Abstract

An industrial kraft pine lignin (Indulin AT, KL) was characterized and treated in both aqueous-buffered media and dioxane to water, either with a partially purified laccase from Fusarium proliferatum or with the laccase plus 2,2′-azino-bis-3-ethylbenzothiazoline-6-sulfonic-acid (ABTS) as mediator. The changes in the lignin after different incubation periods were analyzed through the application of high performance liquid chromatography (HPLC), UV–visible (Vis) spectroscopy and pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS). At the onset of incubation, laccase-treated samples showed a slight polymerization and strong modifications in UV–Vis spectra. Through Py-GC/MS, a decrease in phenolic and methoxy-bearing pyrolysis products was observed, in contrast to an increase in the more oxidized products. After longer incubation periods (48 h) a substantial polymerization was detected by HPLC, along with a decrease in the guaiacyl (G) units. In contrast, the analysis by HPLC of the samples recovered from the laccase-ABTS system (LMS) showed an intense depolymerization, accompanied by a sizeable loss in G units and a decrease in the methyl and ethyl side-chain phenolic compounds. These results provide conclusive evidence of a rapid initial attack of the industrial lignin by laccase and notable modifications in the KL after longer incubation periods with laccase or LMS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

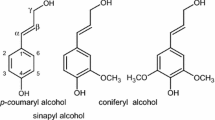

Lignin is a three-dimensional aromatic polymer consisting of phenylpropanoid units with a random distribution of stable carbon–carbon and ether linkages between monomeric units. Industrial lignins, mainly kraft lignin and lignin-sulfonates are readily available and extensively used in biodegradation research (Ander and Eriksson 1978). The results obtained cannot be directly transferred to the biodegradation of natural lignin because the industrial lignins are forms of the natural polymer chemically modified during the pulping process by means of α- and β-aryl-ether bond cleavages, demethylations, shortening of side-chains, ill-defined condensation reactions, etc. (Gierer 1970). In spite of this problem, the study of kraft lignin and lignin sulfide transformation is of considerable environmental significance, either in its own right, or to assess the suitability of these byproducts to be used as alternative raw materials in different industrial applications, e.g., as agglomerants for feed in fish factories, adhesives in the plywood industry, or fertilizer carrier matrix (Gargulak and Lebo 2000). Thus, enhanced reactivity and molecular mass homogeneity should make them more suitable for technological purposes. Because most commercially available lignins are water-insoluble (e.g., kraft lignin) and as such are scarcely accessible to the active sites of an enzyme in heterogeneous phase, their transformation should be studied in media that could solubilize these substrates (Milstein et al. 1990). Different systems were evaluated to achieve this purpose (Milstein et al. 1990; Bourbonnais et al. 1995; Hernández Fernaud et al. 2006a) that usually includes ligninolytic enzymes as tools to attack the lignin preparations.

Laccases are considered useful enzymes because of their ability to produce free radicals from a suitable substrate, and have received increasing attention for potential applications in the field of kraft pulp delignification (Bourbonnais et al. 1997), especially after the discovery that small molecular redox mediators could extend the range of compounds to be oxidized by this enzyme, including the nonphenolic lignins (Bourbonnais and Paice 1990). Laccase-mediator systems are also successfully applied to the degradation of xenobiotic pollutants like phenolic compounds, alkenes, textile dyes, and those contained in industrial effluents and herbicides (Mayer and Staples 2002). Enzymatic modifications of lignin model compounds and kraft lignin by laccase would depend on the catalytic properties of the enzyme used (Morohoshi et al. 1987; Bourbonnais et al. 1995) and the kinetic properties of several laccases were shown to be widely different (Jordaan et al. 2004).

In a recent study we described the UV–visible (Vis) spectral and chromatographic alterations produced on a herbaceous kraft lignin using a novel laccase produced by F. proliferatum under controlled conditions (Hernández Fernaud et al. 2006a). The enzyme showed good thermostability (optimal temperature 60°C and no activity loss after 2 h at 40°C), stability over a broad pH range (2.2–9) and a high affinity for 2,2′-azino-bis-3-ethylbenzothiazoline-6-sulfonic-acid (ABTS) (K m 62 μM; Hernández Fernaud et al. 2006b).

The purpose of the present work was to investigate the potential ability of the laccase produced by F. proliferatum MUCL 31970, either alone or with ABTS as mediator (LMS), to introduce “in situ” modifications in a commercial kraft pine lignin (Indulin AT, KL) using high-performance liquid chromatography (HPLC), UV–Vis spectroscopy and pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS) analytical techniques.

