Abstract

Previous studies have shown that enhanced biological phosphorus removal (EBPR) performance under continuous aerobic conditions always eventually deteriorates; however, the speed at which this happens depends on the carbon source supplied. The published data suggest that propionate is a better carbon source than acetate is for maintaining operational stability, although it is not clear why. A lab-scale sequencing batch reactor was run initially under conventional anaerobic/aerobic conditions with either acetate or propionate as the carbon source. Chemical and microbiological analyses revealed that both sources performed as expected for such systems. When continuous aerobic conditions were imposed on both these established communities, marked shifts of the “Candidatus Accumulibacter” clades were recorded for both carbon sources. Here, we discuss whether this shift could explain the prolonged EBPR stability observed with propionate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Enhanced biological phosphorus removal (EBPR) is an economically and environmentally attractive process to remove phosphorus (P) from wastewater. In the conventional processes, the biomass is cycled through carbon-rich anaerobic and carbon-deficient aerobic phases. These treatment systems, in principal, enrich the environment for growth of the so-called polyphosphate accumulating organisms (PAO) (Mino et al. 1998; Blackall et al. 2002; Seviour et al. 2003; Oehmen et al. 2006) by providing conditions that encourage the anaerobic production of polyhydroxyalkanoate (PHA) and its subsequent aerobic oxidation, thus supplying energy for the accumulation and synthesis of intracellular polyphosphate (polyP) granules. Net P removal is achieved by wasting sludge after the aerobic phase (Mino et al. 1998; Blackall et al. 2002; Seviour et al. 2003; Oehmen et al. 2006).

The traditional metabolic models for the PAO in EBPR systems involve the anaerobic uptake of organic substrates, preferably volatile fatty acids (VFAs), from wastewater and their intracellular storage as PHA. The reducing equivalents and energy to synthesize PHA are provided mainly by glycolysis of internally stored glycogen reserves and hydrolysis of intracellular polyP (Mino et al. 1987). In the subsequent aerobic zone, PAO assimilate orthophosphate from the bulk liquid to synthesize intracellular polyP in excess of that hydrolyzed under anaerobic conditions. The PAO grow aerobically and replenish their glycogen stores, using their PHA stores as carbon and energy sources (Arun et al. 1988; Smolders et al. 1995).

Thus, PAO are thought to achieve dominance in this anaerobic-aerobic process because they can grow aerobically in the absence of any exogenous carbon and energy sources by using the PHA accumulated anaerobically (Seviour et al. 2003). Higher and more stable EBPR performance is usually achieved with propionate rather than acetate as the anaerobic supplied substrate, (Seviour and Nielsen 2010), although some claim the opposite (Shen et al. 2017). Although the anaerobic phase is considered essential for conventional EBPR, some studies have reported successful removal of P under strictly aerobic conditions in lab-scale reactors (Ahn et al. 2002; Guisasola et al. 2004; Pijuan et al. 2005; Ahn et al. 2007). Intermittent supply of carbon creates feast-famine phases (Beun et al. 2000; Dircks et al. 2001) analogous to those imposed in traditional EBPR processes (Guisasola et al. 2004). However, the successful removal of P under such conditions appears unsustainable over long periods (Pijuan et al. 2006).

Glycogen accumulating organisms (GAO) are also often present in EBPR systems and can store organic substrates as PHA under anaerobic/feast conditions. Unlike in the PAO, the reducing equivalents and energy to synthesize PHA in GAO are provided mainly by glycolysis of their internally stored glycogen reserves, and not from hydrolysis of intracellular polyP (Liu et al. 1996; Oehmen et al. 2006). Their glycogen reserves are replenished from stored PHA under aerobic/famine conditions, under which they grow, but no intracellular polyP is produced. Therefore, GAO may compete with PAO for organic substrates as carbon sources under anaerobic/feast conditions (Liu et al. 1996), and their proliferation and dominance lead to a corresponding deterioration in biomass EBPR capacity (Crocetti et al. 2002; Meyer et al. 2006; Schroeder et al. 2008; Schroeder et al. 2009).

Carbon source composition is one factor suggested to have considerable impact on EBPR stability (Vargas et al. 2009). Propionate is considered a better carbon source than acetate for conventional EBPR, and is thought to provide PAO with a competitive advantage over GAO (Oehmen et al. 2006). Furthermore, propionate-enriched PAO populations developed under conventional EBPR conditions appeared to maintain biological phosphate removal under strict aerobic conditions for a longer period (46 days) than acetate-enriched PAO populations did (11 days) (Vargas et al. 2009; Pijuan et al. 2006). However, the advantages, if any, that propionate confers on the PAO under continuous aerobic conditions are still unclear (Vargas et al. 2009).

Improvements in our understanding of the mechanisms underlying such advantages in the propionate system may lead to improved knowledge-based control of EBPR systems and their development as “add-ons” to treatment plants that do not remove P. This would represent a cost-effective and environmentally friendly alternative to the construction of new EBPR plants or the currently applied chemical removal methods (Ahn et al. 2007). Several studies suggest that a phylogenetic diversity exists among the PAO population (Seviour and Nielsen 2010). In particular, PAO belonging to “Candidatus Accumulibacter” (hereafter Accumulibacter) fall into two types (types I and II) (McMahon et al. 2007), which are further grouped into 14 clades (IA-E and IIA-I), based on their polyphosphate kinase gene (ppk) sequences (He et al. 2007; Peterson et al. 2008; Mao et al. 2015; Skennerton et al. 2015; Zhang et al. 2016). Recent studies have also described quantitative PCR (qPCR) assays for members of each current clade of Accumulibacter (He et al. 2007; Ong et al. 2014; Zhang et al. 2016; Camejo et al. 2016). In this study, we operated a lab-scale EBPR reactor, using either acetate or propionate as the major carbon source, under anaerobic-aerobic and subsequent continuous aerobic conditions, and any population shifts among individual Accumulibacter clades associated with changes in EBPR performance were analyzed using qPCR assays.

