Abstract

Enzymes are one of the most significant products produced primarily from microbial sources for human requirements. The purpose of this work was to isolate, screen, and optimize enzyme production under solid-state fermentation. In the present study, amylase-producing bacteria were isolated from the local region of Ambala. A total of six samples were taken, out of which 14 isolates were isolated, among which seven isolates were found to be amylase producing. Highest amylase yield was obtained from isolate A11, further studied for the production of amylase under solid substrate fermentation (SSF), and also optimized the conditions for increased production of amylase. The molecular and biochemical characterization confirmed it as a strain of Alkalihalobacillus clausii. It was observed that growth parameters showed a profound effect on the production. The bacterium produces ample amount (7.3 × 103 IU/g) of alpha amylase using wheat bran using OVAT (one variable at a time) approach. Further using RSM (Response Surface Methodology) resulted in 3.78-fold increase in alpha amylase production, i.e., 27.57 × 103 IU/g.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Intoduction

Enzymes are biological catalysts which are an indispensable component of biological reaction playing a main role in all stages of metabolism and biochemical reaction by speeding up the rate of reaction and lowering the activation energy. So, they play significant role in accelerating reaction, also are important product obtained from microbial sources for human and commercial use. In recent years, the technique of microbial enzymes accounts the major volume.

Nowadays amylase is a foremost used enzyme in industry, as they catalyze the starch by hydrolyzing the glycosidic bond to form small molecules of sugars useful in biological industries and thus became a widely used enzyme in biotechnology [1].

Amylase is being isolated from various sources like plants, animals, and microorganisms [2] but the one obtained from microorganisms meets the demands of industries especially the food industry [3]. Recently, amylase has become the major interest in food, pharma, fermentation, etc., [4]. In order to fulfill the needs of industry it is very important to produce high amounts of amylase with low cost of production.

Amylase has been studied to be obtained by submerged fermentation and Solid-state fermentation, and among both, the later is considered extra economical due to availability of agro waste, which serves as substrates for fermentation as compared to artificial medium being costly and not much economical. Secondly, there is less amount of water used in SSF so there is a decreased chance of contamination [5]. So, SSF is gaining much more attention for producing amylase.

The production of amylase via SSF is influenced by various factors such as substrate, nutritional components, incubation time, and inoculums size [6], so once the inoculum is prepared, the fermentation conditions should be optimized to get higher amount of enzyme production at reduced cost [7].

RSM is a statistical tool which is a combination of statistical methods and mathematical models which involves statistical significance, satisfactory point location, polynomial equations, to find out the interaction between various variables. A statistical approach has been used in this study to maximize the amylase production from Alkalihalobacillus clausii (MH918161).

Keeping in mind the above points, the present study was done to isolate an amylase-producing bacteria and further production of amylase using an agro waste residue under optimized conditions so as to obtain enhanced amount of enzyme is a cost-effective condition. In this study, Box–Behnken Design (BBD)-based RSM was carried out for optimization of the fermentation parameters using Design-Expert software version 6.

Materials and Methods

Soil Sample Collection

For the present study, soil samples were obtained from the local sites of Ambala (30.2862° N, 76.9643° E), Haryana India. Samples were carried in small plastic bags/bottles and preserved at 4 °C for further analysis.

Isolation of Microorganism

The above collected soil samples were diluted with autoclaved distilled water and by using spread plate method, diluted samples were spread over autoclaved nutrient agar medium (100 ml medium consisted peptone, beef extract, and agar). The spread plates were incubated at 37 °C till colonies appear and isolates with discrete morphology were collected for further analysis.

Screening of Strains

Discrete colonies obtained after isolation were screened for amylase by starch agar plate method. The colonies obtained were streaked on selective media (100 ml medium consisted peptone, beef extract, starch, and agar) and incubated. After two days, plates were poured by iodine solution and after 5 min iodine solution was removed from plates followed by washing with water [8]. Then a clear zone is obtained on the starch agar plate which is usually light brown in color due to the presence of iodine solution in it. The strain showing highest zone was selected and was streaked on slant.

Microscopic and Biochemical Characterization of Bacterial Isolate A11

The bacterial isolates were Gram stained and observed under a high-power magnifying lens in light microscope. Endospore staining and motility test were performed to observe the morphology and motility of the cells. The bacterial isolates were characterized biochemically by indole test, methyl red test, Voges–Proskauer test, Simmons citrate test, catalase test, oxidase test, urease test, nitrate reduction test, gelatin hydrolysis test, Starch hydrolysis test, and H2S production.

