Abstract

This study intends to investigate the potentials of chitosan-g-PMMA [poly(methyl methacrylate)] graft copolymers in corneal tissue engineering. The polymerization reaction between chitosan and methyl methacrylate (MMA) was standardized by varying temperature, pH, initiator and monomer concentrations. 113 % grafting yield was obtained at 60 °C, pH 6, 2.1 × 10−3 mol/L of sodium metabisulfite and 1.48 × 10−3 mol/L of potassium persulphate and 1.99 × 10−4 mol/L of monomer concentration. Fourier transform infrared spectroscopy confirmed the grafting of PMMA onto chitosan. The grafts possessed better thermal stability compared to chitosan films. The rough-surfaced (as evidenced by scanning electron microscopy) grafts were able to degrade under in vitro conditions in presence of lysozyme. The grafts exhibited 88 % optical clarity and also supported the proliferation of human corneal epithelial cell line. The above results indicate the potentials of chitosan-g-PMMA and its possible use in corneal tissue engineering applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Research on use of polymeric materials for biomedical applications has been gaining momentum in the recent past owing to their potential properties. They display vibrant characteristics which makes them promising candidates for use in controlled drug delivery system, implants, wound dressings, biosensors, components of inhalers, catheters, etc. Polymer modifications has now received greater attention in light of the need for better starting materials. Alterations in thermal stability, compatibility, flexibility, rigidity, etc., are brought about by polymer modifications [1].

Corneal transplantation is the main mode of treatment to restore corneal blindness. The lack of donor human corneas and increasing demand for it has necessitated the need to develop viable alternatives to human corneas. Though the unique features of cornea viz., strength and transparency are difficult to replicate, efforts are made in the field of corneal tissue engineering to develop biomaterials which are optically transparent, biocompatible, mechanically stable, non-immunogenic and allow cells to adhere, proliferate, migrate, etc., [2, 3].

Chitosan, is a linear nitrogenous biopolymer obtained from the alkaline deacetylation of chitin, which is widely distributed in nature and is the second most abundant polysaccharide after cellulose. The versatile properties viz., biocompatibility, biodegradability, non-toxic nature, etc., make chitosan an ideal biomaterial to be used for biomedical applications such as wound healing, tissue engineering, drug and gene delivery, etc., [4, 5]. Since chitosan is soluble in only few dilute acids, its wide applications have been limited, hence, it triggers a need for chemical modification of chitosan.

Among the different methods, graft copolymerization is most attractive, because it modifies both the physical and chemical properties of natural polymers [6]. Graft copolymer is a macromolecular chain with one or more species of block connected to the main chain as side chain(s) [7]. Grafting results from generation of free radicals on the biopolymer backbone and then allowing these radicals to serve as macroinitiators for the vinyl (or acrylic) monomer [8]. Most of the copolymers are prepared through graft polymerization of vinyl monomers (methyl methacrylate—MMA) onto the biopolymer backbone [9]. A vast repertoire of literature on biomedical materials shows an increasing interest in poly(methyl methacrylate) (PMMA), because of its biocompatible nature [10–13]. PMMA finds potential applications in orthopedics, as adjuvant for vaccines and carrier of many drugs as antibiotics and antioxidants via different routes of administration [14]. Grafting of PMMA onto chitosan is an efficient method to incorporate desirable functions in the resulting graft copolymers, which find potential application in many fields including pharmaceuticals, biomaterials, agriculture, etc., [15].

Free amino groups on deacetylated units and the hydroxyl groups on the C3 and C6 carbons on acetylated or deacetylated units are the two types of reactive groups on chitosan which can be grafted. Grafting of chitosan allows the formation of functional derivatives by covalent binding of a molecule, the graft, onto the chitosan backbone [6]. Though graft modification inculcates improved water solubility and bioactive properties in chitosan, it still retains its biocompatible and biodegradable properties [16, 17].

Grafting of PMMA onto chitosan has been explored using various initiator systems such as potassium persulfate [18], potassium ditelluratocuprate (III) [15], ceric ammonium nitrate [19], etc. The objective of this study was to graft copolymerize MMA onto chitosan and to assess the suitability of the graft for corneal tissue engineering. The optimal conditions for graft copolymerization were standardized and the chemical modifications were confirmed using FTIR, TGA and SEM. The biocompatibility of the graft copolymer was also assessed using human corneal epithelial cell line.

Materials and methods

Materials

Squid pens were purchased from local fish market, Chennai. All other chemicals used were of analytical grade.

