Abstract

The locations of mining-induced horizontal fractures along rock interfaces in the overburden of Donetsk Coal Basin were identified using an original experimental device. The device traps methane from horizontal fracture zone (100–fold coal seam thickness) over an active longwall mining excavation. Presence or absence of horizontal fractures along rock layer interfaces is correlated with physical characteristics of the overburden, such as thickness, uniaxial compressive strength of overburden rock layers, location of rock layer interfaces and thickness of extracted coal seams. As a result, a combined criterion based on these physical characteristics is proposed to predict the presence of overburden horizontal fracturing in coal mine operations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

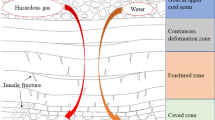

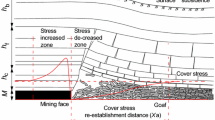

It is known (Karmis et al. 1983; Hasenfus et al. 1988; Whittaker and Reddish 1989; Kendorski 1993; Chekan and Listak 1993; Palchik 2003) that there are three distinct zones (caved zone, fractured zone and continuous deformation zone) of movement in the overburden strata appearing in response to longwall mining (see Fig. 1a; Palchik 2003). In the caved zone located immediately above underground workings, rock layers fall to the mine floor and are broken into irregular shapes of various sizes (Kratzsch 1983; Palchik 2002a). Above the caved zone is the fractured zone, which can be divided into three parts: rock blocks, through-going vertical fractures and horizontal fractures caused by bedding layer separation. In the lower part of the fractured zone (Fig. 1b), rock layers are broken into blocks by through-going vertical fractures and horizontal fractures due to bed separation. In the middle part of the fractured zone (Fig. 1c), there are also horizontal fractures due to bed separation, whereas the number of through-going vertical fractures is less than in the lower part of the fractured zone. In the upper part of the fractured zone (Fig. 1d), the formation of vertical fractures through the thickness of rock layers does not occur, and there are only separate horizontal fractures along weak-strong rock layer interfaces. The thickness of the fractured zone varies greatly amounting to 20 to 100-fold seam thickness (Turchaninov et al. 1977; Peng 1992; Palchik 2003). The zone above the fractured zone is a continuous deformation zone without any major fractures.

Scheme of movement in overburden strata: a all zones of movement (after Palchik 2003); b lower part (rock blocks) of fractured zone; c middle part (through–going vertical fractures) of fractured zone; (d) upper part (separate horizontal fractures) of fractured zone

Horizontal fractures along weak–strong rock layer interfaces play an important role in the movement of an overburden, since they are natural planes of weakness in which separation occurs at overburden lamination. The formation process, thickness and location of horizontal fractures may influence the value and duration of rock mass and ground surface subsidence. Moreover, these fractures are sources of methane and concentrators of maximum tensile deformations, which may be dangerous for mining constructions.

Palchik (2003) has shown that the extent of fractured zone induced by mining can be determined basing the change in natural methane emission from this zone. Mathematical models (Palchik 2002b) were proposed to describe the process of methane emission from fractured zone in time. Field measurements (Palchik 2003) of the extent of fractured zone were performed using the method of tampion. The tampion is moved along a vertical gas well and can block the latter above and below the fractured zone in order to measure gas emission from this zone. As a result, the following extents of the fractured zone were defined:

-

Height of the zone of interconnected fractures (combined thickness of the caved zone and the lower and middle parts of the fractured zone (see Fig. 1a), where horizontal and vertical through-going fractures are interconnected and form a system of through channels.

-

Location of separate horizontal fractures in the upper part (Fig. 1d) of fractured zone.

However, localization of horizontal fractures in lower (Fig. 1b) and middle (Fig. 1c) parts of fractured zone was not performed, since at use of the method of tampion, gas gets into gas meter from several outlets of system of through channels in zone of interconnected fractures.

This paper presents a new approach to the localization of horizontal fractures along rock layer interfaces in all three parts of the fractured zone. In this study, methane is trapped from each of horizontal fractures within rock mass over underground workings. Further, the presence or absence of horizontal fractures is correlated with uniaxial compressive strength and thickness of rock layers, distances from extracted coal seam to rock layer interfaces and thickness of extracted coal seams. Finally, a criterion for predicting the presence of horizontal fracture along a rock layer interface based on the above-mentioned physical characteristics is proposed.