Phylogenetic Analyses of Bacterial Isolate A11

DNA was extracted from the potent enzyme-producing bacteria (A11). High-resolution DNA was evaluated through 0.8% agar gel electrophoresis. DNA sample was processed for 16srRNA sequencing using 8F (5′AGAGTTTGATCCTGGCTCAG 3′) and 1492R (5′-GGTTACCTTGTTACGACTT-3′) primers as forward and reverse primers, respectively. In a reaction mixture, 1 µl of DNA, 400 ng forward and reverse primers, 4 µl dNTPs, 10 µl of 10X Taq DNA polymerase assay buffer, and final volume of 100 µl were made up with nuclease-free water. The amplification was performed using thermocycler (ABI 3130 Genetic Analyzer) with programming as initial denaturation temperature 95 °C for five minutes, denaturation at 94 °C for 30 s, primer annealing at 50 °C for 30 s, primer extension 72 °C for 1.30 min, and final extension at 72 °C for 7 min. The PCR product was analyzed in 0.8% agarose gel with ~ 1500 bp and purified using PCR purification kit wizard® SV gel and PCR clean-Up system. The Purified PCR product was sent for sequencing at Eurofins Labs (Bangalore, India). Pairwise calculation of percentage similar sequence was performed to find out the closest neighbors through EzTaxon global alignment algorithm (https://www.ezbiocloud.net/). The genus level classification of potent isolate was checked through RDP Naive Bayesian rRNA Classifier Version 2.11 and also checked for SeqMatch cores (S_ab) calculated using Ribosomal database Database Project (RDP) server (http://rdp.cme.msu.edu/). The type strains mentioned as superscript T in the phylogenetic tree were selected from the LPSN (List of Prokaryotic names with Standing in Nomenclature) and maximum hits given in EzTaxon server. The close homology sequences were retrieved from NCBI and aligned for multiple alignment software program Clustal W. Neighbor-joining method with 1500 bootstrap replications. Kimura 2-parameter model was applied to compute the evolutionary distances. The phylogenetic analysis was carried out using MEGA 11 software [9].

The evolutionary history was inferred using the Neighbor-Joining method. The optimal tree is shown. The percentage of replicate trees in which the associated taxa clustered together in the bootstrap test (1500 replicates) is shown next to the branches. The evolutionary distances were computed using the Kimura 2-parameter method and are in the units of the number of base substitutions per site. This analysis involved 17 nucleotide sequences. Codon positions included were 1st + 2nd + 3rd + Non-coding. All ambiguous positions were removed for each sequence pair (pairwise deletion option). There were a total of 1492 positions in the final dataset. Evolutionary analyses were conducted in MEGA 11.

Culture Preparation

The inoculum was made by adding 0.1 ml of culture in 50 ml of autoclaved nutrient broth (100 ml broth consisted peptone and beef Extract). The inoculum was kept in shaker incubator at 200 rpm for 1 day at 37 °C. The inoculum was further used for amylase production.

Amylase Production and Extraction

Amylase production was done in a 500 ml flask containing wheat bran with nutrient broth acting as moisture agent in 1:1 ratio. The flask was autoclaved to remove any contaminant and further inoculated with freshly prepared 1 ml of inoculum and incubated for 2 days at 37 °C.

For amylase extraction, 100 ml of water was added to the media, and the content was shaken well and squeezed via muslin cloth. The extract thus procured was centrifuged at 10,000 × g for 30 min under cold conditions. The extract obtained was further assayed for amylase activity.

Amylase Assay

The extract was assayed for activity by using DNSA method for which assay was performed with modified assay as described in Okolo et al.,[10]. The reaction consisted 1% starch, amylase extract (varying concentration), and citrate buffer (pH 6.0). The mixture was incubated at temperature 50 °C. After incubation of 10 min, the reaction was halted by adding DNS reagent and kept in boiling water bath. Further reading was taken at 540 nm using a spectrophotometer. Defined 1 IU of amylase as amount of amylase released 1 µmol of glucose in 1 min under standard conditions. All the tests were performed in triplicates and their mean ± SD was calculated.

Production Parameters Optimized

By one variable analysis, various factors were optimized such as carbon source, nitrogen source, incubation time, moisture level, and size of inoculum that affect the production of enzyme. The factors varied are as follows:

Incubation period was varied as 24 h, 48 h, 72 h, and 96 h of production medium at 37 °C. pH range 6 to 11 was varied for production medium at 37 °C for 48 h. The pH of medium was adjusted by using 1N HCl/NaOH. Temperature was varied as 25 °C, 30 °C, 35 °C, and 40 °C during incubation for 48 h.

