Abstract

The aim of this paper is to investigate the thermal conductivity and viscosity of a hybrid nanofluid containing tetramethylammonium hydroxide (TMAH) coated Fe3O4 nanoparticles and gum arabic (GA) coated carbon nanotubes (CNTs), experimentally. The magnetic nanoparticles and CNTs are physically attached as the result of interaction between the TMAH and GA molecules. The morphology and structure of the samples are characterized with X-ray diffraction (XRD) and transmission electron microscopy (TEM). The experiments are carried out in the magnetic nanoparticles volume concentration range of 0.1–0.9 %, CNT volume concentration range of 0.05–1.35 % and the temperature range of 25–55 °C. The viscosity of the hybrid nanofluid increases with the increase of volume concentration, while it decreases with the increase of temperature. Besides, results show that hybrid nanofluid behaves as a shear thinning fluid. Furthermore, it is observed that the thermal conductivity of the hybrid nanofluid enhances with temperature and volume concentration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ferrofluids are stable colloidal suspensions of single domain nanosized superparamagnetic particles in either aqueous or oil based media. These magnetic particles are magnetite, ferric oxide, and iron nickel oxide of diameters ranging between 5 and 15 nm (nm). These sizes are such that the thermal motion of particles in room temperature prevents them from agglomerating due to magnetic attraction and settling down due to gravity. A surfactant layer covers the surface of the nanoparticles helping them to overcome the Van der Waal’s force by preventing them to come close to each other. Ferrofluids can be used for a variety of applications ranging from bearing sealing to high-fidelity speakers [1].

Many studies have been done on the thermal conductivity and viscosity of ferrofluids. An experimental investigation of effective thermal conductivity and viscosity of magnetic Fe3O4/water nanofluid was reported by Sundar et al. [2]. Their results revealed that the viscosity increment was greater than thermal conductivity enhancement at same volume concentration and temperature. Huminic et al. [3] studied the effects of both temperature and weight concentration on the thermal conductivity and viscosity of FeC/water nanofluid. The experimental results showed that the thermal conductivity of FeC/water nanofluid increases with the increase of both weight concentration of the nanoparticles and temperature. The data also indicate that the influence of weight concentration of the nanoparticles on viscosity becomes less significant for temperatures above 55 °C. Bahiraei and Hangi [4] reviewed and summarized investigations performed on ferrofluids including those conducted on thermophysical properties, natural convection, forced convection, boiling and their practical applications. Frank et al. [5] studied the behavior of a copper–argon nanofluid confined in nanochannels. Using molecular dynamics simulations, they showed that in narrower channels, the thermal conductivity increases approximately by 20 % compared to macroscopic cases. Their results suggested that the structured liquid layers surrounding the solid particles occupy a greater percentage of the system in narrower channels, and hence they enhance the thermal conductivity of the nanofluid. Aminfar et al. [6] carried out molecular dynamic simulations to examine the effects of liquid–nanoparticle interaction strength, size and number of nanoparticles on the aggregation process in liquid-based nanofluid flowing inside nanochannels. The results showed that the increase in liquid–nanoparticle interaction strength leads to the reduction of aggregation rate. In addition, it was found that the increase in the size and number of nanoparticles causes more aggregation rate.