Chitosan preparation

Chitosan was isolated from squid pens of Loligo duvauceli according to Hemalatha et al. [20]. Briefly, the squid pens were washed thoroughly and treated with 40 % NaOH for 3 h at 200 °C and the resultant product was washed with distilled water and the pH was brought to 7. The chitosan obtained was dried at 60–70 °C and stored until further use.

Grafting of chitosan and MMA

1.5 % (w/v) of chitosan solution was prepared in 500-mL three-necked round-bottom flask with a reflux condenser and a gas inlet system under nitrogen atmosphere. After complete dissolution, two redox initiators viz., potassium persulfate and sodium metabisulfite (equal concentration) were added followed by addition of monomer MMA and the contents were left for continuous stirring. After 1–1.5 h, the reaction was stopped and the content was filtered, poured and dried on a Teflon tray and weighed. This crude graft copolymer was extracted with acetone using Soxhlet apparatus for 48 h to remove unbound PMMA homopolymer.

Optimization of polymerization

The polymerization reaction was optimized by changing temperature, initiator concentration, monomer concentration and pH. For all the reactions, weight of chitosan was kept constant. When the initiator concentration was varied from 25 to 60 mg, the other parameters were kept constant. Similarly, monomer concentration was varied from 1.5 to 3.0 mL, temperature was varied from 40 to 70 °C and the pH was varied between 3 and 6. After the specified period of time, the reaction mixture was poured into the Teflon tray for drying. The dried product was extracted by washing with acetone for 48 h to remove the homopolymer. The graft copolymer (chitosan-g-PMMA) was dried to a constant weight. The percentage of grafting was determined by the following equation [21]:

Film preparation

1.5 % [w/v] chitosan (control) or graft copolymer was poured into a Teflon tray (9 × 12 cm) and air dried for 48 h. The films were neutralized with 2 % sodium hydroxide solution and extensively washed with distilled water and stored in a dessicator until further use.

Characterisation

Fourier transform infrared spectroscopy (FTIR)

Infrared spectra of films prepared were measured at a resolution of 4 cm−1 in the frequency range of 4000–500 cm−1 using Nicolet 360 FTIR spectrometer.

Thermogravimetric analysis (TGA)

The TGA was carried out using a Seiko SSC 5200 H in nitrogen atmosphere (80 mL/min) at a heating rate of 10 °C/min. Primary weight loss of these materials as function of temperature was recorded using this study.

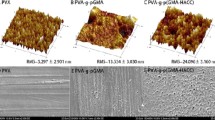

Scanning electron microscopy (SEM)

Films were coated with ultrathin layer of gold using an ion coater (Fisons sputter coater) under the following conditions viz., 0.1 Torr pressure, 200 Ma current and 70 s coating time. Surface structure was visualized by scanning electron microscope (SEM model-LEICA stereoscan 440) using 15 kV accelerating voltage.

Swelling studies

The swelling studies of the films were carried out according to Nagahama et al. [22]. The films were cut into pieces (2 × 2 cm length) and the initial weight was measured (W 0). Then, they were immersed in phosphate-buffered saline (PBS, pH 7.4) at 37 °C. After 24 h, the samples were removed and the weight (W 1) was measured. The swelling rate was calculated using the following equation:

In vitro degradation

In vitro degradation studies were carried out using phosphate-buffered solution (PBS, pH 7.4) at 37 °C containing 1.5 µg/mL of lysozyme (hen’s egg white, Sigma-Aldrich). Films of known dry weights (W 0) were incubated in the lysozyme solution with gentle mechanical agitation for the period of study. The lysozyme solution was refreshed daily to ensure continuous enzyme activity. After 7, 14, 21 and 28 days, samples were removed from the medium, rinsed with distilled water, dried and weighed (W t). To separate between enzymatic degradation and dissolution, control samples were stored for 28 days under the same conditions as described above, but without the addition of lysozyme. The extent of in vitro degradation was expressed as percentage of weight loss of the dried films after lysozyme treatment according to the equation [23]

Optical clarity

Films (3 cm × 3 cm) were examined for transparency by placing them in the light path and scanned within the visible range of wavelength (600–800 nm) with a Beckman DU-800 spectrophotometer (Analytical Instruments, LLC, Minneapolis, MN, USA).

