Abstract

With vanillin as one of the most important flavoring agents, many efforts have been made to optimize its biotechnological production from natural abundant substrates. However, its toxicity against the hosts results in rather low yields and product concentrations. Bacillus subtilis as a soil-dwelling bacterium is a possible lignin-derived compound-degrading microorganism. Therefore, its vanillin and ferulic acid metabolism was investigated. With a rather high tolerance for vanillin up to 20 mM, it is a promising candidate to produce natural vanillin. In this study, the well-studied phenolic acid decarboxylases PadC and BsdBCD could be ascribed to function as the only enzymes in B. subtilis 3NA converting ferulic acid to 4-vinylguaiacol and vanillic acid to guaiacol, respectively. As vanillin also becomes converted to guaiacol, a previous conversion to vanillic acid was assumed. Usage of bioinformatic tools revealed YfmT, which could be shown to function as the only vanillin dehydrogenase in B. subtilis 3NA. Thus, YfmT was further characterized regarding its temperature and pH optima as well as its substrate range. Vanillin and ferulic acid metabolic routes in the tested B. subtilis strain were revealed, a direct conversion of ferulic acid to vanillin, however, could not be found.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Vanillin (4-hydroxy-3-methoxybenzaldehyde), the organoleptic compound of the vanilla flavor, is one of the quantitative most widely used flavoring agents worldwide. The extraction of natural vanillin from cured seed pods of the orchid Vanilla planifolia is too expensive, time consuming, and cannot deliver the amounts necessary for the global market. At present, most of the “nature-identical” vanillin used in the food and beverage industry is synthesized chemically from guaiacol (Ramachandra Rao and Ravishankar 2000). However, the demand has shifted towards a “natural” vanillin due to a rising health and nutrition consciousness of the customers making biotechnological production of “natural” vanillin more and more important (reviewed by Krings and Berger 1998; Priefert et al. 2001).

Besides the attractive, but difficult approach of de novo vanillin biosynthesis from primary metabolites like glucose (Hansen et al. 2009). focus was put on biotransformation strategies using isolated enzymes or different microorgnisms as whole cell biocatalysts to produce vanillin from various substrates like lignin, phenolic stilbenes, and ferulic acid (Havkin-Frenkel and Belanger 2008; Berger 2009). Ferulic acid [3-(4-hydroxy-3-methoxy-phenyl)prop-2-enoic acid] is a constituent of many plant cell walls and thus a highly abundant natural and renewable raw material (Ishikawa et al. 1963; Escott-Watson and Marais 1992; Ishii 1997; Oosterveld et al. 2000). Many efforts were taken to develop a highly efficient method for biotransformation of ferulic acid to “natural” vanillin (reviewed by Rosazza et al. 1995; Priefert et al. 2001). Also many different microorganisms have been evaluated for this production strategy comprising, e.g., Escherichia coli, Pseudomonas sp., Rhodococcus sp., Aspergillus niger, Pycnoporus cinnabarinus, Amycolatopsis ssp., and Streptomyces ssp. (Lesage-Meessen et al. 1996; Muheim and Lerch 1999; Okeke and Venturi 1999; Achterholt et al. 2000; Overhage et al. 2003; Peng et al. 2003; Plaggenborg et al. 2006; Barghini et al. 2007; Hua et al. 2007; Yoon et al. 2007; Di Gioia et al. 2010; Tilay et al. 2010; Fleige et al. 2013; Graf and Altenbuchner 2014).

However, high concentrations of vanillin are toxic due to its highly reactive aromatic aldehyde group. Thus, cells have developed detoxification mechanisms, leading to further degradation to vanillic acid and other degradation products and finally to lower yields regarding biotransformation efforts. Vanillin-tolerant bacterial strains, which are able to convert ferulic acid and thereby accumulate large amounts of vanillin, have to be screened and found in order to overcome this drawback.

Bacillus subtilis is a well-studied, soil-dwelling bacterium. Hence, it is a possible degrader of lignin-derived compounds which can be found abundantly in soil. This makes this microorganism a promising candidate for the production of natural vanillin from ferulic acid via biotransformation. Its vanillin and ferulic acid metabolisms, however, have only been partly investigated in detail. It was shown that B. subtilis converts vanillic acid to guaiacol via the vanillic acid decarboxylase BsdBCD encoded by ubiX, ubiD, bsdD, and yclD (Lupa et al. 2005; Lupa et al. 2008). With PadC, B. subtilis possesses a further decarboxylase which is capable to degrade ferulic, p-coumaric, and caffeic acids (Cavin et al. 1998). In both cases, however, it has not been shown that these phenolic acid decarboxylases are the only enzymes capable to convert the described reactions.

Furthermore, some wild-type strains of B. subtilis seem to be capable of converting ferulic acid over vanillic acid to vanillin via enzymatic activities comparable with the Pseudomonas sp. Fcs (feruloyl-CoA synthetase), Ech (enoyl-CoA hydratase/aldolase), and Vdh (vanillin dehydrogenase) or by simple deacetylase activities (Gurujeyalakshmi and Mahadevan 1987b; Chen et al. 2014). In contrast to Pseudomonas putida KT2440, no genes like ech, fcs, or vdh have been identified in the common laboratory strain B. subtilis 168 (Kunst et al. 1997).

Due to its GRAS status, B. subtilis brings along a prerequisite for the food industry. In order to implement this well-studied microorganism into the row of candidates for biotechnological production of vanillin, its metabolic pathway regarding the conversion of precursor substances into this high-value compound was further investigated in this study to provide a more profound research basis. Focus was set on the identification of the responsible enzymes degrading vanillin and ferulic acid.

