Abstract

This study investigated the applicability of dynamic membrane filter (DMF) technology in an upflow anaerobic sludge blanket (UASB) and DMF-coupled process for the treatment of municipal wastewater. The overall treatment performance and effects of hydraulic retention time (HRT), operating flux, and mesh pore size on the UASB + DMF were assessed. The UASB + DMF-coupled process demonstrated removal efficiencies of over 64 and 86% for TCOD and TSS, respectively. The effects of filtration flux and support mesh pore size were investigated and it was found that while there was little impact on the treatment performance, a 67% increase in operating flux resulted in a 25% increase in fouling rate. Similarly, with smaller mesh pore size (Mesh 500 with pore size of 28 μm) the fouling rate increased by fourfold as compared to Mesh 300 (pore size of 46 μm). In consideration of the operation duration and contaminant removal, the DMF with Mesh 300 support layer and operating at 100 L/m2-h was the most efficient configuration for treating the effluent of the UASB operated with a HRT of 6 h. Microbial analyses of the foulant layer revealed changes in relative abundance as compared to the bulk sludge, particularly with the hydrogenotrophic methanogens completely outcompeting the acetoclastic methanogens. Overall, the coupled process improved the system robustness and reduced variability of the treated effluent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The application of anaerobic processes for the treatment of municipal wastewater has been gaining attention in recent years due to its advantages of lower energy demand, the ability to generate methane-rich biogas as a recoverable energy source, and lower sludge production. In particular the upflow anaerobic sludge blanket (UASB) process, which is traditionally used for treating high-strength industrial wastewaters, has been increasingly applied for the treatment of low-strength municipal wastewaters (Ruiz et al. 1998; Seghezzo et al. 1998; Souza et al. 2011; Smith et al. 2012; Borges et al. 2015). Nevertheless, the complexity and variability of sewage can often result in biomass washouts especially during suspended solids or dissolved organic shock loads (GonÇalves et al. 1994; Leitão et al. 2006). To prevent washouts, the UASB reactors often need to be operated at hydraulic retention times (HRT) of 6 h or longer. The addition of a post-treatment step to retain the expelled sludge could reduce the effluent variability and robustness of the overall treatment system and achieve the same treatment performance while maintaining the same overall HRT. Post-treatment options such as secondary settlers and conventional micro- or ultra-membrane filtration have the disadvantages of having large footprint and high costs, respectively. On the other hand, a self-forming dynamic membrane filter (DMF) could be coupled with the UASB reactor to overcome the mentioned disadvantages. The DMF operates based on the principle that the secondary filtration layer formed by accumulation of rejected solids and foulants modifies contaminant rejection properties (Ersahin et al. 2012; Fuchs et al. 2005; Ho et al. 2007; Yu et al. 2015), hence allowing the use of macroporous filtration materials in place of conventional membranes, leading to significant reduction in the system cost.

The observation of self-forming dynamic membranes in water treatment processes dates back decades but the intentional application of DMFs in biological wastewater treatment only caught attention in the mid-1990s. Pillay et al. (1994) used flexible woven fiber tubes to retain digested sludge and so enhanced the performance of anaerobic digesters by decoupling the solids retention time (SRT) and HRT (Pillay et al. 1994). Kiso et al. also reported that nonwoven fabric could separate activated sludge effectively at very low pressure and thus could replace conventional microfiltration membranes in MBRs (Kiso et al. 2000). In recent years, DMF studies have been mostly focused on membrane bioreactor applications with a few exceptions such as algal dewatering (Zhang et al. 2014) and seawater reverse osmosis pretreatment during red tide event (Kim et al. 2017).

Zhang and co-workers (Zhang et al. 2010, 2011) placed a dynamic membrane at the settling zone of the UASB reactor treating municipal wastewater. They found that the formation of dynamic membrane could be divided into three stages, i.e., the formation of separation layer, the stable growth stage, and the fouling stage. Characterization of the foulant layer also revealed a double-layered structure, i.e., a loosely bound outer layer and a tightly bound internal layer. Due to the large pore size used in their studies (61 μm), the dynamic membrane showed little rejection of soluble macromolecules. It should be noted that the use of dynamic membrane directly within the UASB reactor removes the selection pressure for larger-sized sludge flocs and could affect the granulation process in the UASB reactor. Thus, it might be beneficial to place the dynamic membrane ex-situ of the UASB reactor. In this way, the performance of the UASB reactor and the dynamic membrane filter could also be separately assessed. Additionally, the effects of HRT of the UASB reactor, operating flux of the dynamic membrane and supporting mesh pore size on the dynamic membrane performance have not been adequately addressed.