Carbon nanotubes are cylindrical structures of carbon atoms. They consist of a graphitic plane rolled into a tube with a nanometric diameter. Carbon nanotubes present outstanding mechanical, electrical, thermal and chemical properties. For example, a single nanotube is 100 times stronger than steel. It is one of the best field emission emitters, it can maintain high current density and it has a thermal conductivity comparable to that of diamond. Functionalizing CNTs with magnetic nanoparticles can combine the features of magnetic nanoparticles and CNTs, which may result in materials with novel chemical and physical properties, and thus promising applications [7–9]. Hong et al. [10] reported for the first time that the thermal conductivity of the heat transfer nanofluids can be enhanced by the external magnetic field. Heat transfer nanofluids contain CNTs and magnetic field sensitive nanoparticles of Fe2O3. The reasonable explanation for this interesting result was that the Fe2O3 particles formed aligned chains under applied magnetic field and helped to connect the CNTs which resulted in improved thermal conductivity. A homogeneous mixture of magnetic nanoparticles coated with double surfactant, both oleic acid and sodium dodecyl sulphate coated carbon nanofibers, was studied by Parmar et al. [11]. The magnetic particles adhered to the wall of carbon nanofibers by hydrophobic interactions. Hence, the ferromagnetic property was added to the carbon nanofibers without disturbing the high yield of tube formation. This simple and rapid process resulted in the spatial organization of the carbon nanofibers in the direction of applied magnetic field. Felicia and Philip [12] investigated the effect of CNTs on the magnetorheological properties of an oil based ferrofluid. They observed that the shear resistant plateau observed in a pure ferrofluid disappears when 0.5 wt% of CNTs is incorporated. Additionally, they reported that the yield stress values of the composite system are slightly smaller than those of the pure system. Hence, they concluded that the presence of carbon nanotubes (CNTs) weakens the magnetic field induced microstructure of the ferrofluid due to their interaction that affects the hydrodynamic and magnetic interactions between the dispersed nanoparticles.

To the best knowledge of the authors, only two archival publications reported the effects of the temperature and nanoparticle concentration on the viscosity and thermal conductivity of the water based nanofluids containing Fe3O4 and CNT nanoparticles [13, 14]. These studies considered low concentrations of the Fe3O4/CNT nanocomposite (less than 0.3 %) and the exact concentrations for each type of nanoparticles (Fe3O4 and CNT) were unclear. Additionally, the effect of shear rate on the viscosity behavior of the water based Fe3O4/CNT hybrid nanofluid was not examined in these references. The present investigation is conducted to determine the effects of temperature and volume concentrations of TMAH coated Fe3O4 (up to 0.9 %) and GA coated CNT (up to 1.35 %) on the viscosity and thermal conductivity of the Fe3O4–CNT/water hybrid nanofluid. The interaction between the two surfactants causes the physical attachment of magnetic particles with carbon nanotubes. Furthermore, the viscosity versus shear rate and shear stress versus shear rate behaviors for the water based Fe3O4/CNT hybrid nanofluid at different volume concentrations of Fe3O4 and CNT nanoparticles are studied.

2 Experimental section

2.1 Sample preparation

2.1.1 Ferrofluid

The aqueous ferrofluid used in this study is prepared using a previously described procedure [15, 16]. All the reagents are of analytical grade and purchased from Merck. In a typical process, 1.0 mL of stock FeCl2 solution and 4.0 mL of stock FeCl3 solution are mixed together. Then, 50 mL of 0.7 M aqueous NH3 solution is added dropwise. Magnetite precipitate begins to form immediately. After evacuating the excess liquid, the remaining solution is centrifuged for 1 min at 1000 rpm. As a result, a dark sludge remains at the bottom of the tube. Subsequently, 8 mL of 25 % TMAH solution is added and stirred till the thorough suspension of solid in the liquid happens. Finally, by magnetically stirring the solution for about 30 min, the extra ammonia is evacuated [15, 16].

2.1.2 Multi-wall carbon nanotube-based aqueous nanofluid (CNT nanofluid)

The materials needed for synthesis of carbon nanotube-based aqueous nanofluid are de-ionized (DI) water, GA and multiwalled carbon nanotubes (MWCNT). The nanotubes (purity ~99 %, outer diameter of 10–30 nm and length of 10 µm) were purchased from Research Institute of Petroleum Industry (RIPI, Tehran, Iran). Figure 1a, b illustrate SEM and TEM images of the sample, respectively. GA fine powder was procured from Biochemical. The aqueous CNT nanofluid used in this study is synthesized by the method explained by Garg et al. [17]. In a typical process, GA is dissolved in DI water using a magnetic stirrer. Then, CNTs are added to the solution and the resulting mixture is ultrasonicated for 40 min using an ultrasonicator that has an operating frequency of 20 kHz and a maximum power output of 130 W [17]. It should be noted that the mass concentration of GA fine powder and CNTs are, 0.25 and 1 %, respectively.