Materials and methods

Sequencing batch reactor operation

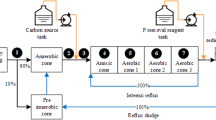

A lab-scale sequencing batch reactor (SBR) with a working volume of 4 L was operated with separate dosing of acetate and propionate as carbon sources. The activated sludge inoculum for the SBR was obtained from an anaerobic-anoxic-aerobic (A2O) biological nutrient removal plant (Yokohama, Japan) treating municipal wastewater. Note that the acetate-fed sludge was discharged before propionate-fed operation. The SBR was first run under alternating anaerobic-aerobic conditions for 33 days with acetate (Run A1) and 46 days with propionate (Run P1) to stabilize EBPR performance. It was then operated under strictly aerobic conditions for the next 20 days with acetate (Run A2) and 39 days with propionate (Run P2). The SBR was operated in a water bath at 20 °C on a 6-h cycle consisting of feed (10 min), alternating anaerobic feast phase (120 min) and aerobic famine phase (190 min) or a single aerobic famine phase (310 min), settling (30 min), and discharge of supernatant (10 min). SRT and HRT were controlled at 8 days and 12 h, respectively. The same reactor volume was maintained by discarding 125 mL of mixed liquor during the aerobic reaction period of each cycle before settling, and 1.75 L of supernatant was removed at the discharge period of each cycle. Bulk liquid dissolved oxygen (DO) concentrations were measured using a galvanic DO probe (DO-24P, DKK-TOA, Tokyo, Japan) and controlled at < 0.10 mg L−1 during the anaerobic feast phase, by turning nitrogen gas on at the beginning of the phase, and at > 2.0 mg L−1 during the aerobic phase, by turning the air from the diffuser on and off as required. The pH was controlled at 7.0 ± 0.1 with 0.5 M HCl/H2SO4 and 0.5 M NaOH, using a pH controller (TPX-98 with FX-300H probe, TOKO, Tokyo, Japan).

Synthetic wastewater

The synthetic wastewater had a similar composition to that used by Nittami et al. (2011), consisting of two separate concentrated solutions, “C-solution” and “P-solution.” The C-solution contained the following ingredients (g L−1 milli-Q water): acetate (CH3COONa), 10.9 or propionate (CH3CH2COONa), 8.51; peptone, 0.5; NH4Cl, 0.84; MgSO4∙7H2O, 1.8; MgCl2∙6H2O, 3.2; CaCl2∙2H2O, 0.84; Bacto yeast extract, 0.4; allylthiourea, 0.01; and a nutrient solution (12 mL) that consisted of (g L−1 milli-Q water): EDTA, 10; ZnSO4∙7H2O, 0.12; MnCl2∙4H2O, 0.12; CoCl2∙6H2O, 0.15; CuSO4∙5H2O, 0.03; FeCl3∙6H2O, 1.5; H3BO4, 0.15; KI, 0.18; NaMoO4∙2H2O, 0.06. The P-solution contained only KH2PO4, 2.46 g L−1 in milli-Q water. The C-solution and P-solution were sterilized separately by autoclaving. At the beginning of the feed period, 100 mL of C-water and 100 mL of P-water were added together to the SBR with 1.8 L of tap water (1:20 dilution). Thus, the initial acetate and P concentration in each cycle were set to 79.8 mg-C L−1 and 14.0 mg-P L−1.

Chemical analysis

CH3COO− and CH3CH2COO− in filtered activated sludge samples were measured using an LC-10A HPLC with a Shim-pack IC-A3 column (Shimadzu, Kyoto, Japan) and Shim-pack SPR-H column (Shimadzu, Kyoto, Japan), respectively. P was analyzed as phosphate in filtered samples and total P (TP) concentration in the mixed liquor after persulfate digestion, using the ascorbic acid method (APHA 1998). MLSS was also determined according to standard methods (APHA 1998). PolyP content of activated sludge biomass during each cycle was also calculated as follows: (average TP concentration during one cycle − phosphate concentration at the end of the aerobic famine phase)/MLSS. Concentrations of biomass PHAs (PHB, PHV, and PH2MV) were quantified using gas chromatography/mass spectrometry (GC/MS), as in a previous study (Mikami et al. 2013). Biomass glycogen levels were also quantified, using the Glucose CII-test kit (Wako, Osaka, Japan), as in the previous study (Mikami et al. 2013).

Activated sludge samples, fixation, and DNA extraction

Activated sludge mixed liquor samples were collected from the acetate- and propionate-fed SBRs on days 1 and 11 in Run A2, 33 in Run P1, and 39 in Run P2. The samples were fixed on site in 4% (w/v) paraformaldehyde (PFA), and then stored at − 20 °C before FISH analysis (in the “Fluorescence in situ hybridization” section). A 1-mL aliquot of mixed liquor collected from the acetate reactor on days 1, 33 (Run A1), and 8 (Run A2) and the propionate reactor on days 1, 46 (Run P1), 21, and 39 (Run P2) were washed with Tris-EDTA buffer (T10E1, pH 8.0) and stored at − 20 °C prior to DNA extraction. DNA extractions were performed using the FastDNA SPIN Kit for soil (Qbiogene, CA, USA) and stored at − 20 °C prior to real-time PCR analysis after measuring the DNA concentration using a spectral photometer NanoDrop ND-2000 spectrophotometer (NanoDrop Technologies, Wilmington, DE, USA).

Fluorescence in situ hybridization

Fluorescence in situ hybridization (FISH) was performed as detailed by Daims et al. (2005), using the oligonucleotide probes listed in Table 1. The probes were labeled with Cy3 or Fluos fluorochromes purchased from Proligo (Sydney, NSW), Nippon Gene (Tokyo, Japan), and Rikaken (Nagoya, Japan). Slides were air dried, mounted in Vectashield® (Vectashield Laboratories, Burlingame, CA), and then viewed on a BX51 epifluorescence microscope (Olympus, Tokyo, Japan).

Real-time PCR

Real-time PCR targeting the 16S rRNA genes of general bacteria and Accumulibacter as well as ppk1 of Accumulibacter clades I, IIA, IIC, IID, and IIF was performed according to a previous study (Ong et al. 2014), using DNA extracted from activated sludge samples. Reactions were performed on a Thermal Cycler CFX 96 Real-Time PCR Detection System (BioRad, USA). Amplification reactions were carried out using the iQ™ SYBR®Green Supermix (BioRad, USA) in a total volume of 20 μL with primer sets targeting the general bacteria 16S rRNA gene, Accumulibacter 16S rRNA gene, and ppk1 genes of Accumulibacter clades I, IIA, IIC, IID, and IIF (Table 1). Each reaction mixture (20 μL) contained 5 ng of template DNA, 10 μL of iQ™ SYBR®Green Supermix, and 0.5 μM of each primer. The optimized temperature programs were as follows: a denaturation (95 °C for 3 min), and 40 cycles of amplification and quantification (94 °C for 30 s, annealing temperature as listed in Table 1 for 45 s, and 72 °C for 30 s). All measurements were performed in triplicate for each run. Standard curves were constructed using the plasmids extracted from Accumulibacter clones belonging to the clades I, IIA, IIC, IID, and IIF obtained in a previous study (Ong et al. 2014). The initial concentrations of the plasmid DNA were measured using a NanoDrop ND-2000 spectrophotometer, and the copy numbers of the 16S rRNA genes of general bacteria and Accumulibacter as well as ppk1 of Accumulibacter clades I, IIA, IIC, IID, and IIF in the plasmid DNAs were calculated as reported previously (Dhanasekaran et al. 2010).

