Abstract

By the use of directed limitations of secondary substrates, the metabolic flux should be deflected from biomass production to product formation. In order to study the impact of directed limitations caused by various secondary substrates on the growth and product formation of the methylotrophic yeast Hansenula polymorpha, the cultivation systems respiration activity monitoring system (RAMOS) and BioLector were used in parallel. While the RAMOS device allows the online monitoring of the oxygen transfer rate in shake flasks, the BioLector enables in microtiter plates the monitoring of scattered light and the fluorescence intensity of the green fluorescent protein (GFP). Secondary substrate limitations of phosphate, potassium, and magnesium were analyzed in batch fermentations. The sole carbon source was either 10 g/L glucose or 10 g/L glycerol. The expression of the GFP gene is controlled by the FMD promoter (formate dehydrogenase). In batch cultures with glucose as carbon source, a directed limitation of phosphate increased the GFP production 1.87-fold, compared to phosphate unlimited conditions. Under potassium-limited conditions with glycerol as sole carbon source, the GFP production was 1.41-fold higher compared to unlimited conditions. A limitation of the substrate magnesium resulted in a 1.22-fold increase GFP formation in the case of glycerol as carbon source.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Limitations of carbon source or oxygen, as well as secondary substrates like phosphate, potassium, or magnesium, vitamins or trace elements can influence the growth of microorganisms significantly (Harder and Dijkhuizen 1983). Due to this understanding, many efforts to optimize bioprocesses are commonly focused on the growth of the microorganisms and not necessarily on the product formation.

However, the question arises in this context, if the optimal growth conditions will generally result in the maximal product formation. The idea is that in a first phase of the cultivation, a specific amount of biomass is formed based on nutrients batched into the initial medium. This medium is designed such that during the cultivation, one secondary substrate is exhausted, limiting further growth. This will have the effect that all the remaining carbon source is now available for product formation and maintenance. This theoretical approach could be proven by complex carbon flux analyses but also by online analysis of growth and product formation. This simple approach is followed within this study by a direct limitation of secondary substrates (phosphate, potassium, and magnesium) in shake flask and microtiter plate cultures.

In first steps of bioprocess development, shake flasks or microtiter plates are commonly used. A major disadvantage of such small scale cultivation systems has been so far the limited information about crucial process parameters that can be gained during cultivation. Although there are many systems for monitoring growth in small scale cultivations available (Betts and Baganz 2006), still many laboratories in industry and academia are not extensively using such online-monitoring systems. Without special devices, only few off-line data can be manually made available such as off-line optical density measurement. Because of the limited reaction volume of shake flasks and microtiter plates, cell dry weight analysis, pH values, and product concentrations are usually only detected at the end of the fermentation. The time in-between cannot usually be covered by measurements because of labor and time issues resulting in a black box cultivation. Such problems can be overcome by performing lab-scale stirred bioreactor cultivations, where it is possible to control and detect various online parameters. However, operating a stirred bioreactor can be too time-consuming and costly in early process development. Therefore, a systematic analysis of culture and medium conditions in many cases is tedious and too expensive.

For the improvement of bioprocess development and screening, the respiration activity monitoring system (RAMOS) for shake flasks (Anderlei and Büchs 2001; Anderlei et al. 2004) and the BioLector system for microtiter plates (Samorski et al. 2005; Kensy et al. 2009) have been developed. With the RAMOS system, the respiration activity of microorganisms can be recorded online, whereas the BioLector technique enables the online-monitoring of the scattered light signal (biomass), the pH value, the dissolved oxygen tension in the culture, and the formation of fluorescent proteins (Kensy et al. 2009). As the green fluorescent protein (GFP) is widely accepted as a reporter for recombinant protein production (Tsien 1998), the online detection of fluorescent proteins in parallel small scale cultivations can contribute strongly to the investigation and development of optimal conditions for product formation.

Elemental analysis of yeast biomass has shown that yeast biomass contains potassium, phosphate, and also magnesium in significant amounts (Aiking and Tempest 1976). As an example for development of a bioprocess focusing on product formation, the influence of these secondary substrates should be analyzed regarding the growth and in particular the product formation. Phosphate is an essential nutrient required for the synthesis of nucleic acids, phospholipids, and cellular metabolites (Wykoff and O’Shea 2001). In yeasts, such as Candida utilis, the amount of phosphorus is around 35 mg/g dry cell weight (Aiking and Tempest 1976). The secondary substrate potassium is important for some enzyme activities (Dixon and Webb 1964), for osmoregulation and maintenance of a functional configuration of ribosomes (Epstein and Schultz 1965; Tempest and Meers 1968). Further, a fundamental function of potassium in the ATP metabolism in C. utilis has been reported (Aiking and Tempest 1976; Aiking et al. 1977). An amount of 20 mg potassium could be measured in the case of a C. utilis glucose-limited chemostat culture (Aiking and Tempest 1976). Magnesium is essential for the tertiary structure of enzyme–substrate complexes and plays an important role in protein biosynthesis (Harder and Dijkhuizen 1983). In elemental analysis of C. utilis, a content of magnesium of around 5 mg/g dry cells could be measured (Aiking and Tempest 1976).