New approach to localization of horizontal fractures

Experimental device

The design of an experimental device used for detecting horizontal fractures along rock layer interfaces above mined coal seams is presented in Fig. 2. A vertical gas well drilled from the ground surface to the mined coal seam is equipped with a plastic casing pipe, and the space between the casing pipe and gas well is filled with cement mortar. The casing pipe is perforated. In order to trap methane from horizontal fractures, a packer-trap with two lateral diametrically opposite openings is used (see Figs. 2 and 3). The plastic packer-trap is moved along vertical mortises in the casing pipe (see Fig. 4) with the help of a lifting rope connected with a hosting drum at the ground surface. Volumetric flow rate of methane emission (v, m3/min) from the packer-trap is measured by gas meter (portable wind-wheel anemometer), which is located at the ground surface. A plastic pipe connects the gas meter to the packer-trap.

Experimental procedure

First the packer-trap is lowered with the help of a lifting rope into the gas well at the top rock layer interface within the limit height of the fractured zone (100-fold coal seam thickness). Top rock layer interface and limit height of fractured zone (HL =100 m) are shown in Fig. 7. Volumetric flow rate of methane emission (v, m3/min) from the packer-trap at the top rock layer interface is measured by a gas meter at the well-head (ground surface). Then the packer-trap is lowered at a neighbouring rock layer interface and gas emission from the packer-trap to a gas meter is again measured. Thus, the packer-trap is moved from upper to lower rock layer interfaces in the direction of the extracted coal seam. Installation of the packer-trap and measurement of methane emission from the packer-trap are performed at each of rock layer interfaces located within 100 m above the underground workings.

The process of horizontal fracture formation along weak–strong rock layer interface is accompanied by the subsidence of rock layer interface. In fact, the thickness (ψ) of horizontal fracture can be presented as a difference between a large subsidence of top boundary of weak rock layer (ηb) below the interface and a relatively small subsidence of the bottom boundary of strong rock layer (ηa) above the interface (see Fig. 5). Such subsidences lead to the formation of cracks in cement mortar in gas wells directly at the rock layer interface where horizontal fracture is formed. Methane from horizontal fracture passes through cracks in cement mortar and then penetrates into the packer-trap through lateral diametrically opposite openings. Volumetric flow rate of methane emission (v, m3/min) from the packer-trap is measured by gas meter at the ground surface. If there is no horizontal fracture along the rock layer interface, cracks in mortar at the rock layer interface are not formed, methane does not penetrate into the packer-trap, and the gas meter at the ground surface shows that v = 0.

The formation of through-going vertical fractures in rock mass is not associated with rock layer interface and does not cause fracture of cement mortar immediately at the rock layer interface. Naturally, vertical fractures may feed methane to horizontal fractures away from gas well, that is, always there is a system of though channels in zone of interconnected fractures. However, in case of use of proposed device, horizontal fracture is the only outlet of the system of through channels through which gas gets into gas meter. If the outlet is open (presence of horizontal fracture) gas meter shows gas flow. When the outlet is close (absence of horizontal fracture), gas flow is zero.

Results of field measurements

Field measurements of locations of horizontal fractures along the rock layer interfaces above underground workings were performed in Donetsk Coal Basin (Ukraine) in ten gas wells 280–450 m deep. Overburden in all observed gas wells consists of layers of limestone, sandstone, calcareous shale, sandy shale and bone coal. For example, Fig. 6 demonstrates the location of horizontal fractures in gas wells# 1345, 5345 and 10789 after all horizontal fractures (within 100 m above the extracted coal seam) were formed. From Fig. 6 it is clear that the overburden in gas wells# 1345, 5345 and 10789 has two, five and four horizontal fractures along rock layer interfaces, respectively. Rock layers above horizontal fractures consist of strong sandstone and limestone, whereas rock layers below these fractures consist of weak sandy shale, bone coal and calcareous shale. Distance from the extracted coal seam to the horizontal fracture is 23. 1 and 45 m; 19.6, 39.9, 54.3, 91.9 and 149.4 m; and 15.4, 71.2, 95.6 and 127.9 m in gas wells# 1345, 5345 and 10789, respectively. Distance between neighbouring horizontal fractures is 22.4 m, 20.3–57.7 m and 24.4–55.8 m in gas wells# 1345, 5345 and 10789, respectively.

