Abstract

Nanobiotechnology is emerging as a new frontier of biotechnology. The potential applications of nanobiotechnology in bioenergy and biosensors have encouraged researchers in recent years to investigate new novel nanoscaffolds to build robust nanobiocatalytic systems. Enzymes, mainly hydrolytic class of enzyme, have been extensively immobilised on nanoscaffold support for long-term stabilisation by enhancing thermal, operational and storage catalytic potential. In the present report, novel nanoscaffold variants employed in the recent past for enzyme immobilisation, namely nanoparticles, nanofibres, nanotubes, nanopores, nanosheets and nanocomposites, are discussed in the context of lipase-mediated nanobiocatalysis. These nanocarriers have an inherently large surface area that leads to high enzyme loading and consequently high volumetric enzyme activity. Due to their high tensile strengths, nanoscale materials are often robust and resistant to breakage through mechanical shear in the running reactor making them suitable for multiple reuses. The optimisation of various nanosupports process parameters, such as the enzyme type and selection of suitable immobilisation method may help lead to the development of an efficient enzyme reactor. This might in turn offer a potential platform for exploring other enzymes for the development of stable nanobiocatalytic systems, which could help to address global environmental issues by facilitating the production of green energy. The successful validation of the feasibility of nanobiocatalysis for biodiesel production represents the beginning of a new field of research. The economic hurdles inherent in viably scaling nanobiocatalysts from a lab-scale to industrial biodiesel production are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Demands for suitable enzymes in a variety of rapidly growing sectors, including the food, pharmaceutical and green industries have climbed in recent times because of the environmental and economic sustainability of biocatalysts and their applications (Illanes et al. 2012). Enzymes are often facile and denatured entities in vitro milieu. Their short catalytic lifespan hampers their usefulness and increases the cost of the enzyme based applications. Enzyme immobilisation, a well-established and mature technology, improves the stability and therefore economic viability of the process, especially at an industrial scale (Mateo et al. 2007; Puri et al. 2010a; Jochems et al. 2011).

Nanobiocatalysis is a new innovative, sub-field of biocatalysis, exploring more advanced materials for the role of enzyme carrier (Kim et al. 2008). This field represents a synergy between nanotechnology and biotechnology and has provided robust nanostructured materials with properties tailored to their applications as enzyme scaffolds. Engineering of the nanomaterials, called nanomaterial functionalisation, is a process designed to improve suitability for their application in nanobiocatalysis (Johnson et al. 2011). The properties of nanomaterials are easily changed, and the functionalised materials are used as nanoscaffolds. The nano-scale dimensions of both the material and the enzymes allow the combined, enzyme-bound nanoscaffold to behave as a free enzyme. Recent research into the development of nanobiocatalytic systems with stabilized enzyme activity and potentially multiple reuses has seen various applications (Pavlidis et al. 2012).

Globally, hike in crude oil prices based on fossil fuel shortage (Puri et al. 2012) and growing environment concerns paves the way for lipase-mediated biodiesel production (Fan et al. 2012). Biodiesel, also known as fatty acid alkyl esters, is produced by transesterification of oil or fat either with chemical or lipase-based catalysis (Singh et al. unpublished). Production of biodiesel by transesterification employing chemical catalyst is industrially acceptable for its high conversion and reaction rates. However, downstream processing costs, environmental issues associated with biodiesel production and by-products recovery have led to the search for alternative eco-friendly production methods (Bisen et al. 2010). Thus, enzyme-mediated biodiesel production is more advantageous over the chemical route since it's eco-friendly, chemically selective and carry reaction at lower temperature. Though various lipases and renewable feedstocks (Puri et al. 2011; Gupta et al. 2012a) have been employed for biodiesel/biofuel production (Tan et al. 2010; Puri et al. 2010c; Gupta et al. 2012b), innovative immobilisation methods (employing novel nanomaterials) with high activity and stability still need to be explored for its cost-effective commercialisation.

Several nanobiocatalysis reviews have eloquently explained the different types of nanomaterials employed for enzyme immobilisation in general, although these typically do not focus on industrial applications with respect to biofuel/biodiesel production (Kim et al. 2006a; Ansari and Husain 2012). In light of this, the present report attempts to address a pressing and important consideration, biodiesel production in the context of nanobiocatlysis. A single model enzyme, lipase, was selected for the discussion. Lipase has broad applications and a unique working mechanism ideal both for nanobiocatalysis using different types of nanomaterials, as well as for the evaluation of different nanobiocatalytic systems for bioenergy applications, from lab to bioreactor scales.

Advantageous nanomaterials in the search for ideal supports for enzyme immobilisation

Nanomaterials such as nanoparticles, nanofibres, nanotubes, nanopores, nanosheets and nanocomposites have found many applications in industrial biotechnology (Fig. 1). Table 1 lists the various types of nanostructured supports that have been employed for enzyme immobilisation. The use of nanomaterials as potential supports for enzyme immobilisation has grown in popularity in recent years. The advantages of enzymes immobilised on micron-sized particles are inherited when nanomaterials are used as solid supports for enzyme immobilisation (Kim et al. 2006a; Gupta et al. 2011; Verma et al. 2011a, 2012; Ansari and Husain 2012). New, generally favourable phenomena arise when the size of the carrier approaches nanometer dimensions. The following factors, presented in the context of nanomaterials, are important considerations in evaluating the suitability of a material for enzyme immobilisation.

-

a)

Surface area to volume ratio: Nanomaterials have large surface area to volume ratios. Nanofibres offer two-thirds of the surface to volume ratio of (nearly) spherical particles of the same diameter (Wang 2006; Gupta et al. 2011).

-

b)

Enzyme loading: Nanometer-scale materials offer high enzyme loading due to their large relative surface area. High enzyme loading leads to better biocatalytic activity and stability. This makes the nanoscaffold an ideal support for enzyme immobilisation as compared to conventional materials.

-

c)

Flow rate: The immobilised nanomaterial behaves as a stable, monodispersed particle in aqueous suspension and exhibiting Brownian motion (Wang 2006). According to the Stokes–Einstein equation, the mobility and diffusivity of nanoparticles have to be smaller than those of free enzymes, owing to their relatively larger sizes. This mobility difference may point to a transitional region between homogeneous catalysis with free enzymes and heterogeneous catalysis with immobilised enzymes. It has been shown that Brownian motion may be responsible for high activities obtained when enzymes are immobilised on nanoparticles (Jia et al. 2002).

-

d)

Mass transfer: Apparent enzyme activity could be improved due to the relieved mass transfer limitation of substrates in nanostructures when compared to macro-scale matrices in conventional enzyme immobilisation. Enzymes immobilised on nanomaterials have low mass transfer resistance and thus have high activity and stability (Kim et al. 2006b).

-

e)

Ease of separation: Magnetic nanomaterials greatly facilitate separation (Fig. 2), allowing for the use of a magnet to quickly and efficiently remove the immobilised enzyme from the product (Safarik and Safarikova 2009; Ren et al. 2011). This allows for greater reusability and preservation of stability of the attached enzyme as compared to conventional matrices, where centrifugation/filtration is only the option to separate the enzyme from the product. Such operations might lead to enzyme leaching/instability due to mechanical shear while mixing the pellet with the appropriate buffer to begin a new reaction (Yiu and Keane 2012). The low process costs of magnetic nanocarriers have therefore shown them to be an interesting and economic option.

-

f)

Reactor design: A number of enzyme reactors have been reported in the literature to improve the performance of enzyme efficiency (Sotowa et al. 2008). Enzyme immobilisation is fundamental for the development of reactors, biosensors or micro total analysis systems (Song et al. 2012a). Nanomaterials, especially nanofibres, offer larger flexibility in reactor design as they are easier to prepare and easier to handle (Nair et al. 2007). The small pressure drop and high flow rate of the nanofibre membrane represents most important advantages of enzyme-immobilised nanofibre membrane bioreactors over the traditional enzyme-immobilised membranes and fixed bed bioreactors. An enzyme-immobilised fibrous membrane bioreactor was established with a continuous steady hydrolysis conversion at a constant flow rate under optimum condition (Huang et al. 2008).

Enzymatic immobilisation strategy

The chemical functionalisation of nanomaterial is a well-established technique for grafting desirable functional groups onto their surface to obtain nanomaterials with desired properties (Shim et al. 2002; Bourlinos et al. 2003). The surface chemistry of the functionalized nanomaterial can affect their dispersability and interactions with enzymes, thus altering the catalytic activity of the immobilised enzyme in a significant manner (Pavlidis et al. 2010).