Because of the importance of these secondary substrates (phosphate, potassium, and magnesium), the methylotrophic yeast Hansenula polymorpha as model organism was used to determine the hypothesis that a limitation of a secondary substrate may deflect the energy/metabolic flux form biomass to product formation. The H. polymorpha strain RB11 pC10-FMD (P FMD -GFP) (Amuel et al. 2000; Gellissen 2000) produces GFP under the control of the FMD promoter. Two different product formation kinetics can be observed for this strain. With glucose as sole carbon source, the product formation is catabolite repressed; with glycerol as sole carbon source, the product formation is partly derepressed (Eggeling and Sahm 1978). Therefore, the impact of the above-mentioned secondary substrates is investigated in combination with different carbon sources in batch cultivations. The experiments are focused on the optimization of the productivity of the model strain and should not analyze in detail the physiological reactions caused by the different secondary substrate limitations.

Materials and methods

Microorganism and media

H. polymorpha RB11 pC10-FMD (P FMD -GFP) was kindly provided by Dr. C. Amuel (Heinrich-Heine Universität, Department of Microbiology, Düsseldorf, Germany) (Amuel et al. 2000; Gellissen 2000). This yeast was grown on Syn-6-MES mineral medium in batch culture. The medium contained per liter: 7.66 g (NH4)2SO4; 1.0 g KH2PO4; 3.3 g KCl; 3.0 g MgSO4 · 7H2O; 0.3 g NaCl; 27.3 g 2-morpholinoethanesulfonic acid (MES) and 1.0 g sodium citrate. The pH was adjusted to 6.4 with concentrated sodium hydroxide solution. After sterilization at 121 °C for 20 min and cooling, the following filter-sterilized vitamins, trace elements, and microelements were added: 1.0 g CaCl2 · 2H2O; 66.7 mg (NH4)2Fe(SO4)2 · 6H2O; 5.34 mg CuSO4 · 5H2O; 20 mg ZnSO4 · 7H2O; 26.7 mg MnSO4 · H2O; 66.7 mg EDTA (Titriplex III); 0.4 mg d-biotin; 133.4 mg thiamine · HCl; 0.333 mg NiSO4 · 6H2O; 0.333 mg CoCl2 · 6H2O; 0.333 mg boric acid; 0.333 mg KI; 0.333 mg Na2MoO4 · 2H2O. A sterile solution of glucose or glycerol was added separately to achieve final carbon source concentrations of 10 g/L. The cultivations were performed at 30 °C.

Preparation of phosphate unlimited media

Two different basal media were prepared. One basal medium was composed as described above (Syn-6-MES) with 100% (1.0 g/L KH2PO4, 698 mg/L PO 3−4 ) of the phosphate concentration and one without any phosphate. To make sure that the osmotic pressure is comparable in both media and to avoid a potassium limitation, the phosphate source of the medium (1.0 g/L KH2PO4) was replaced with 0.547 g/L KCl to achieve the same molar concentration of potassium. Media with different phosphate concentrations were then prepared by mixing the two basal media in different ratios. The percentage of phosphate in the resulting medium is normalized to the above-mentioned phosphate-containing medium as 100%. Consequently, 100% refers to 277 mg phosphorous (P), 50% to 138.5 mg P, 25% to 69.25 mg P, 15% to 41.55 mg, 12.5% to 34.63 mg P, 10% to 27.7 mg P, and 7% to 19.39 mg P. Concerning the elemental analysis done by Aiking and Tempest (1976), an amount of 35 mg phosphorus per gram dry cell weight can be assumed. The media of all experiments contain 10 g/L carbon source. Therefore, maximal 5–6.5 g dry cell weight can be produced. For unlimited growth, a minimal amount of around 228 mg phosphorus should be sufficient.

