Abstract

Studying the anisotropic physical properties of hexagonal closed-packed (hcp) iron is essential for understanding the properties of the Earth’s inner core related to the preferred orientation of the inner core materials suggested by seismic observations. Investigating the anisotropic physical properties of hcp iron requires (1) the synthesis of hcp iron samples that exhibit several distinctive types of strong lattice preferred orientation (LPO) and (2) the quantitative LPO analysis of the samples. Here, we report the distinctive LPO of hcp iron produced from single-crystal body-centered cubic (bcc) iron compressed along three different crystallographic orientations ([100], [110], and [111]) in a diamond anvil cell based on synchrotron multiangle X-ray diffraction measurements up to 80 GPa and 300 K. The orientation relationships between hcp iron and bcc iron are consistent with the Burgers orientation relationship with variant selection. We show that the present method is a way to synthesize hcp iron with strong and characteristic LPO, which is beneficial for experimentally evaluating the anisotropic physical properties of hcp iron.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Seismological observations have repeatedly suggested that the Earth’s inner core, an iron-rich sphere with a radius of approximately 1300 km at the center of the Earth, is anisotropic (e.g., Deuss 2014; Romanowicz and Wenk 2017; Tkalčić 2015). The origin of the anisotropic properties is crucial for understanding the growth history of the inner core and its relationship with the outer core. The lattice preferred orientation (LPO) of iron-dominated crystals can explain the observed inner core anisotropy and strongly influence their thermal evolution. The elastic properties of solid iron at high pressure provide a direct link between geophysical models of the inner core and seismic observations to constrain the chemical composition and anisotropic structure of the inner core (e.g., Antonangeli and Ohtani 2015). It has been speculated that the iron’s crystal orientation-dependent transport properties, i.e., electrical conductivity, thermal conductivity, and viscosity, if present, affect the cooling process of the inner core and thus its internal structure and outer core dynamics (Secco and Balog 2001). Iron exhibits a pressure-induced structural phase transformation from a body-centered cubic (bcc) structure to a hexagonal close-packed (hcp) structure at approximately 13 GPa and 300 K. Hcp iron has a wide stability field under pressure and temperature conditions beyond the Earth's inner core (Smith et al. 2018; Tateno et al. 2010) and serves as a reasonable starting point for modeling the physical properties of the Earth’s inner core. Therefore, synthesizing hcp iron with several characteristic LPOs is crucial for studying its anisotropic physical properties. However, despite its importance, there have been few investigations regarding the anisotropy of various physical properties of hcp iron due to the difficulty of synthesizing single-crystalline or polycrystalline hcp iron with strong LPO textures (Antonangeli et al. 2004; Dewaele et al. 2023; Lin et al. 2010; Ohta et al. 2018).

Since hcp iron cannot be recovered under ambient conditions, hcp iron must be synthesized with a strong LPO texture, and then physical property measurements can be performed in situ at high pressures. The characteristic texture relationship between the bcc and hcp phases of iron has been studied on many experimental platforms and time scales via, e.g., dynamic compression (Hawreliak and Turneaure 2021; Kalantar et al. 2005; Merkel et al. 2021) and static compression (Dewaele et al. 2023, 2015; Fréville et al. 2023; Ishimatsu et al. 2020; Merkel et al. 2012, 2013, 2020; Miyagi et al. 2008; Ohta et al. 2018). In all cases, the transition is reported as martensitic, with large portions of the sample following the Burgers orientation relationship (Burgers 1934).

Ohta et al. (2018) used three different polycrystalline bcc iron starting materials (foil, sintered powder, and wire) to synthesize hcp iron with different LPOs. These researchers observed the LPO of hcp iron up to 44.5 GPa by performing X-ray diffraction (XRD) measurements through a Kapton and cBN composite gasket along a radial direction, perpendicular to the compression axis of a diamond anvil cell (DAC). To achieve a stronger LPO and to evaluate it at higher pressures with greater accuracy, in this study, multiangle XRD measurements are conducted using single-crystal bcc iron with different crystallographic orientations as the starting material.