Moreover, protein surface chemistry and functionality of each enzyme is different and unique. Therefore, optimized enzyme immobilisation protocols for a particular enzyme will not be applicable to other enzyme variants. Different enzymes therefore have different immobilisation methods (Hanefeld et al. 2009). Optimum enzyme immobilisation for a specific application can be achieved by considering a number of technical, commercial and practical considerations. Hence, immobilisation processes need to be optimized for development of robust nanobiocatalytic systems by examining immobilised time, cross-linker concentration, crosslinking time, enzyme concentration, initial buffer pH and temperature values of enzyme solution (Mateo et al. 2007; Puri et al. 2010a; Verma et al. 2012). Different methods of enzyme immobilisation have employed either physical or covalent methods. Adsorption is more desirable and quite simple as it is a chemical free mediated enzyme binding process (Chronopoulou et al. 2011). However, leaching of the enzyme from the immobilised enzyme preparation after a certain number of reuses limits its commercial application. Despite this, it is still a popular method. The aforementioned shortcoming can be overcome by the use of a covalent-binding method using suitable cross-linkers, e.g. glutaraldehyde (GA), dicyclohexyl carboiimide (DCC) and 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) (Sheldon 2007; Xie and Ma 2009, 2010). Covalent binding methods produce quite stable immobilised enzyme preparations with more reusability as compared to the physical adsorption method (Puri et al. 2010b). Enzymes can be immobilised using physical adsorption, covalent methods or in combination of both (Ansari and Husain 2012). In certain cases, a combination of two immobilisation methods has been employed in a stable immobilised system. Firstly, the enzyme is immobilised by adsorption methods followed by treatment of the cross-linkers to avoid the enzyme leaching. Use of cross-linkers in the immobilisation method depends on the applicability of the concerned immobilised system. For example, the use of GA/DCC/EDC for enzyme coupling in immobilisation at higher concentration (>4 %) is not a good choice for its applications since it may cause great reduction of the recovered enzyme activity (Chang and Juang 2007; Pan et al. 2009). However, the same cross-linker bonding might be applicable in the bioenergy sector. Nanomaterial activation of either glutaraldehyde or carbodiimide has been most commonly and successfully employed for covalent immobilisation (Huang et al. 2003; Verma et al. 2012; Pavlidis et al. 2012).

Although there have been numerous attempts to immobilise the enzymes with nanomaterials, there are insufficient studies on the influence that the nanomaterial properties (such as composition, morphology and surface chemistry) have on the structure and function of conjugated enzymes (Asuri et al. 2007). Investigating the structure and function of enzymes immobilised on nanomaterials will be crucial for developing a better understanding of enzyme-nanomaterial interactions and for designing functional protein-nanomaterial conjugates (Cruz et al. 2010).

Many analytical techniques have been used to characterise in situ structural stability of enzymes immobilised on support/particles (Ganesan et al. 2009). The conformational changes of enzymes upon immobilisation and confirmation of the success of the immobilisation methods have been investigated by many researchers using sophisticated analytical techniques such as Brunauer-Emmett-Teller (BET) analysis, Atomic Force Microscopy (AFM), Scanning Electron Microscope (SEM), Transmission Electron Microscopy (TEM), Circular Dichroism (CD) spectroscopy, Fourier Transform Infrared Spectroscopy (FTIR), XPS (X-ray Photoelectron spectroscopy) and X Ray diffraction (XRD) pattern. The size and morphology of nanomaterial have been observed by TEM and SEM. The binding of lipase by either covalent or adsorption method on the nanomaterials has been confirmed by FTIR, XPS and TEM observations. CD spectroscopy has also been used to analyse the influence of physical/covalent attachments on the secondary structure of enzyme; for example, 62 % retention of the α-helix content of the native lipase after immobilisation (Ji et al. 2010). AFM has been quite useful to confirm enzyme immobilisation in vitro on the graphene oxide nanosheet (Zhang et al. 2010). The lipase-bound nanomaterials exhibited the same XRD patterns as the native nanomaterials (Huang et al. 2003).

Lipase-mediated nanobiocatalysis

Enzymes are considered novel biocatalysts, which are widely recognized for their powerful catalysis with very high substrate specificity and stereo-selectivity. Lipases (EC 3.1.1.3) are the “workhorses” in biocatalysis and have been extensively studied due to their exceptionally high stability in aqueous as well as non-aqueous media (Verma et al. 2008, 2011b; Verma and Kanwar 2008, 2010; Kralovec et al. 2010). Lipases from different sources have been investigated for their transesterification activity on different oils. Lipases catalyse esterification and transesterification reactions in non-aqueous media. Advantages like mild reaction conditions, one-step synthesis without protection and deprotection steps and easy application in food processing are associated with these enzyme-controlled reactions. Thus, it is economically important to develop suitable biocatalytic methods for the production of such esters, for example, biodiesel and nutraceutical products enriched with EPA/DHA from cheaper and broadly available raw materials (Sheldon 2007).

Enzymatic transesterification of vegetable oils offers an environmentally attractive alternative to biodiesel production (Xie and Ma 2009; Tan et al. 2010). Even the transesterification of fish oil produces value-added ethyl esters of DHA and EPA (Kralovec et al. 2012). The lipase catalysed transesterification in organic solvents is an emerging industrial application exploited in the production of cocoa butter equivalent, human milk fat substitute “Betapol”, pharmaceutically important polyunsaturated fatty acids rich/ low calorie lipids, designers fats or lipids and production of biodiesel from vegetable oils (Hasan et al. 2006; Kralovec et al. 2012). The conversion in transesterification using other esters as a substrate is also generally high compared to that in the condensation reaction. In order to use lipase more economically and efficiently in aqueous as well as in non-aqueous solvents, their activity and operational stability needs to be improved by an appropriate selection of a suitable immobilisation technique (Lee et al. 2009).

Recent development of lipase-mediated nanobiocatalysis using different novel nanomaterials variants (Table 2) will be discussed in the following section.

Nanoparticles

Nanoparticles (NP) provide a particularly useful platform for nanobiocatalysis, demonstrating unique properties with potentially wide-ranging industrial applications (Johnson et al. 2011). The surface and core properties of versatile nanoparticles can be engineered as per the need of the applications (De et al. 2008). Nanoparticles scaffolds have improved the biocatalytic efficiency of a variety of lipases, in terms of activity, stability and reusability.

Magnetic as well as non-magnetic nanoparticles have been employed in nanobiocatalysis. But, non-magnetic nanoparticle-attached enzymes dispersion in reaction solutions and the subsequent recovery for their reuse is often a difficult task and requires high speed centrifugation for longer periods of time. The need of this can be overcome by using magnetic nanoparticles, which can be separated from the reaction medium simply using a magnet. Magnetic iron oxide is of great interest among nanoparticles because of its biocompatibility, stability, large surface area, super-paramagnetic property and low cost of synthesis. This strategy was demonstrated by a study in which a lipase was attached to γ-Fe2O3 nanoparticles via covalent bonds (Dyal et al. 2003). For the covalent attachment of enzyme molecules, the nanoparticle surface was activated with either acetyl or amine groups that can directly react with or be connected by glutaraldehyde to the amine groups on the surface of enzyme molecules. Higher enzyme loading (5.6 wt.%) was achieved on γ-Fe2O3 nanoparticles (20 nm). Operational stability of the immobilised enzyme was greatly enhanced. Long-term stability of immobilised lipase was reported.

Fe3O4 nanoparticles often need to be chemically modified for better enzyme tethering (Wang et al. 2009). Fully characterised surface-modified nano-sized magnetite (S-NSM) was used as a support for the immobilisation of porcine pancreas lipase (PPL). Sodium dodecyl sulphate was used to generate a hydrophobic surface around the NSM particles (8–12 nm) so that hydrophobic lipase strongly adsorbed onto a hydrophobic surface via a sulphate ester bond. Immobilised PPL has shown higher specific activity of oil hydrolysis than free PPL (Lee et al. 2009). A similar study with different coating materials was carried out by Ponvel et al. (2009). Nano-sized magnetite (NSM) particles (10 nm) were coated by an alkyl benzenesulfonate (ABS) to provide a hydrophobic surface. Immobilised PPL showed enhanced durability in the reuse for hydrolysis of olive oil.

Candida rugosa lipase (CRL) was covalently bound onto Fe3O4 magnetic nanoparticles via carbodiimide activation. The Fe3O4 magnetic nanoparticle (12.7 nm)-bound lipase exhibited 1.41-fold enhanced activity, 31-fold improved stability, and better tolerance to the variation of solution pH as compared to the free enzyme (Huang et al. 2003). Activation energy (6.4 kJ/mol), maximum specific activity and K M value of the immobilised enzyme revealed that the available active sites of lipase and their affinity to substrate increased after covalent binding to magnetic nanoparticles.

Jiang et al. (2009) studied the CRL immobilisation on magnetic nanoparticles (55 nm). Magnetic nanoparticles supported in ionic liquids were obtained by covalent bonding of ionic liquids-silane on magnetic silica nanoparticles. A large quantity of lipase (63.89 %, w/w) was loaded on the support through ionic adsorption. The activity of immobilised lipase for butyl oleate synthesis was higher than that of the native lipase. High thermal stability of immobilised lipase was observed. Immobilised lipase retained 60 % of its initial activity after eight repeated batches reaction. Ionic liquid-assisted magnetic nanoparticles provided a novel support with enhanced lipase stability due to a positive effect of their tuneable properties/structure (Jiang et al. 2009). Hu et al. (2009) studied the enzymatic synthesis of Diltiazem intermediate using Serratia marcescens lipase immobilised onto amino-functionalized magnetic nanoparticles. The immobilised lipase demonstrated a high enantioselective towards (+)-MPGM (E-value > 121) and improved thermal stability as compare to the free enzyme. High hydrolytic activity, even after ten consecutive cycles of more than 100 h, indicated high stability in a practical setting (Hu et al. 2009). In a similar study with different enzymes, functionalized superparamagnetic nanoparticles were used a support for Candida antarctica lipase B (CALB) immobilisation. Enantioselective transesterification of secondary alcohol was significantly improved by immobilised CALB. The immobilised enzyme was reused multiple times with negligible loss of activity (Netto et al. 2009).