Different carbon sources were investigated by supplementing the substrate with 10 g agro waste residue such as wheat bran, rice bran, banana peel, potato peel, mustard oil cake, papaya peel, and sugarcane bagasse incubated for 48 h at 37 °C. Different nitrogen sources were added such as peptone, beef extract, NH4NO3, NaNO3, KNO3, peptone + beef extract, and incubated for 48 h at 37 °C. Different metal ions were added to production media such as NaCl, CaCl2, MgCl2, and KCl in different flasks and incubated for 48 h at 37 °C. Moisture level was varied by adding different volumes of moistening agent (2 ml, 4 ml, 6 ml, 8 ml, and 10 ml) in each flask containing production media and then incubated for 48 h at 37 °C. Size of inoculums was varied by adding inoculum as 0.5 ml, 1 ml, 1.5 ml in each flask containing production media and then incubated for 48 h at 37 °C. All the tests were performed in triplicates and their mean ± SD was calculated.

Experimental Design Using Response Surface Methodology (RSM)

In the present experimental set, Box–Behnken design (BBD) was explored for making various combinations both physiological and physiochemical factors [11]. In the present study, BBD of RSM was used to optimize factors in order to get maximum amylase production from Alkalihalobacillus clausii (MH918161).

Box–Behnken Design (BBD)

Once the independent variables having extensive influence on the enhancement of amylase potential were identified, BBD was used to optimize the levels of these independent variables. The statistical software package Design-Expert_6.0 Stat-Ease, Inc., (Minneapolis, USA) was used to analyze the experimental design. A set of 29 experiments were generated. All the tests were performed in triplicates and their mean ± SD was calculated. The design matrix with different variables was set at three levels (− 1, 0, + 1). All the variables optimized by OVAT were taken at a central coded value considered as zero. The minimum and maximum ranges of variables were investigated. The experimental values of antioxidant potential were obtained from following quadratic polynomial equation analyzed by the standard analysis of variance (ANOVA), which resulted in the following equation.

where Y = amylase activity; Xi and Xj = independent variables which affect the response; b0 defines regression coefficient for the intercept, bi for linear, bij for cross product terms, and bii for quadratic [11].

Statistical Analysis and Modeling

The data on the enhancement of amylase production were subjected to analysis of variance (ANOVA) appropriate to design the experiments. The mathematical relationship of the independent variables and the response amylase production) was calculated by second-order polynomial equation. This equation is used to evaluate the linear, quadratic, and interactive effects of independent variables on the selected response. The response for each run was subjected to multiple non-linear regressions using the software ‘Design Expert’ to obtain the coefficients of the second-order polynomial equation included in the final models. The f-test was used to evaluate the significance of the models. Values close to 1 indicate a good model. Three-dimensional plots were generated to present the amount of antioxidant potential in terms of % scavenging produced under optimized conditions. The centric circles in the 3D plots represent the region of maximum amylase production.

Validation of Response Surface Model

In order to determine the accuracy of the model, the concentration of four factors (temp, pH, fermentation time, and moisture level), which have a major influence on amylase production as obtained by response surface methodology were randomly selected within the design space [11].

Confirmatory Test for Alpha Amylase (CERALPHA Method)

After statical optimization (RSM) to ensure the alpha amylase production by the bacterial isolated (A11), a confirmatory assay was conducted by using CERALPHA method (Megazyme Kit, K-CERA) as described. Dispense 200 µl of amylase HR reagent in to the test tubes and pre-incubate the tubes and content at 40 °C for 5 min. each test tubes containing amylase HR reagent solution (200 µl), add 200 µl of bacterial enzyme directly in bottom of test tubes. All the reaction mixtures were incubated for 10 min at 40 °C. Then 3.0 mL of stopping reagent was added and the test tube was stirred vigorously. The absorbance of the solution as well as reaction blank at 400 nm against double distilled water were analyzed.

Units (CU)/mL or gram of original preparation:

All the tests were performed in triplicates and their mean ± SD was calculated.

Statistical Analysis

All the assays were performed in triplicates, and the data were represented in terms of mean ± standard deviation. The results were analyzed by ANOVA followed by Tukey post hoc test (p < 0.05). Statistical analysis was performed using Graph Pad Prism 7 software and p < 0.05 was considered significant.

Results

The present study showed that amylase producers are prevalent in the soil sample taken from Ambala. A total of six samples were collected from local region of Ambala, such as Subhash park, B.D mills, Babyal, Patel Park, B.C. Bazaar, S.D college and from these 14 morphologically different isolates (A11, A12, A21, A22, A23, A31, A32, A33, A41, A42, A43, A51, A52, A61) were obtained after serial dilution and were selected for screening of amylase production.

Isolates were screened for amylase production by observing zone of clearance on starch hydrolysis. Among 14 isolates obtained, seven (A11, A12, A22, A23, A31, A42, A43) were found to be amylase producing, out of which strain A11 showed the maximum zone (1.8 cm diameter) and was chosen for further studies.