Mechanical properties

Mechanical properties of the films viz., tensile strength (TS) and elongation at break (E) were evaluated with Instron Universal Testing Machine (Model 1405, Instron Engineering Corp., Canton, MA, U.S.A.). Initial grip separation was set at 20 mm and crosshead speed was set at 10 mm/min. TS and E measurements were replicated 3 times.

Biocompatibility study

Human corneal epithelial cell line (ATCC CRL-11515™) was cultured on Dulbecco’s modified eagle medium (DMEM, Gibco) with 10 % fetal bovine serum (FBS, GeneX India Bioscience Pvt. Ltd), 1 % antibiotic (Sigma) and 1 % human corneal growth supplement (Invitrogen). The cells were incubated at 37 °C in an atmosphere of 95 % air–5 % CO2. Films sterilized for 4 h with 100 % ethylene oxide at 30 °C were used for the study. MTT [3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide] assay [24] was carried out to determine the biocompatibility nature of the chitosan scaffolds. ATCC CRL-11515™ cells (25 × 103 cells/mL) were seeded on films in a 24-well plate. After 30 min, 10 % medium was added and the cells were incubated for 24 and 48 h. At the end of the incubation period, MTT was added and the plates were incubated for 4 h at 37 °C. Following incubation, media was aspirated completely and MTT formazan crystals formed were dissolved by the addition of dimethylsulfoxide, and the reading was taken at 570 nm using SpectraMax M4. The cell growth on the culture plate without film was taken as control. The percentage of cell viability was calculated compared to the control.

Statistical analysis

Results were expressed as mean ± standard deviation (SD) for 3 individual experiments (n = 3). The comparison between means was done by one-way analysis of variance (p < 0.05) followed by Duncan’s multiple range analysis using statistical software package SPSS, version 13.0.

Results and discussion

In this study, chitosan (degree of deacetylation 80 %) derived from squid pen was used as a substrate to graft methyl methacrylate by free radical polymerization using potassium persulfate and sodium metabisulfine as redox initiators. Fairly high percentage of grafting was observed, probably due to numerous active sites on the backbone [25].

Optimization of polymerisation

When the initiator concentration was varied between 25 and 60 mg, maximum grafting % was exhibited at 40 mg (2.1 × 10−3 and 1.48 × 10−3 mol/L of sodium metabisulfite and potassium persulphate, respectively) concentration (Table 1a). 2 mL (1.99 × 10−4 mol/L) of monomer addition gave the maximum grafting value; however, increase in concentration up to 3.0 mL significantly reduced the grafting efficiency (Table 1b). This decrease could be ascribed to the non-availability of reaction sites on chitosan proportional to monomer [19]. The grafting reactions were carried out at different temperatures between 40 and 70 °C. Grafting (%) increased with increase in temperature from 40 to 60 °C, after which a decrease was observed (Table 1c). This could be attributed to the fact that increasing temperature favored the activation of macroradicals as well as accelerated the diffusion and mobility of the monomers from the aqueous phase to the backbone whereas a further increase led to the acceleration of termination reaction [15]. Optimisation of pH also plays an important role in polymerization reactions, wherein highest grafting % was observed at pH 6 (Table 1d). Qudsieh et al. [26] has reported a maximum of 90 % grafting using MMA on to sago starch under optimized conditions, using potassium persulfate as redox initiator.

Characterisation

1.5 % (w/v) chitosan and chitosan-g-PMMA films prepared using the optimized polymerization condition (viz., chitosan 1.5 g, 40 mg initiator, 2 mL monomer, at pH 6 and temperature 60 °C) were used for further experiments.

FTIR

FTIR spectrum of chitosan (Fig. 1a) revealed the characteristic peaks around 3450 cm−1 which represented the presence of hydrogen bonded –OH group. Amide I and II bands were observed at 1650 and 1590 cm−1, respectively. Peak at 1485–1380 cm−1 represented C–H bending of CH2 group, while peak at 1082 cm−1 corresponded to skeletal vibration involving the C–O stretch of glucosamine residue [27]. In the graft copolymer (Fig. 1b) the presence of the carbonyl absorption peak at 1732 cm−1 confirmed the grafting reaction between chitosan and MMA [19]. Increased intensity of peak at 2966 cm−1 was observed due to the interaction between chitosan and PMMA [28].