The objective of this study was to investigate the performance of the novel UASB + DMF-coupled process for municipal wastewater treatment and optimize the system configuration. Chemical and microbial community analyses of the foulant layer were also performed for characterization of the dynamic membrane.

Materials and methods

Wastewater source and seed sludge

Municipal wastewater was obtained from the inlet (before the primary settling tank) of a local wastewater treatment plant in Singapore. The feed had a total COD (TCOD) of 375 ± 94 mg/L, soluble COD (SCOD) of 92 ± 20 mg/L, and total suspended solid (TSS) of 225 ± 67 mg/L. The UASB reactors were seeded with anaerobic sludge obtained from the digester unit of the same wastewater treatment plant.

Experimental setup and procedure

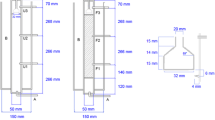

The laboratory-scale setup used in this study is shown in Fig. S1 in the Supplementary Information. Two identical UASB reactors, each with a working volume of 6.9 L, were set up in parallel for the first-stage treatment of the municipal wastewater and operated under the ambient temperature of 25–30 °C at HRT of 6 h (R6h) and 3 h (R3h), respectively. This corresponds to organic loading rates (OLRv) of 1.5 and 3.0 gCOD/L-day for R6h and R3h, respectively. To reduce sludge washout during startup, Mg2+ (1.4 mmol/L) and Ca2+ (2 mmol/L) in chloride form were added to the feed during the first 2 days of reactors startup. According to a previous study, Mg2+ and Ca2+ could enhance nucleic formation and granule growth, respectively (Cao et al. 2014).

Once the UASB reactors were stabilized, individual UASB effluent was allowed to overflow to a membrane holder containing the DMF. A second overflow from the membrane tank was imposed such that when the HRT of the UASB reactor was shortened, excess flow to the DMF was removed via the overflow. In this way, the HRT and the membrane flux were decoupled. Sludge was not withdrawn during the operation; thus, the SRT was infinite. The specifications of the DMF are detailed in Table S1 in the Supplementary Information. Each DMF comprised of a flat-sheet dynamic membrane module having a total filtration area of 50 cm2. Polyethylene terephthalate (PET) mesh was used as the support layer on which the dynamic membrane could form. Two peristaltic pumps (Longer BT-100, China) were used to feed wastewater to the UASB reactor and extract permeate from the DMF. The transmembrane pressure across the DMF was measured using a digital pressure meter (SMC, ZSE50F). In this study, no in situ backwash was performed.

To determine the effects of DMF operating flux, DMF mesh pore size and UASB reactor HRT on the performance of the coupled process, several experiments were run. Two pore sizes of mesh were tested: Mesh 500 corresponding to 28 μm (M500) and Mesh 300 corresponding to 46 μm (M300). Permeate fluxes tested were 100, 60, and 30 L/m2-h. The designation in the subsequent sections follows the format “(UASB) + (Mesh)-(Flux)”, e.g., R3h + M300-100 refers to the R3h UASB reactor coupled with a Mesh 300 DMF and operated at a permeate flux of 100 L/m2-h.

The operating conditions are summarized in Table S2 in the Supplementary Information.

Chemical analytical methods

COD, MLSS, and MLVSS were tested according to the Standard Methods (APHA 2012). Extracellular polymeric substances (EPS) extraction was performed in accordance to Ye et al. (2011) with slight modifications (Ye et al. 2011). Sludge samples were centrifuged at 6000×g for 10 min and filtered through 0.45-μm membranes (Pall, USA). The supernatant obtained was the soluble microbial product (SMP). The sludge pellet was then washed with deionized (DI) water to remove the loose slime polymers, re-suspended by vortex, and sonicated for 2 min. This was then heated at 70 °C for 30 min and centrifuged at 11,000×g for 15 min. The supernatant collected after filtering through a 0.45-μm membrane was considered as the total EPS. Carbohydrate content was determined by colorimetry using the phenol-sulfuric acid method (Dubois et al. 1956), while proteins were measured by the corrected Lowry method (Lowry et al. 1951; Frøund et al. 1995). Glucose and bovine serum albumin (BSA) were used as the respective calibration standards. Fractions distribution of dissolved organic matters (DOMs) was determined by liquid chromatography-organic carbon detection (LC-OCD, Dr. Huber, DOC-LAB) equipped with a size-exclusion column, Toyopearl HW-50S (Tosoh, USA). Biogas composition was analyzed using a gas chromatograph (GC17A, Shimadzu, Japan) equipped with two parallel columns for permanent gases and CO2 analysis (CP-Molsieve 5 Å in tandem with CP-PoraBOND Q, Agilent Technologies) and a barrier ionization discharge (BID) detector. Particle size distributions were measured using ZetaPALS Particle Sizer (Brookhaven Instruments Corp).