Microscopic and Biochemical Characterization of Bacterial Isolate A11

Culture isolate (A11) was found potent in production of alpha amylase and were further investigated for microscopic and biochemical characterizations. Bacterial isolate A11 was found Gram-positive rods in chain, spore-forming (Fig. S1, Fig. S2), non-motile, indole and methyl red-negative, Voges–Proskauer test and Simmons citrate test positive, catalase test and oxidase tests also show the positive result for culture isolate A11.

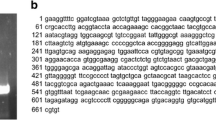

Phylogenetic Analyses of Bacterial Isolate A11

The potent enzyme producing bacterial isolate was subjected for 16 s rRNA sequencing. A 1168 bp sequence was obtained by 16 s rRNA sequencing. The sequence was submitted at Gene bank, NCBI with accession number MH918161.2. Based on phylogenetic analysis, the isolates showed homology to Alkalihalobacillus clausii DSM 8716 (CP019985). The 16 s rRNA sequences were also evaluated for RDP Naive Bayesian rRNA Classifier suggesting that the isolates belong to domain Bacteria, phylum Firmicutes, class Bacilli, order Bacillates, family Bacillaceae, and genus Alkalihalobacillus. The seqMatch showed 0.980 s_ab scores by RDP server and Eztaxon server suggesting the 99.91 similarity with Alkalihalobacillus clausii DSM 8716 (CP019985) (Fig. 1).

Phylogenetic relationships of bacterial isolate A11 (Alkalihalobacillus clausii) based on the 16S rDNA sequencing. Sequence alignment and phylogenetic inferences were obtained using the Neighbor-Joining method within MEGA 11 software. The numbers at the nodes are percentages of bootstrap values obtained by repeating the analysis 1500 times to generate a majority consensus tree

Amylase Production

The bacterial strain A11 produced maximum amylase among others, which was further selected for optimization of culture condition. In the present study, the various parameters optimized were inoculum size, carbon and nitrogen source, metal ion, and incubation time. The optimization studies showed that the production was highest under conditions, i.e., wheat bran, yeast, and MgCl2 at incubation time 48 h and using 2 ml of inoculum.

Effect of Inoculums Size

Effect of variation of inoculums size was studied for amylase activity and a significant difference among inoculum size was obtained by One-way ANOVA analysis. In the present study, various inoculum sizes such as 0.5 ml, 1.0 ml, 1.5 ml, 2.0 ml, and 2.5 ml were screened for maximum alpha amylase production by Alkalihalobacillus clausii in solid-state fermentation using wheat bran as substrate. Highest activity of 1.7 × 103 IU/g was obtained when substrates were inoculated with 2 ml of inoculum, above and below, where the activity decreased as shown in Fig. 2.

Effect of Temperature

The effect of various temperatures on amylase production was studied and optimized and a significant difference among their means was obtained by One-way ANOVA analysis. Amylase production for the bacterial isolate A11 was observed at temperature ranging from 20 to 50 °C. Thee temperature influenced amylase production, and the optimum temperature for maximal production was found to be 35 °C, compared to minimum (20 °C) and maximum (50 °C) temperature as shown in Fig. 2. There was major decline in the amylase production as temperature was increased above 35 °C. Hence, further optimization was carried out at 35 °C.

Effect of Incubation

To study the effect of incubation of bacterial isolate, Alkalihalobacillus clausii (A11) was inoculated into wheat bran as substrate for fermentation and incubated for 24–96 h. Enzyme was extracted at different days of incubation and the activity of amylase produced was recorded. The amylase activity observed was as high as 4.1 × 103 IU/g in 48 h of incubation. Significant difference was observed between alpha amylase productions at different incubation periods obtained by One-way ANOVA analysis. At 24 h of incubation, activity was observed as 1.5 × 103 IU/g, at 72 h it was 3.4 × 103 IU/g, and at 96 h it was 2.0 × 103 IU/g (Fig. 2).

Effect of Moisture Ratio

Effect of variation of nutrient broth was studied for amylase activity and found significant difference between alpha amylase productions at different moisture ratios obtained by One-way ANOVA analysis. Best results were obtained when 20 ml of NB was poured on the substrate (amylase activity was 5.8 × 103 IU/mg). However, when 10 ml of NB was taken, amylase activity was observed as 2.7 × 103 IU/g, at 15 ml it was 5.5 × 103 IU/g, at 25 ml it was 4.8 × 103 IU/g, and at 30 ml it was 4.9 × 103 IU/g. (Fig. 1).

Effect of Nitrogen Sources

Peptone, beef extract, NH4NO3, NaNO3, KNO3, peptone + beef extract, and yeast were used as nitrogen source. Best results of amylase activity were obtained with yeast, which was 5.9 × 103 IU/g, followed by peptone (5.1 × 10 3 IU/g), and least activity was obtained with the combination of peptone + beef extract (1.3 × 103 IU/g) as shown in Fig. 2. One-way ANOVA analysis reveals that nitrogen sources had statically significant effect on alpha amylase production in solid-state fermentation. Hence, further optimization was carried out using the yeast extract as a nitrogen source. It was also observed that high yeast concentration had negative impact on alpha amylase production.