2.1.3 Hybrid nanofluid

The hybrid nanofluid is prepared by adding the desired amount of CNT nanofluid to the synthesized ferrofluid, followed by sonication of the aqueous mixture for 5 min. The considered volume ratios between the CNT nanofluid and ferrofluid are 1:2, 1:1 and 2:1. The volume concentration of the Fe3O4 and CNT nanoparticles in the prepared hybrid nanofluid samples are presented in Table 1.

2.2 Characterization

The phase and purity of the prepared samples are examined using Siemens D-500 diffractometer equipped with a rotating anode and a CuKα radiation source (λ = 0.15148 nm). TEM (CM120, 120 kV) is used for determination of the surface morphology and size of the synthesized samples.

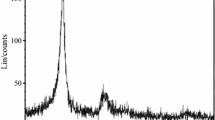

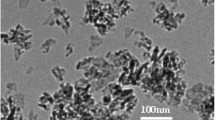

Figure 2a shows the XRD pattern of uncoated Fe3O4 nanoparticles. The pattern represents different reflection planes indexed as (111), (220), (311), (222), (400), (511) and (440), which is quite identical to pure magnetite pattern. Also, no characteristic peaks, which represent the impurities, are observed [18, 19]. The average diameter of sample evaluated according to (311) reflection by utilizing Scherrer’s [20] equation is approximately 13 nm. The TEM image of Fe3O4 nanoparticles is presented in Fig. 2b. According to the TEM image, the average diameter of nanoparticles is of the order of 10 nm, which is in good agreement with the XRD analysis.

Figure 3a–c show the TEM result, photograph of the synthesized hybrid nanofluid and its response to a magnet, respectively. The black powder is attracted towards the magnet in a few seconds, demonstrating high magnetic sensitivity.

2.3 Measurement of viscosity

The viscosity of the ferrofluid and hybrid nanofluid samples is measured in the temperature range of 25–55 °C and shear rate range of 10–100 s−1 using a Paar Physica MCR 300 (SN634038) parallel disc rheometer with a specified accuracy of ±0.5 %. A 0.15 mL ferrofluid or hybrid nanofluid sample is placed in the rheometer test section which has a 0.5 mm gap separating the rotating disc from the platen. The temperature is regulated by a Paar Physica circulating bath and a controlled peltier system (TEZ 150P/MCR) with an accuracy of ±0.1 °C.

2.4 Measurement of thermal conductivity

In the present work, the thermal conductivity is measured using a KD2-pro instrument (Decagon devices, Inc., USA), which acts based on the transient hot wire method. The instrument has a probe of 60 mm length and a 1.3 mm diameter (KS−1) and closely approximates the infinite line heat source which gives least disturbance to the sample during measurements. The instrument uses a heating element, a thermo-resistor and a microprocessor to control and measure the conduction in the probe with a specified accuracy of ±5 %. The samples are maintained at several temperatures using a temperature-controlled chiller. After the temperature of the sample reached the required temperature, the sample is kept at that temperature for further 30 min to ensure temperature equilibrium before each measurement. The thermal conductivities of the samples are measured in the temperature range of 25–55 °C with 5 °C intervals.

3 Results and discussion

3.1 Viscosity data

Hereafter, the pure ferrofluid and the hybrid nanofluid are referred to as FF and FF + CNT, respectively. The variation of dynamic viscosity of the FF and FF + CNT with the effect of volume concentration and temperature are presented in Fig. 4a–e. The shear rate for viscosity measurement is 10 s−1. As the accuracy of viscosity measurements is ±0.5 %, the error band of viscosity data are smaller than the symbol size. It is observed that the viscosity of the FF increases with increase of volume concentration, but decreases with increase of temperature. This result is consistent with the findings of Khedkar et al. [21] and Gu et al. [22]. Viscosity enhancements of 2.66–3.19 and 72.21–95.85 % are observed at 0.1 and 0.9 % FF, respectively, in the temperature range of 25–55 °C. This is because the hydrodynamic interactions between particles become important as the disturbance of the fluid around one particle interacts with that around other particles at higher volume concentrations [14]. Moreover, the results demonstrate that the viscosity of the FF increases by the addition of the CNT nanofluid. Viscosity increments of 0.85–7.81 and 20.88–29.62 % are observed at 0.1 % FF + 0.05 % CNT and 0.9 % FF + 1.35 % CNT, respectively, in the temperature range of 25–55 °C. Sundar et al. [14] reported viscosity enhancements of 14.37–32.96 and 23.86–47.72 % at 0.1 and 0.3 % volume concentrations of water based Fe3O4/CNT hybrid nanofluids, respectively, in the temperature range of 25–55 °C compared to the base fluid. It is worth mentioning that the shear rate for viscosity measurement was not mentioned by Sundar et al. [14] and, hence, it is not possible to compare their viscosity data with the results of this study.