Results

EBPR in acetate-fed reactor

Anaerobic-aerobic operation (Run A1)

The SBR was run under an anaerobic-aerobic operation regime using acetate as the major carbon source for 33 days, before switching to continuous aerobic operation (Run A2). Figure 1a shows the reactor performance on day 33. In the anaerobic period, the dosed acetate was completely consumed, and 36 mg-P (as phosphate) g-MLSS−1 was released into the bulk water. In the following aerobic period, 43 mg-P g-MLSS−1 was removed from the bulk liquid and net P removal was achieved. These transformations are typical of an EBPR biomass and were observed after day 16.

Continuous aerobic operation (Run A2)

The acetate SBR was then run under continuous aerobic operation for 20 days. Figure 1b shows the reactor performance on day 1, where the dosed acetate was completely consumed within the initial 10 min of the cycle. After 20 min, 10 mg-P (as phosphate) g-MLSS−1 had been released into the bulk water, 18 mg-P g-MLSS−1 was removed from the bulk liquid, and net P removal was achieved. This trend was similar to that observed with acetate under continuous aerobic conditions in previous studies (Guisasola et al. 2004; Pijuan et al. 2005, 2006), and analogous to that in the anaerobic-aerobic periods of Run A1 (Fig. 1a).

However, the chemical transformations after 11 days showed marked differences compared to those for day 1 in Run A2 (Fig. 1c). In both cycles, the acetate consumption ratios were similar, but on day 11, 4.7 mg-P g-MLSS−1 remained at the end of the cycle, despite the feed P release (16 mg-P g-MLSS−1) and famine uptake (26 mg-P g-MLSS−1) during the first 20 min of the cycle being higher than those recorded on day 1.

The last cycle under continuous aerobic conditions on day 20 (Fig. 1d) showed further changes. Similar acetate consumption rates to those seen on days 1 and 11 (Fig. 1b, c) were seen. However, P release during the feast phase (6.2 mg-P g-MLSS−1) and P uptake during the famine phase (7.0 mg-P g-MLSS−1) were both lower than those recorded on days 1 and 11. In addition, the switch from P release to P uptake, which occurred after approximately 10 min, occurred earlier than that on days 1 and 11 (Fig. 1b, c). Moreover, no net P removal was achieved and > 10 mg-P g-MLSS−1 remained at the end of the cycle on day 20.

EBPR in propionate-fed reactor

Anaerobic-aerobic operation (Run P1)

After the acetate-fed sludge in Run A2 (in the “EBPR in acetate-fed reactor” section) was removed from the SBR, anaerobic-aerobic operation using a new inoculum and propionate as the major carbon source was performed for 46 days (Run P1). Figure 2a shows the reactor performance on day 46. In the anaerobic feed cycle period, the dosed propionate was completely consumed, and 14 mg-P g-MLSS−1 of phosphate was released into the bulk water. In the following aerobic famine cycle period, 19 mg-P g-MLSS−1 of phosphate was removed from the bulk liquid. These typical trends of EBPR were also observed after day 20 in Run P1.

Continuous aerobic operation (Run P2)

The propionate SBR was then run under continuous aerobic operation for 39 days. Figure 2b shows the reactor performance on day 7, where the dosed propionate was completely consumed within the initial 20 min. P release (16 mg-P g-MLSS−1) was completed within 10 min, although the unassimilated propionate remained. This trend was consistent throughout reactor operation in Run P2, similar to that reported in previous studies (Vargas et al. 2009).

However, there were marked differences from when acetate was used in Run A2 (Pijuan et al. 2005, 2006), where P release in the feed stage continued until or after acetate depletion. In the following Run P2 famine stage, phosphorus was uptaken (20 mg-P g-MLSS−1) and a net P removal was achieved, although 1.4 mg-P g-MLSS−1 remained at the end of the cycle. This P removal performance was observed until day 39, which is similar to that observed in a previous study (Vargas et al. 2009). However, the performance on day 39 of Run P2 (Fig. 2c) showed marked changes to those on day 7 (Fig. 2b); a higher propionate consumption ratio and incomplete P removal were recorded, with > 5 mg-P g-MLSS−1 of P remaining at the end of the cycle.

Figure 3 shows the mixed liquor P concentrations at the end of the cycles in both the acetate- and propionate-fed SBRs. Once the systems had switched from anaerobic-aerobic operations (Runs A1 and P1) to continuous aerobic operations (Runs A2 and P2), P removal in the acetate-fed reactor (Run A2) deteriorated more rapidly than it did in the propionate-fed reactor (Run P2). The mixed liquor P concentration reached 10 mg-P g-MLSS−1 on day 20 in the acetate SBR (Run A2), whereas it remained at ≤ 3.4 mg-P g-MLSS−1 until day 32 in the propionate SBR (Run P2).

Biomass storage polymer levels

To investigate whether biomass storage compound levels corresponded with EBPR performance, glycogen and PHA levels were measured periodically in both the acetate- and propionate-fed SBR biomasses (Table 2).

In the acetate-fed SBR, total PHA, glycogen, and polyP levels rose from 9.94 mg-C g-MLSS−1, 7.69 mg-C g-MLSS−1, and 8.77% (day 33, Run A1) to 12.7 mg-C g-MLSS−1, 11.61 mg-C g-MLSS−1, and 10.0% (day 1, Run A2), respectively, after switching from anaerobic-aerobic operation to continuous aerobic operation. However, subsequently, PHA and glycogen levels fell to 2.16 and 3.10 mg-C g-MLSS−1, respectively, under continuous aerobic conditions on day 20. Only biomass polyP levels maintained a concentration of more than 9.55% under continuous aerobic operation. The main PHA component synthesized in the acetate-fed SBR was PHB, irrespective of operational conditions (i.e., anaerobic-aerobic or continuous aerobic), which is in agreement with all previous data obtained with acetate as the carbon source (Table 3). The proportion of PHB in the total PHA accounted for 87.9 to 93.7% (Table 2).