Here, we report the unique combination of synchrotron multiangle XRD measurements of hcp iron transformed from single-crystal bcc iron with three different crystallographic orientations ([100], [110], and [111]) loaded in a DAC up to 80 GPa and 300 K (Table 1). The hcp iron samples prepared from the single-crystal bcc iron starting materials exhibited stronger and more pronounced LPOs than those in our previous study (Ohta et al. 2018) and are more suitable for estimating the anisotropic physical properties of hcp iron.

Materials and methods

Starting materials and diamond anvil cell assembly

The samples were bcc iron single-crystal wafers. Each wafer had a diameter of ~ 80 μm and was cut from a larger single-crystal cube (99.99% purity, Crystal Base Co., Ltd.) by UV pulse laser processing. The wafers were then embedded in solid wax (Adfix A, Maruto Instrument Co., Ltd.) and polished with 3M lapping film (3.0 micron film) to achieve a thickness of approximately 10 μm. The mosaicity of the iron samples were not characterized.

We pressurized single-crystal bcc iron disks with the surface normal parallel to [100], [110], and [111] using a symmetric-type DAC to undergo the hcp phase transition. We used NaCl or a combination of silicone oil (A12728, Alfa Aesar) and fused silica as the pressure transmitting medium. The pressure quality (i.e., nonhydrostaticity) of NaCl is not so different from that of silicone oil at 300 K (Tateiwa and Haga 2009). The culet size of the diamond anvils was 300 μm. To fabricate a gasket for the DAC experiments, rhenium foil with a thickness of 250 μm was preindented to a thickness of 30–40 μm, and sample chambers with a diameter of 80–100 μm were fabricated in the center of the preindented part of the rhenium gasket. The diamond anvils were mounted on tungsten carbide seats with a 90° opening to maximize the number of diffraction peaks collected while rotating the DAC stage (Fig. 1).

Synchrotron XRD measurements and texture analysis

Crystallographic information on the produced hcp iron was obtained from synchrotron XRD experiments at beamline BL10XU at SPring-8 (Hirao et al. 2020). Monochromatic X-rays with an energy of 62 keV were used (Hirao and Ohishi 2022). The XRD patterns of the samples were collected with a two-dimensional imaging plate (IP) detector (Rigaku R-Axis V++). For reliable LPO analysis, diffraction patterns from lattice planes oriented at different angles were collected by rotating the DAC around the vertical axis (up to 25°) and rotating the compression axis of the DAC (up to 270°) during the experiments (Fig. 1). There are missing angles in our diffraction experiments because the X-rays were blocked by various obstacles, such as the tungsten carbide seats, the mechanical posts of the DAC, and the rhenium gasket. However, since hcp iron has high crystal symmetry, the pole figure coverage in this study is sufficient for texture analysis (Merkel et al. 2020). The pressure was determined from the lattice volume of hcp iron and its equation of state (Dewaele et al. 2006). Thermal annealing was not performed in this study.

After obtaining two-dimensional XRD patterns of the hcp iron samples in situ at high pressures, Rietveld analysis—using MAUD software on the collected diffraction patterns—was performed for texture characterization (Lutterotti et al. 2014). Rietveld analysis is a structure refinement technique for powder diffraction data. It uses the structural information of the sample to calculate the diffraction intensity and refines the model parameters to minimize the residual function between the observed and calculated data (Fig. 2). We used the E-WIMV algorithm for texture analysis of hcp iron, which is a modified version of the Williams-Imhof-Matthies-Vinel (WIMV) algorithm (Lutterotti et al. 2004). For the experiments at ~ 80 GPa, we chose an ODF resolution of 10° for texture analysis. For the experiments at ~ 20 and ~ 40 GPa, an ODF resolution of 5° was used to closely reproduce the single-crystal-like patchy diffraction patterns. There are several analysis packages other than MAUD for crystallographic orientation analysis of single crystal samples, such as GrainSpotter and Recipro (Schmidt 2013; Seto and Ohtsuka 2022). In this study, the same analysis method should be used to analyze the crystallographic orientation of polycrystalline iron that has been fine-grained by phase transition and pressurization from a single crystal iron sample. Also, in our previous study (Ohta et al. 2018), which we would like to directly compare, MAUD was used for LPO analysis. For these reasons, MAUD was consistently adopted as the analysis method in this study.

