Abstract

We developed a novel strategy for constructing yeast to improve levels of amylase gene expression and the practical potential of yeast by combining δ-integration and polyploidization through cell fusion. Streptococcus bovis α-amylase and Rhizopus oryzae glucoamylase/α-agglutinin fusion protein genes were integrated into haploid yeast strains. Diploid strains were constructed from these haploid strains by mating, and then a tetraploid strain was constructed by cell fusion. The α-amylase and glucoamylase activities of the tetraploid strain were increased up to 1.5- and tenfold, respectively, compared with the parental strain. The diploid and tetraploid strains proliferated faster, yielded more cells, and fermented glucose more effectively than the haploid strain. Ethanol productivity from raw starch was improved with increased ploidy; the tetraploid strain consumed 150 g/l of raw starch and produced 70 g/l of ethanol after 72 h of fermentation. Our strategy for constructing yeasts resulted in the simultaneous overexpression of genes integrated into the genome and improvements in the practical potential of yeasts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Along with the exhaustion of fossil fuels and environmental issues such as global warming and acid rain, utilization of the biomass as a fuel source particularly of ethanol has recently become an attractive option. Utilization of the biomass to produce alternative fuels such as ethanol is globally desirable because it is abundant, renewable, and has favorable environmental properties. Therefore, an efficient method of producing ethanol from the biomass is required for worldwide consumption.

Starchy materials are abundant in the biomass, and Saccharomyces cerevisiae is a yeast that can efficiently produce ethanol. However, this yeast lacks the amylolytic activity required to utilize starch as a carbon source, and thus ethanol production from the starchy biomass by classical yeast fermentation is expensive, and the process is complex and time-consuming. This process typically consists of the gelatination of raw starch by cooking, liquefaction using α-amylase, and enzymatic saccharification to glucose by glucoamylase. The costs associated with the extensive energy and enzyme consumption involved in this process are extremely high. Several investigators have described ethanol production from starch using recombinant S. cerevisiae that expresses amylolytic enzymes (Innis et al. 1985; Cole et al. 1988; Inlow et al. 1988; Ibragimova et al. 1995; Nakamura et al. 1997; Birol et al. 1998). A recent study suggests that recombinant S. cerevisiae that co-expresses Streptococcus bovis α-amylase and Rhizopus oryzae glucoamylase/α-agglutinin fusion protein can directly and efficiently ferment raw starch to ethanol (Shigechi et al. 2002; Yamada et al. 2009).

The yeast episomal plasmid (YEp) has been used to genetically manipulate yeasts to overexpress foreign genes (Broach 1983). However, YEp vectors are mitotically unstable under non-selective conditions such as long-term industrial operation in poorly defined media (Murray and Szostak 1983; Romanos et al. 1992). Although, yeast integrative plasmids (YIp) allow stable foreign gene expression, YIp is unsuitable as an overexpression vector because only one copy of a gene can be integrated into the yeast genome (Romanos et al. 1992). The rate-limiting step is starch degradation during direct ethanol fermentation from starch materials, thus both high amylolytic activity and stable expression are critical to efficient ethanol production (Khaw et al. 2005).

Here, we developed an efficient method of ethanol fermentation from raw starch using α-amylase that was overexpressed by combining δ-integration with polyploidization. Multi-copy integration methods such as δ-integration and rDNA-integration are evidently the most suitable methods for overexpressing foreign genes (Sakai et al. 1990; Lopes et al. 1991; Lee and Da Silva 1997; Nieto et al. 1999). We amplified multi-copy integrated genes by polyploidization, which allowed significant overexpression. Moreover, two studies have shown that breeding polyploid strains can improve ethanol productivity or the quality of fermentation products of industrial yeast strains without recombinant techniques (Higgins et al. 2001; Hashimoto et al. 2006). We investigated ethanol fermentation from raw starch using a tetraploid recombinant yeast strain constructed by δ-integration and cell fusion.