Preparation of potassium-limited media

Similar to the phosphate media, two different basal media were prepared, one with 100% (1.0 g/L KH2PO4 and 3.3 g/L KCl) of the potassium concentration and one without any potassium (0% media). The potassium sources KH2PO4 and KCl were replaced by NH4H2PO4 (0.845 g/L) and NaCl (2.59 g/L) in the potassium free medium. The different limited media were prepared as a mixture of the potassium-containing basal medium and the basal medium without potassium. The percentages of potassium are normalized to the above-mentioned basal medium as 100%. Consequently, 100% refers to 2,018 mg potassium and, for example, 5% refers to 101 mg potassium. Eight different media were prepared containing 100%, 5%, 4%, 3%, 2%, 1%, 0.5%, and 0% of the initial potassium. Aiking and Tempest (1976) have found an amount of around 20 mg potassium per gram dry cell weight for C. utilis. The 100% medium contains 2,018 mg potassium. If with 6.5 g/L cell dry weight, the biomass maximum is reached, a minimum of 130 mg potassium has to be available. Because of the fact that the original medium contains a 15.5-fold higher concentration of potassium, the first limitation medium contains only 5% of potassium compared to the 100% medium.

Preparation of magnesium limitation media

A basal medium with 100% and one basal medium without magnesium were prepared. The magnesium source in the medium MgSO4 · 7H2O was replaced by Na2SO4 (1.81 g/L). To prepare a 100%, 3%, 2.5%, 2%, 1.5%, 1%, 0.5%, and 0% medium, both media were mixed accordingly. Aiking and Tempest (1976) showed that C. utilis contains around 5 mg magnesium in a glucose-limited culture. Therefore, to build 6.5 g/L dry cell weight, a minimal content of 33 mg magnesium should be available. The 100% medium contains 296 mg magnesium, around ninefold higher as required. To achieve a limitation of magnesium in the cultivation, we prepared a 3% medium which contains 8.9 mg magnesium. The 2.5% medium refers to 7.4 mg magnesium, the 2% medium to 7.4 mg magnesium, 2% to 5.9 mg magnesium, 1.5% to 4.4 mg magnesium, 1% to 3 mg magnesium, 0.5% to 1.5 mg magnesium, and 0% is without magnesium.

Fermentation and online measurement of the scattered light, the GFP fluorescence, and the oxygen transfer rate

The inoculum for all experiments was grown in a 250 mL flask with 20 mL filling volume on a rotary shaker (Multitron 2, Infors AG, Bottmingen, Switzerland) at a shaking frequency of 300 rpm, shaking diameter of 50 mm, and 30 °C. This culture was inoculated with a cryo-culture, incubated, and harvested at the middle of the exponential growth phase after approximately 11 h and centrifuged for 5 min at 4 °C and 2,500 g. The pellet was washed with sterile sodium chloride solution (0.9% NaCl). This was done to eliminate all remaining media components. Then, the different media were inoculated with the cells, and the initial optical density (600 nm) was adjusted to about 0.1. The batch cultivations at all limitation levels were performed in parallel in both the RAMOS (Anderlei and Büchs 2001; Anderlei et al. 2004; commercialized by HiTech Zang, Herzogenrath, Germany or Kühner AG, Birsfelden, Switzerland) and the microtiter plate cultivation system BioLector (Samorski et al. 2005; Kensy et al. 2009; commercialized by m2p-labs GmbH, Aachen, Germany). The modified 250 mL Erlenmeyer shake flasks of the RAMOS were used with a filling volume of 12.5 mL. All cultivations were carried out with a shaking frequency of 300 min−1 and a shaking diameter of 50 mm on a Lab-Shaker LS-K (Kühner, Birsfelden, Switzerland). For the BioLector cultivation, the wells of a 96-well plate (Cat. 655087, Greiner Bio One, Frickenhausen, Germany) were filled with 200 µL each. The shaking frequency was 950 min−1 with a shaking diameter of 3 mm. The scattered light was measured using a 620 nm excitation filter and no emission filter. The fluorescence of the GFP was measured through a 485 nm excitation filter and a 520 nm emission filter. The GFP and scattered light are expressed as arbitrary units (a.u.). Every level of limitation for every secondary substrate was performed in parallel experiments in eight wells. In order to compare shake flask scale to microtiter plate scale, both systems should be able to transfer comparable amounts of oxygen. The oxygen transfer in shake flasks has been intensively investigated by Maier (2002). There, a correlation was developed that enables an estimation of the maximum achievable oxygen transfer rate (OTR). For the chosen conditions of this study, the maximal OTR in shake flask is approximately 0.045 mol/L/h, according to this correlation. Similar studies to that of Maier (2002) have been executed for the microtiter scale as well (Kensy F, manuscript in preparation). For 96-well plates and under culture condition comparable to that applied in this study, they have determined maximal OTR values of 0.035 mol/L/h. Thus, the oxygen transfer characteristic of the 96-well plate scale can be considered as comparable to that of the shake flask scale.