Chen et al. (2009) studied Pseudomonas cepacia lipase (PCL) immobilisation on modified zirconia nanoparticles used for asymmetric synthesis in organic media. Various carboxylic acids with different alkyl chain lengths (valeric acid, caprylic acid, stearic acids, oleic acids, linoleic acid and 1,10-decanedicarboxylic acid) were grafted to zirconia nanoparticles. PCL immobilised on modified nanoparticles with stearic acid gave the best activity/enantioselectivity for the resolution of (R,S)-1-phenylethanol (E-value > 91.6) through acylation in isooctane. The initial activity was ca. 10 times higher, a feature attributed to the interaction between the long hydrophobic chain of the modifier and the lipase, leading to an interfacial activation effect. Dandavate et al. (2009) studied the immobilised CRL by covalent attachment to glutaraldehyde-activated silica nanoparticles (100 nm). The activation energy of immobilised lipase was lower in comparison to free lipase. A change in conformation of the enzyme after covalent binding to nanoparticles led to a requirement for lower energy on the surface of the nanoparticles. Aside from good reusability, immobilised CRL exhibited a 7-fold higher esterification activity, in comparison to the free enzyme.

Burkholderia cepacia lipase (BCL) was immobilised on superparamagnetic nanoparticles (10 nm) using adsorption and chemisorption methodologies (Rebelo et al. 2010). Immobilised BCL was efficiently applied as a recyclable biocatalyst in the enzymatic kinetic resolution of (RS)-1-(phenyl) ethanols via transesterification reactions. The reactions catalysed with BCL immobilised by the glutaraldehyde method showed the best results in terms of reusability, preserving the enzyme activity (conversion 50 %, E > 200) for eight successive cycles. These results were attributed to the efficient covalent binding of lipase to the magnetic nanoparticles using glutaraldehyde. Miletić et al. (2010) studied the effect of support surface hydrophobicity and enzyme solution pH on immobilisation process of hydrophobic polystyrene and lipase. Hydrophobic binding of lipases by adsorption was reported. Immobilised CRL performed higher hydrolytic activity than crude enzyme powder and commercially available immobilised CALB (Novozyme 435 from Novozymes).

A comparative study of three different immobilisation methods for BCL immobilised on superparamagnetic nanoparticles was carried out (Andrade et al. 2010). An excellent improvement in immobilised lipase catalytic efficiency (E-value > 200) was observed, that was higher than free lipase (E-value < 30), as determined for the kinetic resolution of (RS)-2-bromo-1-phenylethanol. Of the three tested immobilisation methods (adsorption, chemisorptions with carboxibenzaldehyde and chemisorptions with glutaraldehyde), chemisorptions with glutaraldehyde was the best one in terms of temperature stability and product yield. The best kinetic resolution results yielding the ester in high enantiomeric excess (>99 %) and E-value (E > 200) were obtained using vinyl acetate as acetyl donor and toluene as solvent. In another study, two different sizes (7 and 10 nm) of chitosan nanoparticles were prepared in a-water-in-oil (W/O) microemulsion using two different solvents and precipitants (Wu et al. 2010). The lipase adsorption capacity using small nanoparticle (7 nm) reached 156 mg/g and activity retention compared to free enzyme was as high as 66.7 %. The activity retention of large nanoparticle (10 nm) bound lipase was 62.8 %. This study revealed the effect of the nanoparticle size on enzyme loading potential and biocatalytic efficiency.

Chronopoulou et al. (2011) prepared poly-dl-lactic acid (PDLLA) nanoparticles (220 nm) using an innovative patented methodology. Immobilised CRL on PDLLA nanoparticles (220 nm) via an adsorption method enhanced lipase activity and stability as compared with the free enzyme. In another study, the immobilised CRL on magnetic nanoparticles (15 nm) exhibited higher esterification efficiency compared with free lipase for the synthesis of ethyl isovalerate (Dandavate et al. 2011). High reusability, low values of activation energy and K M parameters of the immobilised enzyme indicated efficient immobilised lipase preparation.

Nanofibres

Nanofibres are promising support materials for enzyme immobilisation. They possess high specific surface area for high enzyme loading per unit mass, fine porous structure allowing ready accessibility to active sites and the low diffusion resistance, easy recoverability as well as potential applicability for continuous operations (Wang et al. 2006; Nair et al. 2007).

Nanofibres modified with phospholipid moieties (90 nm) were used for CRL lipase immobilisation by adsorption method (Huang et al. 2006). High enzyme loading and enhanced lipase activity was attributed to high surface-volume ratio and porosity of the support. Effects of pH, temperature, and additive concentration were investigated on the adsorption capacity of polysulfone nanofibres (Wang et al. 2006). K M and V max for the immobilised lipases were higher and lower than those for free lipase, respectively. Thermal stability for immobilised enzyme was enhanced as compared to free enzyme.

Nanofibres electrospun from poly (acrylonitrile-co-maleic acid) were used for lipase immobilisation with their reactive carboxyl groups (Ye et al. 2006). The amount and activity retention of lipase immobilised on the nanofibres were high, with 21.2 mg/g fibres and 37.6 % activity retention, while those on the corresponding hollow fibre membrane were low, with 2.36 mg/g membrane and 33.9 % activity retention. Good immobilisation affinity was attributed to lower K M value of the nanofibre bound lipase than the free enzyme. Li et al. (2007) immobilised lipase onto pristine polyacrylonitrile nanofibres by an amidination coupling method. This enzyme immobilisation method showed the best performance among various immobilised lipase systems using the same source of lipase and substrate when considering protein loading, activity retention, and kinetic parameters. Polystyrene/polystyrene-maleic anhydride was electrospun into hydrophobic composite nanofibres followed by treatment with aqueous alcohol solution. These tightly aggregated hydrophobic nanofibres could be dispersed in water to form a loosely entangled structure after the ethanol pretreatment. The dispersion of polystyrene nanofibres increased the enzyme loading up to ~8 times and augments the steady-state conversion of a continuous flow reactor filled with enzyme-loaded nanofibres (Nair et al. 2007).

Nakane et al. (2007) studied a PVA-nanofibres-immobilised lipase. The specific surface area of the nanofibre (5.96 m2/g) was ca. 250 times larger than that of PVA-film-immobilised lipase (0.024 m2/g). The esterification activity of the nanofibre-bound lipase was equivalent to that of commercially available immobilised lipase (Novozym-435). The relative ester conversions of the four immobilisation systems, nanofibres, Novozym-435, a film and lipase powder, reached 99.5 %, 100 %, 11.5 %, and 81.1 % at specific time, respectively. The activity of the nanofibre-immobilised enzyme was equivalent to that of Novozym-435. The nanofibre-immobilised lipase showed higher activity for the esterification than lipase powder and film attributed to high specific surface area and high dispersion state of lipase molecules in PVA matrix.

Wang and Hsieh (2008) studied CRL immobilisation onto nanofibres (100–500 nm) produced by electrospinning of aqueous mixtures of lipase and PVA. High enzyme loading (50 %) was achieved. The catalytic activity of the fibre-bound lipase was the same as the soluble enzyme, showing no adverse effects from either electric charges or PVA on the structure or functions of the enzyme proteins. Immobilised lipase exhibited far superior activity, as compared with the soluble enzyme, following exposures to elevated temperatures and humidity levels. Sakai et al. (2008) entrapped lipase in electrospun PVA fibres (1 μm) and evaluated the transesterification activity by converting (s)-glycidol to glycidyl n-butyrate with vinyl n-butyrate. The initial transesterification rate of the entrapped lipase was 5.2-fold faster than that of non-treated lipase. The fibrous membrane could be used as a component of a flow-through reactor for continuous transesterification.

An enzyme-immobilised fibrous membrane bioreactor was employed for continuous hydrolysis, and a steady hydrolysis conversion (3.6 %) was obtained at constant flow rate under optimum condition (Huang et al. 2008). Covalent immobilisation of CRL onto electrospun poly(acrylonitrile-co-2-hydroxyethyl methacrylate) nanofibre was achieved by activating their surface functional groups (hydroxyl) with epichlorohydrin, cyanuric chloride or p-benzoquinone, respectively. The enzyme loading on the fibrous membrane (80–150 nm) was three times that of the fibrous membrane (800–1,000 nm). Stability of the immobilised lipase was significantly improved. Electrospun polyacrylonitrile (PAN) nanofibrous membranes (150 to 300 nm) were activated using amidination to enable immobilisation of CRL with covalent binding (Li and Wu 2009). The activity retention of the immobilised lipase was 87.5 % that of the free enzyme. The immobilised lipase retained 65 % of its initial conversion efficiency after 20 additional batch reactions. PCL was immobilised onto electrospun PAN fibres (Sakai et al. 2010a). The immobilised lipase was used for the conversion of (S)-glycidol with vinyl n-butyrate to glycidyl n-butyrate in isooctane. The rate of reaction was 23-fold higher than the initial material. After ten reaction cycles, the initial reaction rate remained at 80 % of the original rate.

Response surface methodology (RSM) was applied to model cellulose nanofibre synthesis and the modification conditions were optimised, namely NaIO4 content, reaction time, reaction temperature and reaction pH (Huang et al. 2011). Correlating models were established for the residual activity of the immobilised CRL onto electrospun cellulose nanofibre using a covalent immobilisation method (R 2 = 0.9228 and 0.8950). The authors obtained high enzymatic activity of the biocatalyst (of 29.6 U/g) with optimum operational conditions. The immobilised lipase exhibited significantly higher thermal stability and durability than the equivalent soluble enzyme. An et al. (2011) used polystyrene-poly(styrene-co-maleic anhydride) nanofibre for CRL immobilisation. This immobilised CRL coatings onto the nanofibres, yielding high activity and stability, and creating an economically viable nanobiocatalytic system for efficient use of expensive enzymes.