Materials and methods

Strains, plasmids, and media

Table 1 summarizes the genetic properties of all strains and plasmids used in this study. In brief, the host for recombinant DNA manipulation was the Escherichia coli strain, NovaBlue (Novagen, Madison, WI, USA), and α-amylase and glucoamylase were expressed in the haploid yeast strains S. cerevisiae MT8-1 and NBRC1440ΔHUWL that can be polyploidized (Yamada et al. 2009). The diploid strain S. cerevisiae MNII/δGS and the tetraploid strain MNIV/δGS were constructed by mating and protoplast fusion from MT8-1/δGS and NBRC1440/δGS as described below.

E. coli transformants were grown in Luria-Bertani medium (10 g/l of tryptone, 5 g/l of yeast extract, and 5 g/l of sodium chloride) supplemented with 100 µg/ml of ampicillin. Transformants and fusants were screened in SD medium (6.7 g/l of yeast nitrogen base without amino acids (Difco Laboratories, Detroit, MI, USA), 20 g/l of glucose) supplemented with appropriate amino acids and nucleic acids. Yeast cells were aerobically cultured in SDC medium (6.7 g/l of yeast nitrogen base without amino acids, 20 g/l of glucose, 20 g/l of casamino acids (Difco Laboratories, Detroit, MI, USA)) supplemented with appropriate amino acids and nucleic acids, and in YPD medium (10 g/l of yeast extract, 20 g/l of Bacto-peptone (Difco Laboratories, Detroit, MI, USA), 20 g/l of glucose). Ethanol fermentation proceeded in YPRS medium (10 g/l of yeast extract, 20 g/l of Bacto-peptone, and 200 g/l of raw corn starch (Wako Pure Chemical Industries Ltd., Osaka, Japan)) containing 0.5 g/l of potassium disulfide to prevent contamination by anaerobic bacteria such as lactic acid bacteria.

Plasmid construction and yeast transformation

Table 2 summarizes the polymerase chain reaction (PCR) primers used in this study. The δ-integrative fundamental-vector plasmids pδW (TRP1 as selective marker) and pδU (URA3 as selective marker) were constructed as follows: The Sac I-Sac I DNA fragment encoding the 5′ half of the δ-sequence was amplified from S. cerevisiae genomic DNA by PCR using the primer pair, 5′DSF (Sac I) and 5′DSR (Sac I). The Kpn I-Kpn I DNA fragment encoding the 3′ half of the δ-sequence was amplified from S. cerevisiae genomic DNA by PCR using the primer pair, 3′DSF (Kpn I) and 3′DSR (Kpn I). These fragments were subcloned into the Sac I and Kpn I sites of the plasmid pBluescript II KS+ (Stratagene, La Jolla, CA, USA). The resulting plasmids were named pδseq. The Xho I-Xho I DNA fragment encoding large portion of promoter-deficient TRP1 (TRP1d) was amplified from pRS404 by PCR using the primer pair, TRP1dF (Xho I) and TRP1dR (Xho I) (Lopes et al. 1991). The Xho I-Xho I DNA fragment encoding large portion of promoter-deficient URA3 (URA3d) marker gene was amplified from pRS406 (Stratagene) by PCR using the primer pair URA3dF (Xho I) and URA3dF (Xho I; Lopes et al. 1991). These fragments were subcloned into the Xho I site of plasmid pδseq, and the resulting plasmids were named pδW and pδU, respectively.

