Abstract

Overexpression of the gene encoding the poly-3-hydroxy-n-phenylalkanoate (PHPhA) depolymerase (phaZ) in Pseudomonas putida U avoids the accumulation of these polymers as storage granules. In this recombinant strain, the 3-OH-acyl-CoA derivatives released from the different aliphatic or aromatic poly-3-hydroxyalkanoates (PHAs) are catabolized through the β-oxidation pathway and transformed into general metabolites (acetyl-CoA, succinyl-CoA, phenylacetyl-CoA) or into non-metabolizable end-products (cinnamoyl-CoA). Taking into account the biochemical, pharmaceutical and industrial interest of some PHA catabolites (i.e., 3-OH-PhAs), we designed a genetically engineered strain of P. putida U (P. putida U ΔfadBA-phaZ) that efficiently bioconverts (more than 80%) different n-phenylalkanoic acids into their 3-hydroxyderivatives and excretes these compounds into the culture broth.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

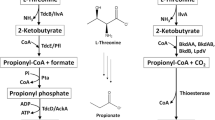

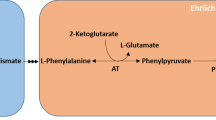

Pseudomonas putida U and other well known pseudomonads are able to accumulate different polymers with plastic properties as storage materials (García et al. 1999; Madison and Huisman 1999; Witholt and Kessler 1999; Sudesh et al. 2002; Olivera et al. 2001a; Steinbüchel 2001; Rehm et al. 1998; Fiedler et al. 2002; Rehm 2003; Luengo et al. 2003). These compounds (poly-3-hydroxyalkanoates; PHAs) are used by these bacteria as an energy source (Anderson and Dawes 1990; Luengo et al. 2003) and are built from different aliphatic or aromatic monomers (García et al. 1999; Abraham et al. 2001; Olivera et al. 2001a). In P. putida U, the biosynthetic pathway of all these PHAs (integrated by aliphatic, aromatic or mixed aliphatic/aromatic monomers) involves the transport of the fatty acid precursor of the monomer, its activation to the CoA thioester, the introduction of a double bond at the β-position and, finally, synthesis of the (S)-3-OH-acyl-CoA derivative (García et al. 1999; Olivera et al. 2001b). In a further step, this compound can be either isomerized to the (R)-enantiomer, as reported for other bacteria (Fukui et al. 1998; Tsuge et al. 1999, 2003) and polymerized into PHAs (storage granules), or it may be catabolized through the β-oxidation pathway (see Fig. 1). Once the carbon sources present in the growth media are exhausted, the bacteria start to mobilize the PHA granules using a PHA-depolymerase enzyme (PhaZ), which releases (R)-3-OH-acyl-CoA derivatives (García et al. 1999; Jendrossek and Handrick 2002; De Roo et al. 2002). Later, these thioesters are isomerized to their (S)-enantiomers and catabolized by a protein complex (FadBA) showing five enzymatic activities (enoyl-CoA hydratase, 3-OH-acyl-CoA dehydrogenase, cis-Δ3-trans-Δ2-enoyl-CoA isomerase, 3-OH-acyl-CoA epimerase, 3-ketothiolase; Olivera et al. 2001b).

Several years ago, we reported that deletion of the genes involved in the fadBA operon in P. putida U led to a genetically engineered mutant that accumulated large amounts of plastic polymers. In this mutant more than 90% of the bacterial cytoplasm was occupied by PHA granules (Olivera et al. 2001a). We also reported that, in this mutant, a second β-oxidation system (βII) was induced which restored the ability to grow in media containing n-alkanoates. Owing to the existence of the βII system, mutants lacking βI-FadBΔ are able to synthesize new PHAs and poly-3-OH-n-phenylalkanoates (PHPhAs) efficiently. However, they are unable to degrade the latter polymers (Olivera et al. 2001b), becoming overproducer mutants (Fig. 2).

Electron micrographs of P. putida U (wild type; a), P. putida ΔfadBA (b), P. putida phaZ (c) and P. putida ΔfadBA-phaZ (d) cultured in chemically defined medium containing 4-OH-phenylacetic acid (4OHPhAc; 10 mM) to support the bacterial growth and 7-phenylheptanoic acid (10 mM) as the PHPhA precursor. Scanning micrographs of P. putida ΔfadBA (e) and P. putida ΔfadBA-phaZ (f) cultured in the same medium and conditions

In this report we show for the first time that these mutants, which are of undoubted industrial interest, can be manipulated to overproduce certain PHPhA biosynthetic intermediates (3-OH-n-PhAs), a group of products not commercially available of a high scientific interest and broad biotechnological applications.

Materials and methods

Materials

DNA reagents and molecular biology products were supplied by Amersham. n-PhAs and other aromatic compounds were obtained from Merck (Germany), Lancaster Synthesis (France) or Sigma (USA).