Materials and methods

Plasmids, bacterial strains, and growth conditions

Relevant bacterial strains and plasmids used in this study are summarized in Table 1. Standard recombinant DNA techniques were used (Sambrook et al. 1989). Cloning steps were performed with E. coli JM109 (Yanisch-Perron et al. 1985). E. coli JM109 was transformed with plasmid DNA using the TSS heat shock method as described before (Chung et al. 1989). B. subtilis 3NA (Michel and Millet 1970) was transformed according to the modified “Paris method” (Harwood and Cutting 1990). Growth was performed at 37 °C using LB (Bertani 1951) or MG1 minimal salts medium (Wenzel and Altenbuchner 2015). MG1 contents per 1 l—2 g (NH4)2SO4, 6 g KH2PO4, 14 g K2HPO4, 1 g trisodium citrate, 0.2 g MgSO4, and 5 g glucose or 5 mM of a given carbon source. If necessary, additional 200 mg casamino acids and 1 ml of a 1000-fold trace element solution (TES) were added per liter. TES contains 0.5 g l−1 CaCl2, 0.18 g l−1 ZnSO4 × 7 H2O, 0.1 g l−1 MnSO4 × H2O, 10.05 g l−1 Na2-EDTA, 8.35 g l−1 FeCl3, 0.16 g l−1 CuSO4 × 5 H2O, and 0.18 g l−1 CoCl2 × 6 H2O. Antibiotics were used in the following concentrations: ampicillin (amp), 100 μg ml−1; spectinomycin (spc), 100 μg ml−1; and erythromycin (erm), 5 μg ml−1.

Chemicals and other materials

Chemicals were supplied by Sigma-Aldrich Chemie GmbH (Taufkirchen, Germany) and Carl Roth GmbH (Karlsruhe, Germany). DNA oligonucleotides were purchased from Eurofins MWG Operon GmbH (Ebersberg, Germany), and restriction enzymes and DNA-modifying enzymes were from Roche Diagnostics Deutschland GmbH (Mannheim, Germany), New England Biolabs GmbH (Frankfurt am Main, Germany), and Fermentas GmbH (part of Thermo Fisher Scientific, St. Leon-Rot, Germany), respectively. PCRs were run with high-fidelity PCR enzyme mix from Fermentas GmbH on a TPersonal Thermocycler from Biometra GmbH (Goettingen, Gemany).

Bioconversion assays

The bioconversion assay was basically conducted as previously described for P. putida (Graf and Altenbuchner 2014). B. subtilis strains were inoculated 1:50 in fresh LB medium using overnight cultures grown in LB. Expression of genes encoding the respective degrading enzymes was induced by addition of 5 mM of the corresponding substance after 2 h at 37 °C incubation in shaking flasks (200 rpm) at 0.25 ± 0.02 OD600. After further growth for 4 h at 37 °C, the cultures reached 2.75 ± 0.21 OD600. Approximately 1010 cells were harvested by centrifugation (10 min, 3500×g, room temperature), washed, and resuspended with 2 ml of 50 mM sodium phosphate buffer (pH 7.2). A total of 10 mM of the respective substances to get converted (ferulic acid, vanillin, vanillic acid, and protocatechuic acid) was added to the cell suspension. The bioconversion was conducted in long glass culture tubes at 37 °C under shaking conditions (200 rpm). Samples of 200 μl were taken for HPLC analysis at the given points in time. After a centrifugation step (10 min, 16,000×g, room temperature) to pellet the cells of the sample, 100 μl of the supernatant was collected and stored at −70 °C until HPLC analysis.

HPLC analysis

The analytical HPLC method was conducted as previously described for P. putida (Graf and Altenbuchner 2014). samples taken from the bioconversion assay were diluted 1:10 with 0.2 % acetic acid prior to HPLC application on a Merck-Hitachi HPLC system (Merck, Darmstadt, Germany) equipped with a RP Purospher®-Star RP-18e column (250 × 4.6 mm, 5 μm), a LiChroCART® guard column (4 × 4 mm, 5 μm), an L7612 degasser, an L6200A gradient pump, a D6000A interface module, an L4200 UV–visible detector, a Rheodyne injection valve 7125 with a 100-μl sample loop, and D7000 HPLC System Manager software. For measurements, a modified procedure was used as described previously (Sinha et al. 2007). methanol, acetonitril, and 0.2 % acetic acid (3:3:14) were used as the mobile phase. The flow rate was 1 ml min−1, and the absorbance was measured at 231 nm for 20 min. Solutions of several aromatic compounds with seven different concentrations (0.05, 0.1, 0.2, 0.3, 0.4, 0.5, and 1 mM) were used for calibration. All standards were of analytical grade. Retention times of the standards were as follows: protocatechuic acid (4.63 min), ferulic acid (13.51 min), vanillin (11.11 min), vanillic acid (7.39 min), vanillyl alcohol (4.89 min), catechol (7.08 min), guaiacol (15.42 min), 4-vinylguaiacol (51.99 min), 3-hydroxy-4-methoxybenzaldehyde (9.41 min), 4-hydroxybenzaldehyde (9.2 min), 3-hydroxybenzaldehyde (10.97 min), 3,4-dihydroxybenzaldehyde (5.96 min), 3-ethoxy-4-hydroxybenzaldehyde (17.82 min), benzaldehyde (22.47 min), salicylaldehyde (25.55 min), 4-hydroxy-3-methoxycinnamaldehyde (15.31 min), and cinnamaldehyde (55.6 min).

Colony PCR

Mutant and wild-type clones of B. subtilis were streaked out on LB agar plates and grown overnight at 37 °C. A sufficient amount of cells was taken from these plates and resuspended in 100 μl H2O (deionized). After heating the suspension for 10 min at 99 °C, a cold shock for 20 min at −70 °C followed by a further heating step (10 min at 99 °C) was performed. After centrifugation of the cell suspension, 10 μl of the supernatant containing chromosomal DNA was used in a 30-μl PCR preparation using the Thermo Scientific™ DreamTaq™ DNA Polymerase.