The secretory expression of α-amylase proceeded in plasmid pδW-GPSBA constructed from the δ-integrative vector plasmid pδW. The Not I-Not I DNA fragment encoding the glyceraldehyde 3-phosphate dehydrogenase (GAPDH) promoter from S. cerevisiae, the secretion signal of the R. oryzae glucoamylase gene, the S. bovis α-amylase mature gene, and the GAPDH terminator from S. cerevisiae was obtained by digesting pIU-GluRAG-SBA (Yamada et al. 2009) with Not I. The fragment was inserted into the Not I site of the plasmid pδW to generate the plasmid pδW-GPSBA (Fig. 1A). The plasmid pδU-PGGluRAG was constructed from the δ-integrative vector plasmid pδU, which expressed glucoamylase on the cell surface expression via the 3′-half of α-agglutinin. The Xba I-Xba I DNA fragment encoding the S. cerevisiae PGK1 promoter, the R. oryzae glucoamylase gene with a secretion signal sequence, and the 3′-half of the α-agglutinin gene with a terminator was amplified from S. cerevisiae genomic DNA and pIU-GluRAG-SBA by overlap extension PCR with the primers pPGKF(Xba I), pPGKRO.L., GluRFO.L., and tAGα1R(Xba I). The fragment was digested with Xba I and inserted into the Xba I site of the plasmid pδU to generate pδU-PGGluRAG (Fig. 1B).

The control plasmids for α-amylase and glucoamylase expression via classical integration were pIW-GPSBA and pIU-PGGluRAG, respectively. The plasmid pIW-GPSBA was constructed as follows: The Not I-Not I DNA fragment encoding the GAPDH promoter from S. cerevisiae, the secretion signal of the R. oryzae glucoamylase gene, the S. bovis α-amylase mature gene, and the GAPDH terminator from S. cerevisiae was obtained by Not I digestion of pδW-GPSBA and inserted into the Not I site of the classical integration vector plasmid pRS404 (Stratagene) to generate pIW-GPSBA. The plasmid pIU-PGGluRAG was constructed as follows: The Xba I-Xba I DNA fragment encoding the PGK1 promoter from S. cerevisiae, R. oryzae glucoamylase gene with a secretion signal sequence, and the 3′-half of the α-agglutinin gene with a terminator was obtained by Xba I digestion of pδU-PGGluRAG. The fragment was inserted into the Xba I site of the classical integration vector plasmid pRS406 to yield pIU-PGGluRAG.

Plasmids were transformed into S. cerevisiae using lithium acetate as described (Chen et al. 1992). The transformants with the highest amylase activity was selected from several colonies and used in the subsequent experiments.

Mating and protoplast fusion

The diploid MNII/δGS strain was constructed by mating the haploid strains MT8-1/δGS and NBRC1440/δGS. Both strains were grown on SDC liquid medium for 24 h, harvested, spread together on SDC plates, and incubated for 72 h at 30°C. The strains were then replica-plated onto SD plates and incubated for 3 days at 30°C. The resulting diploid strain formed single colonies on SD plates.

The tetraploid MNIV/δGS strain was constructed by protoplast formation and fusion between the diploid MNII/δGS and MNII/δGS/405 strains as described (Harashima et al. 1984).

Determination of DNA content of yeast cells

Yeast genomic DNA was extracted from mid-exponential phase cells as described (Hereford et al. 1979) and then the DNA concentrations were adjusted based on the assumption that the coefficient of one absorbance unit is equal to 50 µg of DNA/ml at 260 nm. The cell number was counted microscopically in a Bürker Türk hemocytometer with appropriate dilution of cultures.

Amylase activities

Yeast cells were grown aerobically in YPD medium at 30°C for 72 h, and then α-amylase and glucoamylase activities in the culture broth were measured as described (Yamada et al. 2009).

Cell growth and ethanol fermentation from glucose

Yeast cells were cultivated aerobically in 50 ml of YPD liquid medium at 30°C for 96 h, and then the cell density was determined at OD600 by spectrophotometry (Model U-2000A, Hitachi, Tokyo, Japan).

Yeast cells were grown aerobically in YPD medium at 30°C for 72 h, washed twice with water, and then 50 g of wet yeast cells/l were inoculated into YP medium containing glucose (100 g/l). Ethanol fermentation then proceeded under anaerobic conditions.