TGA

TGA results depicted the thermal stabilities of chitosan and chitosan grafts. Both the films exhibited a two-step weight loss, wherein weight loss around 100–150 °C could be attributed to the evaporation of water molecules in the samples. Weight loss between 200 and 400 °C in chitosan film (Fig. 2a) could be due to the degradation of chitosan main chains. The remaining residue at 800 °C was mostly due to the formation of inorganic complex containing C, N and O [29]. From the TGA curve of chitosan-g-PMMA (Fig. 2b), it is clearly evident that grafting has enhanced the initial decomposition temperature. The higher thermal stability of the chitosan-g-PMMA could be attributed to the higher decomposition temperature of PMMA [30]. Das et al. [31] reported that PMMA envelops the chitosan surface and thus increased the overall thermal stability of the grafted chitosan. Chitosan grafted with 2-hydroxyethylmethacrylate (HEMA) also possessed higher initial decomposition temperature which was attributed to the formation of cyclic structure of modified chitosan as a result of dehydration of poly(HEMA) [16].

SEM

SEM micrographs clearly depicted the homogeneity of the chitosan-g-PMMA blend films. Compared to chitosan films (Fig. 3a), chitosan grafts (Fig. 3b) exhibited rough surface which may be due to PMMA grafting on to the surface of chitosan [30].

Swelling studies

There was a significant increase in swelling (%) in the graft copolymers compared to chitosan films (Table 2). This increase in hydrophilicity could be attributed to the graft polymerization of MMA chains onto chitosan. Due to the presence of strong intermolecular hydrogen bonding among the –NH2 and –OH groups of the adjacent linear chains, chitosan is highly crystalline. Grafting with PMMA could have altered this strong intermolecular hydrogen bonding in chitosan, and thereby it has increased the hydrophilicity of chitosan grafts [19]. Though PMMA is a hydrophobic polymer, the acidic environment may hydrolyse the methacrylate group to some extent conferring hydrophilic nature to the copolymer [32].

In vitro degradation

Biodegradation is an important property for a biomaterial, especially for its use in tissue engineering applications, wherein the biomaterial is expected to disintegrate naturally along with cells growth. The degradation studies were conducted along with lysozyme enzyme because chitosan are mainly depolymerized by lysozyme which is naturally present in human serum and tears. Lysozyme acts primarily on β-(1–4) glycosidic bonds between polysaccharide [33]. Apart from lysozyme, chitosan could also be degraded by non-specific enzymes like collagenase in the human body [34, 35]. Though there was an increase in degradation (%) with increase in time (Fig. 4), it could be observed that there was a significant (p < 0.05) decrease in the degradation properties of chitosan graft copolymers compared with chitosan films from second week [36]. Ozcelik et al. [37] reported ~50 % mass loss in chitosan-poly(ethylene glycol) (PEG) hydrogel films after 55 days, in presence of lysozyme and l-cysteine at concentrations 100 times greater than those in the human aqueous humour. Slower degradation rate of films would be more favorable for tissue engineering applications, as it could allow the cell’s natural migration to maintain a confluent corneal endothelium and migrate to the corneal stromal surface as the film is degraded and cleared from the anterior chamber of the cornea.

Mechanical properties

The results (Table 2) clearly revealed that there was a significant (p < 0.05) reduction in the mechanical properties (tensile strength and elongation at break %) of the chitosan graft copolymer compared to chitosan films. Singh and Ray [16] explain that this reduction was due to grafting which occurs due the compactness of molecular chains in the amorphous region. This increases the brittleness of the polymer backbone and thereby it fails to withstand higher load and breaks easily at lower loads.

Optical clarity

The films exhibited an increase in light transmission measurements in the visible spectrum (400–700 nm) (Fig. 5). Human cornea allows light transmittance in a monotonically increasing manner of approximately 30–75 % at 310–400 nm and 75–95 % at 400–700 nm [38]. Chitosan and chitosan grafts were also >70 % optically transparent at 450 nm with no significant difference between the two groups. Both the films exhibited a maximum of 87–88 % optical clarity which was much nearer to the transparency of human cornea (maximum ~90 %) [37].

Biocompatibility

Biomaterials designed for tissue engineering application should provide support for cell attachment, proliferation and migration. This in turn reflects the ability of the scaffold to make contact with the cells. MTT assay, which reveals the viability of cells at a given time point was used to determine CEC’s viability at 24 and 48 h (Fig. 6). Cells exhibited >80 % viability at 48 h with a significant (p < 0.5) difference between the groups. Non-toxic nature of chitosan grafts have also been demonstrated earlier in fibroblasts [15]. Hence, the results clearly indicate that both chitosan and chitosan-g-PMMA films allowed cell attachment and proliferation and could find potential applications in corneal tissue engineering [39].