Figure 7 presents a schematic geological profile of overburden showing observed thicknesses of rock layers and distances from extracted coal seam to rock layer interfaces. Here, 1, ..., i−1, i, i+1, ..., n is the number of rock layer interface: 1st rock layer interface is the lowest interface above the caved zone, whereas nth rock layer interface is the top layer interface within 100 m above the extracted coal seam; H1,..., Hi-1, H i ,Hi+1,..,Hn is the distance from extracted coal seam to the 1st,..., (i−1)th, ith, (i+1)th, ..., nth rock layer interface, respectively; ha(1), ..., ha(i-1), ha(i) and ha(i+1)is the thickness of rock layer above the 1th, ..., (i−1)th, ith and (i+1)th rock layer interface, respectively; hb(i-1), hb(i), hb(i+1)and hb(n) is the thickness of rock layer below the (i−1)th, ith, (i+1)th and nth rock layer interface, respectively; m is the thickness of extracted coal seam; hd is the thickness of the so-called “layer-bridge” which is the stiffest rock layer within the limit height (HL=100 m) of fractured zone.

The samples for uniaxial compressive testing were extracted from each the of rock layers within 100 m over underground workings in all ten gas wells. Uniaxial compressive strength (σa(1), ..., σa(i-1), σa(i), σa(i+1), ..., σa(n)) of rock layer above the 1st, ..., (i−1)th, ith, (i+1)th, ..., nth rock layer interface, respectively, and uniaxial compressive strength (σb(i-1), σb(i), σb(i+1), ..., σb(n)) of rock layer below the (i−1)th, ith, (i+1)th and nth rock layer interface, respectively, were tested.

Values of H, ha, σa, ha, σb and hb and the presence or absence of horizontal fractures for all rock layer interfaces within 100 m above the extracted coal seam in all ten examined gas wells are presented in Table 1. The latter also includes values of extracted coal seams (m) and thickness of “layer -bridge” (hd) in each of ten gas wells under study. The value of H ranges from 9.8 to 164.7, and the thickness (m) of extracted coal seam is between 0.8 m and 1.6 m. Thickness (ha and hb) and uniaxial compressive strength (σa and σb) of rock layers range from 0.9 m to 44.7 m and from 7 MPa to 99.1 MPa, respectively. Thickness of rock “layer-bridge” (hd) varies from 10.1 m to 44.7 m.

Observations of presence or absence of horizontal fractures in overburden

Presence or absence of horizontal fractures along rock layer interface at different H/m and distances (H) from the rock layer interface to extracted coal seam is shown in Fig. 8. Here, all 79 rock layer interfaces observed in ten gas wells are presented, 30 of them having horizontal fractures. As can be seen from Fig. 8, although the number of horizontal fractures decreases above H/m=75, three (marked by the values of H/m) horizontal fractures exist at large H/m=85.3, 93.4 and 97.2. These three horizontal fractures (H=127.9 m in gas well# 10789, H=149.4 m in gas well# 5345 and H=131.2 m in gas well# 7679, respectively) were formed along rock layer interfaces where the rock layer above the interface has a high uniaxial compressive strength (σa = 79, 45.1 and 34.6 MPa, respectively), whereas the rock layer below the interface exhibits a relatively low uniaxial compressive strength (σb = 11, 9 and 14.5 MPa, respectively). Thickness of the layer above the interface (ha = 8, 15.3 and 23.5 m, respectively) is also larger than the thickness of the layer below the interface (hb = 2, 13.7 and 1.6 m, respectively). This fact suggests that not only the value of H/m, but also the ratio between physical properties of rock layers above and below the interface, may influence the presence or absence of fracture along rock layer interface.

Figure 9 shows the presence or absence of horizontal fracture at different values of ratio σa/σb multiplied by ratio ha/hb and different distances (H) from rock layer interface to extracted coal seam. Value of (σa/σb) (ha/hb) is between 0.018 and 300. As can be seen from Fig. 9, probability of the presence of fractures increases with increasing (σa/σb) (ha/hb). When small 0.018 < (σa/σb) (ha/hb) < 2, only one presence and 46 absences of horizontal fracture were observed. When 2 < (σa/σb) (ha/hb) < 5.5, there are 11 presences of horizontal fracture and only 3 absences of horizontal fracture. At large values of (σa/σb) (ha/hb) = 5.5 – 300, 18 horizontal fractures are observed and there are no rock layer interfaces where fractures are absent.