Ethanol fermentation from raw starch

Yeast cells were grown aerobically in YPD medium at 30°C for 72 h, harvested by centrifugation at 3,000 × g for 5 min, washed twice with water, and re-suspended in 50 ml of YPRS medium. Ethanol fermentation proceeded at 30°C with mild agitation in 100 ml bottles equipped with a bubbling CO2 outlet. The initial cell concentration was adjusted to 50 g of wet cells/l. Wet cell weight was determined by weighing a cell pellet that was harvested by centrifugation at 3,000 × g for 5 min. The estimated dry cell weight for all strains was approximately 0.15-fold the wet cell weight.

Other analytical methods

Ethanol and glucose concentrations were simultaneously determined by high performance liquid chromatography (HPLC; Shimadzu, Kyoto, Japan) using a Shim-pack SPR-Pb column (Shimadzu, Kyoto, Japan). The operating conditions were 80°C, water mobile phase, flow rate of 0.6 ml/min, and then ethanol and glucose concentrations were determined using a refractive index detector (Shimadzu RID-10A). Culture supernatant was separated from the culture broth by centrifugation at 14,000 × g for 10 min and then analyzed by HPLC. Total sugars were determined using the phenol sulfuric acid method as described (Dubois et al. 1956). The α-amylase and glucoamylase activities of the recombinant yeast strain were assayed using kits for α-amylase and saccharification-ability (Kikkoman Corp., Chiba, Japan), respectively.

Results

Construction of yeast strains

The five recombinant yeast strains constructed in this study are shown in Fig. 2. The haploid strains MT8-1/δGS and 1440/δGS were constructed by δ-integration of the glucoamylase and α-amylase genes into their chromosomal DNA, respectively. Integrated amylase gene expression was enhanced in the diploid strains MNII/δGS, MNII/δGS/405, and mating or protoplast fusion of these δ-integrant strains, respectively, yielded the tetraploid strain MNIV/δGS. Because the amylase activities and fermentation abilities of the haploid strains MT8-1/δGS and 1440/δGS and of the diploid strains MNII/δGS and MNII/δGS/405 were similar (data not shown), the amylase δ-integrant strains MT8-1/δGS, MNII/δGS, and MNIV/δGS were included in subsequent experiments.

Determination of DNA contents of yeast cells

To confirm the formation of the polyploid yeast fusants, we determined the cellular DNA contents of individual yeast cells. Table 3 shows that the DNA contents per cell increased with increasing ploidy, thus confirming the formation of polyploid fusants.

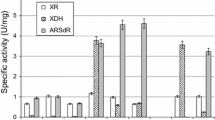

Amylase activities of δ-integrant polyploid fusants

To investigate the effect of δ-integration, mating, and protoplast fusion on amylase activities, amylase activities of each recombinant yeast cells were measured after cultivation in YPD medium. Table 4 shows that the activities of glucoamylase (33.1 U/l) and of α-amylase (722.6 U/l) in the δ-integrant haploid strain MT8-1/δGS were about twofold and 20-fold higher, respectively, than those of the general integrant strain MT8-1/IGS. The activities of glucoamylase and α-amylase improved with increasing ploidy, reaching 330.0 and 1,115.8 U/l, respectively, in the tetraploid strain MNIV/δGS. These values were about 1.5- and tenfold higher than the respective activities of the δ-integrant haploid strain, MT8-1/δGS.