Results

Influence of different phosphate concentrations on growth and product formation

The effect of different concentrations of phosphate with glucose as sole carbon source in the medium (Fig. 1a, b, and c) or with glycerol as sole carbon source (Fig. 1d, e, f) on growth and GFP formation is summarized in Fig. 1. The 100% and the 50% cultures show a typical OTR graph of an unlimited growing culture (Anderlei and Büchs 2001). The curves of all cultures start growing with the same growth rate. After about 3 h, the cultures transit to an exponential growth, except for the culture without phosphate where no growth of the cells can be observed. All other cultures show the same growth rate in the beginning of the exponential growth phase. In case of the 12.5% culture, the OTR terminates its exponential increase at about 10 h. This point of time is indicated in the Fig. 1a, b, and c by the vertical line 1. With decreasing phosphate concentration in the medium, the time point where the OTR ceases to increase exponentially is shifted to the left, and also, the time until the maximum of the OTR is reached increases. The vertical line 2 in Fig. 1 indicates the maximum of the OTR peak in the case of the 12.5% P culture. The higher the limitation of phosphate, the lower is the absolute maximum of the OTR.

Effect of different concentrations of phosphate on the growth and product formation of H. polymorpha RB11 pC10-FMD (P FMD -GFP). Culture conditions: synthetic medium Syn-6-MES, buffered at pH 6.4 at 30 °C. The percentages of phosphate are normalized to the original medium (containing 1.0 g/L KH2PO4) as 100%. a, b, c Cultivation with 10 g/L glucose and d, e, f cultivation with 10 g/L glycerol as sole carbon source. a and d Oxygen transfer rate (OTR) measured via a RAMOS device (shaking frequency 300 min−1; shaking diameter 50 mm; 250 mL RAMOS shake flask; filling volume 12.5 mL). b and e Scattered light measurement via MTP cultivation system BioLector (shaking frequency 950 min−1; shaking diameter 3 mm; 96-well plate; filling volume 200 µL) at 620 nm excitation and without emission filter. c and d Fluorescence measurement of GFP via MTP cultivation system BioLector (same conditions like in b and e) at 485 nm excitation and 520 nm emission filter. The vertical lines indicate the time were (1) the phosphate limitation and (2) the glucose limitation exemplary for the 12.5% culture can be assumed. Note that c and f have different scales. The GFP and scattered light are expressed as arbitrary units (a.u.)

In Fig. 1b, the trend of the scatter light signal over the fermentation time is depicted. The unlimited cultures 100% and 50% achieve a lower maximum scattered light signals than the limited cultures (≤25% phosphate). With decreasing phosphate concentration in the medium, the maximum of the scatter light signal increases, and also, this maximum is reached later in time. After reaching the maximum of the scattered light, suddenly, all curves drop down and finally end up in one equivalent stationary level. The maxima of the scattered light signals correlates quite well with the maxima of the oxygen transfer rates (Fig. 1a). The cultures showing a short peak in the scatter light signal tends also to show a distinct peak in the oxygen transfer rate (for example the 100% and 50% cultures). At the point where the OTR tends to zero, the scatter light signal in parallel flattens off. The vertical line 2 in Fig. 1 indicates this point in time for the 12.5% culture as an example. It is emphasized that OTR (Fig. 1a) and the scattered light signal (Fig. 1b) are obtained from different reactors, RAMOS shake flasks and microtiter plate, respectively, which are operated in parallel. The closely related results from both culture systems indicate that both were operated at very similar conditions.

The GFP formation is represented by the fluorescence signal in Fig. 1c. The GFP formation of the 100% and the 50% cultures starts at the point where the oxygen transfer rate brakes down at about 12.5 h. The GFP formation of the cultures with lower phosphate concentrations than 50% starts already earlier. For example, in the case of the 12.5% culture, an increase in fluorescence can already be seen at the point where the OTR curve shifts from exponential to linear increase (vertical line 1, Fig. 1). Then, with the starting decrease of the OTR and the scattered light (indicated by line 2, Fig. 1), the product formation rate increases further. The lower the phosphate concentration in the medium, the higher fluorescence signals are reached. In the case of the 12.5% culture, the maximum of the measured fluorescence is approximately 23,644 U compared to 12,656 U in the case of the 100% culture.