Observed presence or absence of horizontal fracture along rock layer interface at different values of (σa/σb) (ha/hb) and different distances (H) from rock layer interface to extracted coal seam. P presence of fracture and A absence of fracture: a 0 < (σa/σb) (ha/hb) < 40, b 40 < (σa/σb) (ha/hb) < 300

Field measurements of subsidence of undermined rock mass (Palchik 1989, 2000) show that the subsidence of rock layers of overburden and separation at laminations and formation of fractures along rock layer interfaces may be restrained by thick and strong rock layers of overburden. One of such rock layers is the so-called “layer-bridge” (see Fig. 7), which is the stiffest layer in the overburden and has the largest value of h×σ among others rock layers within the distance of 100 m over underground workings. Figure 10 shows presence or absence of horizontal fracture at different ratio between the thickness of “layer-bridge” (hd) and thickness of rock layer (ha) above interface and different distances (H) from rock layer interface to extracted coal seam. Value of hd/ha ranges from 0.73 to 38.5. As can be seen from Fig. 10, probability of the presence of fractures decreases with increasing hd/ha. When 0.73 < hd/ha < 2.5, 27 presences and 17 absences of horizontal fracture were observed. When 2.5 < hd/ha < 6, only 3 presences and 16 absences of horizontal fracture were observed. At large 6 < hd/ha < 38.5, there are no horizontal fractures, and same number (n=16) of rock layer interfaces without horizontal fractures were observed.

Thus, Figs. 8, 9, 10 demonstrate a combined influence of H/m, value of (σa/σb) (ha/hb), and ratio between hd and ha on the probability of the presence of horizontal fracture along the rock layer interface.

Criterion for predicting the presence of horizontal fracture

Observations of presence or absence of horizontal fractures at different physical characteristics of overburden show that:

-

Probability of the presence of horizontal fracture along rock layer interface increases with increasing (σa/σb) (ha/hb). The larger the difference between physical characteristics of strong rock layer above and weak rock layer below the interface, the higher the probability of the presence of horizontal fracture along the rock layer interface.

-

On the other hand, the probability of the presence of horizontal fracture along rock layer interface decreases with increasing H/m and hd/ha.

Palchik (1989) has found that the thickness of horizontal fractures along rock layer interface in overburden increases with increasing value of ξ = f(A) (m/H)0.5, where parameter A reflects the combined influence of physical characteristics of overburden, and (m/H)0.5 reflects the combined influence of extracted coal seam and location of rock layer interface. We assume that ξ value may also be used for predicting the presence of horizontal fractures. In this case, we may suggest that the parameter A = (σa/σb) (ha/hb), since the value of (σa/σb) (ha/hb) influences the probability of the presence of fractures, as shown above. Thus, the expression of ξ for possible prediction of the presence of horizontal fractures may be:

where f (A) is an implicit function of A, A = (σa/σb) (ha/hb).

Since an increase in ξ contributes to the formation of fractures, whereas an increase in the ratio of hd/harestrains the formation of fractures, the relationship suggests that the formation of fracture along rock layer interface occurs when the following inequality is satisfied:

Here

where a is an unknown statistical coefficient.

Inequality 2 may be used to predict the presence of horizontal fractures only when the value of coefficient a (Eq. 3) and explicit function f(A) (Eq.1) are known. Inserting initially assumed values of a = 0.1, 0.2, ...1 and then 0.01, 0.02, ..., 0.1 into Eq.3 using a statistical method of successive approximations and then comparing calculated values of λ with values of ξ = exp (A)(m/H)0.5, ξ = ln(A)(m/H)0.5, ξ = kA(m/H)0.5 and ξ = Ak (m/H)0.5, establishes that the inequality ξ > λ is satisfied in the presence of all 30 horizontal fractures when ξ = ln (A) (m/H)0.5 and at the value of a = 0.07.

Comparison of the values of ξ = ln (A)(m/H)0.5 and λ (Eq. 3, a = 0.07) for each of all 79 observed rock layer interfaces in ten gas wells is presented in Fig. 11. Values of ξ range from −0.53 to 1.68, while the value of λ is between 0.07 and 2.69.

Inserting ξ = ln (A)(m/H)0.5 and Eq. 3 in Eq. 2, gives the final criterion for predicting the presence of horizontal fracture along rock layer interface:

where H is the distance from extracted coal seam to rock layer interface; m is thickness of extracted coal seam; σa and σb are uniaxial compressive strengths of rock layers above and below rock layer interface, respectively; ha and hb are thicknesses of rock layers above and below rock layer interface, respectively; hd is thickness of rock “layer - bridge” within the distance of 100 m from extracted coal seam; a = 0.07 is a derived statistical coefficient.

