(AN/MA) copolymer suggest a different reaction mechanism and relatively much slower propagation for producing ladder polymers.

4 Conclusion

The electrospun P(AN/MA) nanofibers were stabilized and oxidized under plasma environments at different contents of oxygen (10 %, 20 % and 30 %) and various times of exposure (5, 10 and 15 min). These nanofibers can be used in the production of carbon nanofibers under further heat treatment. Different techniques including FT-IR, DSC and FE-SEM were applied to investigate chemical reaction, kinetics of the stabilization and the morphology of the electrospun and oxidized PAN nanofibers.

Based on the FT-IR analysis, the intensities of oxygen-containing groups, namely C=O and –OH groups, were increased with plasma exposure time and oxygen content in the oxidation and stabilization under plasma environment due to effective conversion of C–C into C=C bands. However, the extent of cyclization reaction in the conversion of C≡N bands into C=N ones was decreased at higher contents of oxygen and plasma exposure times. According to the FE-SEM observations, some clues were formed on the surface of the treated nanofibers under plasma physical etching or strong ion bombardment with increasing exposure time and oxygen content. The average fiber diameters were reduced from 377 nm in the electrospun P(AN/MA) nanofiber to 180, 150 and 130 nm in the stabilized ones under 10 %, 20 % and 30 % of oxygen for 15 min of plasma exposure, respectively.

The DSC thermograms exhibited two exothermic peaks initiated at about 227 and 281 °C (22.7 and 28.1 min, respectively) in the case of electrospun P(AN/MA) nanofiber, while only one exothermic peak appeared in the case of the oxidized samples, which is initiated at higher temperatures. The occurrence of two peaks in the electrospun samples is believed to be attributed to the PAN and MA as a comonomer which causes the reactions to initiate at a lower temperature due to the initiating effect of MA. On the other hand, the presence of only one exothermic peak may be related to the strong oxidative reaction under plasma oxygen environment. The heat released by the reaction (ΔH) is diminished with increasing exposure time under 10 % and 30 % of oxygen contents, while, in the case of 20 % O2 flow, it is first increased from 1868 J/g−1 to 2020 J/g−1 and then decreased under further exposures. Among the treated copolymers, on the basis of t i values, it seems that the 10 % PA5, 20 % PA5 and 30 % PA10 initiate the reaction at lower temperatures. However, the lowest ΔH values among the treated copolymers under different contents of oxygen belong to 10 % PA15, 20 % PA15 and 30 % PA15, resulting in fewer nitriles being oligomerized and indicates the degree of cyclization. Based on FT-IR, FE-SEM and DSC data, 20 % PA10 is considered as an optimum stabilization condition for producing high-performance carbon nanofiber.

Although in the present work we have investigated the effect of plasma treatment on the stabilization of PAN at various oxygen contents and different exposure times, carbon nanofibers have not been produced. Hence, a comparison between the carbon nanofibers produced on the plasma- and heat-treated samples can be a possible extension to this work.

References

K.J. Lee, N. Shiratori, G.H. Lee, J. Miyawaki, I. Mochida, S. Yoon, J. Jang, Activated carbon nanofiber produced from electrospun polyacrylonitrile nanofiber as a highly efficient formaldehyde adsorbent. Carbon 48, 4248–4255 (2010)

S.K. Nataraj, K.S. Yang, T.M. Aminabhavi, Polyacrylonitrile-based nanofibers—a state-of-the-art review. Prog. Polym. Sci. 37, 487–513 (2012)

Z. Wangxi, L. Jie, Effect of post-spinning modification on the PAN precursors and resulting carbon fibers. J. Wuhan Univ. Technol. 21, 44–48 (2006)

L. Jie, Z. Wangxi, Structural changes during the thermal stabilization of modified and original polyacrylonitrile precursors. J. Appl. Polym. Sci. 97, 2047–2053 (2005)

D. Esrafilzadeh, M. Morshed, H. Tavanai, An investigation on the stabilization of special polyacrylonitrile nanofibers as carbon or activated carbon nanofiber precursor. Synth. Met. 159, 267–272 (2009)

M.S.A. Rahaman, A.F. Ismail, A. Mustafa, A. Mustafa, A review of heat treatment on polyacrylonitrile fiber. Polym. Degrad. Stab. 92, 1421–1432 (2007)

Q. Ouyang, L. Cheng, H. Wang, K. Li, Mechanism and kinetics of the stabilization reactions of itaconic acid-modified polyacrylonitrile. Polym. Degrad. Stab. 93, 1415–1421 (2008)

H. Kakida, K. Tashiro, Mechanism and kinetics of stabilization reactions of polyacrylonitrile and related copolymers. III. Comparison among the various types of copolymers as viewed from isothermal DSC thermograms and FT-IR spectral changes. Polym. J. 29, 557–562 (1997)

N. Grassie, R. McGuchan, Pyrolysis of polyacrylonitrile and related polymers. VI. Acrylonitrile copolymers containing carboxylic acid and amide structures. Eur. Polym. J. 8, 257–269 (1972)

X. Wu, X. Zhang, C. Lu, L. Ling, Termo-chemical reactions and structural evolution of acrylamide-modified polyacrylonitrile. Chin. J. Polym. Sci. 28, 367–376 (2010)

S. Hajir Bahrami, P. Bajaj, K. Sen, Thermal behavior of acrylonitrile carboxylic acid copolymers. J. Appl. Polym. Sci. 88, 685–698 (2003)

A.K. Gupta, D.K. Paliwal, P. Bajaj, Effect of the nature and mole fraction of acidic comonomer on the stabilization of polyacrylonitrile. J. Appl. Polym. Sci. 59, 1819–1826 (1996)