Different phosphate concentrations with glycerol as sole carbon source in the medium were also analyzed. In this part of the experiment, the influence of different phosphate concentrations in a partly derepressed system can be analyzed. Figure 1 shows the results of the OTR (Fig. 1d), the scattered light (Fig. 1e), and the fluorescence (Fig. 1f) measurements. The lower the phosphate concentration, the earlier the OTRs stop their exponential increase compared to the unlimited 100% and 50% cultures (Fig. 1d). This is the same phosphate dependent behavior as already detected with glucose as carbon source (Fig. 1a). However, in the case of glycerol as carbon source, a more distinct “shoulder” can be observed after the main peak below phosphate concentrations of 15%. The scatter light signals of the cultures (Fig. 1e) were in their order comparable to the trend of the cultures with glucose as carbon source (Fig. 1b) but on a higher absolute value of the scattered light signal. In Fig. 1b, the maximum of the scattered light signal correlates with the maximum of the OTR; whereas in the case of Fig. 1e, the maximum of the OTR more correlates with the “shoulder” of the OTR signal after the main peak. On the contrary to the glucose cultures (Fig. 1c), the product formation (Fig. 1f) begins right from the start of the cultivation and seems directly coupled with the biomass production. The lower the phosphate content in the medium, the lower is also the fluorescence intensity of the culture. Exception is the 25% culture, which reaches a slightly higher GFP fluorescence compared to the 100% culture. With glycerol as carbon source the absolute value of fluorescence reached 48,125 U (100%) and is 3.8-fold higher compared to the media with glucose as carbon source (12,656 U, 100%).

Influence of different potassium concentrations on growth and product formation

The influence of different potassium concentrations was analyzed in the case of glucose being the sole carbon source. The OTR of the 100% culture is lower than the cultures with less potassium (5% to 1%; Fig. 2a). Furthermore, lower potassium concentrations in the medium lead to a later drop of the OTR. The scattered light signals also show a graduated pattern (Fig. 2b). The unlimited culture (100%) reaches at first its maximum. For lower potassium concentrations, the cultures reach their scattered light maximum later on. The trend of the GFP fluorescence formation is shown in Fig. 2c. The unlimited culture (100%) is the first one producing GFP (at approximately 10 h). This correlates with the drop of the OTR at the same time. The lower the potassium concentration in the medium, the later the product formation occurs.

Effect of different concentrations of potassium on the growth and product formation of H. polymorpha RB11 pC10-FMD (P FMD -GFP). Culture conditions: synthetic medium Syn-6-MES, buffered at pH 6.4 at 30 °C. The percentages of potassium are normalized to the original medium (containing 1.0 g/L KH2PO4 and 3.3 g/L KCl) as 100%. a, b, c Cultivation with 10 g/L glucose and d, e, f cultivation with 10 g/L glycerol as sole carbon source. a and d Oxygen transfer rate (OTR) measured via a RAMOS device (shaking frequency 300 min−1; shaking diameter 50 mm; 250 mL RAMOS-shake flask; filling volume 12.5 mL). b and e Scattered light measurement via MTP cultivation system BioLector (shaking frequency 950 min−1; shaking diameter 3 mm; 96-well plate; filling volume 200 µL) at 620 nm excitation and without emission filter. c and d Fluorescence measurement of the GFP protein via MTP cultivation system BioLector (same condition like in b and e) at 485 nm excitation and 520-nm emission filter. The GFP and scattered light are expressed as arbitrary units (a.u.)

With glycerol as carbon source, the results of the cultivations are depicted in Fig. 2d–f. The OTR curves of the cultures show a staggered arrangement (Fig. 2d). The unlimited culture (100%) is the fastest growing and reaching the highest oxygen transfer rate. The other cultures reach the maximum OTR in the order of descending potassium concentration in the medium. The scattered light signals in Fig. 2e are comparable to the trend of the scattered light signals in Fig. 2b (glucose as carbon source), although the absolute values differ. The same is true for the GFP formation (compare Fig. 2f with 2c). The 100% culture reaches a maximal fluorescence value of 46,244 U, and the maximum of the 2% culture is 65,230 U. The trend shows that lower potassium concentrations in the medium lead to higher amounts of produced GFP. Thus, the GFP formation starts with the beginning of increasing OTR (Fig. 2d) and increasing scattered light (Fig. 2e).