In a recent study, the biocatalytic potential of encapsulated lipase in polycaprolactone (PCL) nanofibres has been investigated in aqueous and non-aqueous media (Song et al. 2012b). The enzymatic activity of the encapsulated nanofibre was higher in the hydrolysis reaction than transesterification reaction. Pretreament of encapsulated nanofibre with acetone further enhanced its biocatalytic value. This immobilised B. cepacia lipase retained its half activity in non-aqueous medium till tenth recycle.

Nanotubes

Carbon nanotubes (CNTs) possess unique structural, mechanical, thermal and biocompatibility properties (Asuri et al. 2007). CNTs have attracted considerable research interest in enzyme immobilisation and subsequent application in biosensors. CNTs, including both single-walled carbon nanotubes (SWNTs) and multi-walled carbon nanotubes (MWNTs), typically have a diameter ranging from an order of one to tens of nanometers and a length of up to several hundred micrometers (Sotiropoulou et al. 2003; Shi et al. 2007; Lee et al. 2010a). Nanotube composites like polymer-single-walled carbon nanotube were prepared and examined for biocatalytic performance (Rege et al. 2003). Improved enzyme activity was observed in comparison to similar enzyme-containing composites without using SWNTs. The use of SWNTs, which possess a high specific surface area, may effectively adsorb enzyme molecules and retain the enzyme within the polymer matrix, whereas other forms of enzyme composites may suffer from enzyme loss via leaching when they are placed in contact with aqueous solutions.

To fully explore potential applications of CNTs, it is often required to increase CNTs' solubility in common organic solvents through appropriate functionalisation. These functionalisation reactions can be divided into two approaches, a direct attachment of functional groups to the graphitic surface and the use of nanotube-bound carboxylic acids from intrinsic or induced defects (Sun et al. 2002). Much effort has therefore been applied to the biological functionalisation of CNTs for potential applications in biosensor and enzyme immobilisation (Shi et al. 2007; Yang et al. 2007; Wang and Jiang 2011).

Yu et al. (2005) used the peptide nanotube for the immobilisation of lipase through hydrogen bonding between nanotube amidic groups and complementary groups on the protein surface. CRL was immobilised only in the internal cavity of the nanotubes that was large enough to allow the entry of the substrates. Immobilised CRL exhibited a high thermal stability. Enzyme activity enhancement in bound form is attributed to induction of the conformation change of protein to enzymatically active structure. Shi et al. (2007) used an enzymatic functionalisation method to improve the solubility of CNTs in organic solvents. CRL was covalently anchored onto acid-treated MWNTs through a self-catalytic mechanism. The MWNTs-lipase biocomposites showed significantly increased solubility in some commonly used organic solvents, such as tetrahydrofuran, dimethylformamide and chloroform. These studies provided a novel and simple route for covalent modification of carbon nanotubes, expanding the potential utilisation of both lipases and MWNTs in the fields of biocatalysis and biosensor (Shi et al. 2007). The stable and active enzyme system on conductive CNTs could have a significant impact on the field of biofuel production.

Shah et al. (2007) immobilised CRL on the MWCTs through physical adsorption and observed high retention of their catalytic activity (97 %). The immobilised biocatalyst showed 2.2- and 14-fold increases in the initial rates of transesterification activity in nearly anhydrous hexane and water immiscible ionic liquid [Bmim] [PF6], respectively, as compared to the lyophilized powdered enzyme. The immobilised lipase also showed high enantioselectivity as determined by kinetic resolution of (±) 1-phenylethanol in ionic liquid. Immobilised enzyme has higher catalytic activity (37 % conversion with > 99 % enantiomeric excess) compared to free CRL (5 % conversion). The interaction with the hydrophobic surface of the nanotubes resulted in conformational changes leading to the ‘open lid’ structure of CRL and enhanced immobilised enzyme efficiency.

Lipase was covalently attached to MWNTs. The MWCNT-lipase was used for the resolution of the model compound (R,S)-1-phenyl ethanol in n-heptane (Ji et al. 2010). Nanotube-bound enzyme has significantly affected the performance of the lipase in terms of temperature dependence and resolution efficiency. The activity of MWNT-lipase was less temperature-dependent compared with that of the native lipase. Reusability and high resolution efficiency were improved with MWNT-lipase without decrease of the selectivity of the native lipase. Pavlidis et al. (2010) investigated the immobilisation of CALB on functionalized MWCNTs through physical adsorption. MWCNTs were functionalized with carboxyl-, amine- and ester- terminal groups on their surface. High enzyme loading was attained, up to 25 % of the weight of the carbon nanotubes. The MWCNT-lipase exhibited high catalytic activity and increased storage and operational stability. The catalytic behaviour of the immobilised enzyme depends on the terminal group of the carbon nanotubes, the concentration of the enzyme and the immobilisation method employed.

Lee et al. (2010b) studied the effect of additives (MWNTs) on the immobilisation of lipase during sol–gel-derived silica process. Three sol–gel immobilised lipases (C. rugosa, C. antarctica type B, Thermomyces lanuginosus) with 0.33 % (w/w) MWNT showed much higher activities than lipase immobilised without MWNT. In a hydrolysis reaction, immobilised lipase containing 1.1 % pristine MWNT showed seven times higher activity than lipase immobilised without MWNT. The lipase co-immobilised with 2.7 % shortened MWNT showed 10 times higher activity in an esterification reaction, compared with lipase immobilised without MWNT. The lipase co-immobilised with 2.7 % shortened MWNT retained 96 % of initial activity after five times reuse, while the lipase immobilised without MWNT was fully inactivated under the same conditions. The observation that nanotube additives protect enzyme inactivation during the immobilisation process and subsequently enhance enzyme efficiency and stability is certainly supportive of their use.

Lee et al. (2010a, b) immobilised PCL onto SWNTs in two different ways in each of two solvent systems (buffer and ionic liquid). The most efficient immobilisation was achieved in ionic liquid (1-butyl-3-methylimidazolium tetrafluoroborate, BMIM-BF4). Carbon nanotubes were first functionalized noncovalently with 1-pyrenebutyric acid N-hydroxysuccinimide ester and then subject to the coupling reaction with a lipase in ionic liquid. The resulting immobilised lipase displayed the highest activity in the transesterification of 1-phenylethyl alcohol in the presence of vinyl acetate in toluene. This study demonstrated how to control the inherent insolubility of CNTs in aqueous (buffer) medium arising from Van der Waals forces of SWNTs by replacing with ionic liquid and resulting in an efficient enzyme immobilisation process.

To overcome the enzyme leaching, 3D structure change and diffusion resistance, Wang and Jiang (2011) introduced a detailed site-specific enzyme immobilisation method. This method was based on the specific interaction between His-tagged enzyme and single-walled carbon nanotubes modified with Nα,Nα-bis(carboxymethyl)-l-lysine hydrate. This method does not require enzyme purification and the resulting nanoscale biocatalyst can maintain high enzyme activity and stability. The enzyme-loading capacity is also comparable with the reported immobilisation capacity on carbon nanotubes by either covalent binding or adsorption. Furthermore, the enzyme-immobilised nanomaterials with easily regeneration possibility, render to efficiently reused, thus lowering the cost of specific nanosupport, for example l-lysine tagged, for other recombinant His-tagged enzyme immobilisation.

In a recent study, the enzyme–carbon nanotube interactions significantly improved the thermal stability and catalytic activity of enzymes, resulting in an increase up to 60 % of the catalytic efficiency of lipases (Pavlidis et al. 2012). A more active and rigid structure of enzyme after the immobilisation was confirmed by fluorescence and circular dichroism studies. This study also confirmed that a significant confirmation is controlled by the functional group on the nanomaterial's surface and less on their geometry (Pavlidis et al. 2012).

Nanoporous materials

Nanoporous materials possess nanometer-scale sized pore spaces and large interior surfaces making them a novel nanoporous material for enzymes immobilisation (Kim et al. 2006b). Several modifications to nanoporous materials like the enlargement of the inlet pore size and the modified morphologies of materials were successfully carried out for the quick adsorption of enzymes in mesoporous materials e.g., silica (Fan et al. 2003). The stability of adsorbed enzymes is dependent on the pore size of nanosaffold and charge interaction. High pore size may lead to the leaching of lipases from the channels in the adsorption process, which also accounted for a decrease in enzyme loading as well as causing enzyme instability (Takahashi et al. 2001; Vinu et al. 2006). The ideal pore size of mesoporous materials should be ideally similar to or larger than that of enzymes for successful enzyme adsorption. Otherwise, mesoporous materials with large pore sizes usually result in poor enzyme stability by allowing the adsorbed enzymes to leach-out rapidly from the mesopores. The size matching between pore size and the molecular diameter of enzymes is an important point in consideration for achieving high stability of adsorbed enzymes (Takahashi et al. 2000).