Materials and methods

Microorganism, culture conditions, and laccase production and purification

In the present study, a ligninolytic F. proliferatum strain (MUCL 31970; Regalado et al. 1997) was used. The strain was grown in an enrichment medium containing the polymeric fraction of KL as the only carbon and energy source and was maintained at 4°C. To enhance the laccase production, a medium containing starch-free commercial wheat bran (2% w/v) in 66 mM Sørensen buffer with a pH of 6 was used (Pickard et al. 1999). The substrate was purified from commercial bran (Comeztier SA), as described by Mackenzie et al. (1987). Cultures were inoculated as previously described by Rodríguez et al. (1994). To proceed with the laccase purification, cultures were grown in 10-l flasks containing 600 ml of the above medium and were incubated for 13 days along with uninoculated controls. The extracellular laccase activity was partially purified following the steps described by Hernández Fernaud et al. (2006a) and then dialyzed in McIlvaine buffer (0.1 M citric acid/0.2 M disodium phosphate) adjusted to pH 6.

Enzyme assays

Different enzyme activities were assayed periodically throughout the incubation period. For this, aliquots from the supernatant obtained from the production medium were centrifuged (9,000 × g), discarding the pellet; then extracellular enzyme activities were determined spectrophotometrically in 1-ml reaction volumes using a UV–Vis Beckman Coulter DU 800 spectrophotometer. For each activity, a unit (U) was defined as the amount of enzyme capable of transforming 1 μmol min−1 of its target substrate.

Laccase was tested by monitoring the oxidation of ABTS using a modified assay from that described by Wolfenden and Wilson (1982). For this, 2 mM ABTS, 0.1 M sodium succinate and lactate buffers at pH 4.5, and 50–200 μl culture filtrate were used. Other enzymes involved in lignin metabolism such as lignin peroxidase, manganese peroxidase, aryl alcohol oxidase, and other oxidases (methyl glyoxal, glyoxal, d-cellobiose, d-glucose, d-galactose, and oxalic acid oxidases) capable of generating H2O2 were assayed, as described elsewhere (Anderson et al. 2005).

Protein determination

The protein content of the samples was determined spectrophotometrically at 595 nm with the Coomassie blue method (Bradford 1976), using bovine albumin fraction V as protein standard (BioRad Protein Assay).

Lignin origin

The lignin preparation used throughout the study was a kraft pine lignin, Indulin AT, supplied by Westvaco, Charleston, SC, USA.

Lignin preparation for HPLC study

Control lignin

A KL aliquot (1 mg) was dissolved in 3 ml of 0.1 M NaOH by shaking in a vortex (10 min) and then treated with ethyl acetate (2 ml) containing 50 mM Aliquat 336 (Sigma), centrifuged (10 min at 3,000 × g), and the aqueous phase discarded; the organic phase was washed three times with 1% NaCl (w/v; 2 ml) and then centrifuged again (10 min at 3,000 × g). Ethyl acetate was evaporated under speed vacuum (Speed vac, Savant SPD, model 121P equipped with a vacuum pump model OFP400). The dry residue was redissolved in tetrahydrofuran (THF; UV cut-off 212 nm; 200 μl) for the HPLC analysis described below.

Enzyme-treated lignin with or without mediator in aqueous media

Partially purified laccase (dialyzed against McIlvaine buffer), either alone or using ABTS as mediator, was used to transform the lignin preparation. All the assays were performed in 1.5-ml Eppendorf tubes containing 1 mg of the lignin sample (stock solution 10 mg ml−1 in 50 mM NaOH) in each of the different reaction mixtures (1 ml) at a final pH 6. The purified laccase activity was concentrated by ultrafiltration [Amicon; molecular mass (MM) 10 kDa] to reach 250 mU ml−1 and then was added (0.8 ml) to the reaction mixtures. When necessary, ABTS (0.1 ml) was added to the reaction to obtain 1 mM of the final concentration. Controls were prepared under the same conditions using heat-inactivated enzyme. All assays were run in triplicate at 37°C under shaking (1,400 rpm; Thermomixer, Eppendorf).

To determine the optimal incubation period to transform lignin by the laccase activity, previous assays were performed in the absence of a mediator. For this, reaction mixtures were incubated and withdrawn at 0, 12, 24, 48, and 72 h. Lignin was recovered from each reaction mixture by adding 2 ml of 0.1 M NaOH and treated as above for HPLC studies.

Lignin preparation for Py-GC/MS

In this case, 1 mg of the lignin sample (0.1 ml from a stock solution of 10 mg ml−1 in dioxane) was treated in glass tubes with 0.8 ml of laccase solution (pH 6) obtained and concentrated as above but dialyzed against distilled water. When necessary, 0.1 ml of ABTS was added to the reaction as indicated above. Controls were prepared under the same conditions using heat-inactivated enzyme. All assays were run in triplicate.