Metal Ion Effect

It was well documented that metal ion can significantly impact on biological production of alpha amylase by exchanging the electrons. In the present study, different chloride metal ions such as NaCl, CaCl2, MgCl2, KCl, FeCl3, and CoCl3 were studied for alpha amylase activity. MgCl2 showed the best yields (2.7 × 103 IU/g), whereas NaCl, KCl, and CoCl3 yielded 2.5 × 103 IU/g, 2.3 × 10 3 IU/g, and 2.1 × 103 IU/g, respectively. Least yield of amylase was obtained with CaCl2 (1.0 × 103 IU/g) as compared to others (Fig. 2). Significant difference was also observed between alpha amylase productions at different metal ions obtained by One-way ANOVA analysis.

Effect of pH

The pH of the any production medium is a crucial factor that has an influence on the growth and production of any bioactive compound. Therefore, in this experiment, bacterial strain A11 was grown in the wheat bran medium at a different pH in the range of 3–11 (Fig. 3) at 350C and was maximized for amylase production. It was observed at neutral pH 7.0 (4.5 × 103 IU/g) that the highest amount of amylase was produced. Significant difference was observed between alpha amylase productions at different incubation periods obtained by One-way ANOVA analysis. The amylase output was observed to be reduced when the pH was changed below or above the optimum (Fig. 3). There was no growth observed at pH < 3 and pH > 11. There was decline in amylase production on increasing pH from 7 to 10. Hence, neutral pH (7.0) was used as optimum pH for further experiments.

Carbon Source Effect

Different carbon sources were studied such as potato peels, papaya peels, wheat bran, sugarcane bagasse, apple peels, and banana peels for amylase activity. Wheat bran showed the best yield (7.3 × 103 IU/g) followed by papaya peels (6.7 × 103 IU/g), potato peels (3.5 × 103 IU/g), sugarcane bagasse (2.4 × 10 3 IU/g), apple peels (2.1 × 103 IU/g), and banana peels (1.1 × 103 IU/g) as shown in Fig. 2.

Optimized Condition for Production

In the study for amylase production, the optimized parameters included agro waste residue (10 g wheat bran) with moistening agent (nutrient broth, pH 7) in the ratio 1:2 and with 1.5 ml inoculum followed by incubation period of 48 h at 35 °C. The strain A11 using the above-mentioned optimized conditions showed the amylase production of 7.3 × 103 IU/g of substrate which was found to be higher than that reported earlier. So, A11 showed an elevated level of amylase production using agro-residue only in 48 h.

Response Surface Methodology (RSM)

RSM is statistical method to check the interaction between most influencing factors responsible for the production of secondary metabolites. Here, in the present study, after OVAT method the final yield of alpha amylase was 7.3 × 103 IU/g of amylase, which was obtained in the presence of physiochemical parameter (pH, temp, and fermentation time and moisture level) from the strain of Alkalihalobacillus clausii (MH918161.2) after 48 h of incubation. However, in this approach, process optimization of amylase production from Alkalihalobacillus clausii (MH918161.2) was carried out by using a statistical approach known as Response Surface Methodology (RSM). Here, the interactions between the most influencing factors obtained from OVAT approach were taken into account to design RSM using Box–Behnken design (BBD) [Design-Expert 6.0.8 Stat-Ease, Inc., (Minneapolis, USA)] for maximum amylase production from Alkalihalobacillus clausii (MH918161.2).

Box–Behnken Design (BBD)

George E. P. Box and Donald Behnken developed the Box–Behnken designs, which are experimental designs for the response surface methodology, in 1960. Each independent variable, or factor, is assigned to one of three evenly spaced values, which are often coded as −1, 0, and + 1. Based on the Design-Expert 6.0.8 Stat-Ease, Inc., (Minneapolis, USA), a set of 29 experiments were generated (Table S1). As per the design matrix data, a set of 29 experiments in different permutations and combinations of the selected variables were prepared in triplicate. These flasks were set with different parameters according to the design matrix data. After the desired incubation period, the culture was harvested and each sample was analyzed for amylase production by spectrophotometer. Table (S2) and Fig. 4 present the mean observed value of amylase production and mean predicted value of amylase. The experimental values of amylase production were the results of triplicates and the predicted values were obtained from the following quadratic polynomial equation analyzed by the standard analysis of variance (ANOVA), which resulted as in the following equation:

where Y = Amylase production, A = Temperature, B = pH, C = Fermentation time, D = Moisture level.