The most suitable pore diameter for PPL immobilisation was 13 nm (Kang et al. 2007). Pore-size is probably the most important parameter in the enzyme immobilisation process (Serra et al. 2008), while other textural properties, such as the nature of the pores (channel-like or cage-like), the connectivity of the porous network, total pore volume as well as surface area, do not have obvious effects. Serra et al. (2008) studied the loss of the adsorbed lipase and found 30 % of enzyme leaching from the support within 2 h. The influences of pore diameter and cross-linking method on the immobilisation efficiency of CRL (molecular weight between 45 and 60 kDa) in a mesoporous material (15.6 nm) have been investigated amongst five kinds of SBA-15 with different pore-sizes (6.8–22.4 nm) (Gao et al. 2010). The material with a pore diameter of 15.6 nm was shown to be more suitable as an immobilisation support when the loading amount reached 343.6 mg/g, as compared to its counterparts. To solve the leaching problem of the adsorbed enzyme, chitosan and glutaraldehyde were used as the “bridge unit” and “cross-linking agent”, respectively, with the aim of immobilising lipase molecules by adsorbing them on the surface of pores into a mesh-like layer. The experimental results showed that the activities of the immobilised CRL were much higher than that of free lipase and retained 80.5 % of the initial activity after six cycles in 48 h (Gao et al. 2010).

Mesoporous silica particles (15.8 nm) were used as carrier for immobilisation of CRL (Nikolic et al. 2009). The average pore size of the material was 15.8 nm, which allowed enzyme adsorption inside the pores and high enzyme loading. A loading of 100 mg lipase × g dry silica−1 was obtained at initial enzyme concentration of 1.8 mg mL−1 by physical adsorption. Immobilised lipase showed enhanced thermal stability. Desorption of the enzyme from the mesoporous support, which would allow material reuse was also achieved. Another enzyme PPL was successfully incorporated into the ionic liquid modified SBA-15 material by physical adsorption (PPL-IL-SBA). Compared with parent SBA-15 immobilised lipase (PPL-SBA), the enzymatic properties have dramatically improved; especially the optimized activity, which increased from 594 to 975 U/g PPL after modification. The pore structure and surface properties of SBA-15 materials have changed due to IL modification, resulting in enriching the lipase catalysis environment (Zou et al. 2010).

Itoh et al. (2010) encapsulated lipase in mesoporous silica (FSM) coupled with alkyltrimethylammonium (CTAB). The enzymatic activity of the immobilised lipase was linearly related to the concentration of lipase, whereas that of non-immobilised lipase showed saturation due to self-aggregation at a high concentration. The conjugated lipase had increased thermal resistance. In addition, encapsulation prevented dissociation and denaturing of the enzyme and remained stable even in the presence of urea and trypsin. This conjugate had much higher activity and much higher stability for hydrolysing esters when compared to the native lipase.

Matsuura et al. (2011) developed a microreactor containing lipase-nanoporous material composites and employed it in the hydrolysis reaction of a triglyceride. Lipase used as a model enzyme was encapsulated in two types of folded-sheet mesoporous silicas, FSM4 (4 nm) and FSM7 (7 nm). The lipase-FSM composites contained in the microreactor displayed higher enzymatic activity than those in a batch experiment.

Nanocomposites

Magnetic nanoparticles are non-porous nanomaterial (Sen and Bruce 2009) which could cause damage to naked nanoparticles due to erosion of reacting agents (Lu et al. 2007). In order to avoid environmental reaction, these NP are coated by the deposition of a layer of silica/gold/polymer like poly ethylene glycol (PEG) on the magnetic nanocores, creating nanocomposites (NC) or hybrid nanomaterials (Long et al. 2004; Drechsler et al. 2004). Encapsulation/coating of nanoparticle with desired organic/inorganic molecules is advanatageous to their function as a nanosupport. NC adds high versatility to nanoparticle for surface modification, becoming a novel target for enzyme binding and improving biocompatibility for broader biological application due to their hydrophilic properties. So NC is therefore amenable to easier grafting with functional groups. This makes NC an ideal nanosupport for enzyme immobilisation (Chaubey et al. 2009). Modification of core-shell magnetic nanoparticles with superparamagnetic magnetite (Fe3O4) core and silica shell have been extensively studied (Deng et al. 2008).

Dyal et al. (Dyal et al. 2003) first reported magnetic (maghemite) nanoparticles for the immobilisation of CRL and its use in the hydrolysis of long chain synthetic ester. Fabrication of novel hierarchically ordered porous magnetic nanocomposites with interconnecting macroporous windows and meso-microporous walls containing well-dispersed magnetic nanoparticles were used as a support to immobilise lipase for the efficient hydrolysis of esters (Sen et al. 2010).

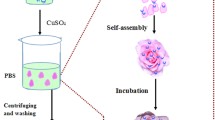

An example of a novel material for lipase immobilisation is provided by Kim et al. (2009). Magnetic particles (10 nm) were coated with silica (40 nm) by a sol–gel method and charged with Cu2+ ions via a multidentate ligand, iminodiacetic acid (IDA), for the immobilisation of His-tagged Bacillus stearothermophilus L1 lipase. The silica-coated magnetic nanoparticles (SiMNs) are known for several advantages over magnetic nanoparticles. Firstly, silica can screen the magnetic dipolar attraction between magnetic nanoparticles, which favour the dispersion of nanoparticles in a liquid medium and protect them from leaching in an acidic environment. Secondly, the surface can be easily functionalised owing to the presence of abundant silanol groups on the silica layer. Thirdly, the silica layer provides a chemically inert surface for the application of magnetic nanoparticles in biological systems (Deng et al. 2005). The lipase immobilised on the SiMNs exhibited the highest specific activity and retained 70 % of its initial activity after fivefold use. CRL was immobilised onto the polymer-grafted magnetic nanoparticles (Yang et al. 2008). Functionalised superparamagnetic particles were prepared by graft polymerization of glycidyl methacrylates and methacryloxyethyl trimethyl ammonium chloride onto the surface of modified-Fe3O4 nanoparticles. Immobilised CRL had better thermal stability compared to free lipase.

In a recent study, the core-shell nanocomposite Fe3O4-SiO2 was employed for B. cepacia lipase C20 immobilisation (Tran et al. 2012). The nanoparticles grafted with a long chain alkyl group to produce functional surface materials has shown high protein loading compared to nontreated with alkyl group and are shown to be a good matrix for lipase immobilisation. The immobilised lipase exhibited high catalytic activity as well as high reusability and has shown potential in commercial applications. Two strategies have employed encapsulating superparamagnetic by single-shell non-porous and double shell mesoporous silica (Kalantari et al. 2012). Enzyme loading capacity of porous NC was higher than non-porous NC as expected due to high surface area. Similar encouraging results like high thermal stability and good reusability have also been obtained using PCL on magnetic silica nanocomposite.

Nanosheets

Graphene, a carbon-based nanomaterial, has attracted considerable interest among nanostructured materials for their unique structural, physiochemical properties as well as supports for biomacromolecules immobilisation (Cang-Rong and Pastorin 2009; Pavlidis et al. 2010). Graphene oxide (GO), a derivative of graphite, is a basic material for the preparation of individual graphene sheets in bulk quantity. In the recent past, scientists have reported the immobilisation of a few enzymes on GO, investigating the influence of carbon-based nanomaterial's properties on the immobilisation efficiency, function and structure of enzymes (Li et al. 2008; Park and Ruoff 2009; Tung et al. 2009). In addition, the incredibly large specific surface area (two accessible sides), the abundant oxygen containing surface functionalities, such as epoxide, hydroxyl and carboxylic groups, and the high water solubility afford GO sheets great promise for many more applications (Li et al. 2008; Park and Ruoff 2009). However, few studies about the non-covalent binding of enzymes to GO have been reported to date (Zhang et al. 2010). The difference in graphene curvature results in different properties, such as the higher water dispersability of graphene oxide derivatives (Kuchibhatla et al. 2007).

A graphene oxide (GO) nanosheet has been used to study enzyme immobilisation with and without cross-linker and additional surface modifications (Zhang et al. 2010). The atomically flat surface enabled the observation of the immobilised enzyme in the native state directly using atomic force microscopy (AFM). Recently, an innovative method was developed for the immobilisation of recombinant lipase on GO sheets using physical and covalent methods (Pavlidis et al. 2012). The results showed that the thermostability and reusability of immobilised enzyme have been obviously improved compared to the free enzyme. The immobilised enzyme preparation exhibited good operational stability.

Nanobiocatalysis assisted biodiesel production from Lab to reactor scales

Major issues in enzyme-assisted biodiesel synthesis are enzyme denaturation, high cost and scale-up at reactor level. Enzymes in biodiesel synthesis processes are inactivated by substrates/by-products, i.e. methanol and glycerol, respectively (Kumari et al. 2009). Methanol, the most commonly used acyl acceptor, renders enzyme deactivation and thereby decreases biocatalyst efficiency (Ghamguia et al. 2004). Furthermore, a hydrophilic by-product, glycerol, is easily adsorbed onto the surface of the immobilised lipase leading to a detrimental effect on catalytic activity. Hence, ideal selection of acyl acceptor is important step in biodiesel production. Several protective measurements including stepwise addition of methanol to the reaction mixture, use of methyl or ethyl acetate as acyl acceptors, and use of longer alkyl chains alcohols such as t-butanol, have been attempted to overcome this enzyme inactivation process (Royon et al. 2007; Kumari et al. 2009).

The high cost of ultra-purified lipase can be reduced to a greater extent using novel nanoscale supports for enzyme immobilisation by developing a robust nanobiocatalytic system for effective and multiple reuses. Magnetic nanobiocatalytic system is the best choice due to the ease of its recovery from the reaction mixture, enhanced thermostability, reusability and economics consideration. Development of appropriate reactors for the production of biodiesel was a limiting factor. Shear stress from the stirring in the batch reactor would disrupt the enzyme carrier. This prohibits reuse of immobilised enzymes for large number of cycles. This limitation can be overcome by using packed bed reactor (PBR) having well suited for automation (Wang et al. 2011a).