Optical microscope observation

The DMF (i.e., the support mesh together with the adhered foulant layer) was removed at the end of the operation cycle and placed under an optical microscope (Keyence VHX-500 and VH-Z250R) for observation to investigate the porosity and morphology of the foulant layer (note: no cutting of the mesh was performed). The results were compared with the virgin support mesh.

Microbial community analysis

To identify and compare the microbial communities of the UASB bulk sludge and the foulant layer, fresh samples of the foulant layer at the end of the R6h + M500-100 cycle and R6h UASB sludge at different heights of the reactor were collected, centrifuged to remove the supernatant, and DNA extraction performed using PowerSoil DNA isolation kit (MoBio Laboratories, USA) according to the manufacturer’s protocol. Concentrations of the extracted DNA were measured using NanoDrop equipment (Thermo Scientific, USA) and the 16S rRNA gene fragments from each sample were amplified using DreamTaq Green PCR Master Mix (Thermo Scientific, USA), characterized using 454 high-throughput pyrosequencing method in accordance to Shi et al. (Shi et al. 2015). The sequencing data was uploaded to the NCBI Sequence Read Archive with the BioProject Accession Number PRJNA378579. The Venn diagram was plotted using Venny 2.1 (Oliveros 2007).

Results

Effect of HRT on UASB + DMF performance

The operational and treatment performances of the R6h + DMF and R3h + DMF processes were compared and are summarized in Table 1. The results indicate that the UASB + DMF-coupled process was effective in the removal of COD and SS from the municipal wastewater even at short HRTs. It was noted, however, that the fouling rate of the DMF treating R3h effluent was 4× higher than that treating R6h effluent (Fig. 1). This was because at a HRT of 3 h, the UASB reactor was more prone to biomass washouts which would be retained by the DMF, contributing to its TMP increase. In spite of this, the UASB + DMF was still able to achieve high COD and SS removal efficiencies signifying the benefits of having the DMF as second-stage treatment after the UASB reactor to improve the overall process robustness and reliability.

In the absence of any in situ cleaning measures, the TMP of the R3h + M500-100 process reached 40 kPa after 6 days. Online fouling control methods such as air/gas sparging, brushing, or backwash may be implemented to extend the operation time of the DMF (Xue et al. 2012; Ersahin et al. 2014; Fakhimi and Mehrnia 2015; Li et al. 2016). For the subsequent tests, since there was no in situ cleaning, R6h was used in the coupled process.

Effect of operating flux on UASB + DMF performance

R6h + M500 DMFs were operated at three different fluxes (100, 60, and 30 L/m2-h) and the results are presented in Table 2. At all the test fluxes, the UASB + DMF process was able to achieve removal efficiencies of over 67 and 86% for total COD and TSS, respectively. There was little observable difference in the treated permeate qualities obtained at the different fluxes. However, the highest rate of increase in TMP was observed for the DMF operating at 100 L/m2-h (Fig. 2). This trend is intuitive as operation at higher fluxes meant that the solids accumulation rate on the support mesh was faster, leading to higher fouling rate. Interestingly, the fouling rate did not increase remarkably when the operating flux was increased from 30 to 60 L/m2-h. This could be explained by the concept of threshold flux, which describes the flux above which the membrane system experiences an elevated increase in rate of fouling, while at fluxes below the threshold flux, the operation would generate much slower fouling (Field and Pearce 2011). In a previous fouling study using TiO2 suspension, it was found that at fluxes below 75 LMH, the fouling rate was very low and similar even at different flux rates (Tung et al. 2014). In our present study, the threshold flux probably also lied between 60 and 100 L/m2-h, resulting in the observed trend. The results also suggest that operation at 100 L/m2-h would be more efficient as a 67% increase in flux resulted only in a 25% reduction in the operation time.