Effect of increasing of ploidy on growth and fermentation in δ-integrant polyploid fusants

The relatively low growth rate and cell yield of the haploid strain MT8-1/δGS under aerobic conditions is shown in Fig. 3a. The growth rate and cell yield of the diploid and tetraploid strains MNII/δGS and MNIV/δGS, respectively, were similarly increased. Their abilities to ferment ethanol from glucose under anaerobic conditions were also similar and higher than that of the haploid strain (Fig. 3b).

a Aerobic cultivation of haploid MT8-1/δGS (triangles), diploid MNII/δGS (squares), and tetraploid MNIV/δGS (diamonds). b Time course of ethanol fermentation from glucose by haploid MT8-1/δGS (triangles), diploid MNII/δGS (squares), and tetraploid MNIV/δGS (diamonds). Filled and unfilled symbols represent ethanol and glucose concentrations, respectively. Data are means from three independent experiments

Ethanol fermentation from raw starch

We examined the abilities of the recombinant yeast strains to directly ferment ethanol from raw starch under anaerobic conditions. The ethanol productivity from raw starch was improved with increasing ploidy, as shown in Fig. 4; the tetraploid strain consumed 150 g/l of raw starch and produced 70 g/l of ethanol after 72 h of fermentation. The amounts of ethanol produced by the haploid, diploid, and tetraploid strains after 72 h of fermentation were 0.55, 0.72, and 0.93 g/l/h, respectively. Table 5 shows that directions of maximal glucoamylase and α-amylase activities were identical during ethanol fermentation and that amylase activities were highest in the tetraploid strain.

Discussion

The combination of δ-integration and cell fusion of yeasts generated an efficient direct fermentation process from raw starch. Two mitotically stable recombinant haploid yeast strains were constructed by the δ-integration of multiple α-amylase and glucoamylase genes into their chromosomal DNA. Two diploid strains were constructed by mating from these δ-integrant haploid strains, and one tetraploid strain was constructed by protoplast fusion. The cell growth, amylase activities, and ethanol productivity of these strains were investigated.

Increasing the amylase activity is critical to efficiently produce ethanol from starchy materials. Here, we repeated two δ-integrations through two types of auxotrophic markers to introduce as many copies of glucoamylase and α-amylase into the yeast genome. We finally increased glucoamylase and α-amylase activities two- and 20-fold improved, respectively, in the haploid strain MT8-1/δGS, compared with the haploid strain MT8-1/IGS, in which genes were introduced by general integration (Table 4). The expression of a single δ-integrant gene is usually two- to tenfold higher than that obtained with general integration (Parekh et al. 1996; Lee and Da Silva 1997; Choi et al. 2002). This is the first study to demonstrate that repeated δ-integration through two types of auxotrophic markers significantly improves the activities of two amylases. Neither gene was overexpressed in the glucoamylase and α-amylase double cassette δ-integrated vector (data not shown) because this vector is very large. These results agreed with other findings (Ghang et al. 2007) and suggested that repeated δ-integration using a single cassette vector would be a more useful strategy for overexpression.

In our previous study, amylase expressing diploid strain constructed by mating of general integrant haploid strains showed high ethanol productivity (0.46 g/l/h) with 290 U/l of glucoamylase and 950 U/l of α-amylase maximum activity (Yamada et al. 2009). In contrast, in this study, δ-integrant tetraploid strain MNIV/δGS showed appropriately twofold higher ethanol productivity (0.93 g/l/h) than our previous results with 843 U/l of glucoamylase and 1,580 U/l of α-amylase maximum activity (Fig. 4 and Table 5). This result suggests that ethanol productivity from raw starch deeply depend on the amylase activities, and our novel strategy using δ-integration and cell fusion is effective for overexpression of genes and improvement of ethanol productivity from raw starch.

The rates of ethanol fermentation by diploid and tetraploid strains from glucose were similar (Fig. 3), whereas those from raw starch were significantly higher in the latter than in the former strain (Fig. 4). This is because α-amylase and glucoamylase activities were significantly improved in the tetraploid strain (Table 5). These findings indicated that the rate-limiting step in ethanol production from raw starch is the degradation of raw starch to glucose, even though it is very difficult to determine the exact amount of insoluble raw corn starch in the early fermentation phase using phenol sulfuric methods. Hence, combining δ-integration with polyploidization is efficient to construct yeasts that can directly ferment ethanol from raw starch.