Nanomaterials have been successfully employed in biodiesel production (hypothesised in Fig. 3 and Fig. 4). Xie and Ma reported a high conversion of biodiesel production (90 %) from covalently immobilised T. lanuginosus lipase-amino-functionalized magnetic nanoparticles preparation (Xie and Ma 2009, 2010). Trans-esterification efficiency of 40 % immobilised lipase using GA cross-linker was higher than 60 % immobilised lipase using EDC cross-linker to achieve high biodiesel production (90 %). Immobilised magnetic Fe3O4 nanoparticle-P. cepacia lipase (PCL) yielded full percent conversion of biodiesel production (Wang et al. 2009).

An electrospun polyacrylonitrile nanofibre-bound PCL has been used for the butyl-biodiesel production (Sakai et al. 2010b). About 94 % conversion to butyl-biodiesel was achieved in 48 h using simple adsorption method. The immobilised PCL using a polyacrylonitrile nanofibre showed good biocatalytic activity for biodiesel production (Li et al. 2011). The biodiesel production achieved was 91 % of its original conversion even after ten recycles.

Immobilised lipase achieved a higher conversion of biodiesel production (90 %) than the free lipase (74 %) at 24 h. This was established by simple and efficient adsorption of P. cepacia lipase onto the nanopores of a nanoporous gold support (Wang et al. 2011b). The extraordinary catalytic performance of biocomposites using nanoporous support was validated. Magnetic nanocomposites have recently been exploited in biodiesel production. Magnetic nanocomposite bound lipase yielded a conversion of high biodiesel production (>90 %) within 30 h in batch operation and further validated the novel support and good selection of immobilisation method. This immobilised lipase from Burkholderia sp. has high methanol tolerance and reusability as compared to earlier studies (Tran et al. 2012).

Wang et al. (2009) set up a nanobiocatalytic system for biodiesel production and set up a PBR system for effective and continuous biodiesel production based on soybean oil methanolysis using lipase–Fe3O4 nanoparticle biocomposite. The biocomposite showed high activity and stability in the single-PBR at an optimal flow rate. The maximum conversion rate (75 %) was recorded at 12 h. Wang et al. (2011a, 2011b) developed an effective nanobiocatalytic system for the biodiesel production, designing a four-PBR system for repeated and highly efficient use of lipase. Aside from the stability, the conversion rate achieved using the four-packed bed reactor system was much higher than that achieved using the single PBR. The conversion of biodiesel was maintained at a high rate of over 88 % for 192 h, and it only slightly dropped to approximately 75 % after 240 h of reaction. These results were quite promising as compared to an earlier study (Hama et al. 2007; Thanh et al. 2010).

High conversion rate and good stability in the four-packed bed reactor was attributed the longer residence time of the reaction mixture in the reactor and reduction in the inhibition of the lipase-nanoparticle biocomposite by-products. Effective stability and reusability of the immobilised enzyme preparation further contributes to lowering of the cost of biodiesel production. Thus, the advantages of using an immobilised nanobiocatalytic system could outweigh the increased cost of immobilisation. These reactor-scale studies highlight the possibility of designing and operating even larger-scale enzymatic systems for biodiesel production.

Conclusions and horizons

A good understanding of the chemistry of nanomaterials, performing their functionalisation, and the nature of selected enzymes, combined with suitable selection of the immobilisation technique can lead to the development of novel robust nanobiocatalytic systems.

Enzyme inactivation by solvents during biodiesel production can be avoided by searching for a robust, solvent-stable/tolerant lipase. This will be possible through protein engineering such as via iterative saturated mutagenesis (ISM) or other molecular biology approaches, which can produce novel and robust recombinant biocatalysts with improved biocatalytic efficiency and stability with the potential for multiple reuses. ISM has proven to be considerably more efficient than all previous systematic efforts utilising error-prone polymerase chain reaction at different mutation rates, saturation mutagenesis at hot spots, and/or DNA shuffling. Pronounced positive epistatic effects were found to be the underlying reason for this (Reetz 2010).

The interdisciplinary combination of biotechnology and nanotechnology represents a promising opportunity, opening the door to enhancing the quantity and efficiency of biodiesel production. Repeated use of stable and efficient nanobiocatalytic systems could greatly improve the economic viability of biodiesel in the future.

References

An HJ, Lee HJ, Jun SH, Hwang SY, Kim BC, Kim K, Lee KM, Oh MK, Kim J (2011) Enzyme precipitate coatings of lipase on polymer nanofibers. Bioprocess Biosyst Eng 34:841–847

Andrade LH, Rebelo LP, Netto CGCM, Toma HE (2010) Kinetic resolution of a drug precursor by Burkholderia cepacia lipase immobilised methodologies on superparamagnetic nanoparticles. J Mol Catal B: Enzym 66:55–62

Ansari SA, Husain Q (2012) Potential applications of enzymes immobilised on/in nanomaterials: a review. Biotechnol Adv 30:512–523

Asuri P, Bale SS, Pangule RC, Shah DA, Kane RS, Dordick JS (2007) Structure, function, and stability of enzymes covalently attached to single-walled carbon nanotubes. Langmuir 23:12318–12321

Bisen PS, Sanodiya BS, Thakur GS, Baghel RK, Prasad GB (2010) Biodiesel production with special emphasis on lipase-catalyzed transesterification. Biotechnol Lett 32:1019–1030

Bourlinos AB, Gournis D, Petridis D, Szabó T, Szeri A, Dékány I (2003) Graphite oxide: chemical reduction to graphite and surface modification with primary aliphatic amines and amino acids. Langmuir 19(15):6050–6055

Cang-Rong JT, Pastorin G (2009) The influence of carbon nanotubes on enzyme activity and structure: investigation of different immobilization procedures through enzyme kinetics and circular dichroism studies. Nanotechnology 20:255102

Chang M, Juang R (2007) Use of chitosan–clay composite as immobilisation support for improved activity and stability of β-glucosidase. Biochem Eng J 35:93–98

Chaubey A, Parshad R, Taneja SC, Qazi GN (2009) Arthrobacter sp. lipase immobilisation on magnetic sol–gel composite supports for enatioselectivity improvement. Process Biochem 44:154–160

Chen YZ, Ching CB, Xu R (2009) Lipase immobilisation on modified zirconia nanoparticles: studies on the effects of modifiers. Process Biochem 44:1245–1251

Chronopoulou L, Kamel G, Sparago C, Bordi F, Lupi S, Diociaiuti M, Palocci C (2011) Structure-activity relationships of Candida rugosa lipase immobilised on polylactic acid nanoparticles. Soft Matter 7:2653–2662

Cruz JC, Pfromm PH, Tomich JM, Rezac ME (2010) Conformational changes and catalytic competency of hydrolases adsorbing on fumed silica nanoparticles: I. Tertiary structure. Colloids Surf B 79:97–104

Dai T, Miletic N, Loos K, Elbahri M, Abetz V (2011) Electrospinning of poly[acrylonitrile-co-(glycidyl methacrylate)] nanofibrous mats for the immobilisation of Candida antarctica lipase B. Macromol Chem Phys 212:319–327

Dandavate V, Keharia H, Madamwar D (2009) Ethyl isovalerate synthesis using Candida rugosa lipase immobilised on silica nanoparticles prepared in non-ionic micelles. Process Biochem 44:349–352

Dandavate V, Keharia H, Madamwar D (2011) Ester synthesis using Candida rugosa lipase immobilised on magnetic nanoparticles. Biocatal Biotransform 29:37–45

De M, Ghosh PS, Rotello VM (2008) Applications of nanoparticles in biology. Adv Mater 20:4225–4241

Deng YH, Wang CC, Hu JH, Yang WL, Fu SK (2005) Investigation of formation of silica-coated magnetite nanoparticles via sol–gel approach. Colloids Surf A 262:87–93

Deng YH, Qi D, Deng C, Zhang X, Zhao D (2008) Superparamagnetic high-magnetization microspheres with an Fe3O4–SiO2 core and perpendicularly aligned mesoporous SiO2 shell for removal of microcystins. J Am Chem Soc 130:28–29

Diaz JF, Balkus KJ Jr (1996) Enzyme immobilisation in MCM-41 molecular sieve. J Mol Catal B: Enzym 2:115–126

Drechsler U, Fischer NO, Frankamp BL, Rotello VM (2004) Highly efficient biocatalysts via covalent immobilisation of Candida rugosa lipase on ethylene glycol-modified gold–silica nanocomposites. Adv Mater 16:271–274

Dyal A, Loos K, Noto M, Chang SW, Spagnoli C, Shafi KVPM, Ulman A, Cowman M, Gross RA (2003) Activity of Candida rugosa lipase immobilised on gamma-Fe2O3 magnetic nanoparticles. J Am Chem Soc 125:1684–1685

Fan J, Lei J, Wang L, Yu C, Tu B, Zhao D (2003) Rapid and high-capacity immobilisation of enzymes based on mesoporous silicas with controlled morphologies. Chem Commun 17:2140–2141

Fan X, Niehus X, Sandoval G (2012) Lipases as biocatalyst for biodiesel production. Methods Mol Biol 861:471–483

Ganesan A, Moore BD, Kelly SM, Price NC, Rolinski OJ, Birch DJS, Dunkin IR, Halling PJ (2009) Optical spectroscopic methods for probing the conformational stability of immobilised enzymes. Chem Phys Chem 10:1492–1499