Analytical procedures

Spectrophotometric analysis

The lignin UV–Vis absorption spectrum was obtained at room temperature using a sample (3.2 ml) containing 50 μg ml−1 of KL in 0.1 M NaOH. The absorbance was measured in the range of 210–500 nm using a UV–Vis Beckman Coulter DU 800 spectrophotometer.

HPLC analysis

A 20-μl aliquot of the lignin dissolved in THF was injected into an HPLC system (Thermo Separation Products) equipped with a diode array UV–Vis spectrum detector (Waters 2996) and a Rheodyne injector 7125, using both a TSK-gel G 3,000 HXL and a G 4,000 HXL column (both Toso-Haas; 6 i.d. × 300 mm) connected in series and a HXL guard-column (Toso-Haas, 7.8 i.d. × 40 mm). The mobile phase was THF with 20 mM Aliquat 336. The system was calibrated using polystyrene standards in the MM range 800–400,000 Da and 1-hydroxybenzotriazole (135 Da). The analysis time was 70 min at a flow rate of 0.5 ml min−1. Polymer elution profiles were obtained at 280 nm, and the spectra of the different fractions between 212 and 400 nm by monitoring 1 spectrum s−1. Data were analyzed by the Empower software (supplied by Waters).

Py-GC/MS analysis

The pyrolysis of KL freeze-dried samples (1 mg) was performed at 500°C with a double-shot pyrolyzer (model 2020, Frontier Laboratories) directly connected to a GC-MS system Agilent 6890 equipped with a fused silica capillary column HP 5MS (30 m × 250 μm × 0.25 μm i.d.). The detector consisted of an Agilent 5973 mass selective detector (EI at 70 eV). The final temperature was achieved at a rate of 20°C min−1. The GC-MS conditions were as follows: oven temperature was held at 50°C for 1 min and then increased up to 100°C at 30°C min−1, from 100 to 300°C at 10°C min−1, and isothermal at 300°C for 10 min using a heating rate of 20°C min−1 in the scan modus. The carrier gas used was helium with a controlled flow of 1 ml min−1.

Pyrolysis products were identified on the basis of the Wiley and Nist computer libraries and on the retention times and spectra reported in the literature for lignocellulosic material.

Estimation of Klason lignin and reducing sugar content in the KL

Lignin content in the KL preparation was estimated gravimetrically as the acid-insoluble fraction lignin obtained after precipitation of a 10-mg aliquot of KL sample with 0.2 ml of 96% (v/v) sulfuric acid (Klason lignin) (Crawford and Pometto 1988). Furthermore, reducing sugar content was estimated spectrophotometrically by Somogyi method at 500 nm in a Beckman Coulter DU 800 spectrophotometer (Crawford and Pometto 1988). A curve of glucose (Sigma) in a range of 10–1000 μg ml−1 was used as standard.

Results

Characterization of the KL (control lignin)

The UV–Vis spectrum of the control lignin presented a maximum at 220 nm and three shoulders at 245, 280, and 340 nm, respectively (Fig. 1a). The HPLC chromatogram revealed a MM distribution pattern corresponding to a heterogeneous mixture of compounds mostly ranging between 87 and 0.135 kDa (Fig. 1b). Py-GC/MS was used to analyze this lignin and the identities and origin of all released pyrolysis products are shown in Table 1. The pyrograms showed the KL composition in terms of a series of typical carbohydrates and lignin-derived compounds: p-hydroxyphenyl (H), guaiacyl (G; 4-hydroxy, 3-methoxyphenyl), and syringyl (S; 4-hydroxy, 3,5-dimethoxyphenyl), the three phenylpropanoid lignin units. In addition, their methyl-, ethyl-, vinyl-, allyl- and propylphenol derivatives and their phenolic aldehyde, ketone, and acid derivatives were identified. Moreover, typical pyrolysis products of polysaccharides, mainly furfural (3), 2-acetylfuran (9), 2,3-dihydro-5-methylfuran-2-one (10), 2-cyclopenten-1-one-2,3-dimethyl (13), and 2-hydroxy-3-methyl-2-cyclopenten-1-one (21) were detected (Table 1). The summed areas of the relevant peaks corresponding to carbohydrates and lignin were normalized to 100% and the data for two repetitive pyrolysis experiments were averaged. Taking into account the relative abundance of these compounds, 79% lignin- and 21% carbohydrate-derived products were estimated. The molar ratio H to G to S for this lignin was estimated as 6.7:68:2.9. Klason hydrolysis of the industrial lignin showed a 22% dry weight loss. Moreover, 0.12% reducing sugar content was estimated in the acidified supernatant.