Results showed that the interaction of the most influential factors resulted in a amylase concentration, which was found to be 27.57 × 103 IU/g when compared to the initial concentration, i.e., 7.3 × 103 IU/g shows 3.78-fold increase from initial amylase production.

ANOVA Analysis

An analysis of variance (ANOVA) was used to determine the significance and correctness of the BBD model (Table S1). Fisher’s F test was used to check the efficacy of the model. The significance difference of the model in terms of each coefficient was determined using the F and P values of the model. The F value of 11.47 for the model indicates that it is significant. There is only a 0.01% chance that a “Model F-Value” could occur due to noise. Values of “Prob > F” less than 0.0500 indicate model terms are significant. In this case, A, B2, AD are significant model terms. Values greater than 0.1000 indicate that the model terms are not significant.

The “Lack of Fit F-value” of 1.31 implies the Lack of Fit is not significant relative to the pure error. There is a 42.72% chance that a “Lack of Fit F-value” this large could occur due to noise. Non-significant lack of fit is good—we want the model to fit.

In the present study, the R2 value (0.9198) demonstrates that 91.98% variation in the model is caused by the variables and only 8.02% variation could not be explained by the model which indicates that the model is fit for the production of alpha amylase under solid-state fermentation.

The “Pred R-Squared” of 0.6168 is not as close to the “Adj R-Squared” of 0.8396 as one might normally expect. This may indicate a large block effect or a possible problem with your model and/or data. Things to consider are model reduction, response transformation, outliers, etc. “Adeq Precision” measures the signal-to-noise ratio. A ratio greater than 4 is desirable. In the present study, ratio of 13.057 indicates an adequate signal. This model can be used to navigate the design space.

The three-dimensional response surface curves were then plotted to investigate the interaction between the many physico-chemical parameters involved in alpha amylase production and to determine the optimum concentration of each factor. All other elements were maintained at fixed values. The 3D response surface plot is a function of two parameters at a time. These diagrams aid in comprehending both the individual and interaction impacts of these two variables (Fig. 5).

3D surface and contour plots showing the effect of different variables on amylase production; a reveals the interaction between fermentation time and pH, b reveals interaction between moisture and ph, c reveals the interaction between fermentation time and moisture, d reveals the interaction between pH and temperature

Validation of Model

Utilizing the ideal circumstances that the model predicted, tests were carried out to validate the model. The response surface plots predicted the following optimal levels: temp (A), pH (B), fermentation time (C), moisture level (D), which were optimized for RSM design. Table S3 presents the amylase production of each individual experiment along with the predicted response. The results verify the previous model that temperature at 40 °C, pH at 7.0, fermentation time 72.0 h, and moisture level 20.0 ml were found as best combination for obtaining the maximum amylase production. The maximum yield 27.67 (IU/g) was obtained experimentally and this was closer to the predicted value of 26.79 (IU/g). The predicted results matched well with the experimental results obtained using optimal conditions, which validate the RSM models with good correlation (Table S3, Fig. 5).

Confirmatory Test for α-Amylase (CERALPHA Method)

CERALPHA method (Megazyme Kit, K-CERA) was used to ensure the α-amylase production in our bacterial isolate (A11). This method is based on the use of a defined oligosaccharide substrate, non-reducing-end blocked p-nitrophenyl maltoheptaoside, in the presence of excess levels of a thermostable α-glucosidase. Here, we used final statically optimized (RSM) parameters to check the α-amylase activity. The strain A11 using the above-mentioned optimized conditions showed the α-amylase activity of 21.54 × 103 IU/g.

Discussion

Amylase is one of the blockbuster enzymes ever known and needs an hour having more than 25% of the enzyme market. Amylases have multifarious applications in the various food sectors, biochemical industries, and pharmaceutical as well as agrochemical industries. There are several reports on biological production of alpha amylase using solid-state fermentation. In the present study soil sample taken from local region of Ambala to isolation and screening for most prominent isolate which was producing alpha amylase in free fermentative condition. In the present study, the A11 isolates showed potent amylase activity. The isolate was identified as Gram-positive and endospore-forming bacillus bacteria which was further confirmed by 16 s rRNA sequencing. The taxonomical classification was done on the basis of most likely neighboring phylogenic and analysis confirmed as Alkalihalobacillus clausii. Alkalihalobacillus clausii is basionym of Bacillus clausii [18].