Results and discussion

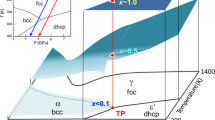

We pressurized three single crystals of bcc iron, each with a different orientation relative to the compression axis of the DAC, to approximately 20, 40, and 80 GPa and observed the preferred orientation of the synthesized hcp iron (Table 1). Although the crystallographic orientation dependence of the pressure of the bcc-hcp transition was discussed in the literature (Kadau et al. 2002; Liu et al. 2018; Wang et al. 2014), the onset pressure of hcp iron among bcc iron with each orientation ([100], [110], and [111]) was not precisely determined in this study. The diffraction patterns of bcc iron are consistent with its crystallographic orientation and show slight polycrystallization, possibly due to mechanical polishing and the UV laser processing during sample preparation (Fig. 3a). Figure 3b shows a representative XRD pattern of hcp iron at 19 GPa. The (0002) peak of the hcp iron corresponds to the (110) peak of the former bcc iron. This relationship can be explained by the transformation mechanism proposed by Burgers (Burgers 1934). The Burgers model explains the bcc-hcp transition as a result of shear deformation along the < 111 > direction and mixing motion in the {110} plane in bcc iron. Since there are two equivalent < 111 > directions on each {110} plane in a bcc structure, hcp iron with two different crystallographic orientations can arise from a single {110} plane of bcc iron. This is manifested by the splitting of the (10–10) and (10–11) peaks in the diffraction pattern of hcp iron (Ishimatsu et al. 2020) (see inset in Fig. 3b).

Representative XRD patterns (stage rotation 0°) of a single-crystal bcc iron foil with a surface normal parallel to ([111]bcc) under ambient conditions and b hcp iron produced by pressurizing a single-crystal bcc iron foil with a surface normal parallel to [111] at 19 GPa (run #3). The inset is an enlarged view of (b) showing the splitting of the (10–10) and (10–11) diffraction peaks (yellow arrows)

From a Rietveld analysis of the two-dimensional diffraction patterns, we obtained pole figures that allowed us to graphically assess the texture evolution in hcp iron (Fig. 4). Up to pressures of ~ 40 GPa, the pole figures of hcp iron show orientation relationships between (1) the basal plane of hcp iron and (110) bcc and (2) the a-axis of hcp iron and [111]bcc or [100]bcc. Since bcc iron has six equivalent (110) bcc planes, the bcc-to-hcp phase transformation produces six different orientations of the basal planes in hcp iron in the absence of variant selection. Dewaele et al. (2015) showed that there is no variant selection during bcc-to-hcp phase transformation, while other experimental studies have shown evidence of strong variant selection (Ishimatsu et al. 2020; Merkel et al. 2020; Yadav et al. 2013). Since Dewaele et al. (2015) used single-crystal bcc iron with [100]bcc parallel to the compression axis, their result can be attributed to the unique angular relationship between the compression axis of the DAC and < 111 > bcc shear deformation (Ishimatsu et al. 2020). Interestingly, the pole figures at ~ 20 GPa in this study show evidence of variant selection during transformation from bcc iron, with the compression axis parallel to [110]bcc and [111]bcc. For example, the pole figure of hcp iron transformed from bcc iron with [111]bcc parallel to the compression axis shows only four major c-axis density concentrations (Fig. 4). On the other hand, the starting material with [100]bcc parallel to the compression axis produced all six possible basal planes of hcp iron, suggesting no variant selection, as in previous static compression studies (Dewaele et al. 2015). Here we used NaCl and silicone oil as pressure media. While there is no significant difference in the pressure quality (i.e., non-hydrostaticity) of these materials, they are less hydrostatic than helium and neon (Tateiwa and Haga 2009), which was used in many previous studies (Dewaele et al. 2015; Freville et al. 2023; Ishimatsu et al. 2020; Merkel et al. 2020). In this respect, this study is a less hydrostatic experiment than most of the previous studies using DAC. The degree of non-hydrostaticity can affect the mechanism of the phase transition of iron from bcc to hcp. For the extreme case, a uniaxial shock compression induced different orientation relationship between bcc and hcp iron from static compression (Hawreliak and Turneaure 2021).