C.S. Bhat, H. Peebles, A.S. Abhiraman, F. Cook, Rapid stabilization of acrylic fibers using ammonia: effect on structure and morphology. J. Appl. Polym. Sci. 49, 2207–2219 (1993)

F. Pashaloo, S. Bazgir, M. Tamizifar, M. Faghihisani, S. Zakerifar, Preparation and characterization of carbon nanofibers via electrospun PAN nanofibers. Text. Sci. Technol. J. 13, 1–10 (2009)

A. Nadarajah, J. Lawrence, Development and commercialization of vapor grown carbon nanofibers: a review. Key Eng. Mater. 380, 193–206 (2008)

Z.F. Ren, Z.P. Huang, J.W. Xu, J.H. Wang, P. Bush, M. Siegal, P.N. Provencio, Synthesis of large arrays of well-aligned carbon nanotubes on glass. Science 282, 1105–1107 (1998)

V. Merkulov, A. Melechko, M.A. Guillorn, Controlled alignment of carbon nanofibers in a large-scale synthesis process. Appl. Phys. Lett. 80, 4816–4818 (2002)

D.H. Reneker, I. Chun, Nanometer diameter fibers of polymer, produced by electrospinning. Nanotechnology 7, 216–223 (1996)

S. Arumuganathar, S.N. Jayasinghe, A novel direct fibregeneration technique for fabricating membranes with micro- and nanofibers. Nano Commun. Netw. 2, 213–219 (2007)

D. Yang, B. Lu, Y. Zhao, X. Jiang, Fabrication of aligned fibrous arrays by magnetic electrospinning. Adv. Mater. 19, 3702–3706 (2007)

E. Smit, U. Buttner, R.D. Sanderson, Continuous yarns from electrospun fibers. Polymer 46, 2419–2423 (2005)

K. Lafdi, W. Fox, M. Matzek, E. Yildiz, Effect of carbon nanofiber heat treatment on physical properties of polymeric nanocomposites, Part I. Nanomaterials 2007, 1–6 (2007)

Z. Zhao, J. Li, D. Zhang, C. Chen, Nanofiltration membrane prepared from polyacrylonitrile ultrafiltration membrane by low-temperature plasma Graft of acrylic acid in gas. J. Mater. Sci. 232, 1–8 (2004)

K.S. Kim, K.H. Lee, K. Cho, C.E. Park, Surface modification of polysulfone ultrafiltration membrane by oxygen plasma treatment. J. Mater. Sci. 199, 135–145 (2002)

C. Tendero, C. Tixier, P. Tristant, J. Desmaison, P. Leprince, Atmospheric pressure plasmas: a review. Spectrochim. Acta, Part B, At. Spectrosc. 61, 2–30 (2006)

M. Laroussi, T. Akan, Arc-free atmospheric pressure cold plasma jets: a review. Plasma Process. Polym. 4, 777–788 (2007)

J. Van Durme, J. Dewulf, C. Leys, H. Van, Combining non-thermal plasma with heterogeneous catalysis in waste gas treatment: a review. Appl. Catal. B 78, 324–333 (2008)

T.H. Ko, H. Ting, C. Lin, J. Chen, The microstructure of stabilized fibers. J. Appl. Polym. Sci. 35, 863–874 (1988)

G. Yong, H. Peng, L. Jie, S. Mark, Z. Jiang, W. Wei, Z. Jing, Z. Xingping, S. Donglu, Effects of surface modification, carbon nanofiber concentration, and dispersion time on the mechanical properties of carbon nanofiber polycarbonate composites. J. Appl. Polym. Sci. 103, 3792–3797 (2007)

A.J. Clarke, J.E. Bailey, Oxidation of acrylic fibers for carbon fiber formation. Nature 243, 146–150 (1973)

D.L. Pavia, G.M. Lampman, G.S. Kriz, J.R. Vyvyan, Introduction to Spectroscopy, 4th edn. (Thompson Learning, Washington, 2009)

H. Lee, Y.S. Jeong, S. Jeong, S. Park, J.S. Bae, H. Kim, C. Cho, Role of reactive gas in atmospheric plasma for cell attachment and proliferation on biocompatible poly-ϵ-caprolactone film. Appl. Surf. Sci. 254, 5700–5705 (2008)

L. Wan, Z. Xu, X. Huang, A. Che, Z. Wang, A novel process for the post-treatment of polyacrylonitrile-based membranes: performance improvement and possible mechanism. J. Membr. Sci. 277, 157–164 (2006)

Y.H. Kang, K. Ahn, S.Y. Jeong, J.S. Bae, J.S. Jin, H.G. Kim, S.W. Hong, C.R. Cho, Effect of plasma treatment on surface chemical-bonding states and electrical properties of polyacrylonitrile nanofibers. Thin Solid Films 519, 7090–7094 (2011)

S. Juthawan, J. Sujinda, N. Manit, M. Chidchanok, S. Pitt, Preparation and characterization of ultrafine electrospun polyacrylonitrile fibers and their subsequent pyrolysis to carbon fibers. Polym. Int. 55, 825–833 (2006)

Acknowledgements

The authors gratefully acknowledge Dr. Reza Hoseinnezhad at RMIT University, Australia, for his comments and discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamideh Mortazavi, S., Pilehvar, S., Ghoranneviss, M. et al. Plasma oxidation and stabilization of electrospun polyacrylonitrile nanofiber for carbon nanofiber formation. Appl. Phys. A 113, 703–712 (2013). https://doi.org/10.1007/s00339-013-7707-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-7707-2