Conclusion

Chitosan-g-PMMA, graft copolymers were prepared using redox initiators. The graft copolymers were biodegradable in presence of lysozyme, which is naturally present in the cornea. The films allowed the growth and proliferation of CECs. The properties of chitosan-g-PMMA viz., biocompatibility, optical transparency, mechanical stability and biodegradability indicate its possible use in corneal tissue engineering applications.

References

Bhattacharya A, Ray P (2009) Introduction. In: Bhattacharya A, Rawlins JW, Ray P (eds) Polymer grafting and crosslinking. John Wiley, New Jersey, pp 1–6

Shah A, Brugnano J, Sun S, Vase A, Orwin E (2008) The development of a tissue-engineered cornea: biomaterials and culture methods. Pediatr Res 63:535–544

Liu Y, Gan L, Carlsson DJ, Fahgerholm P, Lagali N, Watsky MA, Munger R, Hodge WG, Priest D, Griffith M (2006) A simple, cross-linked collagen tissue substitute for corneal implantation. Invest Ophthalmol Vis Sci 47:1869–1875

Prabaharan M (2008) Review paper: chitosan derivatives as promising materials for controlled drug delivery. J Biomater Appl 23:5–36

Azuma K, Izumi R, Osaki T, Ifuku S, Morimoto M, Saimoto H, Minami S, Okamoto Y (2015) Chitin, chitosan, and its derivatives for wound healing: old and new materials. J Funct Biomater 6:104–142

Jayakumar R, Prabaharan M, Reis RL, Mano JF (2005) Graft copolymerized chitosan—present status and applications. Carbohydr Polym 62:142–158

Athawale VD, Rathi SC (1999) Graft polymerization: starch as a model substrate. J Macromol Sci Rev Macrocol Chem Phys C39:445–480

Zohuriaan MJ (2005) Advances in chitin and chitosan modification through graft copolymerization: a comprehensive review. Iran Polym J 14:235–265

Mahdavinia GR, Zohuriaan-Mehr MJ, Pourjavadi A (2004) Modified chitosan III super absorbency, salt- and pH sensitivity of smart ampholytic hydrogels from chitosan-g-polyacrylonitrile. Polym Adv Technol 15:173–180

Changerath R, Nair PD, Mathew S, Nair CP (2009) Poly(methyl methacrylate)-grafted chitosan microspheres for controlled release of ampicillin. J Biomed Mater Res B Appl Biomater 89:65–76

Panahi-Bazaz Mahmoud-Reza, Zamani Mitra, Abazar Bijan (2009) Hydrophilic acrylic versus PMMA intraocular lens implantation in pediatric cataract surgery. J Ophthalmic Vis Res. 4:201–207

Jaeblon T (2010) Polymethylmethacrylate: properties and contemporary uses in orthopaedics. J Am Acad Orthop Surg 18:297–305

Abid CK, Jain S, Jackeray R, Chattopadhyay S, Singh H (2015) Formulation and characterization of antimicrobial quaternary ammonium dendrimer in poly(methyl methacrylate) bone cement. J Biomed Mater Res B Appl Biomater. doi:10.1002/jbm.b.33553 [Epub ahead of print]

Bettencourt A, Almeida AJ (2012) Poly(methyl methacrylate) particulate carriers in drug delivery. J Microencapsul 29:353–367

Liu Y, Li Y, Juan LV, Guodong Wu, Li Junbo (2005) Graft copolymerization of methyl methacrylate onto chitosan initiated by potassium ditelluratocuprate (III). J Macromol Sci Pure Appl Chem 42:1169–1180

Singh DK, Ray AR (1998) Characterization of grafted chitosan films. Carbohydr Polym 36:251–255

Xie WM, Xu PX, Wang W, Lu Q (2002) Preparation and antibacterial activity of water-soluble chitosan derivative. Carbohydr Polym 50:35–40

Prashanth H, Tharanathan RN (2003) Studies on graft copolymerization of chitosan with synthetic monomers. Carbohydr Polym 54:343–351

Radhakumary C, Nair PD, Mathew S, Reghunadhan Nair CP (2005) Biopolymer composite of chitosan and methyl methacrylate for medical applications. Trends Biomater Artif Organs 18:117–124