Influence of different magnesium concentrations on growth and product formation

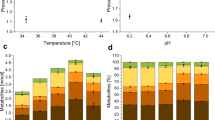

The influence of different magnesium concentrations with glucose or with glycerol as carbon source was analyzed. The OTR curves (Fig. 3a and d) show a comparable picture to the phosphate-limited cultures (Fig. 1a and d). Figure 3b shows the signal of the scatter light for glucose as the carbon source. It is widely comparable to the trend of the phosphate cultures with glucose as carbon source (Fig. 1b). Figure 3c depicts the product formation of cultures with different magnesium concentrations and with glucose as carbon source. The GFP formation begins with the decrease of the OTR of the cultures (Fig. 3a). Low concentrations of magnesium in the medium result in low maximal fluorescence values. Only the 1% and 1.5% (magnesium) cultures seem to follow another trend in product formation and reached higher levels of fluorescence compared to the other limited cultures (3%–2%). However, compared to the unlimited 100% culture, the absolute value is lower. The influence of different magnesium concentrations on the OTR (Fig. 3d), the scattered light intensity (Fig. 3e), and the fluorescence intensity (Fig. 3f) is not that marked when glycerol is the carbon source compared to cultures with glucose as carbon source. In the case of the scattered light signal, a decrease can be observed only at concentrations below 1% (Fig. 3e). Figure 3f shows the GFP formation. The unlimited 100% culture reached a maximal value of GFP fluorescence of 33,439 U. The limited 3% culture reached 40,800 U of fluorescence. Below concentrations of 1%, no increase of product formation can be observed.

Effect of different concentrations of magnesium on the growth and product formation of H. polymorpha RB11 pC10-FMD (P FMD -GFP). Culture conditions: synthetic medium Syn-6-MES, buffered at pH 6.4 at 30 °C. The percentages of magnesium are normalized to the original medium (containing 3.0 g/L MgSO4 · 7H2O) as 100%. a, b, c Cultivation with 10 g/L glucose and d, e, f cultivation with 10 g/L glycerol as sole carbon source. a and d Oxygen transfer rate (OTR) measured via a RAMOS device (shaking frequency 300 min−1; shaking diameter 50 mm; 250 mL RAMOS-shake flask; filling volume 12.5 mL). b and e Scattered light measurement via MTP cultivation system BioLector (shaking frequency 950 min−1; shaking diameter 3 mm; 96-well plate; filling volume 200 µL) at 620 nm excitation and without emission filter. c and d Fluorescence measurement of the GFP protein via MTP cultivation system BioLector (same condition like in b and e) at 485 nm excitation and 520-nm emission filter. The GFP and scattered light are expressed as arbitrary units (a.u.)

Discussion

Influence of different phosphate concentrations

Figure 1a, b, and c makes clear that the concentration of the secondary substrate phosphate strongly influences the growth and also the product formation. In contrast to the common belief that a limitation results in a decreased growth and, thus, decreased product formation, an increase in product formation was observed for example in cultures with lower than 50% phosphate in the medium. Vertical line 1 indicates for the 12.5% culture, the point where phosphate can be assumed to be exhausted, and from this point onwards, the culture is phosphate limited. The 12.5% culture indicates this assumption by a limited increase of the OTR (Fig. 1a). The OTR peak is lower than that of an unlimited culture (100% and 50%). The culture does not completely stop growing. Only a reduction in the growth rate can be seen in the scattered light signal (Fig. 1b) and also in the OTR. Hence, it is possible that the internal phosphate pools of the cells are utilized for further growth and the content of phosphate per cell is slowly decreased. Corynebacterium glutamicum, for example, is able to continue growth after dissolved phosphate in the culture broth is exhausted. The microorganism reduces the phosphorus content of the cell mass (Büchs et al. 1988). The second vertical line indicates the time where in the case of the 12.5% culture, glucose can be assumed to be exhausted. The OTR trend (Fig. 1a) demonstrates this as a complete derepression of the curve. Also the scattered light signal reached its maximum of intensity at that point (Fig. 1b). In the beginning of the exponential growth, the product formation (Fig. 1c) is repressed by the strongly regulated FMD promoter. If glucose is used as carbon source, the promoter is repressed, and expression starts normally only if the glucose is completely exhausted (Eggeling and Sahm 1978; Kensy et al. 2009). In the case of the 12.5% culture, the product formation starts at the time (vertical line 1) where the OTR curve shifts from exponential to linear increase and, therefore, from phosphate unlimited to phosphate limited conditions. Here, the GFP formation begins even though glucose is still present in the medium. Once glucose is fully exhausted, a further drastical increase in GFP formation can be observed (Fig. 1c, vertical line 2).Hence, it is possible to increase the product formation of a catabolite-repressed system in batch fermentations simply via directed phosphate limitation. In case of a phosphate limited culture, obviously, the catabolite repression is partially bypassed resulting in a 1.87-fold increase in product formation. The decay in the scattered light signal measured by the BioLector (Fig. 1b after vertical line 2) is elucidated by other experimental setup and described elsewhere (Kottmeier et al. 2009). The analysis of off-line samples with a flow cytometer showed that the sharp decay in the scattered light correlates with a formation of two subpopulations with different light scattering properties. With decreasing phosphate concentration, the interval of time till the stationary level reached is higher. This effect can be explained due to a higher inhomogeneity within the phosphate limited cultures compared to the glucose limited one. The rate of transition of the yeast from one subpopulation to the other appears to be correlated with the rate of decrease in the light scatter signal. The formation of the subpopulations may be caused by an increased asymmetry in the cell cycle due to the phosphate limitation (Kottmeier et al. 2009). A similar picture can be seen in all scatter light measurements (Figs. 1e, 2b, and e and 3b and e). It is assumed that the drop in the light scatter signal is caused by an asymmetric division of the yeast. However, to prove this in detail, further analyses have to be done. With glycerol as carbon source, the FMD promoter is partly derepressed, and the product formation of the GFP is more or less coupled with the biomass production (Fig. 1e and f; Eggeling and Sahm 1978), so there is no significant catabolic repression if glycerol is the carbon source in a concentration of 10 g/L of the fermentation. The phosphate limitation of these cultures generated no significant increase in product formation. The pattern of growth (OTR and scattered light) is comparable to the cultures with glucose as carbon source (Fig. 1e and f compared to Fig. 1b and c).