Microbial strains and vectors

The P. putida U strain (Coleccion Española de Cultivos Tipo, 4848) was from our own collection (Martínez-Blanco et al. 1990). P. putida ΔfadBA was a mutant in which the fadBA cluster encoding the βI-oxidation set of enzymes was deleted. This bacterium overproduces PHAs and PHPhAs. Escherichia coli pRK600 was used as a helper strain in triparental mating (Herrero et al. 1990). E. coli XL1Blue (Stratagene, USA) was used to overexpress the plasmid pQE-32 (Qiagen, USA) according to the instructions of the manufacturer. Listeria innocua (Colección Española de Cultivos Tipo, CECT 910), L. ivanovii (CECT 913), L. monocytogenes (CECT 4031), E. coli (CECT 731), Salmonella enteritidis (ATCC 13076) and Staphylococcus aureus (ATCC 12600), used for the determination of the antibacterial activity of n-phenyl and 3-OH-n-PhAs, were supplied by Dr. Naharro (Departamiento de Patología Animal, Universidad de León). Plasmid pBBR1MCS-3 (Tc resistance; Kovach et al. 1995) was used to transform P. putida U. DNA manipulation, sequence analyses and cloning strategies were carried out as reported previously (Olivera et al. 1998; García et al. 1999; Luengo et al. 2001).

PCR conditions

PCRs were performed in a Perkin Elmer DNA Thermal Cycler 2400. Each independent reaction (50 μl) contained 75 mM Tris-HCl buffer, pH 9, 50 mM KCl, 20 mM (NH4)2SO4, 100 ng of genomic DNA, 0.4 μmol of each independent primer, 2 mM MgCl2, 0.4 mM dNTPs and a mixture of the thermostable DNA polymerase (2 units) from Thermus thermophilus (Biotools, Spain) and Pfu DNA polymerase (1 unit) from Pyrococcus furiosus (Promega, USA; Miñambres et al. 2000). The annealing temperature was 60°C and an extension time of 1 min was used. The oligonucleotides used to perform the amplification of the gene encoding the PHA depolymerase (phaZ) in P. putida U were 5′-GCGGATCCCGGAACCCTACATCTTCAGGACCGTCG-3′ (Depol-BamHI) and 5′-CACTCTCTAGACTTACCCGATGCTTGG-3′(Depol-XbaI). Using these degenerated oligonucleotides, we introduced two restriction sites (BamHI, XbaI) that facilitated the cloning of the PCR-amplified fragment into: (1) the overexpression plasmid pQE-32 (Qiagen, USA), (2) the plasmids pKB-2 (a derivative of the commercial pBlueScript KS (Stratagene, USA) containing a modified multicloning site) and (3) pBBR1MCS-3, a plasmid that replicates in Pseudomonas (Kovach et al. 1995; Fig. 3). Expression of this genetic construction generates a modified PhaZ that contains two extra amino acids in the amino terminus, the sequence becoming MNRIPEPYI, from MPEPYI. This modification has no influence on depolymerase activity (García 2004).

Culture media and growth conditions

P. putida U and its mutants were maintained and cultured in a chemically defined medium (MM) as reported by Martínez-Blanco et al. (1990). The medium used to culture the bacteria contained mineral salts and either 4-hydroxyphenylacetic acid (10 mM), n-phenylalkanoic acids (10 mM) or combinations of both, as carbon sources (García et al. 1999). In experiments in which P. putida ΔfadBA or its derivatives were used, 4-OH-phenylacetic acid (4OHPhAc) supported bacterial growth, since this compound is neither a substrate of PHA polymerase nor generates catabolites that can be polymerized to PHPhAs. When solid media were required, agar (2.5%, w/v) was added.

Identification of PHPhAs and their derivatives

The accumulation of PHPhAs by P. putida U or its mutants was confirmed by direct microscopic observation, as reported by García et al. (1999). The polymers accumulated were extracted and quantified as indicated by Lageveen et al. (1988). The PHPhA structures and physicochemical properties were analyzed as indicated by Abraham et al. (2001). The structure of the polymers synthesized was established by NMR and gas chromatography, as indicated by Fritzsche et al. (1990).

To analyze the catabolic intermediates released into the medium by the recombinant strain P. putida ΔfadBA-phaZ, the microorganism was cultured in MM (Martínez-Blanco et al. 1990) containing as carbon sources 4OHPhAc to support the bacterial growth and several n-phenylalkanoic acids (6-phenylhexanoic acid, 7-phenylheptanoic acid, 8-phenyloctanoic acid) as sources of intermediates. The bacteria were incubated in a rotary shaker (250 rpm) at 30°C until the late stationary phase of growth (72 h). Then, they were harvested by centrifugation (12,000 g) and the culture broth was collected and filtered throughout Millipore filters (0.2 μm) to eliminate residual microbes. The culture was acidified to pH 1.5 with 10 M HCl and extracted with an equal volume of diethyl ether. The organic and aqueous phases were separated in a decantation funnel and the water phase was extracted twice with ether (0.1 vol.). Then, the organic phases were mixed, diluted with a similar volume of sterile distilled water and adjusted to pH 8.0 with 20 M KOH. The organic and aqueous phases were separated and the organic phase was washed once with an additional volume of water and discarded. The two aqueous phases were mixed, adjusted to pH 1.0 and extracted with diethyl ether. After three successive extractions, the organic phases were mixed, dried over anhydrous sodium sulfate and filtered. Finally, the ether was evaporated off under a vacuum and the residual aromatic oils were analyzed by NMR and characterized (see Appendix).