In vitro enzyme activity assays

Enzyme activity was determined in a discontinuous assay by measuring metabolite formation using HPLC, since a spectrophotometric assay could not be used due to the same absoption maxima of vanillin and NADH at 340 nm. In general and in accordance to similar experiments with Amycolatopsis sp. (Fleige et al. 2013). the reaction mixture contained, in a total volume of 1 ml, 0.1 mM potassium phosphate buffer (pH 7.0), 2 mM NAD+, 1.25 mM substrate, and 250 μg ml−1 of the enzyme preparation. Enzyme activity is stated in units (U). One unit is defined as the amount of enzyme which converts 1 μmol substrate/min. In general, the assays were started after addition of the substrate and NAD+. Samples of 50 μl were taken, and the reaction stopped by heating to 85 °C for 5 min. The stopped samples were centrifuged and stored at −70 °C until HPLC analysis. To determine the temperature optimum, the assay was performed at 20 to 60 °C in several steps. After determination of the optimum temperature, the effect of pH was investigated at the optimimum temperature by using 50 μg ml−1 of the enzyme preparation in 100 mM of varying buffer systems. Samples were taken immediately and after 60 min incubation. The kinetic assay was performed by taking samples after 0, 1, 2, 3, 4, 5, 10, 15, 20, 30, and 60 min incubation.

Inactivation of chromosomal genes in B. subtilis

For inactivation of single genes, advantage was taken of the Bacillus knockout erythromycin (BKE) strains available from the Bacillus Genetic Stock Center (BGSC; www.bgsc.org). These B. subtilis 168-derived strains carry an erythromycin resistance cassette flanked by FRT sites integrated into one non-essential chromosomal gene. The strain number is derived from the corresponding BSU gene number in the GenoList database for the inactivated gene. Chromosomal DNA of the BKE strains was extracted using the DNeasy Blood and Tissue Kit (QIAGEN, Hilden, Germany) and used from transformation of B. subtilis 3NA. Selection of the strains with inactivated gene function by double-crossover via homologous recombination occurred via selection on LB agar plates containing erythromycin. These strains were streaked out onto LB to get single colonies. Gene inactivation was confirmed by colony PCR.

Overproduction and purification of B. subtilis YfmT with E. coli JM109

YfmT with a C-terminal His6-tag was overexpressed in E. coli JM109/pNG533.1 as follows: cells were grown for 2 h at 37 °C. After induction with 0.2 % (w/v) rhamnose, growth continued at 30 °C for 4 h. Approximately 3 × 1010 cells were harvested by centrifugation. The pelleted cells were washed with 50 mM sodium phosphate buffer (pH 7.2) and either stored at −20 °C or resuspended with 1 ml lysis buffer (50 mM NaH2PO4, 300 mM NaCl, 10 mM imidazole). Crude cell extracts were prepared using ultrasonic sound (3 × 45 s, 50 % duty cycle; Heat Systems-Ultrasonics, Inc., model W-385 sonicator, Farmingdale, New York, USA). After centrifugation, the supernatant containing the soluble protein fraction was used for affinity tag chromatography using Ni-NTA Agarose resin according to the manufacturer’s instructions (QIAGEN, Hilden, Germany). Purified proteins were quantified using the Bradford method (Bradford 1976). Purity was confirmed by SDS-PAGE.

Results

Growth behavior of B. subtilis 3NA on vanillin and ferulic acid

As a representative strain, B. subtilis 3NA (spo0A3, sporulation negative) was chosen to determine metabolic properties regarding the conversion of vanillin and ferulic acid, because of its advantage as a production strain (Wenzel et al. 2011). In comparison with the well-studied P. putida strains as putative vanillin producers (Muheim and Lerch 1999; Overhage et al. 1999; Walton et al. 2000; Priefert et al. 2001; Jiménez et al. 2002; Yamada et al. 2007; Kaur and Chakraborty 2013; Graf and Altenbuchner 2014). its ability to grow on ferulic acid, vanillin, vanillic acid and protocatechuic acid as sole carbon sources was examined. Starter cultures were gained by initial growth in MG1 medium with 0.5 % (w/v) glucose as carbon source. Cells were washed twice with MG1 without carbon source and used for inoculation to 0.05 OD600 in MG1 with 5 mM of one of the aforementioned substances as sole carbon source. The main cultures were grown for 16 h at 37 °C before measuring their final OD600 (Table 2).

Significant growth only occurred with glucose and protocatechuic acid. All cultures were checked microscopically, but no morphological changes could be detected in neither of the tested substrates. Growth on solid MG1 media showed equal results: colony formation was only observed with glucose and protocatechuic acid after incubation for 72 h at 37 °C.

To verify the results from the growth experiments, HPLC analysis was performed. After induction of B. subtilis 3NA with the corresponding substance, bioconversion assays were performed with resting cells. Samples were taken immediately after addition of the substance as well as after 18 h incubation at 37 °C. Ferulic acid was converted to a substance identified as 4-vinylguaiacol (2-methoxy-4-vinylphenol). Beneath its characteristic odor of buckwheat, 4-vinylguaiacol possesses a jellylike constitution. Hence, its application as a standard for HPLC analysis was difficult and thus a truthful quantification not possible. However, no further peak was observed after 18 h conversion time. Vanillin was converted to ca. 97 % guaiacol and 3 % vanillyl alcohol, whereas vanillic acid was completely converted to guaiacol. Interestingly, despite induction no conversion could be observed in the case of protocatechuic acid.

Conversion kinetics with resting cells of B. subtilis 3NA showed that vanillin is converted to guaiacol, forming vanillic acid as an intermediate product in the first few hours (Fig. 1). While vanillic acid disappears after 18 h conversion time, guaiacol further accumulates. Furthermore, vanillyl alcohol was detected as a byproduct after 1 h conversion. Its concentration stayed constant until the end of the conversion experiment.

Conversion kinetics of resting Bacillus subtilis 3NA cells incubated at 37 °C for 18 h with 10 mM vanillin. Samples were taken at the given points of time and analyzed by HPLC. Shown here is a representative example of three conducted independent experiments. The standard deviation was less than 5 % each

Tolerance of B. subtilis 3NA to vanillin and ferulic acid

Since vanillin and ferulic acid are both known to be toxic at certain levels (Krings and Berger 1998; Graf and Altenbuchner 2014). the critical concentration was determined for B. subtilis 3NA. Growth was performed in additionally buffered MG1 with TES and casamino acids to reach higher growth rates and cell densities in order to show the effect of vanillin and ferulic acid. After inoculation with 0.05 OD600 cultures were grown with raising concentrations up to 30 mM of either vanillin or ferulic acid. After 16 h at 37 °C, the OD600 and the pH were measured (Fig. 2).