a UV–Vis spectrum of a sample of KL (50 μg ml−1 in 0.1 M NaOH) between 210 and 500 nm. Arrows indicate wavelength of peaks and shoulders registered. b HPLC chromatogram corresponding to an aliquot of 100 μg of Indulin AT in THF. The insert shows the correlation between molecular weight and elution times for polystyrene standards: 400 (a′), 185 (b′), 90 (c′), 50 (d′), 32 (e′), 24 (f′), 9 (g′), 2 (h′), 0.8 (i′), and 0.135 (j′) kDa

Analysis of KL modifications induced by laccase in aqueous buffer and dioxane to water systems

Laccase-treated KL samples were taken from aqueous buffer and dioxane to water systems at different incubation times (0–72 h) and were analyzed. It is worth noting that laccase was the only enzyme involved in lignin degradation detected in the extracts added in these systems. Furthermore, its activity remained stable from the onset to 72 h of incubation (data not shown).

In general, the main chromatographic, spectroscopic, and pyrolytic changes detected in the treated lignin were observed immediately after mixing lignin with laccase (time 0 h) and after 48 h of incubation. Samples corresponding to other incubation times (12, 24 and 72 h) did not show significant modifications compared with those described for 48 h of incubation (data not shown).

At the onset of the incubation, the laccase-treated lignin in aqueous buffer system showed a 7.6% increase in the MM fractions eluting from 5.67 to 400 kDa when analyzed by HPLC. This was accompanied by a decrease in the fraction eluting below 0.8 kDa upon comparing with the sample treated with the heat-inactivated enzyme (Fig. 2a and Table 2). The UV–Vis spectra corresponding to different fractions of the treated lignin revealed particularly intense changes in absorbance after 27 min of elution (corresponding to the 80 kDa fraction). In those fractions, the most noticeable increase in the absorbance was observed at 220 nm (337% higher than control). The absorbance increases in the spectral band at 260 and 270 nm were also remarkable (Fig. 2b and Table 3). Small differences were also observed from 280 to 300 nm compared with the control (Table 3). In addition, notable shape changes in the visible region (465–500 nm) compared with the control were observed (data not shown).

a HPLC chromatograms of the KL (1 mg) after incubation in the presence of partially purified laccase activity (200 mU) at 0 h (filled triangles), 48 h (filled squares), and heat-inactivated enzyme (open squares) in the aqueous buffer system. b–c UV–Vis spectra of the fractions recovered at 27 min (b) and 30 min (c). a′–d′ indicate the elution times of polystyrene standards (400, 87, 5.67, and 0.8 kDa, respectively)

On the other hand, modifications of the laccase-treated KL in the dioxane to water system were analyzed by Py-GC/MS (Fig. 3a). The H to G to S molar ratio in the treated lignin at time 0 h was only slightly modified in its phenylpropanoid units (Fig. 3a). Nevertheless, in this sample, a 22% decrease in the total phenolic lignin content and a noticeable increase in the aldehyde (64%), ketone (50%) (Fig. 3a), and acid groups (0.21% in the treated KL against 0.12% in controls; Fig. 3a) were detected.

Total lignin, relative molar amount of the lignin moieties (H, G, and S units), and lignin-derived products as estimated in KL dioxane to water system by Py-GC/MS. The KL treatment was performed using 200 mU of laccase for 0 h (a) and 48 h (b) and LMS (1 mM ABTS) for 48 h (c). Relative peak areas were calculated for carbohydrates and lignin products. The summed areas of the relevant peaks were normalized to 100% and the data for two repetitive experiments were averaged. Total lignin: H (p-hydroxyphenyl units) + G (guaiacyl units) + S (syringyl units) + M (methoxyl lignin). Filled bars indicated treated lignin; open bars indicate control (heat-inactivated laccase)

After 48 h of incubation of the industrial lignin with laccase in the aqueous system, there was a 21% increase in the MM fractions above 5.67 kDa, concomitantly with a similar decrease in those below this (Fig. 2a and Table 2). The UV–Vis spectra of the high MM fractions showed similar profiles to controls but with higher absorbance values as observed for the fraction eluting at 30 min (22.07 kDa; Fig. 2c).

Regarding the KL treated with laccase for 48 h in the dioxane to water system and analyzed by Py-GC/MS, a decrease in the total lignin content (10%) was estimated from the pyrogram areas (Fig. 3b) and as consequence the total ratio lignin/carbohydrate was higher in the control than in treated lignin (data not shown). The decrease observed in the G units-derived compounds (10%) was also remarkable with a minor decrease in S units (1%) compared with the control (Fig. 3b). In addition, a noticeable decrease in the ethyl phenolic derivatives (10%) was detected in enzyme-treated lignin. Insignificant variations in the other phenolic and oxidized groups were also observed, compared with those described above for time 0 h.