In the propionate-fed SBR, total PHA and glycogen levels rose from 13.92 and 15.4 mg-C g-MLSS−1 (day 1), respectively, to 25.4 and 39.7 mg-C g-MLSS−1 (day 46) in Run P1, but immediately fell to 10.82 and 21.0 mg-C g-MLSS−1 after switching to continuous aerobic operation on day 1 in Run P2. Both then fell gradually to 6.46 and 17.1 mg-C g-MLSS−1, respectively, by day 39. Biomass polyP content also rose from 2.02% (day 1) to 13.5% (day 46) in Run P1, but immediately fell to 10.2% on day 1 after switching to continuous aerobic operation, and stayed at > 9.21% until the end of the continuous aerobic operation. Thus, total PHA and glycogen levels were generally higher than those detected in the acetate-fed SBR biomass, although biomass polyP contents were similar under both feeding regimes. Moreover, the reduction rates of biomass PHA and glycogen levels in Run P2 (0.11 and 0.10 mg-C g-MLSS−1 day−1) were clearly lower than those in Run A2 of the acetate-fed SBR (0.55 and 0.45 mg-C g-MLSS−1 day−1). Such trends indicate a more stable EBPR performance under continuous aerobic conditions with propionate than with acetate. The main PHA components synthesized with propionate were always PH2MV and PHV again, irrespective of the operational conditions, which is in agreement with all previous data obtained with propionate as the carbon source (Table 3). The contributions of PH2MV and PHV to the total PHA were 30.1 to 58.3% and 35.8 to 63.3% (Table 2), respectively.

Microbial community composition

Acetate-fed reactor

FISH was performed on biomass samples collected during continuous aerobic operation after days 1 and 11 (Run A2) using the PAOmix probe (Cy3) binding to cells of Accumulibacter and the EUBmix probe (Fluos) targeting almost all bacterial cells (Fig. 4a, b). Yellow cells showing hybridization with both the PAOmix and EUBmix probes, and identified as Accumulibacter, were observed on both sampling days 1 (Fig. 4a) and 11 (Fig. 4b), and the cell morphologies appeared to be similar in each sample. Real-time PCR was performed on DNA samples extracted from biomass samples collected on days 1, 33 (Run A1), and 8 (Run A2), using the primer sets targeting the 16S rRNA gene of almost all bacteria and Accumulibacter and ppk1 genes of Accumulibacter clades I, IIA, IIC, IID, and IIF (Table 1). Figure 5a shows the quantified copy numbers of each clade gene.

Absolute gene copy numbers (copies ng-DNA−1) of the 16S rRNA and ppk1 gene determined by qPCR assay ((a) and (c), respectively) and the ratios (%) of the 16S rRNA/ppk1 gene copy number of Candidatus Accumulibacter to the total bacterial 16S rRNA gene copy number ((b) and (d)). EUB and Accum. represent total eubacteria and Candidatus Accumulibacter, respectively

As for the 16S rRNA genes, the copy number of Accumulibacter increased from 2.67 × 106 copies ng-DNA−1 to 5.11 × 107 copies ng-DNA−1 during 32 days in Run A1 and was maintained at 3.83 × 107 copies ng-DNA−1 until day 8 in Run A2. On the other hand, the total bacterial copy number continued to rise from 3.98 × 107 to 2.66 × 108 to 1.13 × 109 copies ng-DNA−1 during the 40 days of operation from Run A1 to Run A2. Consequently, the ratio of copy numbers of Accumulibacter to those of total bacteria changed from 6.7 to 19%, and then to 3.4% (Fig. 5b).

Previous studies have reported that the Accumulibacter genome and other bacterial genomes have 2 and 4.2 (on average) copies of the rrn operon (Garcia et al. 2006; Větrovský and Baldrian 2013), respectively. Therefore, based on the copy numbers of 16S rRNA genes determined by qPCR and the rrn operon, the estimated Accumulibacter abundances were 14, 40, and 7.1% of the total microbial cells on days 1, 33 (Run A1), and 8 (Run A2), respectively. This relative abundance value on day 33 is similar to that reported by other studies using lab-scale SBR sludges enriched with acetate under anaerobic-aerobic conditions (e.g., 50% in Pijuan et al. 2006).

Figure 5a shows the quantified absolute copy numbers of ppk genes. Those of all clades, except for clade IIC, increased after 32 days incubation in Run A1, and maintained this level until day 8 in Run A2, following a similar trend to the copy numbers of the Accumulibacter 16S rRNA gene. This trend suggests that no drastic population changes occurred in the PAO community composition after the initial switch from anaerobic-aerobic operation (Run A1) to continuous aerobic operation (Run A2). However, one striking change was that ppk copy numbers for clade IIC members, minor components of the total Accumulibacter populations under anaerobic/aerobic EBPR conditions, increased markedly under continuous aerobic conditions in Run A2.

Propionate-fed reactor

FISH was performed on biomass samples collected during both anaerobic-aerobic operation (Run P1, at day 33) and continuous aerobic operation (Run P2, day 39), using the PAOmix (Cy3) and EUBmix (Fluos) probes (Fig. 6a, b). Yellow or orange cells (i.e., Accumulibacter) were observed in both samples (Fig. 6a, b), and their morphologies appeared to be similar. The coccoid cells were similar to those seen in the acetate-fed reactor, but their cell diameters appeared to be smaller (Fig. 4). Real-time PCR was performed again on DNA samples extracted from biomass samples collected on days 1, 46 (Run P1), 21, and 39 (Run P2), using the primer sets shown in Table 1. Figure 5c shows the quantified copy numbers of each gene. As with the 16S rRNA genes, the copy numbers of those of Accumulibacter increased from 1.40 × 106 to 5.05 × 107 copies ng-DNA−1 after 45 days in Run P1 and were maintained at 7.09 × 107 and 4.12 × 107 copies ng-DNA−1 on days 21 and 39, respectively, in Run P2. The total bacterial copy numbers also increased from 6.76 × 107 to 1.08 × 108 copies ng-DNA−1 after 45 days in Run P1 and were maintained at 3.44 × 108 and 2.32 × 108 copies ng-DNA−1, respectively, on days 21 and 39 in Run P2. Consequently, the ratio of copy numbers of Accumulibacter and the estimated Accumulibacter abundances were 2.1, 47, 21, and 18% (Fig. 5d) and 4.4, 99, 44, and 38% of the total microbial cells on days 1, 46 (Run P1), 21, and 39 (Run P2), respectively. The Accumulibacter relative abundances (Run P1) on day 46 (99%) are higher than those obtained in other studies using lab-scale SBR sludges fed with propionate under anaerobic-aerobic conditions (e.g., 55% in Pijuan et al. 2004; 65% in Oehmen et al. 2005b; 70% in Vargas et al. 2009; and 90% in Lu et al. 2006).