The optimum production of α-amylase ranges varies with respect to physiochemical conditions like temperature, pH, and source of micro and macronutrients [19]. The microbial source of α-amylase can be bacterial, fungal, and from yeast. The best source of enzymes is considered through microbes as they are more stable and substrate specific, the focus in the present study was to isolate the novel species from different sources for α-amylase production. The isolated microbes can be optimized for physiochemical optimization for maximum enzyme production. Elmansy et al. isolated α-amylase-producing bacterial strain from water sample from Wadi El-Natron and identified as Bacillus sp. NRC22017 on the basis of morphological, biochemical, and 16 s rRNA sequencing. The maximum yield they observed was 15.15 ± 0.47 U/ml at pH 6, temperature 45 °C, and incubated aerobic condition for 72 h [20]. Pranay et al., isolated amylase-producing bacillus from soil and identified by 16 s rRNA sequencing. The amylase production was best till 96 h and declined after 120 h [21]. The present study is comparable with pranay et al., as the source of isolation of bacteria is soil and the difference in the optimum conditions they follow. α-amylase is found to have antibiofilm activity against biofilms forming microbes including Gram positive and Gram negative. It is also revealed that α-amylase obtained from the bacteria viz., Bacillus subtilis bears potential inhibitory action against S. aureus and P. aeruginosa compared to the commercial available α-amylase [1].

In the present study, there is a major decline in amylase production as the temperature was increased above 350C and a similar result was observed where amylase production decreased with further increase in temperature Suman et al., 2010 [12]. In our study, the optimum incubation time for the production of alpha amylase was found to be 72 h. Various reports authenticate our data that show amylase production varied with incubation; less time of incubation is likely for economical production of enzymes [10]. It was found that 48 h of incubation was best for the production of amylase which is a short period for extraction. Similar results were observed which showed maximum activity after 48 h [13]. B. subtilis showed optimal growth at 70% moisture [14]. As the moisture content increases, the enzyme cultivation was lowered because the rate of oxygen transfer is decreased. Earlier studies showed that in A. fumigates peptone, A. niger sodium nitrate, and A. oryzae, casein hydrolysate acts as a good nitrogen supplement [15].

Usually, organic nitrogen sources such as peptone and yeast extract are often reported to enhance amylase production in the medium [16]. In the present study, we also found yeast as the best nitrogen source for alpha amylase production. Using Amaranthus grains, Vishwanathan et al., [18] showed optimistic results for CaCl2 and NaCl, while FeCl3 and MgSO4 exhibited negative influence. The greatest amylase production was found at pH 7.0, according to Aqeel and Umar [17]. These data also support our result, in the present study, we declare that at neutral ph maximum amylase was produced. Suman and Ramesh [12] proposed that starch is a normally accepted source and the best constituent for the production of amylolytic enzyme. The production of enzymes is fully dependent on the physiochemical as well as nutritional parameters of the culture [11]. For optimization and large-scale production, RSM is the best mathematical model which provides the best optimum interaction among all variables to maximize the production of bioactive compounds. Dwibedi et al. [11] applied the RSM approach to maximize the resveratrol production by the endophytic fungus Arcopilus aureus. Using a mathematical model of optimization, we can reduce the cost of enzyme production and also reduce the labor cost that is why it is a cost-effective technology for enzyme production.

Conclusion

The present study showed that the strain (A11) produced enhanced levels of amylase under solid-state fermentation using carbon source as wheat bran, an economical and simply procured agro-residue. From the present study it can be concluded that both OVAT and RSM are complementary methods in optimizing the amylase production Alkalihalobacillus clausii. The bacterium secretes high levels (7.3 × 103 IU/g) of amylase using wheat bran using OVAT (one variable at a time approach). Optimization of amylase production using BBD (Box–Behnken Design) of RSM (Response Surface Methodology) resulted in enhancement of amylase concentration, which was found to be 27.57 × 103 IU/g when compared to the initial concentration, i.e., 7.3 × 103 IU/g shows 3.78-fold increase from initial amylase production. Using strain improvement methods and optimization methods, OVAT and RSM bacterium (Alkalihalobacillus clausii) can be exploited for the commercial production of amylase which increased economic value for its importance in various industries.

References

Lahiri D, Nag M, Sarkar T, Dutta B, Ray RR (2021) Antibiofilm activity of α-amylase from bacillus subtilis and prediction of the optimized conditions for biofilm removal by response surface methodology (RSM) and Artificial Neural Network (ANN). Appl Biochem Biotechnol 193:1853–1872

Bhatt K, Lal S, Srinivasan R, Joshi B (2020) Bioconversion of agriculture wastes to produce α-amylase from Bacillus velezensis KB 2216: Purification and characterization. Biocatal Agric Biotechnol 28:101703

Balakrishnan M, Jeevarathinam G, Kumar SKS, Muniraj I, Uthandi S (2021) Optimization and scale-up of α-amylase production by Aspergillus oryzae using solid-state fermentation of edible oil cakes. BMC Biotechnol 21:1–11