NMR analyses

NMR spectral analyses were recorded at room temperature (21°C), using a Varian 400 Mercury VNMRX spectrometer at 400 MHz (1H) and 100 MHz (13C) , with tetramethylsilane as the internal standard. Spectra were obtained from 25% CDCl3 solutions and a delay time of 2.0 s was applied between pulses.

The assignments of 1H and 13C NMR are reported in the Appendix. A 1H–13C correlation spectrum allowed the specific 13C assignments reported; and the multiplicities were determined by DEPT experiments. The connectivities in the 1H NMR spectrum were confirmed by 1H–1H correlation spectroscopy.

Preparation of 3-hydroxy-n-phenylalkanoic acid methyl esters

3-Hydroxy-n-phenylalkanoic acid methyl esters were obtained from PHPhAs by a procedure similar to that reported for the collection of the 3-OH-monomers that constitute different PHAs (De Roo et al. 2002). Thus, 1 g of each polyester (poly-3-hydroxy-6-phenylhexanoate or other PHPhAs) was dissolved in 100 ml of pure chloroform and placed in a round-bottomed flask equipped with a condenser and a magnetic bar. A solution of 15% (v/v) H2SO4 in methanol (100 ml) was added drop-wise and the reaction mixture was stirred at 100°C for 24 h under an argon atmosphere. The reaction mixture was cooled to room temperature, 40 ml of brine was added and the mixture was stirred for 15 min. The two layers were separated and the aqueous phase was extracted three times with chloroform. The combined organic layers were washed with brine and dried over Na2SO4. Evaporation of the crude afforded 0.9 g of crude methyl 3-hydroxy-6-phenylhexanoate. When required, 3-OH-n-phenylalkanoic acids were obtained from the corresponding methyl esters by saponification (De Roo et al. 2002).

The synthesis of 3-OH-n-phenylalkanoic acids methyl esters was also performed from the free acids accumulated in the culture broth by a recombinant strain of P. putida ΔfadBA containing a plasmid which overexpressed the gene encoding the PHA depolymerase (P. putida ΔfadBA-phaZ). Once purified (see Results) the 3-OH-n-PhAs were treated as follows: 150 mg of 3-hydroxy-6-phenylhexanoic acid was treated with an ethereal solution of diazomethane (Redemann et al. 1967; De Boer and Backer 1967; Moore and Reed 1973) and stirred for 15 min at room temperature. Evaporation of the solvent yielded 155 mg of methyl 3-hydroxy-6-phenylhexanoate. Optical rotations were measured on a digital Perkin–Elmer 241 polarimeter in a 1 dm cell at 589 nm and 21°C.

Antimicrobial determination

The antimicrobial activity of the n-PhAs and 3-OH-n-PhAs were measured by establishing the effect caused by several concentrations of these compounds (ranging from 100 mM to 1 mM) on the growth of different species of bacteria (L. innocua, L. monocytogenes, L. ivanovii, E. coli, Sal. enteritidis, Sta. aureus), according to the microtiter plate procedure described by Floriano et al. (1998). The different bacteria were cultured in the required media in the presence or in absence of the product to be tested and their growth was determined by measuring the optical density of the cultures at 600 nm.

Results

Design of a mutant of P. putida U that accumulates 3-OH-PhAs in the culture broth