These abundance were subsequently reduced considerably to approximately half, under continuous aerobic conditions in Run P2, but the Accumulibacter abundance ratio was 5–6 times higher than that determined for the acetate-fed SBR in Run A2 (7.1%). The copy numbers of all clades, except those of clade IIC (Fig 5c), increased after the 45 days acclimation in Run P1, and these numbers were maintained until day 21/39 in Run P2, following a similar trend to the copy numbers of the Accumulibacter 16S rRNA gene. This result also indicates that there were no drastic changes in the Accumulibacter percentage relative abundances in the propionate-fed reactor after switching from anaerobic-aerobic to continuous aerobic operation. However, only the clade IIC members increased during Run P2 more than they did with acetate-fed communities during Run A2. Thus, it seems that the Accumulibacter members of this clade may be favored under aerobic feed conditions irrespective of the carbon source.

Discussion

This study sets out to compare the stability of EBPR performance under continuous aerobic conditions in response to feeding acetate or propionate as the supplied carbon source. Changing the operating conditions of this EBPR process from anaerobic/aerobic to continuously aerobic led to a rapid deterioration in EBPR capacity, as measured by P release/uptake ratios, levels of intracellular glycogen and PHA, and percentage relative abundances of Accumulibacter PAO in the respective communities. Such trends were seen with both acetate- and propionate-fed communities; however, they were much less marked and occurred more slowly with propionate than with acetate as the carbon source. In particular, the aerobic Accumulibacter population relative abundances remained markedly higher with propionate than with acetate (Fig. 5b, d).

As stated earlier, in conventional anaerobic/aerobic EBPR systems, PAO have a selective advantage over other chemoorganoheterotrophic bacteria in the anaerobic feed stage (Seviour et al. 2003; Oehmen et al. 2007). The carbon source is rapidly assimilated, but instead of supporting anaerobic cell replication, it is used to synthesize PHA or other storage compounds, thus providing the PAO with a carbon and energy source that allows them to grow and assimilate and synthesize polyP. Cells with no storage compounds are outcompeted under aerobic conditions because little or no carbon source is now available to them.

Under aerobic feed conditions, the selective factors imposed on the community are likely to be quite different. It is likely that other aerobic chemoorganotrophs may eventually outcompete the PAO for the carbon source, which is used to support aerobic respiration. Consequently, levels of PAO intracellular storage compounds inevitably decrease. Hence, the PAO no longer have the same selective advantage in the famine stage of the process. The data presented here and in previous studies are consistent with this suggestion. As already stated, the relative abundances of Accumulibacter, expressed as percentages of total bacterial cells, fell markedly under continuous aerobic conditions (Fig. 5b, d), but these organisms persisted after prolonged aerobic periods, especially with a propionate feed. The remarkable metabolic versatility and flexibility of Accumulibacter are well documented (He and McMahon 2011), but the data presented here (Fig. 5a, c) suggest that members of clade IIC are able to adapt to the aerobic conditions used in this study.

There are several explanations as to why propionate might support a more stable aerobic EBPR than acetate might. These include the ability of the same PAO populations to assimilate propionate more efficiently than they do acetate and faster than most other chemoorganoheterotrophs in the aerobic feed stage, and to retain the ability to store some as PHA. Alternatively, propionate may select for other Accumulibacter populations from clades with a more efficient and adaptable PAO metabolism. Vargas et al. (2009) claimed that the only difference between continuously aerobic and anaerobic/aerobic EBPR communities with either acetate or propionate feed was the composition of the stored PHA (i.e., PHB or PHV and PH2MV, respectively). They also suggested, without saying how, that this attribute alone may be responsible for the EBPR stability observed with propionate. Pijuan et al. (2009) also suggested that EBPR microbial communities exposed to acetate and propionate mainly produced PHV and both PHV and PH2MV from propionate, respectively.

16S rRNA gene copy numbers of members of Accumulibacter clade IID had increased by the end of the anaerobic/aerobic operation, regardless of whether acetate or propionate was used as the carbon source (Fig. 5a, c), suggesting that the added carbon source played no role in their enrichment. However, 16S rRNA gene copy numbers of clade I and IIA members had increased substantially more within the propionate-fed community than within the acetate-fed community (Fig. 5a, c). If the earlier suggestions that the PHA composition ultimately decides the performance of continuous aerobic EBPR and only propionate-fed bacteria can synthesize PH2MV are correct, then our qPCR data might suggest that Accumulibacter members of clades I and IIA are responsible for much of the PH2MV accumulation and are thus key players in preserving EBPR capacity under continuous aerobic conditions with propionate. Equally feasible is that other bacterial populations in these communities were responsible for substantial PHA storage; alternatively, members of Accumulibacter clades yet unrecognized may have been responsible.

Not all the published data report the same population trends. For example, Gonzalez-Gil and Holliger (2011) found that Accumulibacter clade IIA members were abundant in both acetate and propionate EBPR reactors, whereas clade I members were abundant only in the acetate-fed reactor. However, no explanations were provided for this observation, and no information was supplied on the chemical components of the PHA, except that their aerobic biomass was organized as granules, whereas flocs were used in the present study and by Pijuan et al. (2009).

The most striking shift in the populations was the increase under continuously aerobic conditions in the relative abundances of Accumulibacter clade IIC members with both acetate and propionate; however, the reason for this enrichment is not clear. Camejo et al. (2016) have investigated the affinity of clade IIC members to oxygen as an electron acceptor; DO levels during active P uptake differing markedly in their lab- and pilot-scale reactors (0.05 versus 0.2 mg L−1) were thought to explain the dominance of clade IIC members in their pilot-scale reactor. Slater et al. (2010) suggested that clade IIC members had a higher affinity for phosphate than clade IA members did, which may give them a competitive edge at low phosphate concentrations. However, whether members of other clades are also less competitive for phosphate under aerobic conditions remains to be determined. Shen et al. (2017) also showed that members of clade IIC were highly abundant in EBPR processes run at high temperature. Moreover, Welles et al. (2015, 2017) suggested that clade IIC members are distinctively metabolically flexible, being able to switch to a mixed PAO-GAO metabolism where both glycogen and polyP are degraded to provide energy for the sequestration of acetate anaerobically when polyP is not stoichiometrically limiting the VFA uptake. From whole genome sequence data, Skennerton et al. (2015) demonstrated that clade IIC members were alone in encoding a gene for nitrate reductase and, hence, capable of denitrification. This observation could explain the enrichment of clade IIC members in reactors capable of nitrate reduction (Kim et al. 2013).