We constructed a polyploid strain based on MT8-1/δGS and 1440/δGS, which significantly improved amylase activity after δ-integration (Table 4), suggesting that polyploidization is useful for increasing and maintaining the stable expression of integrated genes. In addition, tetraploid fusants MNIV/δGS also maintained high ethanol productivity from raw starch for several batch fermentations (data not shown), showing tetraploid fusants MNIV/δGS is mitotically stable sufficiently for practical fermentation process (Brigidi et al. 1988; Hashimoto et al. 2006). Our novel strategy of combining δ-integration and polyploidization thus significantly improved the growth rate, cell yield, amylase activities, and the abilities of yeast strains to efficiently ferment ethanol.

In conclusion, we established a novel strategy for constructing yeasts that can efficiently produce ethanol from raw starch. The fermentation process might be further improved by investigating the reusability of recombinant yeast cells or the application of more practical medium such as corn steep liquor. Our strategy simultaneously achieved the overexpression of genes integrated into the yeast genome and improved the practical potential of yeasts. Recombinant yeasts with an engineered cell surface can also be used as a whole cell biocatalyst in other bioconversions or in fine chemical production processes.

References

Akada R, Kaneko S, Toyonaga D, Ito S, Yamagiwa A, Kitagawa T, Kakihara Y, Hoshida H, Morimura S, Kondo A, Kida K (2006) PCR-mediated seamless gene deletion and marker recycling in Saccharomyces cerevisiae. Yeast 23:399–405

Birol G, Önsan I, Kirdar B, Oliver SG (1998) Ethanol production and fermentation characteristics of recombinant Saccharomyces cerevisiae strains grown on starch. Enzyme Microb Technol 22:672–677

Brigidi P, Matteuzzi D, Fava F (1988) Use of protoplast fusion to introduce methionine overproduction into Saccharomyces cerevisiae. Appl Microbiol Biotechnol 28:268–271

Broach JR (1983) Construction of high copy yeast vectors using 2-µm circle sequences. Methods Enzymol 101:307–325

Chen DC, Yang BC, Kuo TT (1992) One-step transformation of yeast in stationary phase. Curr Genet 21:83–84

Choi EY, Park JN, Kim HO, Shin DJ, Chun YH, Im SY, Chun SB, Bai S (2002) Construction of an industrial polyploid strain of Saccharomyces cerevisiae containing Saprolegnia ferax β-amylase gene and secreting β-amylase. Biotechnol Lett 24:1785–1790

Cole GE, McCabe PC, Inlow D, Gelfand DH, BenBassat A, Innis MA (1988) Stable expression of Aspergillus awamori glucoamylase in distiller’s yeast. Biotechnology 6:417–421

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Ghang DM, Yu L, Lim MH, Ko HM, Im SY, Lee HB, Bai S (2007) Efficient one-step starch utilization by industrial strains of Saccharomyces cerevisiae expressing the glucoamylase and α-amylase genes from Debaryomyces occidentalis. Biotechnol Lett 29:1203–1208

Harashima S, Takagi A, Oshima Y (1984) Transformation of protoplasted yeast cells is directly associated with cell fusion. Mol Cell Biol 4:771–778

Hashimoto S, Aritomi K, Minohara T, Nishizawa Y, Hoshida H, Kashiwagi S, Akada R (2006) Direct mating between diploid sake strains of Saccharomyces cerevisiae. Appl Microbiol Biotechnol 69:689–696

Hereford L, Fahrner K, Woolford J, Rosbash M, Kaback DB (1979) Isolation of yeast histone genes H2A and H2B. Cell 18:1261–1271

Higgins VJ, Bell PJL, Dawes IW, Attfield PV (2001) Generation of a novel Saccharomyces cerevisiae strain that exhibits strong maltose utilization and hyperosmotic resistance using nonrecombinant techniques. Appl Environ Microbiol 67:4346–4348