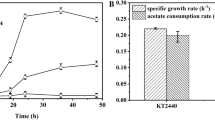

Deletion of the genes encoding the FadBA enzymatic system involved in the βI-oxidation pathway in P. putida U revealed that this strain was also able to catabolize fatty acids throughout a different β-oxidation route (called βII oxidation), which was only induced when βI, a constitutive pathway, is lacking (Olivera et al. 2001b). This second pathway catabolyzed n-alkanoic acids but was unable to completely degrade other structurally related compounds containing an aromatic ring linked to the acyl moiety (n-phenylalkanoic acids). This result indicated that the βI-FadBA enzymes are essential for the β-oxidation of certain n-phenylalkanoyl-CoA derivatives when they reach a critical size. As a consequence, the P. putida ΔfadBA mutant was able to synthesize and intracellularly accumulate different kinds of PHAs, other than those accumulated in the wild type, with regard to both monomer size and relative percentage (built from aromatic, aliphatic or mixed aliphatic/aromatic monomers; Abraham et al. 2001; Olivera et al. 2001a). However, these mutants were unable to degrade these polyesters, being converted into bioplastic-overproducing strains (more than 90% of the bacterial cytoplasm was occupied by these macromolecules; Fig. 2)]. Taking into account that: (1) all these polymers are synthesized from (R)-3-OH-n-phenylalkanoyl-CoA, (2) these intermediates are not commercially available and (3) some of them represent an important class of biological active compounds usually found in lipopeptides with antiviral, antimicrobial or insecticidal activity (Burke et al. 1999; Peypoux et al. 1999; Cardoso et al. 2002; De Roo et al. 2002; Vaysse et al. 2002), we used a P. putida ΔfadBA mutant to bioconvert n-PhAs to 3-OH-n-PhAs. To obtain this strain, we amplified by PCR the phaZ encoding the PHA depolymerase from P. putida U (see Materials and methods). This DNA fragment (892 bp) was cloned into plasmid pKB-2 and either : (1) digested with the restriction enzymes XhoI and XbaI and subcloned into plasmid pBBR1MCS-3, which replicates autonomously in P. putida U (pMCZ), or (2) digested with BamHI and SacI and cloned into the hyperexpression vector pQE-32 (Qiagen, USA), giving pQEDepol (Figs. 3, 4). The P. putida ΔfadBA mutant and its parental strain (P. putida U) were transformed by triparental mating with the pMCZ plasmid and the recombinant strains were analyzed. The morphological aspects of these cultures revealed that, whereas the ΔfadBA mutants acquired an intense white color when cultured in solid medium, due to the intracellular accumulation of PHA, the colonies which overexpressed the phaZ gene lost their cereous appearance (Fig. 5). Microscopic observation of both kind of mutants revealed that, whereas a strong accumulation of PHAs occurred in P. putida ΔfadBA, no PHA granules were found in the cytoplasm of the bacteria that overexpressed the recombinant phaZ gene (henceforth called P. putida phaZ, P. putida ΔfadBA-phaZ; Fig. 2). Furthermore, this latter strain had recovered the original phenotype and did not show the morphological alterations caused by bioplastic accumulation in the P. putida ΔfadBA mutant (Fig. 2). These results indicate that, as expected, overexpression of the depolymerase leads to the rapid mobilization of this polymer and suggest that the 3-OH-n-PhAs must be excreted into the broth, since the βII-oxidation pathway is unable to catabolize these intermediates.

Morphological aspect of cultures of P. putida ΔfadBA (a bioplastic-overproducer mutant; a) and P. putida ΔfadBA-phaZ (a recombinant strain; b), in which the gene encoding PHPhA depolymerase is overexpressed. The bacteria were cultured in chemically defined medium containing 10 mM 4OHPhAc to support bacterial growth and 7-phenylheptanoic acid (10 mM) as the PHPhA precursor

Identification of the products accumulated in the broth

When P. putida ΔfadBA-phaZ was cultured in MM containing 4OHPhAc and 6-phenylhexanoic acid, we observed that the only intermediate accumulated was 3-OH-6-phenylhexanoic acid (see Appendix). However, when the precursors of the PHPhAs were either 7-phenylheptanoic acid or 8-phenyloctanoic acid, the intermediates accumulated in the broths were 3-OH-5-phenylvaleric acid and 3-OH-7-phenylheptanoic acid in the first case and were 3-OH-6-phenylhexanoic acid and 3-OH-8-phenyloctanoic acid in the second case.

In all three cases, the quantities of 3-OH-n-PhAs accumulated by this recombinant strain were: 1.77 g/l [2.25 g/g cell dry weight (cdw)] of 3-OH-6-phenylhexanoic acid; 1.93 g/l (2.45 g/g cdw) of a mixture of 3-OH-5-phenylvaleric acid (30%) and 3-OH-7-phenylheptanoic acid (70%) and 1.92 g/l (2.44 g/g cdw) of a mixture containing 3-OH-6-phenylhexanoic acid (35%) and 3-OH-8-phenyloctanoic acid (65%). These data indicate that the bioconversion yield of n-PhAs into 3-OH-PhAs using the genetically manipulated strain P. putida ΔfadBA-phaZ is higher than 80% (85%, 87%, 81%, respectively) and this strain could therefore be used for the industrial production of these compounds.

Taking into account that the monomers that integrate all known PHPhAs are (R)-enantiomers, it would be expected that the products accumulated by this mutant would also be pure enantiomers. If this were the case, interest in this strain from an industrial point of view would be higher, since its use would allow the collection of (R)-3-OH-n-PhAs, a family of products with broad biotechnological applications (De Roo et al. 2002). However, it is also possible that, once depolymerized, the (R)-enantiomer could become isomerized to the metabolizable enantiomers [(S)-3-OH-n-Pha] and this compound (or a R/S mixture) being released into the culture broth. To clarify this point, the different 3-OH-n-PhAs excreted by the recombinant strain P. putida U ΔfadBA-phaZ, when cultured in chemically defined medium containing 4OHPhAc (10 mM) to support bacterial growth and 6-PhA, 7-PhA, or 8-PhA as sources of intermediates, were purified and analyzed (see Appendix).