However, the present reactor was operated under high DO concentrations during P uptake (> 2.0 mg L−1) and normal temperature (20 °C). The influent contained a high phosphate concentration and allylthiourea to inhibit nitrification, which indicates poor denitrifying activity. Moreover, it is difficult to see how possessing nitrate reductase could provide a competitive advantage to clade IIC members under the conditions used here. Whether by acting as a redox-balancing complex, as suggested by Skennerton et al. (2015), it could assist Accumulibacter in coping with these conditions is also unknown.

Zhang et al. (2016) reported that clade IIC members are well represented in nine geographically and operationally distinct activated sludge WWTPs. Mao et al. (2015) also detected clade IIC members in the majority of full-scale activated sludge WWTPs in six countries and found them to be the most common of the five clades (I, IIA, IIB, IIC, and IID) examined. Moreover, the inoculates used in the present study were collected from municipal WWTPs, which contained all the clades examined (I, IIA, IIC, IID, and IIF); however, only clades IIC and IID showed high ppk1 copy numbers (Fig. 5a, c). Consequently, every result supports that clade IIC was well adaptable in full scale WWTPs, and thus, the reason behind Accumulibacter clade IIC members having a selective advantage in municipal WWTPs should clarify why they have selective advantage under continuously aerobic conditions. The authors hypothesized that this clade could not adapt under strictly controlled long anaerobic conditions during P release, such as those present in lab-scale reactors.

One problem with studies of this kind is the assumption that all members of each Accumulibacter clade share the same metabolic traits. However, as Albertsen et al. (2016) and Saad et al. (2016) reminded us, the foundation of identifying Accumulibacter members of each individual clade is based on the sequences of a single gene, ppk, and its sequence diversity within each clade is approximately 12%. Thus, there is evidence that differences in its sequence embrace Accumulibacters probably with markedly different ecophysiologies.

References

Ahn J, Daidou T, Tsuneda S, Hirata A (2002) Transformation of phosphorus and relevant intracellular compounds by phosphorus accumulating enrichment culture in the presence of both the electron acceptor and electron donor. Biotechnol Bioeng 79(1):83–93. https://doi.org/10.1002/bit.10292

Ahn J, Schroeder S, Beer M, McIlroy S, Bayly RC, May JW, Vasiliadis G, Seviour RJ (2007) Ecology of the microbial community removing phosphate from wastewater under continuously aerobic conditions in a sequencing batch reactor. Appl Environ Microbiol 73(7):2257–2270. https://doi.org/10.1128/AEM.02080-06

Albertsen M, McIlroy SJ, Stokholm-Bjerregaard M, Karst SM, Nielsen PH (2016) “Candidatus Propionivibrio aalborgensis”: a novel glycogen accumulating organism abundant in full-scale enhanced biological phosphorus removal plants. Front Microbiol 7:1033. https://doi.org/10.3389/fmicb.2016.01033

Amann RI, Binder BJ, Chisholm SW, Devereux R, Stahl DA (1990) Combination of 16S rRNA-targeted oligonucleotide probes with flow cytometry for analyzing mixed microbial populations. Appl Environ Microb 56(6):1919–1925

American Public Health Association (APHA) (1998) Standard methods for the examination of water and wastewater, 20th edn. American Public Health Association

Arun V, Mino T, Matsuo T (1988) Biological mechanism of acetate uptake mediated by carbohydrate consumption in excess phosphorus removal systems. Water Res 22(5):565–570. https://doi.org/10.1016/0043-1354(88)90056-5

Beun JJ, Paletta F, Van Loosdrecht MCM, Heijnen JJ (2000) Stoichiometry and kinetics of PHB metabolism in aerobic, slow growing, activated sludge cultures. Biotechnol Bioeng 67(4):379–389. https://doi.org/10.1002/(SICI)1097-0290(20000220)67:4<379::AID-BIT1>3.0.CO;2-2

Blackall LL, Crocetti GR, Saunders AM, Bond PL (2002) A review and update of the microbiology of enhanced biological phosphorus removal in wastewater treatment plants. Antonie Van Leeuwenhoek 81(1–4):681–691. https://doi.org/10.1023/A:1020538429009

Camejo PY, Owen BR, Martirano J, Ma J, Kapoor V, Domingo JS, McMahon KD, Noguera DR (2016) Candidatus Accumulibacter phosphatis clades enriched under cyclic anaerobic and microaerobic conditions simultaneously use different electron acceptors. Water Res 102:125–137. https://doi.org/10.1016/j.watres.2016.06.033

Crocetti GR, Hugenholtz P, Bond PL, Schuler A, Keller J, Jenkins D, Blackall LL (2000) Identification of polyphosphate accumulating organisms and design of 16S rRNA-directed probes for their detection and quantitation. Appl Environ Microbiol 66(3):1175–1182. https://doi.org/10.1128/AEM.66.3.1175−1182.2000

Crocetti GR, Banfield JF, Keller J, Bond PL, Blackall LL (2002) Glycogen-accumulating organisms in laboratory-scale and full-scale wastewater treatment processes. Microbiology 148(Pt 11):3353–3364. https://doi.org/10.1099/00221287-148-11-3353

Daims H, Brühl A, Amann R, Schleifer K-H, Wagner M (1999) The domain-specific probe EUB338 is insufficient for the detection of all bacteria: development and valuation of a more comprehensive probe set. Syst Appl Microbiol 22:434–444

Daims H, Stoecker K, Wagner M (2005) Fluorescence in situ hybridization for the detection of prokaryotes. In: Osborn AM, Smith CJ (eds) Molecular microbial ecology. Taylor & Francis, New York, pp 213–239

Dhanasekaran S, Doherty TM, Kenneth J, TB Trials Study Group (2010) Comparison of different standards for real-time PCR-based absolute quantification. J Immunol Methods 354(1–2):34–39. https://doi.org/10.1016/j.jim.2010.01.004

Dircks K, Henze M, Van Loosdrecht MCM, Mosbæk H, Aspegren H (2001) Storage and degradation of poly-b-hydroxybutyrate in activated sludge under aerobic conditions. Water Res 35(9):2277–2285. https://doi.org/10.1016/S0043-1354(00)00511-X