Analysis of lignin modifications induced by the LMS

HPLC analysis of the KL recovered from the LMS after 48 h of incubation showed a strikingly altered elution profile compared with the control (Fig. 4a). About 22% loss in lignin content was observed in the polymer fractions eluting between 60.5 and 0.135 kDa. On the other hand, the fractions eluting below 0.8 kDa contained 77% of the total eluted lignin compared with 60% in heat-inactivated control samples (Fig. 4a). The HPLC chromatogram of the LMS-treated lignin also presented a new peak at 400 kDa, (Fig. 4a). The spectra of the lignin fragments eluted before 50 min also showed notable differences from the controls (Fig. 4b,c). An intense peak at 220 nm with a 2.2 times higher absorbance than in controls was detected in the fraction eluting at 50 min, along with two peaks at 260 and 320 nm, which were absent in controls (Fig. 4b). The spectrum of the fraction at 66 min showed two intense peaks at 220 and 340 nm, which were not observed in controls (Fig. 4c).

a HPLC chromatograms of the KL corresponding to 48 h of treatment with partially purified laccase activity (200 mU) and 1 mM ABTS as mediator (filled circles) and with 48 h heat-inactivated enzyme (open squares). b–c UV–Vis spectra of the fractions recovered at 50 min (b) and 66 min (c). a′–c′ indicate the elution times of polystyrene standards (400, 60.5, and 0.135 kDa, respectively)

Py-GC/MS analysis of the LMS-treated KL showed a 19% decrease in the total lignin compared with the control (Fig. 3c). In this sample, the most heavily attacked phenylpropanoid units were G units (18% decrease compared with control) whereas H units remained stable and only a slight decrease in the S units was found. The total phenolic content was also lower in the treated lignin than in the control and an increase in the relative abundance of most of the lignin-derived compounds with a higher oxidation degree-ketones and acids (10 and 2%, respectively) was observed. The decrease in methyl (22.1%) and ethyl derivatives (46%) is worth noting (Fig. 3c).

Discussion

The KL characterization showed a MM distribution pattern and spectra similar to those corresponding to other commercially available kraft lignin preparations (Milstein et al. 1990; Janshekar et al. 1981; Sun et al. 1998; Hernández Fernaud et al. 2006a). The sample contained 78% lignin as estimated by Klason hydrolysis and the remaining 22% were solid components ranging between 15–23% for kraft lignin preparations (Marton 1971). Analysis of the lignin by Py-GC/MS revealed carbohydrates and lignin pyrolytic compounds representative of gymnosperm wood (Table 1). The presence of G-, S-, and H-derived compounds was identified according to their mass spectra. Although the G lignin in most conifers is mainly composed of coniferyl alcohol units, small amounts of coumaryl and sinapyl alcohol units (as detected in this study) can be present in this type of lignin (Freudenberg et al. 1962; Erickson and Miksche 1974; Camarero et al. 1999). Besides this, the high phenolic content of this KL (40%) is probably due to the hydrolytic cleavage of alkyl-aryl-ether linkages during the kraft process, which doubles the number of phenolic G nuclei (Marton 1971).

The KL was incubated under different systems to test the ability of the laccase produced by F. proliferatum to transform the substrate both in the absence and presence of ABTS. The chromatographic, spectroscopic, and pyrolytic studies of the laccase-treated lignin recovered from the two systems at the onset of incubation (time 0 h) showed a slight increase in the high MM fractions compared with the control, which points to early polymerization (Fig. 2a and Table 2). When compared to controls, the UV–Vis spectra of the different fractions of the treated lignin suggest an early attack by the laccase, introducing new functional groups into the side-chain of the phenylpropane unit and/or the aromatic ring. This hypothesis is supported by the intense spectral changes detected in the 260–270 nm region (Table 3), which can be attributed to the introduction of auxochrome groups (e.g., carbonyl in the Cα position of the side-chain), new Cα–Cβ double bonds, or new nonconjugated hydroxyl groups in the side-chain phenylpropane unit (Polcin and Rapson 1969; Goldschmid 1971; Sun et al. 1998). If so, the absorbance at 220 nm should be higher in the enzyme-treated samples due to the influence of these conjugated groups on the π-electron cloud of the aromatic ring. Higher values (4×) than in controls were indeed registered at 220 nm. It is interesting to note that spectral changes in the treated KL were found in the visible region (particularly at 480 nm, data not shown), possibly due to the introduction of new quinones, e.g., quinone methide structures (Polcin and Rapson 1969), chromogene groups contributing to wood color. Regarding this, a rapid change from yellowish to a stable brown color was observed in the reaction mixture immediately after laccase addition. Furthermore, the most important modification detected in the pyrograms of treated lignin was a general rise in oxidative groups like ketones, aldehydes (Fig. 3), and acids, which also supports the previously discussed spectral changes registered between 220 and 270 nm. On the other hand, a decrease in the total phenolic groups was also detected in those pyrograms. Because the oxidation of lignin and related model compounds by laccase proceeds easily in the presence of phenolic groups (Kirk and Shimada 1985; Elegir et al. 2005), the phenoxy radicals generated could undergo further reactions, including polymerization via oxidative coupling. This could explain the slight polymerization observed in the recovered lignin at time 0, mentioned above.