In order to establish the enantiomeric nature of the 3-OH-n-PhAs excreted by P. putida U ΔfadBA-phaZ, we first analyzed the PHPhA accumulated by the overproducer mutant P. putida ΔfadBA. Taking into account that these polyesters are integrated only by (R)-enantiomers, the homopolymer was methanolyzed to obtain the (R)-3-OH-6-phenylhexanoic acid methyl ester (see Materials and methods) and treated as reported by De Roo et al. (2002). The optical rotation of this compound is [α]D20=−10 (c=1.26 CHCl3). We then determined the optical rotation of the 3-OH-6-phenylhexanoic acid accumulated in the broths by the recombinant strain P. putida ΔfadBA-phaZ and the value corresponding to its methyl ester (see Materials and methods). The [α]D20 values of the acid and the ester were [α]D20=−0.86 (c=1.70 CHCl3) and [α]D20=−0.77 (c=1.40 CHCl3), respectively, suggesting that no pure (R)-enantiomers had accumulated in the broths.

Antibacterial activity of 3-OH-n-PhAs

It has been reported that some 3-hydroxyalkanoic acids exhibit certain antimicrobial activity (Burke et al. 1999; De Roo et al. 2002). Accordingly, we tested the antibacterial effect on different bacterial species (L. innocua, L. ivanovii, L. monocytogenes, E. coli, Sal. enteritidis, Sta. aureus) caused by several (R)-3-OH-n-phenylderivatives (chemically released from PHPhA) and their n-phenylalkanoic precursors. We showed that the minimal inhibitory concentration (MIC) for all the Listeria species (L. innocua, L. ivanovii, L. monocytogenes) ranges between 3 mM and 6 mM when 3-OH-n-phenylalkanoic acids (from 3-OH-5-phenylvaleric acid to 3-OH-8-phenyloctanoic acid) were tested (see Table 1), whereas they did not affect the growth of the other species assayed, even at concentrations higher than 75 mM. However, when the n-phenylalkanoic acids used as PHPhA precursors (from 5-phenylvaleric acid to 11-phenylundecanoic acid) and other close structural analogues not directly involved in the synthesis of PHPhA (phenylacetic, phenylpropionic or 4-phenylbutyric acids) were tested, none of them caused any effect on the bacterial growth of the different species unless the concentration was higher than 100 mM.

Nevertheless, when we studied the antibacterial effect caused by the 3-OH-n-PhAs excreted into the broths by P. putida ΔfadBA-phaZ, we observed that to cause a similar inhibition on Listeria species, a double concentration of product had to be employed in all the cases (at 7–10 mM; see Table 1). This effect, which suggests that the 3-OH-n-PhAs purified from the broths are less active, is discussed below (see Discussion).

Discussion

A genetically engineered strain of P. putida U, that efficiently bioconverts different n-PhAs into their 3-OH-n-PhAs, was obtained in two steps. First, we isolated a P. putida U mutant unable to catabolyze PHPhAs (it had undergone a deletion of the two linked genes encoding the constitutive β-oxidation pathway) and this strain (P. putida ΔfadBA) was then transformed with a replicative plasmid which overexpresses the phaZ, the gene encoding the depolymerase required for the catabolism of different PHAs.

Morphological study of the P. putida ΔfadBA-phaZ recombinant strain revealed that, when this mutant was cultured in solid chemically defined medium containing 6-phenylalkanoic acid, 7-phenylalkanoic acid, or 8-phenylalkanoic acid, it did not accumulate granules of PHPhAs intracellularly (Fig. 2) and the abnormal phenotype shown by the bioplastic overproducer strain P. putida ΔfadBA had been restored, in such a way that it had the same appearance as the wild type (P. putida U; Fig. 2). These results indicate that overexpression of the PHA depolymerase (encoded by the gene phaZ) caused a drastic mobilization of the polyesters synthesized, avoiding their accumulation as intracellular deposits (PHA granules). Taking into account that, owing to the lack of the enzymes that constitute the βI-oxidation pathway, P. putida ΔfadBA-phaZ is unable to catabolize the 3-OH-n-PhAs, it would be expected that once released from the nascent polymer they would be released into the culture broth in order to avoid the metabolic damage that would cause a high amount of these catabolites (i.e., reduction or exhaustion of the intracellular pool of CoA).

NMR analyses of the products purified from the broths revealed that when P. putida ΔfadBA-phaZ was cultured in a chemically defined medium containing as carbon sources 4OHPhAc (to support bacterial growth) and different n-PhAs (6-phenylalkanoic acid, 7-phenylalkanoic acid, 8-phenylalkanoic acid) as a source of intermediates, these compounds were transformed into several 3-OH-n-PhAs which were released from the bacteria and accumulated in the broths. We also observed that the 3-OH-derivative(s) which accumulated always corresponded to the monomer(s) integrating the bioplastic polyester in its parental β-oxidation mutants (P. putida ΔfadBA). Furthermore, the quantities of 3-OH-derivatives purified from the cultures revealed that this strain efficiently biotransformed (>80%) n-PhAs into 3-OH-n-PhAs, suggesting that this strain could have important biotechnological and industrial applications.