Effect of mesh pore size on UASB + DMF performance

From Table 3, it was observed that UASB + DMF configurations using Mesh 300 and Mesh 500 achieved comparable removal efficiencies for TCOD and TSS, indicating that mesh pore size in the tested range was not a major influencing parameter in terms of contaminant removal. In this study, the two mesh ratings tested (Mesh 500, corresponding to 28 μm, and Mesh 300, corresponding to 46 μm) were sufficiently small for the dynamic layer to be effectively formed over the mesh surface, and the resultant dynamic layer took over as the predominant filtration barrier in place of the macroporous support mesh to remove the particles in the UASB effluent. Particle size distribution (PSD) analysis (Fig. S2 in the Supplementary Information) showed that the mean particle sizes in the Mesh 500 and Mesh 300 permeates were 1.5 and 1.6 μm, which were much smaller than the support mesh pore sizes tested. Nevertheless, the mesh pore size did have a significant impact on the rate of increase in TMP. As indicated in Fig. 3, fouling rate for Mesh 500 was 4× faster than that of Mesh 300. This could be explained by the reason that the Mesh 500 DMF has higher density of PET fibers and smaller effective pore size, which is more prone to pore blocking. This would suggest that for long-term operation at high fluxes, the use of Mesh 300 as the support layer in the DMF might be advantageous.

Biogas production of the UASB + DMF process

The biogas produced from the UASB + DMF process was collected and analyzed to determine the gas composition (Fig. S3 in the Supplementary Information). Over 250 days of operation, the system was able to produce methane-rich (≥66% CH4) biogas, which could be recovered and reused to reduce the overall energy demand of the process. The specific methane production was determined to be 23.4 ± 8.6 mL CH4/gVS-day and methane yield was 354 ± 37 mL CH4/gCODutilized, which is close to the theoretical value of 380 mL CH4/gCODutilized. A previous study (Yue et al. 2015) on AnMBR treating domestic wastewater reported a methane yield of 300 mL CH4/gCODutilized. It was also observed that the percentage of CO2 was rather low (4–6%) as compared to the typical range (20–30%) reported in anaerobic digestion of domestic sewage (Chernicharo 2007). Nevertheless, some lab-scale studies on the anaerobic treatment of municipal wastewater (Lin et al. 2009, 2011) had similarly reported low carbon dioxide contents.

Analysis of the DMF foulant layer

To characterize the DMF foulant layer, which constituted the dynamic membrane, the DMF at the end of the R6h + M500-100 operation cycle was removed for further analysis. The foulant layer was loosely attached to the mesh surface and mostly sloughed off once the module was removed from the reactor. This observation was consistent with previous studies (Fan and Huang 2002; Zhang et al. 2010). The remaining gel-like layer that was not sloughed off was collected for further analysis. Due to the mostly loosely bound nature of the foulant layer, the support mesh could be easily cleaned by flushing with tap water (Fig. S4 in the Supplementary Information) and utilized for the next operation cycle, as opposed to conventional micro- or ultra-filtration membranes which require chemical cleaning.

The optical microscope images of the virgin mesh and fouled mesh at the end of the R6h + M500-100 operation cycle were studied (Fig. S5 in the Supplementary Information). A rather dense foulant layer was formed on the mesh surface, which facilitated contaminant removal by the DMF and contributed to the filtration resistance as indicated by the TMP increase. It was noted that there were some porous regions through which fine particles can pass through, which could lead to deterioration in the permeate quality and which might be compressed if the operating TMP was allowed to further increase. The DM layer appeared to have a very rough structure caused by deposition of the sludge particles in the absence of any external shear forces for fouling control.

EPS and SMP provide adhesion of bacterial cells in bioflocs and biofilms (Wang et al. 2012; Kunacheva and Stuckey 2014; Ersahin et al. 2015); thus, they are important in dynamic membrane systems, both in terms of the functional filtration as well as fouling. The EPS and SMP of the foulant layer were extracted and their DOM fractions were analyzed by LC-OCD and compared with the results obtained from the feed and permeate samples (Fig. 4). It was found that the predominant component of the DM were biopolymers, comprising 31–44% of the total organic carbon content, as compared to 10–15% for the feed and permeate samples. Previous studies have shown that biopolymers are the major foulant in MBRs (Rosenberger et al. 2006; Meng et al. 2011). Proteins constituted 65–72% of the biopolymers for the foulant layer. The predominance of proteins was confirmed through the carbohydrate and protein assays (Fig. 5). The implication is elaborated in the “Discussion” section.

Microbial community analysis

Figure 6 shows the classification by phylum level and relative abundance of bacteria in the foulant layer and R6h UASB bulk sludge. There was little variation, in terms of diversity, of the bacterial phyla in the bulk sludge collected at different heights of the UASB reactor (Fig. S6 in the Supplementary Information). The most predominant bacterial phyla in all the samples were Bacteriodetes, Proteobacteria, Firmicutes, and Cloacimonetes. Bacteriodetes was the most predominant phylum across all samples. It has been reported that Bacteriodetes could potentially contribute to fouling and biofilm formation through the release of proteinaceous EPS (Gao et al. 2010). This supports the chemical analysis results that the foulant layer had relatively high protein content. It is therefore postulated that Bacteriodetes probably played a part in the formation and consolidation of the dynamic membrane on the macroporous mesh.