Tolerance of Bacillus subtilis 3NA to vanillin and ferulic acid. Shown are the OD600 and the pH after growth for 24 h at 37 °C in MG1 minimal medium with the given amounts of vanillin or ferulic acid. Also shown is the mean value of three conducted independent experiments. The standard deviation is given by error bars

Vanillin is tolerated up to 20 mM, while ferulic acid seems to be more toxic, significantly restricting growth at even 10 mM. A pH effect due to the addition of the acidic compounds could not be observed, since the pH value stayed in a rather neutral range.

Role and influence of the phenolic acid decarboxylases BsdBCD and PadC

The phenolic acid decarboxylases BsdBCD and PadC of B. subtilis have been shown in vitro to convert vanillic acid to guaiacol and ferulic acid to 4-vinylguaiacol, respectively (Cavin et al. 1998; Lupa et al. 2008). Although these enzymes have been characterized in detail, it was not yet shown, if there are other isoenzymes in B. subtilis able to catalyze these reactions, too. Thus, mutant strains were constructed and used for conversion assays.

Inactiviation of padC occurred via transformation of B. subtilis 3NA with chromosomal DNA of B. subtilis BKE 34400 (padC::erm trpC2) resulting in strain MWZ 86 (spo0A3 padC::erm). Induction of MWZ 86 with ferulic acid resulted in immediate growth impairment. Thus, 3NA and MWZ 86 were grown without prior induction with ferulic acid before cells were harvested for the conversion assays. Whereas 3NA was still capable of converting ferulic acid to 4-vinylguaiacol, MWZ 86 lost its ability to convert ferulic acid.

However, in case of BsdBCD, strain construction was more laborious, since BsdBCD is encoded by four genes: ubiX, ubiD, bsdD, and yclD (Lupa et al. 2008). Deletion of these genes was conducted using a temperature sensitive vector system with a pE194ts origin of replication (Arnaud et al. 2004; Zakataeva et al. 2010). After PCR amplification of the ubiX up- and yclD downstream flanking regions using primers s9506/s9507 (aaaaaaggatccTATGAGTCAAGTATTTGGTTTTC/ataaaagagctcCATTTCAATCATACTCCTG ATAT) and s9508/s9509 (aaaaaagagctcTAAAAAACAGCCCGCAGATCA/aaaaaaggatccTCGGTGGTTTA CTCGCGCC), respectively, the fragments were inserted via 3-fragment-ligation using BamHI/SacI into pMW521.1 (a pE194ts derivative) giving pNG507.4. The genes ubiX, ubiD, bsdD, and yclD were deleted in the chromosome of B. subtilis 3NA using this vector. The resulting strain was checked by colony PCR (s9506/s9509) and designated MWZ 76. Repeated conversion assays with that strain showed that ferulic acid gets still converted to 4-vinylguaiacol. Vanillin, however, was converted to ca. 95 % vanillic acid and 5 % vanillyl alcohol. No further conversion to guaiacol was observed.

According to the observation that guaiacol-glycerolether is catabolized via catechol in B. subtilis (Gurujeyalakshmi and Mahadevan 1987a), conversion of guaiacol and catechol was also investigated with 3NA and MWZ 76 via HPLC analysis. In all strains, the guaiacol peak slightly declined in the conversion assays, but no catechol peak could be detected. Conversion of catechol itself also showed a slight reduction in all strains, however, revealing no further detectable peaks during HPLC analysis.

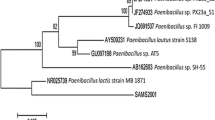

Identification of the vanillin dehydrogenase YfmT

As the aldehyde group of vanillin is oxidized to the carboxyl group of vanillic acid, the enzyme catalizing this reaction is most probably an aldehyde dehydrogenase which has not yet been identified. To reveal that missing link, the sequence of the vanillin dehydrogenase Vdh of P. putida KT2440 (Vdh_ppu) (Nelson et al. 2002) was used as a query in a tBLASTn search (Altschul et al. 1990) with the translated nucleotide database for B. subtilis (taxid:1423). The result showed several candidate genes encoding mostly aldehyde dehydrogenases (Table 3).

Taking advantage of the BKE strain collection of the BGSC, all corresponding strains were tested for their ability to convert vanillin (HPLC analysis). Besides B. subtilis BKE 07350 (yfmT::erm trpC2), all strains converted vanillin to vanillic acid, vanillyl alcohol, and guaiacol. YfmT shows the highest similarity to the vanillin dehydrogenase of P. putida KT2440 and also seems to be the only responsible enzyme for the conversion of vanillin to vanillic acid in B. subtilis. Northern blot analysis and DNA microarrays indicated that yfmT is regulated by σD together with yfmS (Serizawa et al. 2004). It was stated by Serizawa et al. (2004) that YfmT (485 amino acids) and YfmS (286 amino acids) exhibit similarity to benzaldehyde dehydrogenase and methyl-accepting chemotaxis proteins, respectively. Furthermore, the σD consensus sequence was found in the yfmT promoter region. These results indicate that yfmT–yfmS are transcribed by σD RNA polymerase as a polycistronic mRNA. So far, no further characterization of either YfmT or YfmS was performed.

Characterization of the dehydrogenase YfmT

For further characterization of the dehydrogenase YfmT its gene was cloned after PCR amplification with s9986/s9987 (aaataacatATGTTTCAATATGAAGAGTTGAATAA / aaaaaaggatccATAAGGGAAGCTGC GTTTTTCG) via NdeI/BamHI into pMW851.2 (Wenzel and Altenbuchner 2013), resulting in pNG533.1. After overexpression in E. coli JM109 and purification of the C-terminal His6-tagged YfmT, the protein was first used to show its ability to convert vanillin to vanillic acid at standard conditions (37 °C and neutral pH) (Fig. 3).