Pole figures of the c-axis and a-axis of hcp iron made from single-crystal bcc iron with different orientations. For the ~ 20 and ~ 80 GPa experiments, the stage was rotated up to 25°, and the DAC was rotated up to 270° around its compression axis. For the ~ 40 GPa experiments, only a single XRD image taken without rotation was used. The compression axis of the DAC is in the center of the pole figure. Each pole figure represents a different experimental run. a Pole figures of hcp iron produced by pressurizing a single-crystal bcc iron foil with the surface normal parallel to [100], b [110], and c [111]. The direction of DAC compression is in the center of the pole figure

In contrast to the samples at ~ 20 and ~ 40 GPa, which show LPO consistent with the Burgers orientation relationship, the c-axis of hcp iron is essentially parallel to the compression axis of the DAC for all the samples at ~ 80 GPa (Fig. 4). This preferred orientation of the c-axis has been reported and attributed to the deformation of hcp iron by activation of the (0001) < -12–10 > basal slip system under differential stress (Merkel et al. 2013; Miyagi et al. 2008; Nishihara et al. 2018; Wenk et al. 2000). The deformation-induced textures of the samples at ~ 80 GPa can be attributed to the silicone oil pressure medium used in the experiments. Since the quality of silicone oil as a hydrostatic pressure medium deteriorates rapidly after solidification (Klotz et al. 2009; Torikachvili et al. 2015), deformation of the samples occurs. We are hopeful that a more hydrostatic medium, such as helium, could produce hcp iron with a significant difference in LPO at higher pressures.

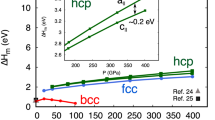

Figure 5 shows the distribution of α, the angle between the c-axis of the hcp iron and the compression axis of the DAC, calculated by MAUD. The distributions at ~ 20 GPa are closely related to the orientations of the {110}bcc in the starting materials. The hcp iron transformed from bcc iron with a surface normal parallel to the [110] axis shows a strong single peak at approximately α = 60°, which is the angle between the compression axis and the normal vectors of the four equivalent {110}bcc. The absence of a peak at approximately α = 90°, where the other {110}bcc is oriented, suggests a variant selection during the phase transformation from bcc iron with [110]bcc parallel to the compression axis. Similarly, samples transformed from single-crystal bcc iron with the surface normal parallel to [100] and [111] show peaks at approximately α = ~ 45 and ~ 35.2°, respectively. Both samples also have a strong peak at α = ~ 90°, as shown in the pole figures. The angle between the compression axis and the c-axis decreases at ~ 40 GPa, probably due to deformation of the samples by differential stress. Although all the samples have c-axes concentrated approximately parallel to the compression axis of the DAC at ~ 80 GPa, the distribution patterns differ among the samples (Fig. 5c). The angle distributions of the samples transformed from single-crystal bcc iron are significantly different from the random angle distributions of hcp iron (Fig. 5d), as reported by Ohta et al. (2018).

Distribution of angles of the c-axis with respect to the compression axis of the DAC (α) under pressure conditions of a ~ 20 GPa, b ~ 40 GPa, and c ~ 80 GPa in this study. d Results for hcp iron produced from polycrystalline bcc iron (Ohta et al. 2018). The black dotted curve represents the theoretical random distribution of hcp iron

What further improvements are needed to make hcp iron with a stronger LPO at even higher pressures? Dewaele et al. (2023) first reported the synthesis of single-crystal hcp iron. These researchers succeeded in synthesizing good-quality single-crystal iron by using single-crystal bcc iron as the starting material and synthesizing hcp iron through a P–T pathway via face-centered cubic (fcc) iron. Dewaele et al. (2023) reported direct measurements of elastic constants of the synthesized single-crystal hcp iron up to 32 GPa. It is not known if this hcp iron single crystal could be maintained to higher pressures. With the recently developed rotational DAC (rDAC), the development of LPO according to the slip system of hcp iron can be achieved by the torsional deformation caused by the rotation of the diamond anvil (Azuma et al. 2017; Nomura et al. 2017; Park et al. 2022). For example, if the dominant slip system of hcp iron is (0001) < -12–10 > , as reported in previous studies (e.g., Merkel et al. 2013; Nishihara et al. 2018), then the rDAC can produce a microstructure where the (0001) normal is aligned in the compression direction and < -12–10 > is oriented in the deformation direction (i.e., rotation direction). In addition to its ability to control strain and strain rate, the rDAC causes torsional deformation of the sample (Azuma et al. 2017), enabling the realization of microstructures with various degrees of LPO along the radial direction from the sample’s rotational axis.