Gao S, Wang YJ, Diao X, Luo GS, Dai YY (2010) Effect of pore diameter and cross-linking method on the immobilisation efficiency of Candida rugosa lipase in SBA-15. Bioresour Technol 101:3830–3837

Georgelin T, Maurice V, Malezieux B, Siaugue JM, Cabuil V (2010) Design of multifunctionalized γ-Fe2O3@SiO2 core-shell nanoparticles for enzymes immobilisation. J Nanopart Res 12:675–680

Ghamguia H, Karra-Chaabouni M, Gargouri Y (2004) 1-butyl oleate synthesis by immobilised lipase from Rhizopus oryzae: a comparative study between n-hexane and solvent-free system. Enzyme Microb Technol 35:355–363

Gupta MN, Kaloti M, Kapoor M, Solanki K (2011) Nanomaterials as matrices for enzyme immobilisation. Artif Cells Blood Substit Biotechnol 39:98–109

Gupta A, Barrow CJ, Puri M (2012a) Omega-3 biotechnology: Thraustochytrdis as a novel source of omega-3 oils. Biotechnol Adv 30:1733–1745

Gupta A, Vongsvivut P, Barrow CJ, Puri M (2012b) Molecular identification of marine yeast and its spetroscopic analysis establishes unsaturated fatty acid accumulation. J Biosci Bioeng 114:411–417

Hama S, Yamaji H, Fukumizu T, Numata T, Tamalampudi S, Kondo A, Noda H, Fukuda H (2007) Biodiesel-fuel production in a packed-bed reactor using lipase-producing Rhizopus oryzae cells immobilised within biomass support particles. Biochem Eng J 34:273–278

Hanefeld U, Gardossi L, Magner E (2009) Understanding enzyme immobilisation. Chem Soc Rev 38(2):453–468

Hasan F, Shah AA, Hameed A (2006) Industrial applications of microbial lipases. Enzyme Microb Technol 39:235–251

Hu B, Pan J, Yu HL, Liu JW, Xu JH (2009) Immobilisation of Serratia marcescens lipase onto amino-functionalized magnetic nanoparticles for repeated use in enzymatic synthesis of Diltiazem intermediate. Process Biochem 44:1019–1024

Huang SH, Liao MH, Chen DH (2003) Direct binding and characterization of lipase onto magnetic nanoparticles. Biotechnol Prog 19:1095–1100

Huang XJ, Xu ZK, Wan LS, Innocent C, Seta P (2006) Electrospun nanofibers modified with phospholipid moieties for enzyme immobilisation. Macromol Rapid Commun 27:1341–1345

Huang XJ, Yu AG, Xu ZK (2008) Covalent immobilisation of lipase from Candida rugosa onto poly(acrylonitrile-co-2-hydroxyethyl methacrylate) electrospun fibrous membranes for potential bioreactor application. Bioresour Technol 99:5459–5465

Huang XJ, Chen PC, Huang F, Ou Y, Chen MR, Xu ZK (2011) Immobilisation of Candida rugosa lipase on electrospun cellulose nanofiber membrane. J Mol Catal B: Enzym 70:95–100

Illanes A, Cauerhff A, Wilson L, Castro GR (2012) Recent trends in biocatalysis engineering. Bioresour Technol 115:48–57

Itoh T, Ishii R, Matsuura S, Mizuguchi J, Hamakawa S, Hanaoka TA, Tsunoda T, Mizukami F (2010) Enhancement in thermal stability and resistance to denaturants of lipase encapsulated in mesoporous silica with alkyltrimethylammonium (CTAB). Colloids Surf B 75:478–482

Ji P, Tan HS, Xu X, Feng W (2010) Lipase covalently attached to multiwalled carbon nanotubes as an efficient catalyst in organic solvent. Aiche J 56:3005–3011

Jia H, Zhu G, Vugrinovich B, Kataphinan W, Reneker DH, Wang P (2002) Enzyme-carrying polymeric nanofibers prepared via electrospinning for use as unique biocatalysts. Biotechnol Prog 18:1027–1032

Jiang Y, Guo C, Xia H, Mahmood I, Liu C, Liu H (2009) Magnetic nanoparticles supported ionic liquids for lipase immobilisation: enzyme activity in catalysing esterification. J Mol Catal B: Enzym 58:103–109

Jochems P, Satyawali Y, Diels L, Dejonghe W (2011) Enzyme immobilisation on/in polymeric membranes: status, challenges and perspectives in biocatalytic membrane reactors (BMRs). Green Chem 13:1609–1623

Johnson PA, Park HJ, Driscoll AJ (2011) Enzyme nanoparticle fabrication: magnetic nanoparticle synthesis and enzyme immobilisation. Methods Mol Biol 679:183–191

Kalantari M, Kazemeini M, Tabandeh F, Arpanaei A (2012) Lipase immobilisation on magnetic silica nanocomposite particles: effects of the silica structure on properties of the immobilised enzyme. J Mater Chem 22:8385–8394

Kang Y, He J, Guo XD, Guo X, Song ZH (2007) Influence of pore diameters on the immobilisation of lipase in SBA-15. Ind Eng Chem Res 46:4474–4479

Kang YJ, Chung H, Han CH, Kim W (2012) All-solid-state flexible supercapacitors based on papers coated with carbon nanotubes and ionic-liquid-based gel electrolytes. Nanotechnology 23:065401

Kim J, Grate JW, Wang P (2006a) Nanostructures for enzyme stabilisation. Chem Eng Sci 61:1017–1026

Kim J, Jia H, Wang P (2006b) Challenges in biocatalysis for enzyme-based biofuel cells. Biotechnol Adv 24:296–308

Kim MI, Ham HO, Oh S-D, Park HG, Chang HN, Choi SH (2006c) Immobilisation of Mucor javanicus lipase on effectively functionalized silica nanoparticles. J Mol Catal B: Enzym 39:62–68

Kim J, Grate JW, Wang P (2008) Nanobiocatalysis and its potential applications. Trends Biotechnol 26:639–646

Kim H, Kwon HS, Ahn J, Lee CH, Ahn IK (2009) Evaluation of silica-coated magnetic nanoparticle for the immobilisation of a His-tagged lipase. Biocatal Biotransform 27:246–253

Kralovec JA, Wang W, Barrow CJ (2010) Production of omega-3 triacylglycerol concentrates using a new food grade immobilised Candida antarctica lipase B. Aust J Chem 63:922–928

Kralovec JA, Zhang S, Barrow CJ (2012) A review of the progress in enzymatic concentration and microencapsulation of omega-3 rich oil from fish and microbial sources. Food Chem 131:639–644

Kuchibhatla SVNT, Karakpti AS, Bera D, Seal S (2007) One dimensional nanostructured materials. Prog Mater Sci 52:699–913

Kumari A, Mahapatra P, Garlapati VK, Banerjee R (2009) Enzymatic transesterification of Jatropha oils. Biotechnol Biofuels 2:1

Lee DG, Ponvel KM, Kim M, Hwang S, Ahn IS, Lee CH (2009) Immobilisation of lipase on hydrophobic nano-sized magnetite particles. J Mol Catal B: Enzym 57:62–66

Lee HK, Lee JK, Kim MJ, Lee CJ (2010a) Immobilisation of lipase on single walled carbon nanotubes in ionic liquid. Bull Kor Chem Soc 31:650–665

Lee SH, Doan TTN, Won K, Ha SH, Koo YM (2010b) Immobilisation of lipase within carbon nanotube-silica composites for non-aqueous reaction systems. J Mol Catal B: Enzym 62:169–172

Li SF, Wu WT (2009) Lipase-immobilised electrospun PAN nanofibrous membranes for soybean oil hydrolysis. Biochem Eng J 45:48–53

Li SF, Chen JP, Wu WT (2007) Electrospun polyacrylonitrile nanofibrous membranes for lipase immobilisation. J Mol Catal B: Enzym 47:117–124

Li D, Muller MB, Gilje S, Kaner RB, Wallance GG (2008) Processable aqueous dispersions of graphene nanosheets. Nat Nanotechnol 3:101–105

Li SF, Fan YH, Hu RF, Wu WT (2011) Pseudomonas cepacia lipase immobilised onto the electrospun PAN nanofibrous membranes for biodiesel production from soybean oil. J Mol Catal B: Enzym 72:40–45

Long JW, Logan MS, Rhodes CP, Carpenter EE, Stroud RM, Rolison DR (2004) Nanocrystalline iron oxide aerogels as mesoporous magnetic architectures. J Am Chem Soc 126:16879–16889

Lu AH, Salabas EL, Schuth F (2007) Magnetic nanoparticles: synthesis, protection, functionalisation, and application. Angew Chem Int Ed Engl 46:1222–1244

Mateo C, Palomo JM, Fernandez-Lorente G, Guisan JM, Fernandez-Lafuente R (2007) Improvement of enzyme activity, stability and selectivity via immobilisation techniques. Enzyme Microb Technol 40:1451–1463

Matsuura SI, Ishii R, Itoh T, Hamakawa S, Tsunoda T, Hanaoka T, Mizukami F (2011) Immobilisation of enzyme-encapsulated nanoporous material in a microreactor and reaction analysis. Chem Eng J 167:744–749

Miletić N, Abetz V, Ebert K, Loos K (2010) Immobilisation of Candida antarctica lipase B on polystyrene nanoparticles. Macromol Rapid Commun 31:71–74

Nair S, Kim J, Crawford B, Kim SH (2007) Improving biocatalytic activity of enzyme-loaded nanofibers by dispersing entangled nanofiber structure. Biomacromolecules 8:1266–1270