Conversion kinetics of purified YfmT using vanillin as substrate. The concentrations of vanillin (closed circles) and vanillic acid (open rectangles) after the given time of incubation at 37 °C and pH 7.0 are shown as the mean value of three independent experiments. Standard deviation is given by error bars

The highest enzyme activity could be observed within the first 5 minutes, where 0.16 μmol vanillin were converted per minute, giving 0.16 U. The specific activity was 0.6 U mg−1 enzyme. This is the maximum enzyme activity, since in further experiments the temperature and pH optimum of YfmT were determined to be 37–40 °C and 7.0, respectively (Fig. 4).

Identification of the temperature (a) and pH (b) optimum using purified YfmT. The percentile conversion after 15 min incubation at pH 7.0 and differing temperatures (a) and at 37 °C and differing pH values (b), respectively, is shown as the mean value of three independent experiments. Standard deviation is given by error bars

For further characterization, the substrate range of YfmT was determined by testing vanillin and some derivatives thereof (Fig. 5). To compare the enzyme affinity for the different substrates, conversion was generally stopped after 15 min incubation at 37 °C and pH 7.0. Reduction of the substrate peaks (reduced substrate concentration) was detected for each compound and expressed in percent for better comparison. After 15 min ca. 80 % of vanillin, 3,4-dihydroxybenzaldehyde, 4-hydroxybenzaldehyde, and 3-ethoxy-4-hydroxybenzaldehyde were converted. 3-hydroxybenzaldehyde and benzaldehyde showed even higher convertion rates since they were nearly completely converted. YfmT was also able to convert 3-hydrox-4-methoxybenzaldehyde and salicylaldehyde at lower levels, whereas 4-hydroxy-3-methoxycinnamaldehyde and cinnamaldehyde were nearly not converted at all.

Identification of the substrate range using purified YfmT and different compounds structurally related to vanillin (4-hydroxy-3-methoxybenzaldehyde; marked by an asterisk). The percentile conversion of the corresponding compound after 15 min incubation at 37 °C and pH 7.0 is shown as the mean value of three independent experiments. Standard deviation is given by error bars

Discussion

In order to apply B. subtilis as a host for the production of secondary metabolites such as the high-value compound vanillin, its metabolism concerning the degradation of vanillin and ferulic acid as well as its tolerance against these aromatic compounds was investigated. The tested B. subtilis 3NA strain does not use vanillin and ferulic acid as carbon or energy sources, because nearly no growth could be detected using these substances in growth experiments. No degradation via protocatechuic acid or catechol like in natural isolates of B. subtilis could be observed (Gurujeyalakshmi and Mahadevan 1987a; Gurujeyalakshmi and Mahadevan 1987b). Vanillin, however, is degraded by YfmT and BsdBCD via vanillic acid to the dead end product guaiacol, while ferulic acid is converted by PadC to the dead end product 4-vinylguaiacol. Furthermore, the bioconversions are forced because of the high potential toxicity of these aromatic compounds. This degradation route for vanillin was also proposed for the natural isolate wild-type strain B. subtilis HS8 starting with isoeugenol (Zhang et al. 2006). In contrast to P. putida KT2440 (Graf and Altenbuchner 2014), B. subtilis 3NA tolerates vanillin in higher concentrations than ferulic acid. Also in B. subtilis, vanillin is converted in small amounts to vanillyl alcohol by a not yet specified mechanism. Since this conversion was only detectable in the beginning, i.e., under high vanillin concentrations, it seems to be a rapid detoxification mechanism. A similar observation was made in yeasts (e.g., Saccharomyces cerevisiae) by Hansen et al. (2009) where a probably unspecific dehydrogenase catalyzed this step. Since the concentration of the formed vanillyl alcohol stayed constant, it is most probably a dead-end product which is not converted back to vanillin.

BsdBCD and PadC are capable to convert different substrates (Cavin et al. 1998; Lupa et al. 2008) and are induced as a result of phenolic acid stress response regulated by σB to avoid cytoplasmic acidification (Duy et al. 2007; Kitko et al. 2009). YfmT also showed a wide substrate range, but its induction is regulated by another sigma factor and is connected to yfmS. YfmS is one of the two soluble chemotaxis sensory transducer proteins (receptors) in B. subtilis, localized at the cell poles and whose ligand is not known yet (Serizawa et al. 2004; Cannistraro et al. 2011). According to the findings in this study, it might respond to environmental changes in the concentration of vanillin and its derivatives, and transduce this signal to the inside of the cell. Future studies might confirm the involvement of YfmS in the signal transduction responding to aromatic compounds.

B. subtilis 3NA was very sensitive against ferulic acid, since addition of even low amounts (10 mM) of this compound to a growing culture stopped growth nearly completely. The inactivation of padC had an even worse effect, since addition of only 5 mM of ferulic acid to a complex medium (LB) stopped growth nearly immediately. In case of vanillin, the inactivation of yfmT and bsdBCD did not affect the growth behavior, confirming a higher tolerance for vanillin. Thus, it can be concluded and confirmed that the bioconversions of vanillin and especially ferulic acid to the dead-end products guaiacol and 4-vinylguaiacol, respectively, seem to be detoxification mechanisms.

However, the aspired establishment of B. subtilis 3NA to produce natural vanillin from ferulic acid was not achieved. Although a reversible reaction mechanism of BsdBCD was observed by Lupa et al. (2008), the conversion of guaiacol to vanillic acid even under high concentrations of solved CO2 was extremely low. In contrast to the findings with isolated wild-type strains or other Bacillus species (Karmakar et al. 2000; Chen et al. 2014), no direct or indirect conversion of ferulic acid to vanillin could be detected in the tested B. subtilis 3NA derived strains. However, it could be shown that there are no isoenzymes for YfmT, PadC, and BsdBCD concerning vanillin metabolism. From the performed experiments, a scheme for the vanillin and ferulic acid metabolism in B. subtilis 3NA could be concluded (Fig. 6). YfmT could be identified and characterized, providing a basis for further aromatic compound studies with B. subtilis.