As shown in several previous studies (e.g., Ohta et al. 2018; Dewaele et al. 2023), various physical properties measured on iron with known crystallographic orientation contribute to the elucidation of the crystallographic anisotropy in iron properties. Compared to the results of Ohta et al. (2018), the present method synthesizes hcp iron at about 40 GPa, where the difference in LPO is more obvious (Fig. 5b,d). In other words, it is possible to determine the crystallographic orientation anisotropy of thermal conductivity with greater precision. Furthermore, measurement techniques of elastic wave velocity (or elastic constants) (e.g., Antonangeli et al. 2004; Dewaele et al. 2023; Lin et al. 2010; Wakamatsu et al. 2018, 2022) and elemental diffusivity (e.g., Park et al. 2023) for hcp iron with strong LPO will contribute to our understanding of the seismic anisotropy observed in the Earth’s inner core and its origin in the dynamics of the inner core.

In summary, in this study, we performed synchrotron multiangle XRD on statically compressed [100], [110], and [111] single-crystal bcc iron at pressures up to 80 GPa and 300 K in a DAC to characterize the LPO of hcp iron and its stability during further compression. Our data show the formation of textured polycrystalline hcp iron, in which the LPO of the hcp phase depends on the three crystallographic compression directions in the bcc phase. It was found that by applying pressure up to 80 GPa, the LPO of hcp iron was strongly affected by plastic deformation due to the uniaxial compression of the DAC. Further efforts to synthesize hcp iron with a stronger LPO at higher pressures are expected to improve our understanding of the velocity anisotropy of seismic waves and the heterogeneous structure of the Earth’s inner core.

Data availability

Data is available upon request.

References

Antonangeli D, Ohtani E (2015) Sound velocity of hcp-Fe at high pressure: experimental constraints, extrapolations and comparison with seismic models. Prog Earth Planet Sci 2:3

Antonangeli D, Occelli F, Requardt H, Badro J, Fiquet G, Krisch M (2004) Elastic anisotropy in textured hcp-iron to 112 GPa from sound wave propagation measurements. Earth Planet Sci Lett 225:243–251

Azuma S, Nomura R, Uesugi K, Nakashima Y, Kojima Y, Doi S, Kakizawa S (2017) Anvil design for slip-free high pressure deformation experiments in a rotational diamond anvil cell. High Pressure Res 38:23–31

Burgers WG (1934) On the process of transition of the cubic-body-centered modification into the hexagonal-close-packed modification of zirconium. Physica 1:561–586

Deuss A (2014) Heterogeneity and anisotropy of earth’s inner core. Annual Rev Earth Planet Sci 42:103–126

Dewaele A, Loubeyre P, Occelli F, Mezouar M, Dorogokupets PI, Torrent M (2006) Quasihydrostatic equation of state of iron above 2 Mbar. Phys Rev Lett 97:215504

Dewaele A, Denoual C, Anzellini S, Occelli F, Mezouar M, Cordier P, Merkel S, Véron M, Rausch E (2015) Mechanism of the α–ε phase transformation in iron. Phys Rev B 91:174105

Dewaele A, Amadon B, Bosak A, Svitlyk V, Occelli F (2023) Synthesis of single crystals of ε-iron and direct measurements of its elastic constants. Phys Rev Lett 131:034101

Fréville R, Dewaele A, Bruzy N, Svitlyk V, Garbarino G (2023) Comparison between mechanisms and microstructures of α−γ, γ−ε, and α−ε−α phase transitions in iron. Phys Rev B 107:104105

Hawreliak JA, Turneaure SJ (2021) Probing the lattice structure of dynamically compressed and released single crystal iron through the alpha to epsilon phase transition. J Appl Phys 129:135901

Hirao N, Ohishi Y (2022) X-ray focusing to 62 keV by compound refractive lenses for high-pressure x-ray diffraction. Rev Sci Instrum 93:083908

Hirao N, Kawaguchi SI, Hirose K, Shimizu K, Ohtani E, Ohishi Y (2020) New developments in high-pressure X-ray diffraction beamline for diamond anvil cell at SPring-8. Matter Radiat Extremes 5:018403