Garcia MH, Ivanova N, Kunin V, Warnecke F, Barry KW, McHardy AC (2006) Metagenomic analysis of two enhanced biological phosphorus removal (EBPR) sludge communities. Nat Biotechnol 24:1263–1269. https://doi.org/10.1038/nbt1247

Gonzalez-Gil G, Holliger C (2011) Dynamics of microbial community structure of and enhanced biological phosphorus removal by aerobic granules cultivated on propionate or acetate. Appl Environ Microbiol 77(22):8041–8051. https://doi.org/10.1128/AEM.05738-11

Guisasola A, Pijuan M, Baeza JA, Carrera J, Casas C, Lafuente J (2004) Aerobic phosphorus release linkedto acetateuptake in bio-P sludge: process modelling using oxygen uptake rate. Biotechnol Bioeng 85(7):722–723. https://doi.org/10.1002/bit.10868

He S, McMahon KD (2011) Microbiology of ‘Candidatus Accumulibacter’ in activated sludge. Microb Biotechnol 4(5):603–619. https://doi.org/10.1111/j.1751-7915.2011.00248.x

He S, Gall DL, McMahon KD (2007) “Candidatus Accumulibacter” population structure in enhanced biological phosphorus removal sludges as revealed by polyphosphate kinase genes. Appl Environ Microbiol 73(18):5865–5874. https://doi.org/10.1128/AEM.01207-07

Hesselmann RPX, Von Rummell R, Resnick SM, Hany R, Zehnder AJB (2000) Anaerobic metabolism of bacteria performing enhanced biological phosphate removal. Water Res 34(14):3487–3494. https://doi.org/10.1016/S0043-1354(00)00092-0

Kim JM, Lee HJ, Lee DS, Jeon CO (2013) Characterization of the denitfirication-associated phosphorus uptake properties of “Candidatus Accumulibacter phosphatis” clades in sludge subjected to enhanced biological phosphorus removal. Appl Environ Microbiol 79(6):1969–1979. https://doi.org/10.1128/AEM.03464-12

Liu WT, Mino T, Nakamura K, Matsuo T (1996) Glycogen accumulating population and its anaerobic substrate uptake in anaerobic–aerobic activated sludge without biological phosphorus removal. Water Res 30(1):75–82. https://doi.org/10.1016/0043-1354(95)00121-Z

Lu H, Oehmen A, Virdis B, Keller J, Yuan Z (2006) Obtaining highly enriched cultures of Candidatus Accumulibacter Phosphatis through alternating carbon sources. Water Res 40(20):3838–3848. https://doi.org/10.1016/j.watres.2006.09.004

Mao Y, Graham DW, Tamaki Y, Zhang T (2015) Dominant and novel clades of Candidatus Accumulibacter phosphatis in 18 globally distributed full-scale wastewater treatment plants. Sci Rep 5:11857. https://doi.org/10.1038/srep11857

McMahon KD, Yilmaz S, He S, Gall DL, Jenkins D, Keasling JD (2007) Polyphosphate kinase genes from full-scale activated sludge plants. Appl Microbiol Biotechnol 77:167–173. https://doi.org/10.1007/s00253-007-1122-6

Meyer RL, Saunders AM, Blackall LL (2006) Putative glycogen-accumulating organisms belonging to the Alphaproteobacteria identified through rRNA-based stable isotope probing. Microbiology 152(Pt 2):419–429. https://doi.org/10.1099/mic.0.28445-0

Mikami Y, Nittami T, Kurisu F (2013) Effect of endogenous carbon source on biological denitrification rate. J Water Environ Technol 11(1):1–9. https://doi.org/10.2965/jwet.2013.1

Mino T, Arun V, Tsuzuki Y, Matsuo T (1987) Effect of phosphorus accumulation on acetate metabolism in the biological phosphorus removal process. In: Ramadori R (ed) Biological phosphate removal from wastewaters (advances in water pollution control 4). Pergamon Press, Oxford, pp 27–38

Mino T, Loosdrecht MCM, Heijnen JJ (1998) Microbiology and biochemistry of the enhanced biological phosphate removal process. Water Res 32(11):3192–3207. https://doi.org/10.1016/S0043-1354(98)00129-8

Muyzer G, De Waal EC, Uitterlinden AG (1993) Profiling of complex microbial populations by denaturing gradient gel electrophoresis analysis of polymerase chain reaction-amplified genes coding for 16S rRNA. Appl Environ Microbiol 59(3):695–700. https://doi.org/10.1007/s00253-017-8571-3

Nittami T, Oi H, Matsumoto K, Seviour RJ (2011) Influence of temperature, pH and dissolved oxygen concentration on enhanced biological phosphorus removal under strictly aerobic conditions. New Biotechnol 29(1):2–8. https://doi.org/10.1016/j.nbt.2011.06.012

Oehmen A, Zeng R, Yuan Z, Keller J (2005a) Anaerobic metabolism of propionate by polyphosphate-accumulating organisms in enhanced biological phosphorus removal systems. Biotechnol Bioeng 91(1):43–53. https://doi.org/10.1002/bit.20480

Oehmen A, Yuan Z, Blackall LL, Keller J (2005b) Comparison of acetate and propionate uptake by polyphosphate accumulating organisms and glycogen accumulating organisms. Biotechnol Bioeng 91(2):162–168. https://doi.org/10.1002/bit.20500

Oehmen A, Saunders AM, Vives MT, Yuan Z, Keller J (2006) Competition between polyphosphate and glycogen accumulating organisms in enhanced biological phosphorus removal systems with acetate and propionate as carbon sources. J Biotechnol 123(1):22–32. https://doi.org/10.1016/j.jbiotec.2005.10.009

Oehmen A, Zeng RJ, Keller J, Yuan Z (2007) Modeling the aerobic metabolism of polyphosphate-accumulating organisms enriched with propionate as a carbon source. Water Environ Res 79(13):2477–2486

Ong YH, Chua ASM, Fukushima T, Ngoh GC, Shoji T, Michinaka A (2014) High-temperature EBPR process: the performance, analysis of PAOs and GAOs and the fine-scale population study of Candidatus “Accumulibacter phosphatis”. Water Res 64:102–112. https://doi.org/10.1016/j.watres.2014.06.038

Pereira H, Lemos PC, Reis MAM, Crespo JPSG, Carrondo MJT, Santos H (1996) Model for carbon metabolism in biological phosphorus removal processes based on in vivo 13C-NMR labelling experiments. Water Res 30(9):2128–2138