References

Achterholt S, Priefert H, Steinbüchel A (2000) Identification of Amycolatopsis sp. strain HR167 genes, involved in the bioconversion of ferulic acid to vanillin. Appl Microbiol Biotechnol 54:799–807. doi:10.1007/s002530000431

Altschul SF, Gish W, Miller W, Myers EW, Lipman DJ (1990) Basic local alignment search tool. J Mol Biol 215:403–410. doi:10.1006/jmbi.1990.9999

Arnaud M, Chastanet A, Debarbouille M (2004) New vector for efficient allelic replacement in naturally nontransformable, low-GC-content, gram-positive bacteria. Appl Environ Microbiol 70:6887–6891. doi:10.1128/AEM.70.11.6887-6891.2004

Barghini P, Di GD, Fava F, Ruzzi M (2007) Vanillin production using metabolically engineered Escherichia coli under non-growing conditions. Microb Cell Fact 6:13. doi:10.1186/1475-2859-6-13

Berger RG (2009) Biotechnology of flavours—the next generation. Biotechnol Lett 31:1651–1659. doi:10.1007/s10529-009-0083-5

Bertani G (1951) Studies on lysogenesis. 1. The mode of phage liberation by lysogenic Escherichia coli. J Bacteriol 62:293–300

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. doi:10.1016/0003-2697(76)90527-3

Cannistraro VJ, Glekas GD, Rao CV, Ordal GW (2011) Cellular stoichiometry of the chemotaxis proteins in Bacillus subtilis. J Bacteriol 193:3220–3227. doi:10.1128/JB.01255-10

Cavin JF, Dartois V, Divies C (1998) Gene cloning, transcriptional analysis, purification, and characterization of phenolic acid decarboxylase from Bacillus subtilis. Appl Environ Microbiol 64:1466–1471

Chen P, Li S, Yan L, Wang N, Yan X, Li H (2014) Draft genome sequence of Bacillus subtilis type strain B7-S, which converts ferulic acid to vanillin. Genome Announc 2. doi:10.1128/genomeA.00025-14. doi:10.1128/genomeA.00025-14

Chung CT, Niemela SL, Miller RH (1989) One-step preparation of competent Escherichia coli: transformation and storage of bacterial cells in the same solution. Proc Natl Acad Sci USA 86:2172–2175. doi:10.1073/pnas.86.7.2172

Di Gioia D, Luziatelli F, Negroni A, Ficca AG, Fava F, Ruzzi M (2010) Metabolic engineering of Pseudomonas fluorescens for the production of vanillin from ferulic acid. J Biotechnol 156:309–316. doi:10.1016/j.jbiotec.2011.08.014

Duy NV, Mäder U, Tran NP, Cavin JF, Tam IT, Albrecht D, Hecker M, Antelmann H (2007) The proteome and transcriptome analysis of Bacillus subtilis in response to salicylic acid. Proteomics 7:698–710. doi:10.1002/pmic.200600706

Escott-Watson PL, Marais JP (1992) Determination of alkali-soluble phenolic monomers in grasses after separation by thin-layer chromatography. J Chromatgr 604:290–293. doi:10.1016/0021-9673(92)85141-F

Fleige C, Hansen G, Kroll J, Steinbüchel A (2013) Investigation of the Amycolatopsis sp. strain ATCC 39116 vanillin dehydrogenase and its impact on the biotechnical production of vanillin. Appl Environ Microbiol 79:81–90. doi:10.1128/AEM.02358-12

Graf N, Altenbuchner J (2014) Genetic engineering of Pseudomonas putida KT2440 for rapid and high-yield production of vanillin from ferulic acid. Appl Microbiol Biotechnol 98:137–149. doi:10.1007/s00253-013-5303-1

Gurujeyalakshmi G, Mahadevan A (1987a) Degradation of guaiacol glyceryl ether (GGE) by Bacillus subtilis. Appl Microbiol Biotechnol 26:289–293. doi:10.1007/BF00286326

Gurujeyalakshmi G, Mahadevan A (1987b) Dissimilation of ferulic acid by Bacillus subtilis. Curr Microbiol 16:69–73. doi:10.1007/BF01588174

Hansen EH, Moller BL, Kock GR, Bunner CM, Kristensen C, Jensen OR, Okkels FT, Olsen CE, Motawia MS, Hansen J (2009) De novo biosynthesis of vanillin in fission yeast (Schizosaccharomyces pombe) and baker's yeast (Saccharomyces cerevisiae). Appl Environ Microbiol 75:2765–2774. doi:10.1128/AEM.02681-08

Harwood CR, Cutting SM (1990) Molecular biological methods for Bacillus. Wiley, Chichester; New York

Havkin-Frenkel D, Belanger FC (2008) Biotechnological production of vanillin. In: Havkin-Frenkel D, Belanger FC (eds) Biotechnology in flavor production, 1st edn. Blackwell, Oxford, pp 83–103. doi:10.1002/9781444302493.ch3

Hua D, Ma C, Song L, Lin S, Zhang Z, Deng Z, Xu P (2007) Enhanced vanillin production from ferulic acid using adsorbent resin. Appl Microbiol Biotechnol 74:783–790. doi:10.1007/s00253-006-0735-5

Ishii T (1997) Structure and functions of feruloylated polysaccharides. Plant Sci 127:111–127. doi:10.1016/S0168-9452(97)00130-1

Ishikawa H, Schubert WJ, Nord FF (1963) Investigations on lignins and lignification. 28. The degradation by Polyporus versicolor and Fomes fomentarius of aromatic compounds structurally related to softwood lignin. Arch Biochem Biophys 100:140–149. doi:10.1016/0003-9861(63)90044-4

Jiménez JI, Minambres B, Garcia JL, Diaz E (2002) Genomic analysis of the aromatic catabolic pathways from Pseudomonas putida KT2440. Environ Microbiol 4:824–841. doi:10.1046/j.1462-2920.2002.00370.x

Karmakar B, Vohra RM, Nandanwar H, Sharma P, Gupta KG, Sobti RC (2000) Rapid degradation of ferulic acid via 4-vinylguaiacol and vanillin by a newly isolated strain of Bacillus coagulans. J Biotechnol 80:195–202. doi:10.1016/S0168-1656(00)00248-0

Kaur B, Chakraborty D (2013) Biotechnological and molecular approaches for vanillin production: a review. Appl Biochem Biotechnol 169:1353–1372. doi:10.1007/s12010-012-0066-1