Figure 5 plots the experimental findings of dynamic viscosity as a function of shear rate (1–100 s−1) for different volume concentrations of FF + CNT at 25 °C. It is apparent from the results that the FF + CNT samples behave as shear thinning fluids since there is a sharp decrease in the viscosity of nanofluids with increase of shear rate at lower shear rates, and the viscosity becomes gradually constant at higher shear rates. The shear-thinning region is up to 70 s−1; for higher shear rates, the viscosity tends to follow the Newtonian pattern. It can be said that there is a greater degree of shear thinning behavior at higher concentrations. The shear thinning effect may be due to the possible de-agglomeration of bundled nanotubes and Fe3O4 nano particles or realignment in the direction of the shearing force, resulting in less viscous drag [17, 23].

The influence of the CNT nanofluid volume concentration on the dynamic viscosity of the FF + CNT samples is graphed in Fig. 6. It is clear that for shear rates greater than 70 s−1, the viscosity of all samples is constant. The results show that adding 0.45, 0.9 and 1.35 % CNT to the 0.9 % FF leads to 5.72, 16.86 and 28.60 % increments in viscosity, respectively, compared to the 0.9 % FF.

Figure 7 contains the variations of shear stress with shear rate at 25 °C for the 0.9 % FF and FF + CNT. From this figure, it is evident that for all nanofluid, at shear rates greater than 20 s−1, the variation of the shear stress with shear rate is linear and the curves approach the origin of the diagram. Hence, the FF + CNT samples behavior is generally Newtonian.

3.2 Thermal conductivity data

The variations of thermal conductivity enhancement, \( \left( {{\text{k}}_{{{\text{FF}}\,{\text{or}}\, {\text{FF + CNT}}}} - {\text{k}}_{{{\text{DI}}\, {\text{water}}}} } \right) \times 100/{\text{k}}_{{{\text{DI}}\,{\text{water}}}} \), of FF and FF + CNT with volume concentration and temperature are presented in Fig. 8a–e. As shown in these figures, thermal conductivity of all samples increases with temperature. A similar trend was observed by Abareshi et al. [24] and Gavili et al. [25] for Fe3O4 nanofluid. The enhanced thermal conductivity is due to micro-convection and Brownian motion of the particles and base fluid. In addition, the thermal conductivity increment depends on the concentration of FF and CNT nanofluid. The higher the particle concentration, the more remarkable such an increment is. Thermal conductivity enhancements of 4.92–7.87 and 22.79–35.03 % are observed at 0.1 and 0.9 % volume concentrations of FF, respectively, in the temperature range of 25–55 °C compared to the base fluid. Additionally, thermal conductivity enhancements of 13–15.59 and 34.43–44.6 % are observed for 0.1 % FF + 0.05 % CNT and 0.9 % FF + 1.35 % CNT, respectively, in the temperature range of 25–55 °C compared to the base fluid.