HPLC analysis of the laccase-treated lignin recovered from the buffered medium after 48 h of incubation showed a much more highly polymerized lignin. Indeed, 57% of the total lignin was eluted above 5.67 kDa, compared with just 36% in controls (Fig. 2a and Table 2). The UV–Vis spectra of this treated KL showed lower absorbance values at 220 nm compared with time 0 (Table 3), which is attributable to a loss in some groups conjugated with the aromatic ring (e.g., hydroxyl groups). This would support the formation of a more polymerized lignin, as detected by HPLC. Moreover, as shown by Py-GC/MS, the laccase-treated samples had undergone a selective attack on the G units (a 10% decrease), suggesting a slight degradation and a decrease in ethylphenol and, to a lesser degree, propenylphenol derivatives (Fig. 3b). This latter could be due to a depolymerization by Cα–Cβ cleavage, a previously noted catalytic laccase property (Kawai et al. 1988). Therefore, although polymerization is the dominant effect registered by HPLC, a simultaneous depolymerization seems to occur, as presumably detected by Py-GC/MS. Leonowicz et al. (1985) reported that laccase both polymerized and depolymerized some lignosulfonates, depending probably on the size of the lignin molecule assayed. Our KL showed a wide MM distribution pattern, potentially facilitating both processes.

The analysis of KL recovered from the LMS after 48 h of incubation by HPLC and Py-GC/MS showed strong depolymerization as a predominant effect when compared with the control, although a slight polymerization was also detected. In contrast, simultaneous addition of laccase and ABTS at the onset of incubation prevented the polymerization of the lignin and only a slight depolymerization was detected after 6 days of incubation (Bourbonnais et al. 1995). Other mediators like acetosyringone and acetovanillone also seem to prevent the repolymerization of degraded lignosulfonate by the laccase (Cho et al. 2004). Lignin degradation mechanisms by laccase-mediator systems are rather complicated, being particularly influenced by the great variety of reactive centers in lignin and the complex character of laccase-mediator catalysis (Balakshin et al. 2000). Thus, radicals produced in the phenolic groups by laccase could preferentially bind to ABTS, as suggested by Bourbonnais et al. (1995), and as consequence, polymerization of the treated lignin should be strongly inhibited as occurred in our assays (compare Figs. 2 and 4). Concerning this, Matsumura et al. (1986) reported that laccase catalyses the coupling of ABTS with phenolic derivatives to produce colored compounds. Thus, the strong dark color observed in our reaction mixture (data not shown) after the addition of laccase and ABTS could confirm the above observation. Furthermore, an intense decrease in G units was also detected by Py-GC/MS (Fig. 3c), which could be a consequence of the aromatic ring cleavage by the laccase. Indeed, if we consider the degradation mechanisms previously described for lignin and related lignin model compounds by laccase and LMS (Kawai et al. 1988; Bourbonnais and Paice 1992; Muheim et al. 1992; Balakshin et al. 2000; d’Acunzo et al. 2006), the aromatic ring cleavage requires the previous formation of phenoxy radicals, which appear unlikely to be formed by the laccase–ABTS couple (Muheim et al. 1992). Because our results demonstrate that the decrease in G units occurs in both treatments (laccase and LMS; Fig. 3b,c), those treated by LMS being more notable, ABTS could also act as laccase activator as described by Balakshin et al. (2000), facilitating this attack on the aromatic ring. Further investigation is necessary to confirm this hypothesis. On the other hand, according to the H atom abstraction mechanism proposed for nonphenolic lignin and lignin-related compounds degradation (Muheim et al. 1992; Kawai et al. 2004), the oxidations detected in our KL preparation (new ketone groups) or the presumably Cα–Cβ cleavage supported by the decreased in the ethyl derivatives (Fig. 3c) could be partially attributed to this mechanism.