Kitko RD, Cleeton RL, Armentrout EI, Lee GE, Noguchi K, Berkmen MB, Jones BD, Slonczewski JL (2009) Cytoplasmic acidification and the benzoate transcriptome in Bacillus subtilis. PLoS One 4, e8255. doi:10.1371/journal.pone.0008255

Krings U, Berger RG (1998) Biotechnological production of flavours and fragrances. Appl Microbiol Biotechnol 49:1–8. doi:10.1007/s002530051129

Kunst F, Ogasawara N, Moszer I, Albertini AM, Alloni G, Azevedo V, Bertero MG, Bessieres P, Bolotin A, Borchert S, Borriss R, Boursier L, Brans A, Braun M, Brignell SC, Bron S, Brouillet S, Bruschi CV, Caldwell B, Capuano V, Carter NM, Choi SK, Cordani JJ, Connerton IF, Cummings NJ, Daniel RA, Denziot F, Devine KM, Dusterhoft A, Ehrlich SD, Emmerson PT, Entian KD, Errington J, Fabret C, Ferrari E, Foulger D, Fritz C, Fujita M, Fujita Y, Fuma S, Galizzi A, Galleron N, Ghim SY, Glaser P, Goffeau A, Golightly EJ, Grandi G, Guiseppi G, Guy BJ, Haga K, Haiech J, Harwood CR, Henaut A, Hilbert H, Holsappel S, Hosono S, Hullo MF, Itaya M, Jones L, Joris B, Karamata D, Kasahara Y, Klaerr-Blanchard M, Klein C, Kobayashi Y, Koetter P, Koningstein G, Krogh S, Kumano M, Kurita K, Lapidus A, Lardinois S, Lauber J, Lazarevic V, Lee SM, Levine A, Liu H, Masuda S, Mauel C, Medigue C, Medina N, Mellado RP, Mizuno M, Moestl D, Nakai S, Noback M, Noone D, O'Reilly M, Ogawa K, Ogiwara A, Oudega B, Park SH, Parro V, Pohl TM, Portelle D, Porwollik S, Prescott AM, Presecan E, Pujic P, Purnelle B, Rapoport G, Rey M, Reynolds S, Rieger M, Rivolta C, Rocha E, Roche B, Rose M, Sadaie Y, Sato T, Scanlan E, Schleich S, Schroeter R, Scoffone F, Sekiguchi J, Sekowska A, Seror SJ, Serror P, Shin BS, Soldo B, Sorokin A, Tacconi E, Takagi T, Takahashi H, Takemaru K, Takeuchi M, Tamakoshi A, Tanaka T, Terpstra P, Togoni A, Tosato V, Uchiyama S, Vandebol M, Vannier F, Vassarotti A, Viari A, Wambutt R, Wedler H, Weitzenegger T, Winters P, Wipat A, Yamamoto H, Yamane K, Yasumoto K, Yata K, Yoshida K, Yoshikawa HF, Zumstein E, Yoshikawa H, Danchin A (1997) The complete genome sequence of the gram-positive bacterium Bacillus subtilis. Nature 390:249–256. doi:10.1038/36786

Lechat P, Hummel L, Rousseau S, Moszer I (2008) GenoList: an integrated environment for comparative analysis of microbial genomes. Nucleic Acids Res 36:469–474. doi:10.1093/nar/gkm1042

Lesage-Meessen L, Delattre M, Haon M, Thibault JF, Ceccaldi BC, Brunerie P, Asther M (1996) A two-step bioconversion process for vanillin production from ferulic acid combining Aspergillus niger and Pycnoporus cinnabarinus. J Biotechnol 50:107–113. doi:10.1016/0168-1656(96)01552-0

Lupa B, Lyon D, Gibbs MD, Reeves RA, Wiegel J (2005) Distribution of genes encoding the microbial non-oxidative reversible hydroxyarylic acid decarboxylases/phenol carboxylases. Genomics 86:342–351. doi:10.1016/j.ygeno.2005.05.002

Lupa B, Lyon D, Shaw LN, Sieprawska-Lupa M, Wiegel J (2008) Properties of the reversible nonoxidative vanillate/4-hydroxybenzoate decarboxylase from Bacillus subtilis. Can J Microbiol 54:75–81. doi:10.1139/W07-113

Michel JF, Millet J (1970) Physiological studies on early-blocked sporulation mutants of Bacillus subtilis. J Appl Bacteriol 33:220–227. doi:10.1111/j.1365-2672.1970.tb05246.x

Muheim A, Lerch K (1999) Towards a high-yield bioconversion of ferulic acid to vanillin. Appl Microbiol Biotechnol 51:456–461. doi:10.1007/s002530051416

Nelson KE, Weinel C, Paulsen IT, Dodson RJ, Hilbert H, Martins dS V, Fouts DE, Gill SR, Pop M, Holmes M, Brinkac L, Beanan M, DeBoy RT, Daugherty S, Kolonay J, Madupu R, Nelson W, White O, Peterson J, Khouri H, Hance I, Chris LP, Holtzapple E, Scanlan D, Tran K, Moazzez A, Utterback T, Rizzo M, Lee K, Kosack D, Moestl D, Wedler H, Lauber J, Stjepandic D, Hoheisel J, Straetz M, Heim S, Kiewitz C, Eisen JA, Timmis KN, Dusterhoft A, Tummler B, Fraser CM (2002) Complete genome sequence and comparative analysis of the metabolically versatile Pseudomonas putida KT2440. Environ Microbiol 4:799–808. doi:10.1046/j.1462-2920.2002.00366.x

Okeke BC, Venturi V (1999) Construction of recombinants Pseudomonas putida BO14 and Escherichia coli QEFCA8 for ferulic acid biotransformation to vanillin. J Biosci Bioeng 88:103–106. doi:10.1016/S1389-1723(99)80185-6

Oosterveld A, Beldman G, Schols HA, Voragen AG (2000) Characterization of arabinose and ferulic acid rich pectic polysaccharides and hemicelluloses from sugar beet pulp. Carbohyd Res 328:185–197. doi:10.1016/S0008-6215(00)00095-1