The second most predominant phylum, Proteobacteria, had an almost 50% reduction in relative abundance in the foulant layer as compared to the bulk sludge. Within the phylum, there was significant reduction in sulfate-reducing δ-Proteobacteria, namely Desulfobulbaceae and Desulfomicrobiaceae, as well as Syntrophorhabdus which is responsible for degradation of aromatic compounds in sewage in syntrophic association with hydrogen-scavenging methanogens (Saia et al. 2016). This observation can be accounted for since degradation of most sulfates and any aromatic compound would have occurred within the UASB reactor. This is further supported by the greater abundance of Halothiobacillaceae which utilizes reduced sulfur for energy needs.

The foulant layer on the DMF contained a higher abundance of Cloacimonetes, of which the family Candidatus Cloacamonas consists of syntrophic fermentation bacteria common in anaerobic digesters and is considered a marker phylotype in low solids loading digesters (Hao et al. 2016). In view of this, the proliferation of this family in the foulant layer might have been caused by the change in solids loading environment from high (within the UASB reactor) to low (in the UASB effluent).

The relative abundance of archaea in the samples is depicted in Fig. 7. The predominant families in all the samples were Methanobacteriaceae, Methanoregulaceae, Methanospirillaceae, Methanotrichaceae, and Methanomassiliicoccacea. There were notable changes in relative abundances of methanogenic families in the foulant layer and the bulk sludge samples. It was observed that the ratio of acetoclastic to hydrogenotrophic methanogens followed a decreasing trend with the process flow: 1.83 at the bottom of UASB sludge blanket (port 1), 0.78 at the top of the UASB sludge blanket (port 4), and 0.14 in the foulant layer. This indicated that while acetoclastic methanogens tend to dominate in stable anaerobic processes for COD reduction via conversion of acetate to methane (Cardinali-Rezende et al. 2013) as in the UASB reactor, the hydrogenotrophic methanogens (Methanobacteriaceae, Methanoregulaceae, and Methanospirillaceae) were completely outcompeting the acetoclastic methanogens (Methanotrichaceae) in the foulant layer as the former were better adapted to the environment in the foulant layer.

Discussion

This study demonstrated that the UASB + DMF-coupled process treating municipal wastewater could achieve excellent contaminant removal performance. The DMF was beneficial in maintaining and improving the effluent quality even in the event of biomass washouts in the UASB. The DMF could operate at high fluxes which translates to high treatment capacity as well as economy of scale. Additionally, the support layer pore sizes tested appeared to exert little effect on contaminant removal once the dynamic layer was formed over the mesh, which was in agreement with the findings of previous dynamic membrane studies (Kiso et al. 2000; Park et al. 2004; Wu et al. 2005; Zhi-Guo et al. 2005; Walker et al. 2009). Further tests over a wider range of pore sizes could be performed to elucidate the effect over contaminant removal and fouling by the DMF. Unlike conventional membranes which require more rigorous cleaning methods such as air/water backwash or chemical cleaning, the foulant layer could be easily washed off the mesh surface by water flushing, thus eliminating the need for additional equipment or chemicals. Most importantly, the dynamic membrane is formed on macroporous filtration materials such as meshes or fabrics, which could be cheaply and easily obtained as compared to conventional membranes, thus bringing down the cost of the treatment system. Consequently, the UASB + DMF-coupled process serves as a feasible and sustainable treatment for municipal wastewater, particularly in resource-scarce regions.

The protein/carbohydrate (P/C) ratio for the EPS of the foulant layer was 2.4 (Fig. 5), which was similar to that reported in an anaerobic dynamic membrane bioreactor (AnDMBR) study (Ersahin et al. 2015). It had been suggested that the affinity between proteins and sludge flocs should generally be higher than that between polysaccharides and flocs (Lee et al. 2003; Massé et al. 2006). Additionally, it was reported that proteins tend to be more hydrophobic and could adhere to membrane surfaces more easily to induce fouling (Meng et al. 2006; Wang et al. 2013). The higher P/C ratio in the bound EPS could hence have aided the formation and stabilization of the dynamic layer, allowing better filtration and contaminant removal performance of the DMF.

The differences observed in the bacterial and archael community structures in the bulk sludge and foulant layer could be attributed to factors such as changes in the organic bioavailability and oxidation-reduction potential in the microenvironments they were in, which in turn allowed proliferation of microbes better adapted to the microenvironments. This presents an opportunity to further investigate the impact of the microenvironment in altering the microbial relative abundance so that desirable bacterial and archael species, for instance those that enhance methane production or removal of target contaminants, can thrive in the system.