Baby and Sundara [13] found 3–5 % and 6.5–10 % thermal conductivity enhancements for 0.005 % and 0.03 % Fe3O4/CNT hybrid nanofluid, respectively, over the temperature range of 30–50 °C compared to the base fluid. Also, Sundar et al. [14] reported a thermal conductivity enhancement of 11.64–15.41 and 18.06–25.93 % at 0.1 and 0.3 % volume concentrations of Fe3O4/CNT hybrid nanofluids, respectively, in the temperature range of 25–55 °C compared to the base fluid. The comparison between the present thermal conductivity data and those obtained by Sundar et al. [14] reveals that the thermal conductivities of 0.1 % FF + 0.05 % CNT and 0.3 % FF + 0.15 % CNT are slightly higher than the results of Sundar et al. [14] for hybrid nanofluids with 0.1 and 0.3 % Fe3O4/CNT nanocomposite. This can be attributed to the higher concentrations of Fe3O4 and CNT nanoparticles in 0.1 % FF + 0.05 % CNT and 0.3 % FF + 0.15 % CNT compared to hybrid nanofluids containing 0.1 and 0.3 % Fe3O4/CNT nanocomposite.

It is evident from the experimental results that the addition of CNT nanofluid increases the thermal conductivity of FF. The variations of enhancement in thermal conductivity in percent, \( \left( {{\text{k}}_{{{\text{a\% FF + b\% CNT}}}} - {\text{k}}_{{{\text{a\% FF}}}} } \right) \times 100/{\text{k}}_{\text{FF}} \), with temperature are presented in Table 2. Thermal conductivity enhancements of 7.71–7.16 and 9.48–7.09 % are observed for 0.1 % FF + 0.05 % CNT and 0.9 % FF + 1.35 % CNT, respectively, in the temperature range of 25–55 °C.

4 Conclusions

In this study, the viscosity and thermal conductivity of water-based hybrid nanofluid containing TMAH coated Fe3O4 nanoparticles and GA coated carbon nanotubes are investigated, experimentally. For this purpose, the aqueous mixture of ferrofluid having an average diameter of 13 nm and CNT nanofluid is homogenized using ultrasonication technique. The experimental results show that the viscosity of FF increases with increase of volume concentration, but decreases with increase of temperature. Additionally, the presented results demonstrate that the viscosity and thermal conductivity of FF are augmented by the addition of CNT nanofluid. Viscosity enhancements of 0.85–7.81 and 20.88–29.62 % are observed at 0.1 % FF + 0.05 % CNT and 0.9 % FF + 1.35 % CNT, respectively, in the temperature range of 25–55 °C. Moreover, thermal conductivity enhancements of 13–15.59 % and 34.43–44.6 % are observed at 0.1 % FF + 0.05 % CNT and 0.9 % FF + 1.35 % CNT, respectively, in the temperature range of 25–55 °C compared to the base fluid. Lastly, results show that the FF + CNT samples behave as a shear thinning media at low shear rates while it exhibits Newtonian behavior at higher shear rates.

References

Chakraborty S, Experimental characterizations of the magnetic and thermal properties of ferrofluid. Master thesis, Jadavpur University, India

Sundar LS, Singh MK, Sousa ACM (2013) Investigation of thermal conductivity and viscosity of Fe3O4 nanofluid for heat transfer applications. Int Commun Heat Mass Transf 44:7–14

Huminic A, Huminic G, Fleaca C, Dumitrache F, Morjan I (2015) Thermal conductivity, viscosity and surface tension of nanofluids based on nanoparticles. Powder Technol 284:78–84

Bahiraei M, Hangi M (2015) Flow and heat transfer characteristics of magnetic nanofluids: a review. J Magn Magn Mater 374:125–138

Frank M, Drikakis D, Asproulis N (2015) Thermal conductivity of nanofluid in nanochannels. Microfluid Nanofluid 19:1–7

Aminfar H, Razmara N, Mohammadpourfard M (2015) Molecular dynamics study of aggregation in nanofluid flow: effects of liquid–nanoparticle interaction strength and particles volume fraction. Int J Appl Mech 7:1550010

Kopyl S, Timopheev AA, Bystrov VS, Bdikin I, Teixeira BMS, Maevskij E, Sobolev NA, Sousa ACM (2014) FMR study of carbon nanotubes filled with Fe3O4 nanoparticles. J Magn Magn Mater 358–359:44–49

Qu S, Wang J, Kong J, Yang P, Chen G (2007) Magnetic loading of carbon nanotube/nano- Fe3O4 composite for electrochemical sensing. Talanta 71:1096–1102