Overhage J, Priefert H, Rabenhorst J, Steinbüchel A (1999) Biotransformation of eugenol to vanillin by a mutant of Pseudomonas sp. strain HR199 constructed by disruption of the vanillin dehydrogenase (vdh) gene. Appl Microbiol Biotechnol 52:820–828. doi:10.1007/s002530051598

Overhage J, Steinbüchel A, Priefert H (2003) Highly efficient biotransformation of eugenol to ferulic acid and further conversion to vanillin in recombinant strains of Escherichia coli. Appl Environ Microbiol 69:6569–6576. doi:10.1128/AEM.69.11.6569-6576.2003

Peng X, Misawa N, Harayama S (2003) Isolation and characterization of thermophilic bacilli degrading cinnamic, 4-coumaric, and ferulic acids. Appl Environ Microbiol 69:1417–1427. doi:10.1128/AEM.69.3.1417-1427.2003

Plaggenborg R, Overhage J, Loos A, Archer JA, Lessard P, Sinskey AJ, Steinbüchel A, Priefert H (2006) Potential of Rhodococcus strains for biotechnological vanillin production from ferulic acid and eugenol. Appl Microbiol Biotechnol 72:745–755. doi:10.1007/s00253-005-0302-5

Priefert H, Rabenhorst J, Steinbüchel A (2001) Biotechnological production of vanillin. Appl Microbiol Biotechnol 56:296–314. doi:10.1007/s002530100687

Ramachandra Rao S, Ravishankar GA (2000) Vanilla flavour: production by conventional and biotechnological routes. J Sci Food Agric 80:289–304. doi:10.1002/1097-0010(200002)80:3<289::AID-JSFA543>3.0.CO;2-2

Rosazza JP, Huang Z, Dostal L, Volm T, Rousseau B (1995) Review: biocatalytic transformations of ferulic acid: an abundant aromatic natural product. J Ind Microbiol 15:457–471. doi:10.1007/BF01570016

Sambrook J, Fritsch EF, Maniatis T (1989) Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory, Cold Spring Harbor, NY

Serizawa M, Yamamoto H, Yamaguchi H, Fujita Y, Kobayashi K, Ogasawara N, Sekiguchi J (2004) Systematic analysis of SigD-regulated genes in Bacillus subtilis by DNA microarray and Northern blotting analyses. Gene 329:125–136. doi:10.1016/j.gene.2003.12.024

Sinha AK, Verma SC, Sharma UK (2007) Development and validation of an RP-HPLC method for quantitative determination of vanillin and related phenolic compounds in Vanilla planifolia. J Sep Sci 30:15–20. doi:10.1002/jssc.200600193

Tilay A, Bule M, Annapure U (2010) Production of biovanillin by one-step biotransformation using fungus Pycnoporous cinnabarinus. J Agric Food Chem 58:4401–4405. doi:10.1021/jf904141u

Walton NJ, Narbad A, Faulds C, Williamson G (2000) Novel approaches to the biosynthesis of vanillin. Curr Opin Biotechnol 11:490–496. doi:10.1016/S0958-1669(00)00125-7

Wenzel M, Altenbuchner J (2013) The Bacillus subtilis mannose regulator, ManR, a DNA-binding protein regulated by HPr and its cognate PTS transporter ManP. Mol Microbiol 88:562–576. doi:10.1111/mmi.12209

Wenzel M, Altenbuchner J (2015) Development of a markerless gene deletion system for Bacillus subtilis based on the mannose phosphoenolpyruvate-dependent phosphotransferase system. Microbiology [Epub ahead of print]. doi:10.1099/mic.0.000150

Wenzel M, Müller A, Siemann-Herzberg M, Altenbuchner J (2011) Self-inducible Bacillus subtilis expression system for reliable and inexpensive protein production by high-cell-density fermentation. Appl Environ Microbiol 77:6419–6425. doi:10.1128/AEM.05219-11

Yamada M, Okada Y, Yoshida T, Nagasawa T (2007) Purification, characterization and gene cloning of isoeugenol-degrading enzyme from Pseudomonas putida IE27. Arch Microbiol 187:511–517. doi:10.1007/s00203-007-0218-9

Yanisch-Perron C, Vieira J, Messing J (1985) Improved M13 phage cloning vectors and host strains: nucleotide sequences of the M13mp18 and pUC19 vectors. Gene 33:103–119. doi:10.1016/0378-1119(85)90120-9

Yoon SH, Lee EG, Das A, Lee SH, Li C, Ryu HK, Choi MS, Seo WT, Kim SW (2007) Enhanced vanillin production from recombinant E. coli using NTG mutagenesis and adsorbent resin. Biotechnol Prog 23:1143–1148. doi:10.1021/bp070153r

Zakataeva NP, Nikitina OV, Gronskiy SV, Romanenkov DV, Livshits VA (2010) A simple method to introduce marker-free genetic modifications into the chromosome of naturally nontransformable Bacillus amyloliquefaciens strains. Appl Microbiol Biotechnol 85:1201–1209. doi:10.1007/s00253-009-2276-1

Zhang Y, Xu P, Han S, Yan H, Ma C (2006) Metabolism of isoeugenol via isoeugenol-diol by a newly isolated strain of Bacillus subtilis HS8. Appl Microbiol Biotechnol 73:771–779. doi:10.1007/s00253-006-0544-x

Acknowledgments

We would like to thank Dr. Juergen Wiegel (distinguished research professor emeritus, University of Georgia, USA) for helpful information and hints on the phenolic acid decarboxylase BsdBCD.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors assure and declare that the research was not funded, and they have no competing interests (financial or non-financial). Furthermore, no human participants were involved, and no animals were harmed or killed during this study.

Additional information

Nadja Graf and Marian Wenzel contributed equally to this work.

Rights and permissions

About this article

Cite this article

Graf, N., Wenzel, M. & Altenbuchner, J. Identification and characterization of the vanillin dehydrogenase YfmT in Bacillus subtilis 3NA. Appl Microbiol Biotechnol 100, 3511–3521 (2016). https://doi.org/10.1007/s00253-015-7197-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-7197-6