Influence of different potassium concentrations

If potassium is the limiting substrate and glucose is the carbon source (Fig. 2a, b, and c), no increase in product formation could be observed. The scattered light signal and the trend of the fluorescence intensity (Fig. 2b and c) show a typical pattern for limited cultures: The growth and also the product formation decrease because of the limitation of essential potassium. The OTR trend (Fig. 2a) shows an unusual arrangement. Nearly all limited cultures (1%–5%) show an increase in the respiration activity compared to unlimited culture (100%). Since the K+ concentration in the culture broth is generally much lower than that present in the cytoplasm, the cells must expend energy to maintain a certain transmembrane K+ gradient. It is expected that this gradient is dependent upon the extracellular K+ concentration and will be maximized under potassium limitation (Harder and Dijkhuizen, 1983). Tempest and Neijssel (1981) showed that there was a linear relationship between the specific rate of oxygen uptake by potassium limited cells and the electrochemical potential of the potassium gradient. This behavior of the OTR is not visible if glycerol is used as carbon source (Fig. 2d). Perhaps the above mentioned effect of potassium is influenced by the uptake of the carbon source. Regarding product formation, a potassium limitation is not appropriate to improve the productivity in batch cultures with glucose as carbon source (Fig. 2c). In contrast to that, in the case of glycerol as carbon source, an increase of fluorescence can be observed in potassium limited cultures (Fig. 2f). It is, though, possible to increase the product formation 1.41-fold (65,230 U for 2%, 46,244 U for 100%) via potassium limitation.

Influence of different magnesium concentrations

If glucose is the carbon source, a magnesium limitation below 2% results in a decrease in growth, visible in the OTR and also in the scattered light trends (Fig. 3a and b). Also, the GFP formation (Fig. 3c) is influenced negatively due to the magnesium limitation. A less distinct pattern can be observed if the carbon source is glycerol (Fig. 3d, e, and f). It seems that there is a little increase in product formation. In the case of the 3% culture, the maximal value of fluorescence is 40,800 U compared to 33,439 U (100%).

Furthermore, the influence of the carbon source is much more important on the product formation than the concentration of the secondary substrate in batch cultures. The productivity of a culture with glycerol as carbon source is considerably higher compared to glucose as carbon source caused by the regulation mechanism of the FMD promoter. For example, the unlimited 100% phosphate culture reached a maximal value of 12,656 U of fluorescence for glucose compared to 48125 U, if glycerol is the carbon source. A completely different picture may be observed, if the glucose is fed in a fed-batch operating system. If the culture grows under conditions of carbon starvation, the expression of genes controlled by the FMD promoter is derepressed (Stöckmann et al. 2009). Jeude et al. (2006) demonstrated in shake flasks that using a controlled release technique to feed glucose, the product formation could be increased 35-fold in Syn-6-MES mineral medium compared to batch culture conditions.

Finally, the hypothesis that the metabolic/energy flux can be deflected from biomass production to product formation with the application of a directed secondary substrate limitation has been proven. Furthermore, the RAMOS device and also the BioLector have proved to be suitable tools to find optimal cultivation parameters for fermentation processes. In a batch fermentation of H. polymorpha with the GFP gene under the control of the FMD promoter, it is possible to increase the product formation significantly by the use of a potassium limitation in glycerol cultures or a phosphate limitation in glucose culture. This study pointed out that it is important to investigate the effects of different secondary substrates like phosphate, potassium, and magnesium, in order to prevent negative effects of a limitation and, on the other hand, to take the advantage, if a limitation results in an increased product formation.