Ishimatsu N, Miyashita D, Kawaguchi SI (2020) Strong variant selection observed in the α−ε martensitic transition of iron under quasihydrostatic compression along [111]α. Phys Rev B 102:054106

Kadau K, Germann TC, Lomdahl PS, Holian BL (2002) Microscopic view of structural phase transitions induced by shock waves. Science 296:1681–1684

Kalantar DH, Belak JF, Collins GW, Colvin JD, Davies HM, Eggert JH, Germann TC, Hawreliak J, Holian BL, Kadau K, Lomdahl PS, Lorenzana HE, Meyers MA, Rosolankova K, Schneider MS, Sheppard J, Stolken JS, Wark JS (2005) Direct observation of the alpha-epsilon transition in shock-compressed iron via nanosecond x-ray diffraction. Phys Rev Lett 95:075502

Klotz S, Chervin JC, Munsch P, Le Marchand G (2009) Hydrostatic limits of 11 pressure transmitting media. J Phys D Appl Phys 42:075413

Lin J-F, Mao Z, Yavaş H, Zhao J, Dubrovinsky L (2010) Shear wave anisotropy of textured hcp-Fe in the Earth’s inner core. Earth Planet Sci Lett 298:361–366

Liu X, Mashimo T, Kawai N, Sano T, Zhou X (2018) Isotropic phase transition of single-crystal iron (Fe) under shock compression. J Appl Phys 124:215101

Lutterotti L, Chateigner D, Ferrari S, Ricote J (2004) Texture, residual stress and structural analysis of thin films using a combined X-ray analysis. Thin Solid Films 450:34–41

Lutterotti L, Vasin R, Wenk H-R (2014) Rietveld texture analysis from synchrotron diffraction images. I. Calibration basic analysis. Powder Diffr 29:76–84

Merkel S, Gruson M, Wang Y, Nishiyama N, Tomé CN (2012) Texture and elastic strains in hcp-iron plastically deformed up to 17.5 GPa and 600 K: experiment and model. Modelling Simul Mater Sci Eng 20:024005

Merkel S, Liermann HP, Miyagi L, Wenk HR (2013) In situ radial X-ray diffraction study of texture and stress during phase transformations in bcc-, fcc- and hcp-iron up to 36 GPa and 1000 K. Acta Mater 61:5144–5151

Merkel S, Lincot A, Petitgirard S (2020) Microstructural effects and mechanism of bcc-hcp-bcc transformations in polycrystalline iron. Phys Rev B 102:104103

Merkel S, Hok S, Bolme C, Rittman D, Ramos KJ, Morrow B, Lee HJ, Nagler B, Galtier E, Granados E, Hashim A, Mao WL, Gleason AE (2021) Femtosecond visualization of hcp-iron strength and plasticity under shock compression. Phys Rev Lett 127:205501

Miyagi L, Kunz M, Knight J, Nasiatka J, Voltolini M, Wenk HR (2008) In situ phase transformation and deformation of iron at high pressure and temperature. J Appl Phys 104:103510

Nishihara Y, Ohuchi T, Kawazoe T, Seto Y, Maruyama G, Higo Y, Funakoshi K-i, Tange Y, Irifune T (2018) Deformation-induced crystallographic-preferred orientation of hcp-iron: an experimental study using a deformation-DIA apparatus. Earth Planet Sci Lett 490:151–160

Nomura R, Azuma S, Uesugi K, Nakashima Y, Irifune T, Shinmei T, Kakizawa S, Kojima Y, Kadobayashi H (2017) High-pressure rotational deformation apparatus to 135 GPa. Rev Sci Instrum 88:044501

Ohta K, Nishihara Y, Sato Y, Hirose K, Yagi T, Kawaguchi SI, Hirao N, Ohishi Y (2018) An experimental examination of thermal conductivity anisotropy in hcp iron. Front Earth Sci 6:176

Park Y, Azuma S, Okazaki K, Uesugi K, Yasutake M, Nishihara Y, Nomura R (2022) Development of lattice-preferred orientations of MgO periclase from strain rate controlled shear deformation experiments under pressure up to 120 GPa. Geophys Res Lett 49:e2022GL100178