Zhan Y, Zhao R, Lei Y, Meng F, Zhong J, Liu X (2011) Preparation, characterization and electromagnetic properties of carbon nanotubes/Fe3O4 inorganic hybrid material. Appl Surf Sci 257:4524–4528

Hong H, Wright B, Wensel J, Jin S, Ye XR, Roy W (2007) Enhanced thermal conductivity by the magnetic field in heat transfer nanofluids containing carbon nanotube. Synth Met 157:437–440

Parmar MA, Virpura HA, Dave V, Patel RJ (2014) Aligning carbon nanofibers using magnetic nanofluids. AIP Conf Proc 1591:330–332

Felicia LJ, Philip J (2014) Magnetorheological properties of a magnetic nanofluid with dispersed carbon nanotubes. Phys Rev E 89:022310

Baby TT, Sundara R (2011) Surfactant free magnetic nanofluids based on core-shell type nanoparticle decorated multiwalled carbon nanotubes. J Appl Phys 110:064325

Sundar LS, Singh MK, Sousa ACM (2014) Enhanced heat transfer and friction factor of MWCNT–Fe3O4/water hybrid nanofluids. Int Commun Heat Mass Transf 52:73–83

Berger P, Adelman NB, Beckman KJ, Campbell DJ, Ellis AB, Lisensky GC (1999) Preparation and properties of an aqueous ferrofluid. J Chem Educ 76:943–948

Mohammadi M, Mohammadi M, Ghahremani AR, Shafii MB, Mohammadi N (2014) Experimental investigation of thermal resistance of a ferrofluidic closed-loop pulsating heat pipe. Heat Transf Eng 35:25–33

Garg P, Alvarado JL, Marsh C, Carlson TA, Kessler DA, Annamalai K (2009) An experimental study on the effect of ultrasonication on viscosity and heat transfer performance of multi-wall carbon nanotube-based aqueous nanofluids. Int J Heat Mass Transf 52:5090–5101

Alveroglu E, Sozeri H, Baykal A, Kurtan U, Senel M (1037) Fluorescence and magnetic properties of hydrogels containing Fe3O4 nanoparticles. J Mol Struct 2013:361–366

Demir A, Baykal A, Sozeri H, Topkaya R (2014) Low temperature magnetic investigation of Fe3O4 nanoparticles filled into multiwalled carbon nanotubes. Synth Mater 187:75–80

Hong RY, Pan TT, Han YP, Li HZ, Ding J, Han S (2007) Magnetic field synthesis of Fe3O4 nanoparticles used as a procedure of ferrofluids. J Magn Magn Mater 310:37–47

Khedkar RS, Kiran AS, Sonawane S, Wasewar KL, Umare SS (2013) Thermo-physical properties measurement of water based Fe3O4 nanofluids. Carbon Sci Technol 5:187–191

Gu H, Tang X, Hong RY, Feng WG, Xie HD, Chen DX, Badami D (2013) Ubbelohde viscometer measurement of water-based Fe3O4 magnetic fluid prepared by coprecipitation. J Magn Magn Mater 348:88–92

Halelfadl S, Mare T, Estelle P (2014) Efficiency of carbon nanotubes water based nanofluids as coolants. Exp Thermal Fluid Sci 53:104–110

Abareshi M, Goharshadi EK, Zebarjad SM, Fadafan HK, Youssefi A (2010) Fabrication, characterization and measurement of thermal conductivity of Fe3O4 nanofluids. J Magn Magn Mater 322:3895–3901

Gavili A, Zabihi F, Isfahani TD, Sabbaghzadeh J (2012) The thermal conductivity of water base ferrofluids under magnetic field. Exp Thermal Fluid Sci 41:94–98

Acknowledgments

The authors would like to acknowledge Dr. Yadollah Mortazavvi and Catalyst and Nano-Structures laboratory assistants for their helpful advice on various technical issues examined in this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahsavar, A., Saghafian, M., Salimpour, M.R. et al. Effect of temperature and concentration on thermal conductivity and viscosity of ferrofluid loaded with carbon nanotubes. Heat Mass Transfer 52, 2293–2301 (2016). https://doi.org/10.1007/s00231-015-1743-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-015-1743-8