Kiran S, Kumari S, Singh A, Prabha C, Kumari S (2018) Extracellular amylase production under submerged fermentation by Bacillus subtilis RK6. Int J Pharm Biol Sci 8:376–383

Akula S, Golla N (2020) 11 Significance of process parameters on fungal cellulase production. In: Srivastava N, Srivastava M, Mishra PK, Gupta VK (eds) Biofuel production technologies critical analysis for sustainability. Springer, Singapore

Benabda O, Mhir S, Kasmi M, Mnif W, Hamdi M (2019) Optimization of protease and amylase production by Rhizopus oryzae cultivated on bread waste using solid-state fermentation. J Chem 2019:1–9

Šibalić D, Šalić A, Tušek AJ, Sokač T, Brekalo K, Zelić B, Tran NN, Hessel V, Tišma M (2020) Sustainable production of lipase from Thermomyces lanuginosus: process optimization and enzyme characterization. Ind Eng Chem Res 59:21144–21154

Gamal R, Abou-Taleb K, Abd-Elhalem B (2017) Isolation, identification and production of amylases from thermophilic spore forming Bacilli using starch raw materials under submerged culture. AASCIT J Biosci 3:52–68

Peak KK, Duncan KE, Luna VA, King DS, McCarthy PJ, Cannons AC (2011) Bacillus strains most closely related to Bacillus nealsonii are not effectively circumscribed within the taxonomic species definition. Int J Microbiol 2011:673136

Okolo BN, Ezeogu LI, Mba CN (1995) Production of raw starch digesting amylase by Aspergillus niger grown on native starch sources. J Sci Food Agric 69:109–115

Dwibedi V, Rath SK, Prakash R, Saxena S (2021) Response surface statistical optimization of fermentation parameters for resveratrol production by the endophytic fungus Arcopilus aureus and its tyrosinase inhibitory activity. Biotech Lett 43:627–644

Suman S, Ramesh K (2010) Production of a thermostable extracellular amylase from thermophilic Bacillus species. J Pharm Sci Res 2:149

Nahas E, Waldemarin MM (2002) Control of amylase production and growth characteristics of Aspergillus ochraceus. Rev Latinoam Microbiol 44:5–10

Almanaa TN, Vijayaraghavan P, Alharbi NS, Kadaikunnan S, Khaled JM, Alyahya SA (2020) Solid state fermentation of amylase production from Bacillus subtilis D19 using agro-residues. J King Saud Uni-Sci 32:1555–1561

Pedersen H, Nielsen J (2000) The influence of nitrogen sources on the α-amylase productivity of Aspergillus oryzae in continuous cultures. Appl Microbiol Biotechnol 53:278–281

Aslam F, Ansari A, Aman A, Baloch G, Nisar G, Baloch AH, Rehman HU (2020) Production of commercially important enzymes from Bacillus licheniformis KIBGE-IB3 using date fruit wastes as substrate. J Genet Eng Biotechnol 18:1–7

Aqeel M, Umar M (2010) Effect of alternative carbon and nitrogen sources on production of alpha-amylase by Bacillus megaterium. World Appl Sci J 8:85–90

Nielsen P, Fritze D, Priest FGJM (1995) Phenetic diversity of alkaliphilic Bacillus strains: proposal for nine new species. Microbiology 141:1745–1761

Farooq MA, Ali S, Hassan A, Tahir HM, Mumtaz S, Mumtaz S (2021) Biosynthesis and industrial applications of α-amylase: a review. Arch Microbiol 203:1281–1292

Elmansy EA, Asker MS, El-Kady EM, Hassanein SM, El-Beih FM (2018) Production and optimization of α-amylase from thermo-halophilic bacteria isolated from different local marine environments. Bull Natl Res Cent 42:1–9

Pranay K, Padmadeo SR, Jha V, Prasad B (2019) Screening and identification of amylase producing strains of Bacillus. J Appl Biol Biotechnol 7:5–2

Acknowledgements

The author acknowledges the Chandigarh University for providing facilities.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or non-profit sectors.

Author information

Authors and Affiliations

Contributions

AM: Conceived the idea, designed the experiments, and carried out the experiments and wrote the manuscript. MJ: Carried out the experiments and wrote the manuscript. SKR: Data creation, Software, Formal analysis, and Review and editing. DS: Investigation, Formal analysis, and Review and editing. VD: Conceptualization, Methodology, Validation, Project Administration, and Review and editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing financial interest.

Consent for Publication

Not applicable.

Research Involving Human and Animal Rights

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mittal, A., Joshi, M., Rath, S.K. et al. Isolation of Alpha Amylase-Producing Bacteria from Local Region of Ambala and Production of Amylase Under Optimized Factors Using Solid-State Fermentation. Curr Microbiol 79, 375 (2022). https://doi.org/10.1007/s00284-022-03081-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00284-022-03081-3