Thus, the criterion for predicting the presence of horizontal fracture along rock layer interface is based on four ratios between:

-

Uniaxial compressive strength of rock layers above and below rock layer interface.

-

Thickness of rock layers above and below rock layer interface.

-

Thickness of the stiffest rock layer (within the limit height of fractured zone) and thickness of rock layer above rock layer interface.

-

Thickness of coal seam and distance from extracted coal seam to rock layer interface.

Value of K (Eq. 4) is shown graphically in Fig. 12 for all observed rock layer interfaces. Here, the value of K is between −3.07 and 1.61. From Fig. 12 it is clear that the horizontal fracture along rock layer interface is formed only when inequality (Eq. 4) is satisfied (i.e. K > 0). Otherwise, rock layer interface does not have horizontal fracture.

Conclusion

Localization of mining-induced horizontal fractures along rock layer interfaces in the overburden was performed by trapping methane from an overburden in Donetsk Coal Basin. A packer-trap used in this study traps methane directly from each of horizontal fractures within the limit height of fractured zone over active underground workings in order to define more precisely the locations of these fractures.

Formation of horizontal fractures occurs along weak–strong rock layer interfaces at a distance between 12.9 m and 149.4 m from the extracted coal seam. Number of horizontal fractures within the limit height of fracture zone ranges from 2 to 5, and the distance between neighbouring horizontal fractures is between 5.7 m and 59.7 m.

Presence or absence of horizontal fractures at different physical characteristics of the overburden are observed. A criterion for predicting the presence of horizontal fractures is proposed. It is based on four ratios between:

-

Uniaxial compressive strength of rock layers above and below rock layer interface,

-

Thickness of rock layers above and below rock layer interface,

-

Thickness of the stiffest rock layer (within the limit height of fractured zone) and thickness of rock layer above the rock layer interface and

-

Thickness of coal seam and distance from extracted coal seam to the rock layer interface.

References

Chekan G, Listak J (1993) Design practices for multiple-seam longwall mines. Information Circular 9360. US Bureau of Mines, Pittsburgh PA, p 35

Hasenfus GJ, Johnson KL, Su DWH (1988) A hydrogeomechanical study of overburden aquifer response to longwall mining. In: Proceedings of the 7th Conference of Ground control in mining. West Virginia University, Morgantown, pp 144–152

Karmis M, Triplett T, Haycocks C, Goodman G (1983) Mining subsidence and its prediction in an Appalachian coalfield. In: Proceedings of the 24th US symposium on Rock mechanics. Balkema, Rotterdam, pp 665–675

Kendorski FS (1993) Effect of high-extraction coal mining on surface and ground waters. In: Proceedings of the 12th Conference on ground control in mining. West Virginia University, Margantown

Kratzsch H (1983) Mining subsidence engineering. Springer, Berlin Heidelberg New York

Palchik V (1989) Analytical and empirical prognosis of rock foliation in rock mass. J Coal Ukraine 7:45–48

Palchik V (2000) Prediction of hollows in abandoned underground workings at shallow depth. Geotech Geol Eng 18(1):39–51

Palchik V (2002a) Influence of physical characteristics of weak rock mass on height of caved zone over abandoned subsurface coal mines. Environ Geol 42(1): 92–101

Palchik V (2002b) Use of Gaussian distribution for estimation of gob gas drainage well productivity. Math Geol 34(6): 743–765

Palchik V (2003) Formation of fractured zones in overburden due to longwall mining. Environ Geol 44(1): 28–38

Peng SS (1992) Surface subsidence engineering. Society for Mining, Metallurgy and Exploration Inc., Lilleton

Turchaninov IA, Iofis MA, Kasparian EV (1977) Principles of rock mechanics. Nedra, Leningrad

Whittaker BN, Reddish DJ (1989) Subsidence: occurrence, prediction and control. Elsevier Science, Barking

Acknowledgements

I thank the anonymous reviewer for his valuable comments which helped to improve the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palchik, V. Localization of mining-induced horizontal fractures along rock layer interfaces in overburden: field measurements and prediction. Environ Geol 48, 68–80 (2005). https://doi.org/10.1007/s00254-005-1261-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00254-005-1261-y