Analysis of the optical rotation of the 3-OH-6-phenylhexanoic acid methyl ester released after methanolysis of the poly-3-OH-6-phenylhexanoate accumulated intracellularly by P. putida ΔfadBA revealed that the [α]D20 value was −10 (see Results). Taking into account that these polymers are only integrated by (R)-enantiomers (De Roo et al. 2002; Luengo et al. 2003), it would be expected that the optical rotation of the methyl esters prepared from the purified 3-OH-6-phenylhexanoate accumulated in the broths by P. putida ΔfadBA-phaZ (after being cultured for 72 h in MM with 10 mM 4OHPhAc, 10 mM 6-phenylhexanoate; see Materials and methods) would have a similar value. However, the [α]D20 determined was −0.77, indicating that, although the (R)-enantiomer was mainly accumulated in the broth (57.7%), the (S)-enantiomer was also present (42.3%) and that, in sum, the 3-OH-6-phenylhexanoate accumulated in the broths represented an almost racemic mixture. These results could be explained by assuming that, once released from the intracellular polymers by the action of the recombinant depolymerase, part of the (R)-enantiomers are immediately epimerized to the (S)-isomer in order to be catabolized. However, owing to the fact that this mutant has lost the complete βI-oxidation pathway, it is unable to degrade this catabolite and both the (R)-enantiomers and the (S)-enantiomers must be released into the broths in order to avoid their intracellular accumulation and the unnecessary immobilization of CoA.

In contrast, it has been reported that different (R)-3-hydroxyalkanoates exhibit important biological activities. Thus, some of them have antimicrobial, antiviral and/or a potent insecticidal potential (Burke et al. 1999; Peypoux et al. 1999; Cardoso et al. 2002; De Roo et al. 2002; Vaysse et al. 2002). Therefore, in order to establish the antibacterial activity of the (R)-3-OH-n-PhAs chemically released from the PHPhA polymers, we tested the effect caused by some of these compounds (from 3-OH-5-phenylvaleric acid to 3-OH-8-phenyloctanoic acid) and their direct precursors (n-phenylalkanoic acids) on the growth of different bacteria (see Results, Table 1). It is interesting to note that all (R)-3-OH-n-PhAs inhibited the growth of Listeria species, with a MIC of 3–6 mM. However, when the corresponding n-PhAs were tested, the MIC was in all the cases ≥100 mM (Table 1). Moreover, neither 3-OH-n-PhAs nor n-PhAs inhibited the growth of the other bacteria tested (even at concentrations >75 mM).

When the antimicrobial activity of the 3-OH-phenylderivatives accumulated in the broths by the recombinant strain P. putida ΔfadBA-phaZ was tested, we observed that the antibacterial activity of the purified product was qualitatively similar to that described above, although in this case about double the concentration was necessary to cause a similar effect (Table 1). These results can be explained by assuming that the antibacterial activity of this product is only caused (or mainly caused) by the (R)-enantiomer. Taking into account that the 3-OH-n-phenylalkanoic acids released into the broths are almost racemic mixtures, it seems right that a double concentration of product would be needed to cause the same effect as that observed when the pure (R)-enantiomer is employed.

The fact that these compounds and other aromatic molecules reported by Dieuleveux et al. (1998) are effective against L. monocytogenes opens a plethora of possibilities regarding attack against this ubiquitous microorganism, which is able to multiply at refrigeration temperatures, shows a high tolerance to salt and is resistant to both high temperatures and low pH values. For this reason, the collection of a strain able to bioconvert n-PhAs into 3-OH-derivatives with anti-Listeria activity is not only interesting from the biotechnological point of view but also for the implication in human and animal health, since over the past few decades contamination with the food pathogen L. monocytogenes has become a important problem in many countries.

References

Abraham GA, Gallardo A, San Román J, Olivera ER, Jodrá R, García B, Miñambres B, García JL, Luengo JM (2001) Microbial síntesis of poly(β-hydroxyalkanoates) bearing phenylgroups from Pseudomonas putida: chemical structure and characterization. Biomacromolecules 2:562–567

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Burke T, Chandrasekhar B, Knight M (1999) Analogs of viscosin and uses thereof. Peptide Technologies Corp., Washington, D.C.

Cardoso CR, Brito FCF de, Silva KCM da, Miranda ALP de, Fraga CAM, Barreiro EJ (2002) Design, síntesis and pharmacological evaluation of novel pyrazolo[3,4-b]thieno[2,3-d]pyridine acid derivatives: a new class of anti-inflammatory and anti-platelet agents. Bioorg Med Chem Lett 12:9–12

De Boer J, Backer JH (1967) Diazomethane. Org Synth Coll 4:250–253

De Roo G, Kellerhals MB, Ren Q, Witholt B, Kessler B (2002) Production of chiral R-3-hydroxyalkanoic acids and R-3-hydroxyalkanoic acid methylesters via hydrolytic degradation of polyhydroxyalkanoate synthesized by pseudomonads. Biotechnol Bioeng 77:717–722

Dieuleveux V, Pyl D van der, Chataud J, Gueguen M (1998) Purification and characterization of anti-Listeria compounds produced by Geotrichum candidum. Appl Environ Microbiol 64:800–803