From this work we can conclude that the laccase secreted by F. proliferatum produced an immediate oxidative action on an industrial pine lignin (Indulin AT), slightly affecting its MM distribution pattern. After longer incubation periods, treated lignin presents a lower degree of oxidation, accompanied by a substantial polymerization. These modifications could facilitate the biotechnological use of the industrial lignin in both commodity and specialty markets (Gargulak and Lebo 2000). Moreover, the higher degree of oxidation and depolymerization detected in the LMS-treated lignin supports the suitability of this enzyme for biotechnological purposes. The high stability and low dose of laccase combined with its affinity for ABTS are desirable properties in industrial applications. Finally, the cleavage of the aromatic ring produced by both systems assayed could open new perspectives for the degradation of xenobiotic compounds.

References

Ander P, Eriksson KE (1978) Lignin degradation and utilization by microorganisms. In: Bull MJ (ed) Progress in industrial microbiology, vol. 14. Elsevier, Amsterdam, pp 1–58

Anderson AJ, Kwon SI, Carnicero A, Falcón MA (2005) Two isolates of Fusarium proliferatum from different habitats and global locations have similar abilities to degrade lignin. FEMS Microbiol Lett 249:149–155

Balakshin MY, Chen CL, Gratzl JS, Kirman AG, Jacob H (2000) Kinetics studies on oxidation of veratryl alcohol by laccase-mediator system. Part 1: effects of mediator concentration. Holzforschung 54:165–170

Bourbonnais R, Paice MG (1990) Oxidation of non-phenolic substrates. An expanded role for laccase in lignin biodegradation. FEBS Lett 267:99–102

Bourbonnais R, Paice MG (1992) Demethylation and delignification of kraft pulp by Trametes versicolor laccase in the presence of 2,2′-azinobis-(3-ethylbenzthiazoline-6 sulphonate). Appl Microbiol Biotechnol 36:823–827

Bourbonnais R, Paice MG, Reid ID, Lanthier P, Yaguchi M (1995) Lignin oxidation by laccase isozymes from Trametes versicolor and role of the mediator 2,2′-azinobis (3-ethylbenzothiazoline-6-sulfonate) in kraft lignin depolymerization. Appl Environ Microbiol 61:1876–1880

Bourbonnais R, Paice MG, Freiermuth B, Bodie E, Borneman S (1997) Reactivities of various mediators and laccases with kraft pulp and lignin model compounds. Appl Environ Microbiol 63:4627–4632

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Camarero S, Bocchini P, Galletti GC, Martínez AT (1999) Pyrolysis-gas chromatography/mass spectrometry analysis of phenolic and etherified units in natural and industrial lignins. Rapid Commun Mass Spectrom 13:630–636

Cho NS, Shin W, Jeong SW, Leonowicz A (2004) Degradation of lignosulfonate by fungal laccase with low molecular mediators. Bull Korean Chem Soc 25:1551–1554

Crawford DL, Pometto AL III (1988) Acid-precipitable polymeric-lignin: production and analysis. In: Wood WA, Kellogg ST (eds) Methods in enzymology, vol. 161, part B. Academic, San Diego, pp 35–47

d’Acunzo F, Galli C, Gentili P, Sergi F (2006) Mechanistic and steric issues in the oxidation of phenolic and non-phenolic compounds by laccase or laccase-mediator systems. New J Chem 30:583–591

Elegir G, Daina S, Zoia L, Bestetti G, Orlandi M (2005) Laccase mediator system: oxidation of recalcitrant lignin model structures present in residual kraft lignin. Enzyme Microb Technol 37:340–346

Erickson M, Miksche GE (1974) Characterization of gymnosperm lignins by oxidative degradation. Holzforschung 28:135–138

Freudenberg K, Chen CL, Cardinale G (1962) Die oxydation des methylierten natürlichen lignins. Chem Ber 95:2814–2828

Gargulak JD, Lebo SE (2000) Commercial use of lignin-based materials. In: Glasser WG, Northey RA, Schultz TP (eds) Lignin: historical, biological, and material perspectives. American Chemical Society, Washington DC, pp 304–320

Gierer J (1970) The reactions of lignin during pulping—a description and comparison of conventional pulping processes. Sven Papperstidn 73:571–596

Goldschmid O (1971) Ultraviolet spectra. In: Sarkanen KV, Ludwig CH (eds) Lignins: occurrence, formation, structure and reactions. Wiley-Interscience, New York, pp 241–266

Hernández Fernaud JR, Carnicero A, Perestelo F, Hernández M, Arias E, Falcón MA (2006a) Upgrading of an industrial lignin by using laccase produced by Fusarium proliferatum and different laccase-mediator systems. Enzyme Microb Technol 38:40–48

Hernández Fernaud JR, Marina A, González K, Vázquez J, Falcón MA (2006b) Production, partial characterization and mass spectrometric studies of the extracellular laccase activity from Fusarium proliferatum. Appl Microbiol Biotechnol 70:212–221