References

Aiking H, Tempest DW (1976) Growth and physiology of Candida utilis NCYC 321 in potassium-limited chemostat culture. Arch Microbiol 108:117–124

Aiking H, Sterkenburg A, Tempest DW (1977) Influence of specific growth limitation and dilution rate on the phosphorylation efficiency and cytochrome content of mitochondria of Candida utilis NCYC 321. Arch Microbiol 113:65–72

Amuel C, Gellissen G, Hollenberg CP, Suckow M (2000) Analysis of heat shock promoters in Hansenula polymorpha: the TPS1 promoter, a novel element for heterologous gene expression. Biotechnol Bioprocess Eng 5:247–252

Anderlei T, Büchs J (2001) Device for sterile online measurement of the oxygen transfer rate in shaking flasks. Biochem Eng J 7(2):157–162

Anderlei T, Zang W, Papaspyrou M, Büchs J (2004) Online respiration activity measurement (OTR, CTR, RQ) in shake flasks. Biochem Eng J 17(3):187–194

Betts JI, Baganz F (2006) Miniature bioreactors: current practices and future opportunities. Microb Cell Fact 5:21

Büchs J, Mozes N, Wandrey C, Rouxhet PG (1988) Cell adsorption control by culture conditions. Appl Microbiol Biotechnol 29(2–3):119–128

Dixon MD, Webb EC (1964) Enzymes, 2nd edn. Longroans, Green and Co., London

Eggeling L, Sahm H (1978) Derepression and partial insensitivity to carbon catabolite repression of methanol dissimilating enzymes in Hansenula polymorpha. Eur J Appl Microbiol Biotechnol 5:197–202

Epstein W, Schultz SG (1965) Cation transport in Escherichia coli. V. Regulation of cation content. J Gen Physiol 49:221–234

Gellissen G (2000) Heterologous protein production in methylotrophic yeasts. Appl Microbiol Biotechnol 54(6):741–750

Harder W, Dijkhuizen L (1983) Physiological responses to nutrient limitation. Annu Rev Microbiol 37:1–23

Jeude M, Dittrich B, Niederschulte H, Anderlei T, Knocke C, Klee D, Büchs J (2006) Fed-batch mode in shake flasks by slow-release technique. Biotechnol Bioeng 95(3):433–445

Kensy F, Zang E, Faulhammer C, Tan RK, Büchs J (2009) Validation of a high-throughput fermentation system based on online monitoring of biomass and fluorescence in continuously shaken microtiter plates. Microb Cell Fact 8:31. doi:10.1186/1475-2859-8-31

Kottmeier K, Weber J, Müller C, Bley T, Büchs J (2009) Asymmetric Division of Hansenula polymorpha reflected by a drop of light scatter intensity measured in batch microtiter plate cultivations at phosphate limitation. Biotechnol Bioeng. doi:10.1002/bit.22410

Maier U (2002) Gas/Flüssigkeits-Stofftransfer im Schüttelkolben. Dissertation, RWTH Aachen University

Samorski M, Muller-Newen G, Büchs J (2005) Quasi-continuous combined scattered light and fluorescence measurements: a novel measurement technique for shaken microtiter plates. Biotechnol Bioeng 92:61–68

Stöckmann C, Scheidle M, Dittrich B, Merckelbach A, Hehmann G, Melmer G, Klee D, Büchs J, Kang HA, Gellissen G (2009) Process development in Hansenula polymorpha and Arxula adeninivorans, a re-assessment. Microb Cell Fact 8:22. doi:10.1186/1475-2859-8-22

Tempest DW, Meers JL (1968) The influence of NaCI concentration of the medium on the potassium content of Aerobacter aerogenes and on the interrelationships between potassium, magnesium and ribonucleic acid in the growing bacteria. J Gen Microbiol 54:319–325

Tempest DW, Neijssel OM (1981) Metabolic compromises involved in the growth of microorganisms in nutrient-limited (chemostat) environments. Basic Life Sci 18:335–356

Tsien RY (1998) The green fluorescent protein. Annu Rev Biochem 67:509–544

Wykoff DD, O’Shea EK (2001) Phosphate transport and sensing in Saccharomyces cerevisiae. Genetics 159:1491–1499

Acknowledgments

Special thanks go to M. Zimmermann for many stimulating discussion, to A. Knoll for invaluable help during the preparation of the manuscript, and to M. Funke for the help in technical questions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kottmeier, K., Müller, C., Huber, R. et al. Increased product formation induced by a directed secondary substrate limitation in a batch Hansenula polymorpha culture. Appl Microbiol Biotechnol 86, 93–101 (2010). https://doi.org/10.1007/s00253-009-2285-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-2285-0