In summary, the UASB + DMF-coupled process produced consistently good quality of treated effluent and demonstrated to be a viable alternative for municipal wastewater treatment.

References

APHA (2012) Standard methods for the examination of water and wastewater

Borges LI, López-Vazquez CM, García H, van Lier JB (2015) Nitrite reduction and methanogenesis in a single-stage UASB reactor. Water Sci Technol 72:2236–2242

Cao X, Sheng Y, Cao H, Zhang Y (2014) Comparison of Mg2+- and Ca2+-enhancing anaerobic granulation in an expanded granular sludge-bed reactor. Sci China Chem 57:1596–1601. doi:10.1007/s11426-014-5197-5

Cardinali-Rezende J, Araújo JC, Almeida PGS, Chernicharo CAL, Sanz JL, Chartone-Souza E, Nascimento AMA (2013) Organic loading rate and food-to-microorganism ratio shape prokaryotic diversity in a demo-scale up-flow anaerobic sludge blanket reactor treating domestic wastewater. Antonie Van Leeuwenhoek 104:993–1003. doi:10.1007/s10482-013-0018-y

Chernicharo CAL (2007) Anaerobic reactors. IWA Publishing, London

Dubois M, Gilles K, Hamilton J, Rebers P, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. doi:10.1021/ac60111a017

Ersahin ME, Ozgun H, Dereli RK, Ozturk I, Roest K, van Lier JB (2012) A review on dynamic membrane filtration: materials, applications and future perspectives. Bioresour Technol 122:196–206. doi:10.1016/j.biortech.2012.03.086

Ersahin ME, Ozgun H, Tao Y, van Lier JB (2014) Applicability of dynamic membrane technology in anaerobic membrane bioreactors. Water Res 48:420–429. doi:10.1016/j.watres.2013.09.054

Ersahin ME, Tao Y, Ozgun H, Spanjers H, van Lier JB (2015) Characteristics and role of dynamic membrane layer in anaerobic membrane bioreactors. Biotechnol Bioeng 113:761–771. doi:10.1002/bit.25841

Fakhimi N, Mehrnia MR (2015) Control of mixing for optimal formation of dynamic membrane in MBRs. Desalin Water Treat 57:15759–15771. doi:10.1080/19443994.2015.1076354

Fan B, Huang X (2002) Characteristics of a self-forming dynamic membrane coupled with a bioreactor for municipal wastewater treatment. Environ Sci Technol 36:5245–5251. doi:10.1021/es025789n

Field RW, Pearce GK (2011) Critical, sustainable and threshold fluxes for membrane filtration with water industry applications. Adv Colloid Interf Sci 164:38–44. doi:10.1016/j.cis.2010.12.008

Frøund B, Griebe T, Nielsen P (1995) Enzymatic activity in the activated-sludge floc matrix. Appl Microbiol Biotechnol 43:755–761

Fuchs W, Resch C, Kernstock M, Mayer M, Schoeberl P, Braun R (2005) Influence of operational conditions on the performance of a mesh filter activated sludge process. Water Res 39:803–810. doi:10.1016/j.watres.2004.12.001

Gao D-W, Zhang T, Tang C-YY, Wu W-M, Wong C-Y, Lee YH, Yeh DH, Criddle CS (2010) Membrane fouling in an anaerobic membrane bioreactor: differences in relative abundance of bacterial species in the membrane foulant layer and in suspension. J Memb Sci 364:331–338. doi:10.1016/j.memsci.2010.08.031

GonÇalves RF, Charlier AC, Sammut F (1994) Primary fermentation of soluble and particulate organic matter for wastewater treatment. Water Sci Technol 30:53–62

Hao L, Bize A, Conteau D, Chapleur O, Courtois S, Kroff P, Desmond-Le Quéméner E, Bouchez T, Mazéas L (2016) New insights into the key microbial phylotypes of anaerobic sludge digesters under different operational conditions. Water Res 102:158–169. doi:10.1016/j.watres.2016.06.014

Ho JH, Khanal SK, Sung S (2007) Anaerobic membrane bioreactor for treatment of synthetic municipal wastewater at ambient temperature. Water Sci Technol 55:79–86. doi:10.2166/wst.2007.130

Kim B-C, Nam J-W, Kang K-H (2017) Dynamic membrane filtration using powdered iron oxide for SWRO pre-treatment during red tide event. J Memb Sci 524:604–611. doi:10.1016/j.memsci.2016.11.081