Fiedler S, Steinbüchel A, Rehm BHA (2002) The role of the fatty acid β-oxidation multienzyme complex from Pseudomonas oleovorans in polyhydroxyalkanoates biosynthesis: molecular characterization of the fadBA operon from P. oleovorans and of the enoyl-CoA hydratase genes PhaJ from P. oleovorans and Pseudomonas putida. Arch Microbiol 178:149–160

Floriano B, Ruiz Barba JL, Jiménez-Díaz R (1998) Purification and genetic characterization of enterocin I from Enterococcus faecium 6T1a, a novel antilisterial plasmid-encoded bacteriocin which does not belong to the pediocin family of bacteriocins. Appl Environ Microbiol 64:4883–4890

Fritzsche K, Lentz RW, Fuller RC (1990) An unusual bacterial polyester with a phenyl pendant group. Makromol Chem 191:1957–1965

Fukui T, Shiomi N, Doi Y (1998) Expression and characterization of (R)-specific enoyl coenzyme A hydratase involved in polyhydroxyalkanoates biosynthesis by Aeromonas caviae. J Bacteriol 180:667–673

García B (2004) Biosíntesis of polihidroxialcanoatos en Pseudomonas putida U: caracterización genética y bioquímica del sistema responsable de su acúmulo y movilización. PhD thesis, Universidad de León, León

García B, Olivera ER, Miñambres B, Fernández-Valverde M, Cañedo LM, Prieto MA, García JL, Martínez M, Luengo JM (1999) Novel biodegradable aromatic plastics from a bacterial source. J Biol Chem 274:29228–29241

Herrero M, Lorenzo V de, Timmis KN (1990) Transposon vectors containing non-antibiotic resistance selection markers for cloning and stable chromosomal insertion of foreign genes in gram-negative bacteria. J Bacteriol 172:6557–6567

Jendrossek D, Handrick R (2002) Microbial degradation of polyhydroxyalkanoates. Annu Rev Microbiol 56:403–432

Kovach ME, Elzer PH, Hill DS, Robertson GT, Farris MA, Roop RM, Peterson KM (1995) Four new derivatives of the broad-host-range cloning vector pBBR1MCS, carrying different antibiotic-resistance cassettes. Gene 166:175–176

Lageveen RG, Huisman GW, Preusting H, Ketelaar P, Eggink G, Witholt B (1988) Formation of polyesters by Pseudomonas oleovorans. Effect of substrates on formation and composition of poly-(R)-3-hydroxyalkanoates and poly-(R)-3-hydroxyalkenoates. Appl Environ Microbiol 54:2924–2932

Luengo JM, García JL, Olivera ER (2001) The phenylacetyl-CoA catabolón: a complex catabolic unit with broad biotechnological applications. Mol Microbiol 39:1434–1442

Luengo JM, García B, Sandoval A, Naharro G, Olivera E (2003) Bioplastics from microorganisms. Curr Opin Microbiol 6:251–260

Madison LL, Huisman GW (1999) Metabolic engineering of poly(3-hydroxyalkanoates): from DNA to plastic. Microbiol Mol Biol Rev 63:21–53

Martínez-Blanco H, Reglero A, Rodríguez-Aparicio LB, Luengo JM (1990) Purification and biochemical characterization of phenylacetyl-CoA ligase from Pseudomonas putida U. A specific enzyme for the catabolism of phenylacetic acid. J Biol Chem 265:7084–7090

Miñambres B, Olivera ER, García B, Naharro G, Luengo JM (2000) From a short sequence to the complete genome. Biochem Biophys Res Commun 272:477–479

Moore JA, Reed DE (1973) Diazomethane. Org Synth Coll 5:351–355

Olivera ER, Miñambres B, García B, Muñiz C, Moreno MA, Ferrández A, Díaz E, García JL, Luengo JM (1998) Molecular characterization of the phenylacetic acid catabolic pathway in Pseudomonas putida U: the phenylacetyl-CoA catabolón. Proc Natl Acad Sci USA 95:6419–6424

Olivera ER, Carnicero D, Jodrá R, Miñambres B, García B, Abraham GA, Gallardo A, San Román J, García JL, Luengo JM (2001a) Genetically engineered Pseudomonas: a factory of new bioplastics with broad applications. Environ Microbiol 3:612–618

Olivera ER, Carnicero B, García B, Miñambres B, Moreno MA, Cañedo L, DiRusso CC, Naharro G, Luengo JM (2001b) Two different pathways are involved in the β-oxidation of n-alkanoic and n-phenylalkanoic acids in Pseudomonas putida U: genetic studies and biotechnological applications. Mol Microbiol 39:863–874

Peypoux F, Bonmatin JM, Wallach J (1999) Recent trends in the biochemistry of surfactin. Appl Microbiol Biotechnol 51:553–563

Redemann CE, Rice FO, Roberts R, Ward HP (1967) Diazomethane. Org Synth Coll 3:244–248

Rehm BHA (2003) Polyesters synthases: natural catalysts for plastics. Biochem J 376:15–33

Rehm BHA, Krüger N, Steinbüchel A (1998) A new metabolic link between fatty acid de novo synthesis and polyhydroxyalkanoic acid synthesis. J Biol Chem 273:24044–24051