Park Y, Yonemitsu K, Hirose K, Kuwayama Y, Azuma S, Ohta K (2023) Viscosity of Earth’s inner core constrained by Fe–Ni interdiffusion in Fe–Si alloy in an internal-resistive-heated diamond anvil cell. Am Mineral 108:1064–1071

Romanowicz B, Wenk H-R (2017) Anisotropy in the deep earth. Phys Earth Planet Inter 269:58–90

Schmidt S (2013) GrainSpotter: a fast and robust polycrystalline indexing algorithm. J Appl Cryst 47:276–284

Secco RA, Balog PS (2001) On the possibility of anisotropic heat flow in the inner core. Can J Earth Sci 38:975–982

Seto Y, Ohtsuka M (2022) ReciPro: free and open-source multipurpose crystallographic software integrating a crystal model database and viewer, diffraction and microscopy simulators, and diffraction data analysis tools. J Appl Cryst 55:397–410

Smith RF, Fratanduono DE, Braun DG, Duffy TS, Wicks JK, Celliers PM, Ali SJ, Fernandez-Pañella A, Kraus RG, Swift DC, Collins GW, Eggert JH (2018) Equation of state of iron under core conditions of large rocky exoplanets. Nat Astron 2:452–458

Tateiwa N, Haga Y (2009) Evaluations of pressure-transmitting media for cryogenic experiments with diamond anvil cell. Rev Sci Instrum 80:123901

Tateno S, Hirose K, Ohishi Y, Tatsumi Y (2010) The structure of iron in Earth’s inner core. Science 330:359–361

Tkalčić H (2015) Complex inner core of the Earth: the last frontier of global seismology. Rev Geophys 53:59–94

Torikachvili MS, Kim SK, Colombier E, Bud’ko SL, Canfield PC (2015) Solidification and loss of hydrostaticity in liquid media used for pressure measurements. Rev Sci Instrum 86:123904

Wakamatsu T, Ohta K, Yagi T, Hirose K, Ohishi Y (2018) Measurements of sound velocity in iron-nickel alloys by femtosecond laser pulses in a diamond anvil cell. Phys Chem Miner 45:589–595

Wakamatsu T, Ohta K, Tagawa S, Yagi T, Hirose K, Ohishi Y (2022) Compressional wave velocity for iron hydrides to 100 gigapascals via picosecond acoustics. Phys Chem Miner 49:17

Wang K, Xiao S, Deng H, Zhu W, Hu W (2014) An atomic study on the shock-induced plasticity and phase transition for iron-based single crystals. Int J Plastic 59:180–198

Wenk HR, Matthies S, Hemley RJ, Mao HK, Shu J (2000) The plastic deformation of iron at pressures of the Earth’s inner core. Nature 405:1044–1047

Yadav CS, Seyfarth G, Pedrazzini P, Wilhelm H, Černý R, Jaccard D (2013) Effect of pressure cycling on iron: signatures of an electronic instability and unconventional superconductivity. Phys Rev B 88:054110

Acknowledgements

We thank Yasuo Ohishi, Naohisa Hirao, and Saori Kawaguchi-Imada for their help with the synchrotron experiments. Hans Rudolf Wenk and Sébastien Merkel kindly advised us on the texture analysis using MAUD. The synchrotron X-ray diffraction experiments were performed at the BL10XU of SPring-8 (proposal numbers 2019B1781 and 2020A1649). Constructive comments by anonymous reviewers are appreciated.

Funding

This work was supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI (Grant nos. 19H00716, 19H01995, and 18J21664).

Author information

Authors and Affiliations

Contributions

Y.P., T.W., S.A., and K.O. wrote the manuscript. All authors were involved in data interpretation. Y.P. and T.W. prepared the starting material. Y.P., T.W. and K.O. performed XRD measurements. Y.N. helped texture analysis by using MAUD. All authors participated in the discussion of results.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Park, Y., Wakamatsu, T., Azuma, S. et al. Characterization of the lattice preferred orientation of hcp iron transformed from the single-crystal bcc phase in situ at high pressures up to 80 GPa. Phys Chem Minerals 51, 31 (2024). https://doi.org/10.1007/s00269-024-01293-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00269-024-01293-6