Kiso Y, Jung Y-J, Ichinari T, Park M, Kitao T, Nishimura K, Min K-S (2000) Wastewater treatment performance of a filtration bio-reactor equipped with a mesh as a filter material. Water Res 34:4143–4150. doi:10.1016/S0043-1354(00)00201-3

Kunacheva C, Stuckey DC (2014) Analytical methods for soluble microbial products (SMP) and extracellular polymers (ECP) in wastewater treatment systems: a review. Water Res 61:1–18. doi:10.1016/j.watres.2014.04.044

Lee W, Kang S, Shin H (2003) Sludge characteristics and their contribution to microfiltration in submerged membrane bioreactors. J Memb Sci 216:217–227. doi:10.1016/S0376-7388(03)00073-5

Leitão RC, van Haandel AC, Zeeman G, Lettinga G (2006) The effects of operational and environmental variations on anaerobic wastewater treatment systems: a review. Bioresour Technol 97:1105–1118. doi:10.1016/j.biortech.2004.12.007

Li N, Hu Y, Lu Y-Z, Zeng RJ, Sheng G-P (2016) In-situ biogas sparging enhances the performance of an anaerobic membrane bioreactor (AnMBR) with mesh filter in low-strength wastewater treatment. Appl Microbiol Biotechnol 1–9. doi: 10.1007/s00253-016-7455-2

Lin HJ, Xie K, Mahendran B, Bagley DM, Leung KT, Liss SN, Liao BQ (2009) Sludge properties and their effects on membrane fouling in submerged anaerobic membrane bioreactors (SAnMBRs). Water Res 43:3827–3837. doi:10.1016/j.watres.2009.05.025

Lin H, Chen J, Wang F, Ding L, Hong H (2011) Feasibility evaluation of submerged anaerobic membrane bioreactor for municipal secondary wastewater treatment. Desalination 280:120–126. doi:10.1016/j.desal.2011.06.058

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275. doi:10.1016/0304-3894(92)87011-4

Massé A, Spérandio M, Cabassud C (2006) Comparison of sludge characteristics and performance of a submerged membrane bioreactor and an activated sludge process at high solids retention time. Water Res 40:2405–2415. doi:10.1016/j.watres.2006.04.015

Meng F, Zhang H, Yang F, Zhang S, Li Y, Zhang X (2006) Identification of activated sludge properties affecting membrane fouling in submerged membrane bioreactors. Sep Purif Technol 51:95–103. doi:10.1016/j.seppur.2006.01.002

Meng F, Zhou Z, Ni B-J, Zheng X, Huang G, Jia X, Li S, Xiong Y, Kraume M (2011) Characterization of the size-fractionated biomacromolecules: tracking their role and fate in a membrane bioreactor. Water Res 45:4661–4671. doi:10.1016/j.watres.2011.06.026

Oliveros JC (2007) Venny. An interactive tool for comparing lists with Venn’s diagrams. http://bioinfogp.cnb.csic.es/tools/venny/index.html

Park M, Kiso Y, Jung Y, Simase M, Wang W, Kitao T, Min K (2004) Sludge thickening performance of mesh filtration process. Water Sci Technol 50:125–133

Pillay VL, Townsend B, Buckley CA (1994) Improving the performance of anaerobic digesters at wastewater treatment works: the coupled cross-flow microfiltration/digester process. Water Sci Technol 30:329–337

Rosenberger SF, Laabs C, Lesjean B, Gnirss R, Amy G, Jekel M, Schrotter J-C (2006) Impact of colloidal and soluble organic material on membrane performance in membrane bioreactors for municipal wastewater treatment. Water Res 40:710–720. doi:10.1016/j.watres.2005.11.028

Ruiz I, Soto M, Veiga MC, Ligero P, Vega A, Blázquez R (1998) Performance of and biomass characterisation in a UASB reactor treating domestic waste water at ambient temperature. Water SA 24:215–222

Saia FT, Souza TSO, Duarte RTD, Pozzi E, Fonseca D, Foresti E (2016) Microbial community in a pilot-scale bioreactor promoting anaerobic digestion and sulfur-driven denitrification for domestic sewage treatment. Bioprocess Biosyst Eng 39:341–352. doi:10.1007/s00449-015-1520-6

Seghezzo L, Zeeman G, van Lier JB, Hamelers HVM, Lettinga G (1998) A review: the anaerobic treatment of sewage in UASB and EGSB reactors. Bioresour Technol 65:175–190. doi:10.1016/S0960-8524(98)00046-7

Shi X, Ng KK, Li X-R, Ng HY (2015) Investigation of intertidal wetland sediment as a novel inoculation source for anaerobic saline wastewater treatment. Environ Sci Technol 49:6231–6239. doi:10.1021/acs.est.5b00546