Steinbüchel A (2001) Perspectives for biotechnological production and utilization of biopolymers: metabolic engineering of polyhydroxyalkanoates biosynthesis pathway as a successful example. Macromol Biosci 1:1–24

Sudesh K, Gan Z, Matsumoto K, Doi Y (2002) Direct observation of polyhydroxyalkanoate chains by atomic force microscopy. Ultramicroscopy 91:157–164

Tsuge T, Fukui T, Matsusaki H, Taguchi S, Kobayashi G, Ishizaki A, Doi Y (1999) Molecular cloning of two (R)-specific enoyl-CoA hydratases genes from Pseudomonas aeruginosa and their use for polyhydroxyalkanoates synthesis. FEMS Microbiol Lett 184:193–198

Tsuge T, Taguchi K, Taguchi S, Doi Y (2003) Molecular characterization and properties of (R)-specific enoyl-CoA hydratases from Pseudomonas aeruginosa: metabolic tools for synthesis of polyhydroxyalkanoates via fatty acid β-oxidation. Biol Macromol 31:195–205

Vaysse L, Ly A, Moulin G, Dubreucq E (2002) Chain-length selectivity of various lipases during hydrolysis, esterification and alcoholysis in biphasic aqueous medium. Enzyme Microb Technol 31:648–655

Witholt B, Kessler B (1999) Perspectives of medium chain length poly(hydroxyalkanoates), a versatile set of bacterial bioplastics. Curr Opin Biotechnol 10:279–285

Acknowledgements

This investigation was supported by the Comisión Interministerial de Ciencia y Tecnología (CICYT), Madrid, Spain (grant BIO2003-05309-C04-01). A.S. and E.A. are recipients of fellowships from the Universidad de León and CICYT, respectively.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

NMR data for 3-hydroxy-5-phenylpentanoic acid

1H NMR (CDCl3): δ=1.74 (m; 2H, H-4) 2.45 (m; 2H, H-2), 2.74 (m; 2H, H-5), 4.05 (s, broad; 1H, H-3), 7.17–7.27 (m; 5H, aromatic H). 13C NMR (CDCl3): δ=32.09 (C-5), 37.56 (C-4), 41.27 (C-2), 67.38(C-3), 125.60 (C-4′), 128.31(C-2′, C-6′), 128.21 (C-3′, C-5′), 141.55 (C-1′), 175.97 (C-1).

NMR data for 3-hydroxy-6-phenylhexanoic acid

1H NMR (CDCl3): δ=1.55 (m; 2H, H-4), 1.68–1.81 (m; 2H, H-5), 2.54 (m; 2H, H-2), 2.66 (m; 2H, H-6), 4.08 (s, broad; 1H, H-3), 7.30–7.20 (m; 5H, aromatic H). 13C NMR (CDCl3): δ=27.50 (C-5), 35.86 (C-6), 36.12 (C-4), 41.41 (C-2), 68.20 (C-3), 126.10 (C-4′), 128.67 (C-2′, C-6′), 128.62 (C-3′, C-5′), 142.32 (C-1′), 178.39 (C-1).

NMR data for 3-hydroxy-7-phenylheptanoic acid

1H NMR (CDCl3): δ=1.39–1.49 (m, 2H, H-5), 1.53 (m; 2H, H-4), 1.65 (m, 2H, H-6), 2.47 (m; 2H, H-2), 2.62 (m; 2H, H-7), 4.05 (s, broad; 1H, H-3), 7.17–7.27 (m; 5H, aromatic H). 13C NMR (CDCl3): δ=25.10 (C-5), 31.30 (C-6), 35.79 (C-7), 36.28 (C-4), 41.18 (C-2), 68.04(C-3), 125.66 (C-4′), 128.36 (C-2′, C-6′), 128.26 (C-3′, C-5′), 142.45 (C-1′), 176.04 (C-1).

NMR data for 3-hydroxy-8-phenyloctanoic acid

1H NMR (CDCl3): δ=1.36 (m; 2H, H-6), 1.37–1.47 (m; 2H, H-5), 1.47–1.53 (m; 2H, H-4), 1.63 (m; 2H, H-7), 2.51 (m; 2H, H-2), 2.63 (m; 2H, H-8), 4.03 (s, broad; 1H, H-3), 7.18–7.28 (m; 5H, aromatic H). 13C NMR (CDCl3): δ=25.29 (C-5), 29.07 (C-6), 31.35 (C-7), 35.83 (C-8), 36.30 (C-4), 41.09 (C-2), 68.02 (C-3), 125.63 (C-4′), 128.39 (C-2′, C-6′), 128.25 (C-3′, C-5′), 142.62 (C-1′), 178.06 (C-1).

Rights and permissions

About this article

Cite this article

Sandoval, Á., Arias-Barrau, E., Bermejo, F. et al. Production of 3-hydroxy-n-phenylalkanoic acids by a genetically engineered strain of Pseudomonas putida. Appl Microbiol Biotechnol 67, 97–105 (2005). https://doi.org/10.1007/s00253-004-1752-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-004-1752-x