Peterson SB, Warnecke F, Madejska J, McMahon KD, Hugenholtz P (2008) Environmental distribution and population biology of Candidatus Accumulibacter, a primary agent of biological phosphorus removal. Environ Microbiol 10(10):2692–2703. https://doi.org/10.1111/j.1462-2920.2008.01690.x

Pijuan M, Saunders AM, Guisasola A, Baeza JA, Casas C, Blackall LL (2004) Enhanced biological phosphorous removal in a sequencing batch reactor using propionate as the sole carbon source. Biotechnol Bioeng 85(1):56–67. https://doi.org/10.1002/bit.10813

Pijuan M, Guisasola A, Baeza JA, Carrera J, Casas C, Lafuente J (2005) Aerobic phosphorus release linked to acetate uptake: influence of PAO intracellular storage compounds. Biochem Eng J 26(2–3):184–190. https://doi.org/10.1016/j.bej.2005.04.014

Pijuan M, Guisasola A, Baeza JA, Carrera J, Casas C, Lafuente J (2006) Net P-removal deterioration in enriched PAO sludge subjected to permanent aerobic conditions. J Biotechnol 123(1):117–126. https://doi.org/10.1016/j.jbiotec.2005.10.018

Pijuan M, Casas C, Baeza JA (2009) Polyhydroxyalkanoate synthesis using different carbon sources by two enhanced biological phosphorus removal microbial communities. Process Biochem 44(1):97–105. https://doi.org/10.1016/j.procbio.2008.09.017

Puiga S, Coma M, Monclús H, Van Loosdrecht MCM, Colprim J, Balaguer MD (2008) Selection between alcohols and volatile fatty acids as external carbon sources for EBPR. Water Res 42(3):557–566. https://doi.org/10.1016/j.watres.2007.07.050

Saad SA, Welles L, Abbas B, Lopez-Vazquez CM, Van Loosdrecht MCM, Brdjanovic D (2016) Denitrification of nitrate and nitrite by ‘Candidatus Accumulibacter phosphatis’ clade IC. Water Res 105:97–109. https://doi.org/10.1016/j.watres.2016.08.061

Schroeder S, Ahn J, Seviour RJ (2008) Ecophysiology of polyphosphate-accumulating organisms and glycogen-accumulating organisms in a continuously aerated enhanced biological phosphorus removal process. J Appl Microbiol 105(5):1412–1420. https://doi.org/10.1111/j.1365-2672.2008.03857.x

Schroeder S, Petrovski S, Campbell B, McIlroy S, Seviour R (2009) Phylogeny and in situ identification of a novel gammaproteobacterium in activated sludge. FEMS Microbiol Lett 297(2):157–163. https://doi.org/10.1111/j.1574-6968.2009.01676.x

Seviour RJ, Nielsen PH (2010) Microbial ecology of activated sludge. IWA Publishing, London

Seviour RJ, Mino T, Onuki M (2003) The microbiology of biological phosphorus removal in activated sludge systems. FEMS Microbiol Rev 27(1):99–127. https://doi.org/10.1016/S0168-6445(03)00021-4

Shen N, Chen Y, Zhou Y (2017) Multi-cycle operation of enhanced biological phosphorus removal (EBPR) with different carbon sources under high temperature. Water Res 114:308–315. https://doi.org/10.1016/j.watres.2017.02.051

Skennerton CT, Barr JJ, Slater FR, Bond PL, Tyson GW (2015) Expanding our view of genomic diversity in Candidatus Accumulibacter clades. Environ Microbiol 17(5):1574–1585. https://doi.org/10.1111/1462-2920.12582

Slater FR, Johnson CR, Blackall LL, Beiko RG, Bond PL (2010) Monitoring associations between clade level variation, overall community structure and ecosystem function in enhanced biological phosphorus removal (EBPR) systems using terminal-restriction fragment length polymorphism (T-RFLP). Water Res 44(17):4908–4923. https://doi.org/10.1016/j.watres.2010.07.028

Smolders GJF, Van der Meij J, Van Loosdrecht MCM, Heijnen JJ (1994) Model of the anaerobic metabolism of the biological phosphorus removal process; stoichiometry and pH influence. Biotechnol Bioeng 43(6):461–470. https://doi.org/10.1002/bit.260430605

Smolders GJF, Van der Meij J, Van Loosdrecht MCM, Heijnen JJ (1995) A structured metabolic model for anaerobic and aerobic stoichiometry and kinetics of the biological phosphorous removal process. Biotechnol Bioeng 47(3):277–287. https://doi.org/10.1002/bit.260470302

Vargas M, Casas C, Baeza JA (2009) Maintenance of phosphorus removal in an EBPR system under permanent aerobic conditions using propionate. Biochem Eng J 43(3):288–296. https://doi.org/10.1016/j.bej.2008.10.013

Větrovský T, Baldrian P (2013) The variability of the 16S rRNA gene in bacterial genomes and its consequences for bacterial community analyses. PLoS One 8(2):e57923. https://doi.org/10.1371/journal.pone.0057923

Welles L, Tian WD, Saad S, Abbas B, Lopez-Vazquez CM, Hooijmans CM, Van Loosdrecht MCM, Brdjanovic D (2015) Accumulibacter clades Type I and II performing kinetically different glycogen-accumulating organisms metabolisms for anaerobic substrate uptake. Water Res 83:354–366. https://doi.org/10.1016/j.watres.2015.06.045

Welles L, Abbas B, Sorokin DY, Lopez-Vazquez CM, Hooijmans CM, Van Loosdrecht MCM, Brdjanovic D (2017) Metabolic response of “Candidatus Accumulibacter Phosphatis” clade IIC to changes in influent P/C ratio. Front Microbiol 7:2121. https://doi.org/10.3389/fmicb.2016.02121

Zhang AN, Mao Y, Zhang T (2016) Development of quantitative real-time PCR assays for different clades of “Candidatus Accumulibacter”. Sci Rep 6:23993. https://doi.org/10.1038/srep23993

Acknowledgements

The authors express their gratitude to Mr. Shizuo Furukawa, who helped set up the stirred tank system, and Dr. Mamoru Oshiki and Mr. Satoru Motooka, who helped measure the PHA. The Environmental Planning Bureau of the Yokohama City Government is acknowledged for the provision of activated sludge.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Rights and permissions

About this article

Cite this article

Nittami, T., Mukai, M., Uematsu, K. et al. Effects of different carbon sources on enhanced biological phosphorus removal and “Candidatus Accumulibacter” community composition under continuous aerobic condition. Appl Microbiol Biotechnol 101, 8607–8619 (2017). https://doi.org/10.1007/s00253-017-8571-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8571-3