Hemalatha T, Krithiga G, Charanya S, Krishnakumar S, Sastry TP (2014) Characterization and evaluation of squid pen derived chitosan scaffold for corneal tissue engineering. Int J Pharm Ther 5:76–82

Retuert J, Yazdani-Pedram M (1993) Cocatalyst effect in potassium persulfate initiated grafting onto chitosan. Polym Bull 31:559–562

Nagahama H, Maeda H, Kshiki T, Jayakumar R, Furuike T, Tamura H (2009) Preparation and characterization of novel chitosan/gelatin membranes using chitosan hydrogel. Carbohydr Polym 76:255–260

Hsieh WC, Chang CP, Lin SM (2007) Morphology and characterization of 3D micro-porous structured chitosan scaffolds for tissue engineering. Colloids Surf B Biointerfaces 57:250–255

Carmichael J, DeGraff WG, Gazdar AF, Minna JD, Mitchell JB (1987) Evaluation of a tetrazolium based semiautomated colorimetric assay: assessment of radiosensitivity. Cancer Res 47:943–946

Sathian J, Sastry TP, Suguna L, Lakshminarayana Y, Radhakrishnan G (2003) Fibrin as a matrix for grafting 2-hydroxyethyl methacrylate: preparation and characterization of the graft and its in vivo evaluation for wound healing. J Biomed Mater Res A 65:435–440

Qudsieh IYM, Fakhru’l-Razi A, Muyibi SA, Ahmad MB, Ab Rahman MZ, Zin Wan Yunus WM (2004) Preparation and characterization of poly(methyl methacrylate) grafted sago starch using potassium persulfate as redox initiator. J Appl Polym Sci 94:1891–1897

Tripathi S, Mehrotra GK, Dutta PK (2011) Chitosan–silver oxide nanocomposite film: preparation and antimicrobial activity. Bull Mater Sci 34:29–35

Amer ZJA, Ahmed JK, Abbas SF (2014) Chitosan/PMMA bioblend for drug release applications. Int J Eng Technol 4:318–324

Tongnuanchan P, Benjakul S, Prodpran T (2012) Properties and antioxidant activity of fish skin gelatin film incorporated with citrus essential oils. Food Chem 134:1571–1579

An J, Yuan X, Luo Q, Wang D (2010) Preparation of chitosan-graft-(methyl methacrylate)/Ag nanocomposite with antimicrobial activity. Polym Int 59:62–70

Das RK, Basu D, Banerjee A (1999) Study of methyl-methacrylate-viscose fiber graft copolymerization and the effect of grafting on thermal properties. J Appl Polym Sci 72:135–140

Wahlig H, Dingeldom E (1980) Antibiotics and bone cements. Experimental and clinical long-term observations. Acta Orthop Scand 51:49–56

Vårum KM, Myhr MM, Hjerde RJ, Smidsrød O (1997) In vitro degradation rates of partially N-acetylated chitosans in human serum. Carbohydr Res 299:99–101

Kulish EI, Volodina VP, Kolesov SV, Zaikov GE (2006) Enzymatic degradation of chitosan films by collagenase. Polym Sci Ser B 48:244–246

Kulish EI, Volodina VP, Fatkullina RR, Kolesov SV, Zaikov GE (2008) Enzymatic degradation of chitosan films under the action of nonspecific enzymes. Polym Sci Ser B 50:175–176

Zhang Z, Cui H (2012) Biodegradability and biocompatibility study of poly(Chitosan-g-lactic acid) scaffolds. Molecules 17:3243–3258

Ozcelik B, Brown KD, Blencowe A, Daniell M, Stevens GW, Qiao GG (2013) Ultrathin chitosan-poly(ethylene glycol) hydrogel films for corneal tissue engineering. Acta Biomater 9:6594–6605

Beems EM, Best JAV (1990) Light transmission of the cornea in whole human eyes. Exp Eye Res 50:393–395

Krishnan S, Sekar S, Katheem AF, Krishnakumar S, Sastry TP (2012) Fish scale collagen—a novel material for corneal tissue engineering. Artif Organs 36:829–835

Acknowledgments

The author T. Hemalatha gratefully acknowledges Council of Scientific and Industrial Research, India, for the Senior Research Associate fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Hemalatha, T., Yadav, S., Krithiga, G. et al. Chitosan as a matrix for grafting methyl methacrylate: synthesis, characterization and evaluation of grafts for biomedical applications. Polym. Bull. 73, 3105–3117 (2016). https://doi.org/10.1007/s00289-016-1644-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1644-0