Smith AL, Stadler LB, Love NG, Skerlos SJ, Raskin L (2012) Perspectives on anaerobic membrane bioreactor treatment of domestic wastewater: a critical review. Bioresour Technol 122:149–159. doi:10.1016/j.biortech.2012.04.055

Souza CL, Chernicharo CAL, Aquino SF (2011) Quantification of dissolved methane in UASB reactors treating domestic wastewater under different operating conditions. Water Sci Technol 64:2259–2264. doi:10.2166/wst.2011.695

Tung K-L, Damodar H-R, Damodar R-A, Lin N-J, Chuang C-J, You S-J, Li Y-L (2014) Study on the effect of flux on particle fouling in a submerged membrane filtration system using a photo-interrupt sensor. J Water Sustain 4:205–225. doi:10.11912/jws.2014.4.4.205-225

Walker M, Banks CJ, Heaven S (2009) Development of a coarse membrane bioreactor for two-stage anaerobic digestion of biodegradable municipal solid waste. Water Sci Technol 59:729–735. doi:10.2166/wst.2009.012

Wang Z, Mei X, Wu Z, Ye S, Yang D (2012) Effects of biopolymer discharge from MBR mixture on sludge characteristics and membrane fouling. Chem Eng J 193–194:77–87. doi:10.1016/j.cej.2012.04.019

Wang Z, Mei X, Ma J, Grasmick A, Wu Z (2013) Potential foulants and fouling indicators in MBRs: a critical review. Sep Sci Technol 48:22–50. doi:10.1080/01496395.2012.682288

Wu Y, Huang X, Zuo W (2005) Effect of mesh pore size on performance of self-forming dynamic membrane coupled bioreactor for domestic wastewater treatment, future of urban wastewater. In: IWA International Conference

Xue N, Xia J, Huang X (2012) Fouling control of a pilot scale self-forming dynamic membrane bioreactor for municipal wastewater treatment. Desalin Water Treat 18:302–308. doi:10.5004/dwt.2010.1812

Ye F, Ye Y, Li Y (2011) Effect of C/N ratio on extracellular polymeric substances (EPS) and physicochemical properties of activated sludge flocs. J Hazard Mater 188:37–43. doi:10.1016/j.jhazmat.2011.01.043

Yu H, Wang Z, Wu Z, Zhu C (2015) Dynamic membrane formation in anaerobic dynamic membrane bioreactors: role of extracellular polymeric substances. PLoS One 10:e0139703. doi:10.1371/journal.pone.0139703

Yue X, Koh YKK, Ng HY (2015) Effects of dissolved organic matters (DOMs) on membrane fouling in anaerobic ceramic membrane bioreactors (AnCMBRs) treating domestic wastewater. Water Res 86:96–107. doi:10.1016/j.watres.2015.07.038

Zhang X, Wang Z, Wu Z, Lu F, Tong J, Zang L (2010) Formation of dynamic membrane in an anaerobic membrane bioreactor for municipal wastewater treatment. Chem Eng J 165:175–183. doi:10.1016/j.cej.2010.09.013

Zhang X, Wang Z, Wu Z, Wei T, Lu F, Tong J, Mai S (2011) Membrane fouling in an anaerobic dynamic membrane bioreactor (AnDMBR) for municipal wastewater treatment: characteristics of membrane foulants and bulk sludge. Process Biochem 46:1538–1544. doi:10.1016/j.procbio.2011.04.002

Zhang Y, Zhao Y, Chu H, Zhou X, Dong B (2014) Dewatering of Chlorella pyrenoidosa using diatomite dynamic membrane: filtration performance, membrane fouling and cake behavior. Colloids Surf B Biointerfaces 113:458–466. doi:10.1016/j.colsurfb.2013.09.046

Zhi-Guo M, Feng-lin Y, Xing-wen Z (2005) MBR focus: do nonwovens offer a cheaper option? Filtr Sep 42:28–30. doi:10.1016/S0015-1882(05)70558-9

Acknowledgements

The authors acknowledge the financial support by the Ministry of Education, Singapore, for Pei Jun Quek’s PhD program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

ESM 1

(PDF 447 kb)

Rights and permissions

About this article

Cite this article

Quek, P.J., Yeap, T.S. & Ng, H.Y. Applicability of upflow anaerobic sludge blanket and dynamic membrane-coupled process for the treatment of municipal wastewater. Appl Microbiol Biotechnol 101, 6531–6540 (2017). https://doi.org/10.1007/s00253-017-8358-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8358-6