Nakane K, Hotta T, Ogihara T, Ogata N, Yamaguchi SJ (2007) Synthesis of (Z)-3-Hexen-1-yl acetate by lipase immobilised in polyvinyl alcohol nanofibers. J Appl Polym Sci 106:863–867

Netto CGCM, Andrade LH, Toma HE (2009) Enantioselective transesterification catalysis by Candida antartica lipase immobilised on superparamagnetic nanopartricles. Tetrahedron Asymm 20:2299–2304

Nikolic M, Srdic V, Antov M (2009) Immobilisation of lipase into mesoporous silica particles by physical adsorption. Biocatal Biotransform 27:254–262

Pan C, Hu B, Li W, Sun Y, Ye H, Zeng X (2009) Novel and efficient method for immobilization and stabilization of β-galactosidase by covalent attachment onto magnetic Fe3O4–chitosan nanoparticles. J Mol Catal B: Enzym 61:208–215

Park S, Ruoff RS (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4:217–223

Pavlidis IV, Tsoufis T, Enotiadis A, Gournis D, Stamatis H (2010) Functionalized multi-wall carbon nanotubes for lipase immobilisation. Adv Eng Mater 12:B179–B183

Pavlidis IV, Vorhaben T, Gournis D, Papadopoulos GK, Bornscheuer UT, Stamatis H (2012) Regulation of catalytic behaviour of hydrolases through interactions with functionalized carbon-based nanomaterials. J Nanopart Res 14:842–851

Ponvel KM, Lee DG, Woo EJ, Ahn IS, Lee CH (2009) Immobilisation of lipase on surface modified magnetic nanoparticles using alkyl benzenesulfonate. Korean J Chem Eng 26:127–130

Puri M, Gupta S, Pahuja P, Kaur A, Kanwar JR, Kennedy JF (2010a) Cell disruption optimization and covalent immobilisation of beta-d-galactosidase from Kluyveromyces marxianus YW-1 for lactose hydrolysis in milk. Appl Biochem Biotechnol 160:98–108

Puri M, Kaur A, Singh RS, Schwarz WH (2010b) One step purification and immobilization of His-tagged rhamnosidase for naringin hydrolysis. Process Biochem 45:445–451

Puri M, Kaur A, Schwarz WH, Singh S, Kennedy JF (2010c) Hydrolysis of citrus peel naringin by recombinant rhamnosidase from Clostridium stercorarium. J Chem Technol Biotechnol 85:1419–1422

Puri M, Kaur A, Barrow CJ, Singh RS (2011) Citrus peel influences the production of an extracellular naringinase by Staphylococcus xylosus MAK2 in a stirred tank reactor. Appl Microbiol Biotechnol 89:715–722

Puri M, Abraham RE, Barrow CJ (2012) Biofuel production: prospects, challenges and feedstock in Australia. Renew Sustain Energy Rev 16:6022–6031

Rebelo LP, Netto CGCM, Toma HE, Andrade LH (2010) Enzymatic kinetic resolution of (RS)-1-(Phenyl)ethanols by Burkholderia cepacia lipase immobilised on magnetic nanoparticles. J Braz Chem Soc 21:1537–1542

Reetz MT (2010) Laboratory evolution of stereoselective enzymes: a prolific source of catalysts for asymmetric reactions. Angew Chem Int Ed 50:138–174

Rege K, Raravikar NR, Kim DY, Schadler LS, Ajayan PM, Dordick JS (2003) Enzyme-polymer-single walled carbon nanotube composites as biocatalytic films. Nano Lett 3:829–832

Ren Y, Rivera JG, He L, Kulkarni H, Lee DK, Messersmith PB (2011) Facile, high efficiency immobilisation of lipase enzyme on magnetic iron oxide nanoparticle via a biomimetic coating. BMC Biotechnol 11:63

Royon D, Daz M, Ellenrieder G, Locatelli S (2007) Enzymatic production of biodiesel from cotton seed oil using t-butanol as a solvent. Bioresour Technol 98:648–653

Safarik I, Safarikova M (2009) Magnetic nano and microparticles in biotechnology. Chem Pap 63:497–505

Sakai S, Antoku K, Yamaguchi T, Kawakami K (2008) Transesterification by lipase entrapped in electrospun poly(vinyl alcohol) fibers and its application to a flow-through reactor. J Biosci Bioeng 105:687–689

Sakai S, Liu Y, Yamaguchi T, Watanabe R, Kawabe M, Kawakami K (2010a) Immobilisation of Pseudomonas cepacia lipase onto electrospun polyacrylonitrile fibers through physical adsorption and application to transesterification in nonaqueous solvent. Biotechnol Lett 32:1059–1062

Sakai S, Liu YP, Yamaguchi T, Watanabe R, Kawabe M, Kawakami K (2010b) Production of butyl-biodiesel using lipase physically-adsorbed onto electrospun polyacrylonitrile fibers. Bioresour Technol 101:7344–7349

Sen T, Bruce IJ (2009) Mesoporous silica-magnetite nanocomposite: fabrication and application in magnetic bioseparations. Microporous Mesoporous Mater 120:246–251

Sen T, Bruce IJ, Mercer T (2010) Fabrication of novel hierarchically ordered porous magnetic nanocomposites for bio-catalysis. Chem Commun 46:6807–6809

Serra E, Mayoral A, Sakamoto Y, Blanco RM, Diaz I (2008) Immobilisation of lipase in ordered mesoporous materials: effect of textural and structural parameters. Microporous Mesoporous Mater 114:201–213

Shah S, Solanki K, Gupta MN (2007) Enhancement of lipase activity in non-aqueous media upon immobilisation on multi-walled carbon nanotubes. Chem Cent J 1:30

Sheldon RA (2007) Enzyme immobilisation: the quest for optimum performance. Adv Synth Catal 349:1289–1307

Shi Q, Yang D, Su Y, Li J, Jiang Z, Jiang Y, Yuan W (2007) Covalent functionalisation of multi-walled carbon nanotubes by lipase. J Nanopart Res 9:1205–1210

Shim M, Kam NWS, Chen RJ, Li Y, Dai H (2002) Functionalisation of carbon nanotubes for biocompatibility and biomolecular recognition. Nano Lett 2:285–288

Shulga OV, Jefferson K, Khan AR, D’Souza VT, Liu J, Demchenko AV, Stine KJ (2007) Preparation and characterization of porous gold and its application as a platform for immobilisation of acetylcholine esterase. Chem Mater 19:3902–3911

Song J, Kahveci D, Chen ML, Guo Z, Xie EQ, Xu XB, Besenbacher F, Dong MD (2012a) Enhanced catalytic activity of lipase encapsulated in PCL nanofibers. Langmuir 28:6157–6162

Song YS, Shin HY, Lee JY, Park C, Kim SW (2012b) β-galactosidase-immobilised microreactor fabricated using a novel technique for enzyme immobilisation and its application for continuous synthesis of lactulose. Food Chem 133:611–617

Sotiropoulou S, Gavalas V, Vamvakaki V, Chaniotakis NA (2003) Novel carbon materials in biosensor systems. Biosens Bioelectron 18:211–215

Sotowa KI, Takagi K, Sugiyama S (2008) Fluid flow behavior and the rate of an enzyme reaction in deep microchannel reactor under high-throughput condition. Chem Eng J 135S:S30–S36

Sun YP, Fu K, Lin Y, Huang W (2002) Functionalized carbon nanotubes: properties and applications. Acc Chem Res 35:1096–1104

Takahashi H, Li B, Sasaki T, Miyazaki C, Kajino T, Inagaki S (2000) Catalytic activity in organic solvents and stability of immobilised enzymes depend on the pore size and surface characteristics of mesoporous silica. Chem Mater 12:3301–3305

Takahashi H, Li B, Sasaki T, Miyazaki C, Kajino T, Inagaki S (2001) Immobilised enzymes in ordered mesoporous silica materials and improvement of their stability and catalytic activity in an organic solvent. Microporous Mesoporous Mater 44–45:755–762

Tan T, Lu JK, Nie KL, Deng L, Wang F (2010) Biodiesel production with immobilised lipase: a review. Biotechnol Adv 28:628–634

Tang ZX, Qian JQ, Shi LE (2007) Characterizations of immobilised neutral lipase on chitosan nanoparticles. Mater Lett 61:37–40

Thanh LT, Oitsu K, Sadanaga Y, Takenaka N, Maeda Y, Bandow H (2010) A two-step continuous ultrasound assisted production of biodiesel fuel from waste cooking oils: a practical and economical approach to produce high quality biodiesel fuel. Bioresour Technol 101:5394–5401

Tran DT, Chen CL, Chang JS (2012) Immobilisation of Burkholderia sp. lipase on a ferric silica nanocomposite for biodiesel production. J Biotechnol 158:112–119

Tung VC, Allen MJ, Yang Y, Kaner RB (2009) High-throughput solution processing of large-scale grapheme. Nat Nanotechnol 4:25–29

Verma ML, Kanwar SS (2008) Properties and application of Poly (MAc-co-DMA-cl-MBAm) hydrogel immobilised Bacillus cereus MTCC 8372 lipase for synthesis of geranyl acetate. J Appl Polym Sci 110:837–846

Verma ML, Kanwar SS (2010) Purification and characterization of a low molecular mass alkaliphilic lipase of Bacillus cereus 8372. Acta Microbiol Immunol Hung 57:191–207