Ibragimova SI, Kozlov DG, Kartasheva NN, Suntsov NI, Efremov BD, Benevolensky SV (1995) A strategy for construction of industrial strains of distiller’s yeast. Biotechnol Bioeng 46:285–290

Inlow D, McRae J, Ben-Bassat A (1988) Fermentation of corn starch to ethanol with genetically engineered yeast. Biotechnol Bioeng 32:227–234

Innis MA, Holland PC, McCabe PC, Cole GE, Wittman VP, Tal R, Watt KWK, Gelfand DH, Holland JP, Meade JH (1985) Expression, glycosylation, and secretion of an Aspergillus glucoamylase by Saccharomyces cerevisiae. Science 228:21–26

Khaw TS, Katakura Y, Koh J, Kondo A, Ueda M, Shioya S (2005) Evaluation of performance of different surface-engineered yeast strains for direct ethanol production from raw starch. Appl Microbiol Biotechnol 70:573–579

Lee FWF, Da Silva NA (1997) Sequential δ-integration for the regulated insertion of cloned genes in Saccharomyces cerevisiae. Biotechnol Prog 13:368–373

Lopes TS, Hakkaart GAJ, Koerts BL, Rau HA, Planta RJ (1991) Mechanism of high-copy-number integration of pMIRY-type vectors into the ribosomal DNA of Saccharomyces cerevisiae. Gene 105:83–90

Murray AW, Szostak JW (1983) Pedigree analysis of plasmid segregation in yeast. Cell 34:961–970

Nakamura Y, Kobayashi F, Ohnaga M, Sawada T (1997) Alcohol fermentation of starch by a genetic recombinant yeast having glucoamylase activity. Biotechnol Bioeng 53:21–25

Nieto A, Prieto JA, Sanz P (1999) Stable high-copy-number integration of Aspergillus oryzae α-amylase cDNA in an industrial baker’s yeast strain. Biotechnol Prog 15:459–466

Parekh RN, Shaw MR, Wittrup KD (1996) An integrating vector for tunable, high copy, stable integration into the dispersed Ty δ-sites of Saccharomyces cerevisiae. Biotechnol Prog 12:16–21

Romanos MA, Scorer CA, Clare JJ (1992) Foreign gene expression in yeast: a review. Yeast 8:423–488

Sakai A, Shimizu Y, Hishinuma F (1990) Integration of heterologous genes into the chromosome of Saccharomyces cerevisiae using a delta sequence of yeast retrotransposon Ty. Appl Microbiol Biotechnol 33:302–306

Shigechi H, Uyama K, Fujita Y, Matsumoto T, Ueda M, Tanaka A, Fukuda H, Kondo A (2002) Efficient ethanol production from starch through development of novel flocculent yeast strains displaying glucoamylase and co-displaying or secreting α-amylase. J Mol Catal B Enzym 17:179–187

Tajima M, Nogi Y, Fukasawa T (1985) Primary structure of the Saccharomyces cerevisiae GAL7 gene. Yeast 1:67–77

Yamada R, Bito Y, Adachi T, Tanaka T, Ogino C, Fukuda H, Kondo A (2009) Efficient production of ethanol from raw starch by a mated diploid Saccharomyces cerevisiae with integrated α-amylase and glucoamylase genes. Enzyme Microb Technol 44:344–349

Acknowledgments

This work was supported by a Grant-in-aid from the Ministry of Environment, Japan, and was supported in part by Special Coordination Funds for Promoting Science and Technology, Creation of Innovation Centers for Advanced Interdisciplinary Research Areas (Innovative Bioproduction Kobe), MEXT, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamada, R., Tanaka, T., Ogino, C. et al. Novel strategy for yeast construction using δ-integration and cell fusion to efficiently produce ethanol from raw starch. Appl Microbiol Biotechnol 85, 1491–1498 (2010). https://doi.org/10.1007/s00253-009-2198-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-2198-y