Janshekar H, Brown C, Fiechter A (1981) Determination of biodegraded lignin by ultraviolet spectrophotometry. Anal Chim Acta 130:81–91

Jordaan J, Pletschke BI, Leukes WD (2004) Purification and partial characterization of a thermostable laccase from an unidentified basidiomycete. Enzyme Microb Technol 34:635–641

Kawai S, Umezawa T, Higuchi T (1988) Degradation mechanisms of phenolic beta-1 lignin substructure model compounds by laccase of Coriolus versicolor. Arch Biochem Biophys 262:99–110

Kawai S, Iwatsuki M, Nakagawa M, Inagaki M, Hamabe A, Ohashi H (2004) An alternative β-ether cleavage pathway for a non-phenolic β-O-4 lignin model dimer catalyzed by a laccase-mediator system. Enzyme Microb Technol 35:154–160

Kirk TK, Shimada M (1985) Lignin biodegradation: the microorganisms involved and the physiology and biochemistry of degradation by white-rot fungi. In: Higuchi T (ed) Biosynthesis and biodegradation of wood components. Academic, Orlando, pp 579–605

Leonowicz A, Sklarz G, Wojtas-Wasilewska M (1985) The effect of fungal laccase on fractionated lignosulphonates. Phytochemistry 24:393–396

Mackenzie CR, Bilous D, Scheneider H, Johnson KG (1987) Induction of cellulolytic and xylanolytic enzyme systems in Streptomyces spp. Appl Environ Microbiol 53:2835–2839

Marton J (1971) Reactions in alkaline pulping. In: Sarkanen KV, Ludwig CH (eds) Lignin: occurrence, formation, structure and reactions. Wiley-Interscience, New York, pp 639–694

Matsumura E, Yamamoto E, Numata A, Kawano T, Shin T, Murao S (1986) Structures of the laccase-catalyzed oxidation products of hydroxybenzoic acids in the presence of ABTS. Agric Biol Chem 50:1355–1357

Mayer AM, Staples RC (2002) Laccase: new functions for an old enzyme. Phytochemistry 60:551–565

Milstein O, Hüttermann A, Lüdemann HD, Majcherczyk A, Nicklas B (1990) Enzymatic modification of lignin in organic solvents. In: Kirk TK, Chang HM (eds) Biotechnology in pulp and paper manufacture. Butterworth-Heinemann, Boston, pp 375–387

Morohoshi N, Wariishi H, Murasiso C, Nagai T, Haraguchi T (1987) Degradation of lignin by the extracellular enzymes of Coriolus versicolor. IV. Properties of three laccases fractionated from the extracellular enzymes. Mokuzai Gakkaishi 33:218–225

Muheim A, Fiechter A, Harvey PJ, Schoemaker HE (1992) On the mechanism of oxidation of non-phenolic lignin model compounds by the laccase-ABTS couple. Holzforschung 46:121–126

Pickard MA, Vandertol H, Roman R, Vázquez-Duhalt R (1999) High production of ligninolytic enzymes from white rot fungi in cereal bran liquid medium. Can J Microbiol 45:627–631

Polcin J, Rapson WH (1969) Interpretation of UV and visible spectrum of lignin. Pulp Paper Mag Can 70:99–106

Regalado V, Rodríguez A, Perestelo F, Carnicero A, De la Fuente G, Falcón MA (1997) Lignin degradation and modification by the soil-inhabiting fungus Fusarium proliferatum. Appl Environ Microbiol 63:3716–3718

Rodríguez A, Carnicero A, Perestelo F, De La Fuente G, Milstein O, Falcón MA (1994) Effect of Penicillium chrysogenum on lignin transformation. Appl Environ Microbiol 60:2971–2976

Sun R, Mott L, Bolton J (1998) Isolation and fractional characterization of ball-milled and enzyme lignins from oil palm trunk. J Agric Food Chem 46:718–723

Wolfenden BS, Wilson RL (1982) Radical-cations as reference chromogenes in kinetic studies of cro-electron transfer reactions: pulse radiolysis studies of 2,2′-azinobis-(3-ethylbenzothiazoline-6 sulphonate). J Chem Soc Perkin Trans 2:805–812

Acknowledgements

This work was supported partially by the projects PI 2002/064 (Gobierno Autónomo de Canarias) and REN 2002-02732/TECNO (MCT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

González Arzola, K., Polvillo, O., Arias, M.E. et al. Early attack and subsequent changes produced in an industrial lignin by a fungal laccase and a laccase-mediator system: an analytical approach. Appl Microbiol Biotechnol 73, 141–150 (2006). https://doi.org/10.1007/s00253-006-0630-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0630-0